Xbox game rent lcd

Top sales list xbox game rent lcd

Latest Offers

Pakistan (All cities)

Artificial Hymen Pills Price in Pakistan What is Artificial Hymen Pills? Artificial Hymen Pills in Pakistan an Artificial Hymen Could Be a Cellulose Compound That is Developed in 2010 in Germany in a Very Laboratory for Microbiology Stuffed With Synthetic Blood That Imitates Human Blood. Artificial Hymen Pills Are Useful for Fake Virginity by Creating a True Hymen. And Imitate the Loss of Blood That Happens on Your First Time. These Pills Are Formulated With 99.9% Natural Ingredients That Are Extracted From Pure Herbs Used for Hundreds of Years in Asia. Of These Ingredients Are Completely Body-safe and Do Not Have Any Side Effects Whatsoever. All You’ve Got to Try is Just Place the Artificial Pills in Pakistan Inside Your Vagina Between 25-30 Minutes Before You Derive Pleasure From Sexual Activity. Artificial Pills Newtelebrands.com the Natural Hymen of a Lady Protects the Vaginal and Its Canal. If You’ve Lost Your Hymen Due to Any Physical Activity. And You’re Worried About Your Dark That You Simply Cannot Bleed at That Point. So Stop Worrying Because There’s a Product That Comes Dead Set Reduce Your Worries, and Provides You Your Virginity Back by Using Pills. These Artificial Hymen Fake Blood Pills Will Influence the Body Heat and Vaginal Moisture and It Will Then Create a Synthetic Membrane That Acts Sort of a Hymen and Tightens the Vaginal Opening. After Successful Penetration of the Male Organ, the Fake Membrane Will Tear Similar to a True Hymen and Discharge a Touch Blood-like Liquid to Finish the Dramatic Effect. How Artificial Hymen Pills Work? Artificial Hymen Pills in Pakistan Usually Fake Virginity, an Artificial Hymen is a Prosthetic Invention for the Aim of Simulating an Intact Hymen in Women. These Pills Contain a Natural Blend. Which After Inserting in the Vagina Properly Temporarily. Giving the Looks of an Intact Hymen and Releasing a Red Liquid That Appears Like Blood When Subjected to Pressure. Artificial Hymen Kit Consists of Two Layers of Cellulose, the Blood Liquid, and Powder. The Factitious Hymen Reacts to Heat and Moisture That is Present Within the Interior of the Vagina. Thus, the Unreal Hymen/hymen Dissolves Inside the Vagina and Exit as a Blood Trail to Substantiate the Virginity. It Has Been Specifically Designed to Offer You the Chance to Introduce One a Minimum of 2 Hours and Half-hour Before Sexual Activity. Make It Easy With the Included Disposable Plastic Tweezers a Finger Deep. During Sexual Activity, It Dissolves Then Completely. And by the Interior Friction of the Penis, the Cellulose Compounds Mix With the Body Fluids. Hymen Flows Down From the Vagina After Sexual Intercourse. Artificial Hymen Pills in Pakistan This Residue is Seen on the Penis and Sheets That Bring the Result to Substantiate Your Virginity at the Specified Moment. The Utilization of Hymen Gel Also Works With the Employment of Condoms. How To Use? Artificial Pills Just Finger Deep and About 1-3 Hours Before the Planned Sexual Activity. The Capsules Contained Fake Blood Therein Which Then Completely Dissolved. During Gender, It Mixes Along With Your Vaginal Secretions and Runs as a Trace of Blood During a Natural Amount. By Tightening the Vaginal Entrance, It Intensifies the Sensation of Virginity. Use It Half-hour – 2 Hours Before the Planned Sexual Issues and Also Confirms Reliably Your Virginity by Artificial Hymen Pills in Pakistan. With Original Blood, Pills Turns Blood Red Together With Moisture and Dissolves Completely. Use 25-30 Minutes Before Sexual Intercourse: Wash Your Hands and Vagina Before Using. Slightly Insert the Synthetic Hymen Into the Vagina. It Will Dissolve Within 20-30 Minutes After Using It. Benefits of Artificial Hymen Pills? Artificial Pills Will Facilitate Your Desire for a Virgin Again Without Undergoing Vaginal Rejuvenation Surgery or Popping Any Dangerous Pills. They Will Facilitate the Reboot of Your Virginity and Feel Young Again. Artificial Pills in Pakistan Facilitates You to Restore Your Hymen to Their Original Position. And Facilitate Your Experience of Sex Sort of a Virgin. The Factitious Hymens Are the Product of Natural Material. Like Synthetic Blood and Cellulose, is Safe for Your Vaginal Health. Lady Secret Cream the Following Are Advantages of Pills Make the Vaginal Path Tighter Make You Bleed at Your Night It Has No Side Effects. It is Non-toxic and Safe No Painful Surgery, Needles, or Anesthesia From Now on Artificial Pills in Pakistan Price Prevent From Doctor’s Visits and Medications You Do Not Need Any Hymenoplasty. It Appears Like the Original Blood 99.9% Harmless, Risk-free Call & Whats App 0300-0085742 | 0330-2828742 The Largest Online Shopping Website: NewTelebrands.Com

Free

See product

Pakistan

6 left in total 4 youngsters and one proven pair Youngsters 4000 each all gorgeous pastel colours long tail feathers . All closed rung breeding pair at 4000 pair 4 young plus proven pair 5000

Rs 4.000,0

See product

Pakistan (All cities)

Explore the top 10 CNC machines for small businesses in 2024! This comprehensive guide highlights the best machines for precision, reliability, and affordability, ideal for entrepreneurs, hobbyists, and small manufacturers. Whether you're looking for a versatile CNC mill, router, or laser cutter, find the perfect solution to enhance your production capabilities, improve efficiency, and grow your business. https://www.tradebrio.com/exporters/cnc-machines.html

Free

See product

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

Rs 0,0

See product

Pakistan (All cities)

Stunning online presence for your Embroidery Digitizing, Custom Patches & Vector Art Services Looking for a professional and customized website to showcase your embroidery digitizing, patches, and vector artwork services? Look no further! We offer expert website development services tailored to your unique business needs. With our website development services, you can: Showcase your embroidery, patches, and vector artwork services in a visually stunning way Increase your online visibility and reach a wider audience Streamline your business operations with our custom online ordering, payment, employee record system Build customer loyalty with a seamless user experience and responsive design Enjoy ongoing maintenance and support to ensure your website runs smoothly Other Services: Company formation in USA / UK Payment gateways (Paypal, Wise, Stripe, Banks, CashApp, Applepay, Googlepay) Office Address in USA / UK US/UK phone numbers Digital Marketing for Custom Patches, Embroidery Digitizing and Vector Services And many more… Our team of experienced developers will work closely with you to create a website that reflects your brand and meets your business objectives. We use the latest technologies and best practices to ensure your website is fast, secure, and user-friendly. Don't miss out on the opportunity to take your embroidery digitizing, patches, and vector artwork business to the next level with a customized website. Contact us today to learn more and get started! Call us: +92 310 1049 268 Email: edigit@erevotech.com Website: www.erevotech.com

Rs 75.950,0

See product

4 photos

Kandhura (Federally Administered Tribal Areas)

Eagle Racking India is a leading provider of high-quality mezzanine floor in Lucknow, offering cost-effective and space-efficient solutions for warehouses, factories, and commercial establishments. Our mezzanine floors are designed to maximize vertical space utilization, providing an additional floor without the need for expensive building expansions. Constructed with heavy-duty steel and premium-quality materials, our mezzanine floors ensure durability, strength, and safety. They can be customized to meet specific load-bearing capacities and operational requirements, making them ideal for storage, office setups, and retail spaces. Read more: https://eagleracking.com/lucknow/mezzanine-floor

Rs 0,0

See product

Pakistan

KC BRITISHPRIDE BRED English Bulldog Hes The son of Britishpride Royal Ascot. available for STUD. HE IS A PROVEN STUD DOG producing quality puppies.

Free

See product

Lahore (Punjab)

SEO Training in Lahore offers comprehensive courses designed to equip individuals with the skills needed to excel in search engine optimization. Whether you're a beginner or looking to enhance your existing knowledge, our training programs cover everything from basic SEO principles to advanced strategies. You will learn keyword research, on-page and off-page optimization, technical SEO, content marketing, and the latest SEO tools and techniques. Our experienced instructors provide hands-on training with real-world examples, ensuring you can apply what you've learned immediately. The course also includes case studies, projects, and practical

Free

See product

2 photos

Pakistan (All cities)

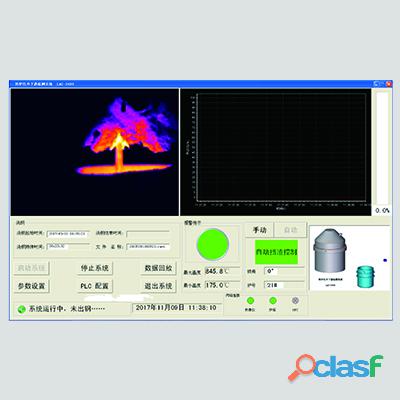

Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content. The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal. As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc. The features of thermal imager 1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set. 2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature. 3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily. 4. With hot zone tracking function 5. Equipped with special 7~14um infrared filter lens The technical parameters 1. Temperature measurement range: 200°C ~ 2000°C 2. Temperature measurement accuracy: 2% 3. Detection accuracy and alarm accuracy: ≥98% 4. Resolution: ≥ 0.5℃ 5. Pixels: 640x240PT 6. Band: 7~14um 7. Field of view: 7.5°×5.5° 8. Frame rate: ≥ 25 frames/sec 9. Equipment service life: ≥5 years 10. The normal operation rate of the automatic control system: ≥99%

Rs 0,0

See product

3 photos

Pakistan (All cities)

Buy the best herbal supplements & medications in USA online at affordable price. Get free delivery across all states. Order Now!

Rs 30.650,0

See product

Abbottabad (Khyber Pakhtunkhwa)

Looking for the perfect way to Send Birthday Gifts to India? We’ve got you covered with our unique selection of Birthday Gifts! From personalized keepsakes to luxury hampers, there’s something special for everyone. Worried about last-minute orders? Birthday Gift Same Day Delivery in India ensures your gift reaches on time. Explore our curated collection and make birthdays memorable. Shop now to find the ideal gift that says “happy birthday” in the most thoughtful way.

Rs 500,0

See product

Islamabad (Islamabad Capital Territory)

In the bustling heart of Delhi, optimizing your workspace is crucial for productivity and employee well-being. Ryan Office System provides premium modular office furniture in Delhi, offering versatile solutions tailored to your unique needs. Our modular designs prioritize flexibility, allowing you to reconfigure your office layout as your business evolves. From sleek workstations and ergonomic chairs to adaptable storage units and collaborative meeting tables, we offer a comprehensive range of furniture to create a dynamic and efficient environment. Why choose Ryan Office System for your modular furniture needs in Delhi? Customization: We understand that every office is different. Our modular systems can be customized to fit your specific space and workflow, ensuring optimal utilization. Quality & Durability: We use high-quality materials and craftsmanship to create furniture that is built to last, providing a long-term investment for your business. Ergonomic Design: We prioritize employee comfort and well-being with ergonomic designs that promote good posture and reduce strain. Space Optimization: Our modular solutions maximize space utilization, creating a more organized and efficient work environment. Professional Aesthetics: We offer a wide range of modern and stylish designs that enhance the professional image of your office. Ryan Office System empowers Delhi businesses to create adaptable and productive workspaces. Our expert team will guide you through the selection and installation process, ensuring a seamless experience. Invest in the future of your office with our premium modular office furniture in Delhi.read more :- https://www.ryanofficesystems.in/delhi/modular-office-furniture

Free

See product

Pakistan (All cities)

GoLogica offers complete online training in data modeling that gives professionals the understanding and skills they need to understand data modeling methods. IT specialists, database developers, business analysts, and data analysts who want to become better in creating and managing data structures may benefit from this course. Basic topics covered in the course include entity-relational diagrams (ERDs), data mapping, normalization strategies, and abstract, logical, and physical data modeling. It also covers database design concepts, demonstrating how to build durable, scalable, and effective data models that correspond with business goals. This course, led by industry experts, gives participants practical knowledge through practical assignments, allowing them to apply what they've learned in actual situations. Whether you're new to data modeling or want to improve your existing skills, GoLogica Data Modeling Online Training provides a solid basis for creating and managing successful data models. Enroll in GoLogica Data Modeling Online Training today to obtain the knowledge you need to boost your career in data management and become a certified Data Modeling expert!

Rs 0,0

See product

Rawalpindi (Punjab)

Programmers Lab Training Institute is the best IT training institute for computer short courses in Rawalpindi Islamabad . Our mission is to empower every student with IT skills and knowledge. With a wide array of job oriented computer short courses, we ensure that our students are prepared to succeed in their careers. Our computer short courses include Website Designing Course In Rawalpindi, React-Native course,SEO course, Graphics Designing course, FUll Stack Web Development Course In Rawalpindi Social Media Marketing course, Digital Marketing course, Php course, Sql, Video Editing course, Content Writing course, Basic IT, course ,MS Office Course, and many more short courses.

Rs 0,0

See product

Pakistan

One is 7 months old (not sexed); freely flying, like to be out of cage all day, freely flying around. Other one is 5 months old (breeder told male, but not sexed) has already started training; steps on a perch now on demand, wing feathers growing back, likes to be outside cage on his stand.

Rs 4.000,0

See product