Wearable wristwatch android phone

Top sales list wearable wristwatch android phone

Latest Offers

Pakistan (All cities)

Wedding Cards Manufacturing in Pakistan, Pakistani Wedding Cards, Wedding Cards from Pakistan, Favour Boxes Pakistan, Nikkah Boxes Pakistan, Bid Box Pakistan, Bidh Box Pakistan, Customized Wddding Cards Pakistan, Wedding Cards Lahore, Wedding Cards Pakistan, Acrylic Wedding Cards, Wax Stamp Wedding Cards, Bes Cards https://cardnboxes.com/

Rs 100,0

See product

Gujranwala (Punjab)

I am a professional logo designer with 4 years of experience, specializing in creating unique and memorable brand identities. My expertise lies in designing logos that effectively communicate your brand’s values and vision. Over the years, I’ve worked with various industries, delivering tailored designs that stand out. I prioritize client satisfaction by ensuring clear communication and timely delivery. My design process is detail-oriented, combining creativity and strategy to create impactful logos. Whether you’re launching a new business or rebranding, I can help elevate your visual presence. Let’s collaborate to bring your ideas to life!

Rs 999,0

See product

Rawalpindi (Punjab)

Discover a curated selection of stylish, handcrafted handbags and clutches at Baglore.com. Each piece is meticulously designed to blend traditional artistry with contemporary flair, offering timeless elegance for every occasion. Whether you need a chic clutch for a special event or a practical yet stylish handbag for everyday use, our collection provides the perfect accessory. Explore Baglore.com now and elevate your fashion statement with unique, high-quality handcrafted bags.

Rs 3.800,0

See product

16 photos

Pakistan (All cities)

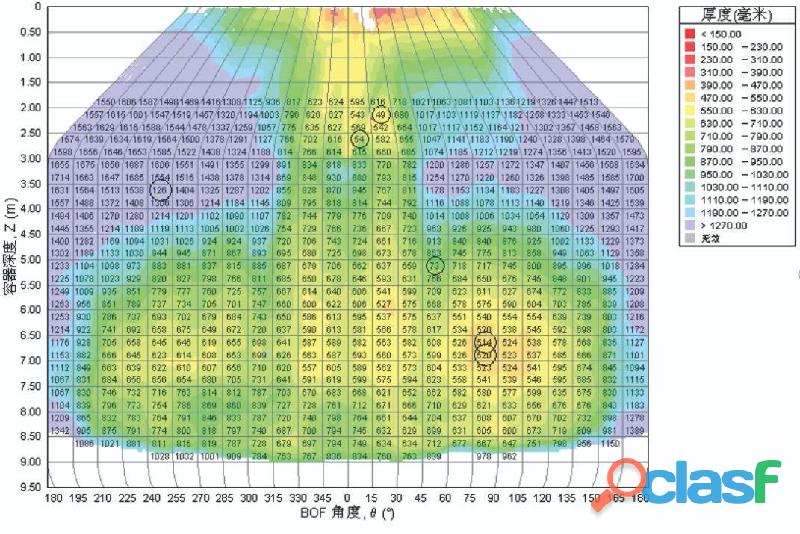

Overview LDT-I200 is a new generation of converter lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the converter, and receives the returned laser light to measure its flight time. Then the system equipment calculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushes the equipment to a certain position on the platform in front of the converter, and the equipment can start to scan and measure the target area of the converter after the equipment performs rapid self-positioning. The Measuring principle The measurement speed of LDT-I200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curve of the entire converter lining can be obtained by combining the measurement data of different positions and angles. During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within 4 minutes, the three-dimensional surface contour of the converter lining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracy up to ±2mm. In order to convert the distance from the internal point of the converter to the thickness gauge into the thickness of the furnace lining at each point, we must know the coordinate relationship between the trolley and the converter. We use the second laser head to position the trolley. When the trolley is pushed to the measurement site, the positioning laser head rotates at high speed to scan the three reflective strips opposite the converter. Through triangulation measurement and calculation, we can calculate the relative position of the trolley to the reflective strips. The coordinates of the reflective strip and the converter are known through mapping, so that the coordinates of the trolley relative to the converter can be accurately obtained. The main components 1. Laser measuring head 2. Wireless communication 3. Battery pack 4. Mobile laser thickness gauge host 5. Converter inclination measurement system 6. Cooling circulation system 7. Positioning auxiliary reflector 8. Laser positioning system The technical indexes Laser reproducibility: ±2mm Laser accuracy: ±2mm Local fastest measurement time: 15s Positioning time: 30s Full image measurement time: 4min The highest measurable lining temperature: 1850℃ Measuring distance: 0.5-25m Actual points are measured per frame: 1500000 points Continuous working time after fully charged: ≥3h Eye-safe laser: Class 1 laser product (doesn't hurt the eyes) The parameters of laser measuring head Measurement principle: According to the flight time and speed of the laser to calculate the distance Laser reproducibility: ±2mm Laser accuracy: ±2mm Scan rate: 2000000 points/second Measuring angle: vertical ±40°, horizontal 360° Maximum measurement temperature: 2200℃ Working temperature: -20℃-80℃ Cooling method: Integrated liquid cooling system, IP64 grade protection Laser wavelength: 1550nm (near infrared)

Rs 0,0

See product

2 photos

Pakistan

6 left in total 4 youngsters and one proven pair Youngsters 4000 each all gorgeous pastel colours long tail feathers . All closed rung breeding pair at 4000 pair 4 young plus proven pair 5000

Rs 4.000,0

See product

Pakistan

THE AMAZING HUGO & BOSS ARE LOOKING FOR THEIR FOREVER HOME. BOTH BOYS ARE LILAC IN COLOUR BUT ARE CARRIERS OF TAN POINTS WHICH IS THE AT GENE,DNA IS dd/bb/AT. PUPS ARE REALLY SHORT AND COBBY. GREAT CONFIRMATION, THE BEST WAY TO DESCRIBE THESE....

Rs 200,0

See product

Pakistan (All cities)

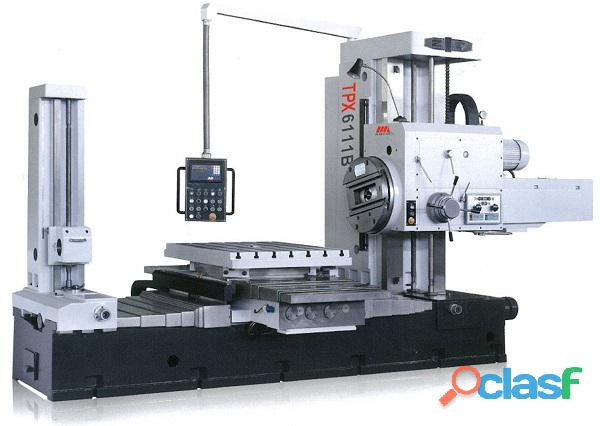

Explore the leading manufacturers of horizontal and vertical boring machines, renowned for their precision engineering, innovative technology, and reliable performance. This guide covers top companies offering high-quality machines for various industries, including construction, mining, and manufacturing. Discover key features, advantages, and the latest trends in boring machine design. Whether you're seeking new or used equipment, find trusted suppliers to meet your project needs with ease. https://www.tradebrio.com/exporters/boring-machine.html

Free

See product

Rawalpindi (Punjab)

Programmers Lab Training Institute is the best IT training institute for computer short courses in Rawalpindi Islamabad . Our mission is to empower every student with IT skills and knowledge. With a wide array of job oriented computer short courses, we ensure that our students are prepared to succeed in their careers. Our computer short courses include Website Designing Course In Rawalpindi, React-Native course,SEO course, Graphics Designing course, FUll Stack Web Development Course In Rawalpindi Social Media Marketing course, Digital Marketing course, Php course, Sql, Video Editing course, Content Writing course, Basic IT, course ,MS Office Course, and many more short courses.

Rs 0,0

See product

Pakistan (All cities)

India Internets is recognized as the Best Web Designing Company in Noida, offering professional and innovative web design solutions for businesses of all sizes. With a team of skilled designers, they create visually appealing, user-friendly, and responsive websites tailored to client needs. Their expertise ensures high-quality design, improved user experience, and strong online presence. Visit: https://www.indiainternets.com/web-design-company-noida.html Address:Alliance Web Solution Pvt Ltd. B-112, Sector-64 Noida - 201301 Phone no.:+91 95604 33318

Free

See product

Pakistan (All cities)

Trusted Fence Installation Company in Maryland & Delaware. Explore wood, vinyl, and aluminum fencing solutions for homes and businesses. Call for a free estimate today https://www.fenceanddeckconnection.com/fencing/

Free

See product

Islamabad (Islamabad Capital Territory)

Apple Hair Color Price In Pakistan - Quickon.pk Apple Hair Color PriceIn Pakistan offers a natural and effective solution for achieving vibrant, long-lasting hair color while maintaining the health and integrity of your hair. With its blend of conditioning agents and natural extracts, it provides a nourishing and protective coloring experience. By following the usage instructions and being mindful of potential side effects, users can enjoy salon-quality results in the comfort of their own home. Whether you are looking to refresh your current color or try a new shade, Apple Hair Color Price In Pakistan is a valuable addition to your hair care routine. FAQs About Apple Hair Color Price In Pakistan: What is Apple Hair Color? Apple Hair Color is a natural hair dye formulated with ingredients derived from apples and other natural sources. It is often used as an alternative to chemical hair dyes. Is Apple Hair Color safe for all hair types? Apple Hair Color is safe for all hair types. Does Apple Hair Color contain any harsh chemicals? Apple Hair Color is usually free from harsh chemicals like ammonia and parabens, making it a gentler option compared to conventional hair dyes. How long does Apple Hair Color last? The longevity of Apple Hair Color varies depending on the hair type and care routine. On average, it lasts for 4-6 weeks before fading. Can Apple Hair Color cover gray hair effectively? Yes, Apple Hair Color can cover gray hair, although the coverage may be less intense compared to synthetic dyes. Multiple applications might be needed for full coverage. Is Apple Hair Color suitable for sensitive scalps? Apple Hair Color is often marketed as suitable for sensitive scalps due to its natural ingredients. How should I prepare my hair before applying Apple Hair Color? It's recommended to wash your hair with a mild, sulfate-free shampoo and avoid using conditioner before applying the hair color for better absorption. Can I use Apple Hair Color on chemically treated or colored hair? Yes, Apple Hair Color can be used on chemically treated or colored hair. How often can I reapply Apple Hair Color? You can reapply AppleHair Color every 4-6 weeks, or as needed, to maintain the desired shade. Are there any special aftercare instructions for Apple Hair Color? To prolong the color, use sulfate-free shampoos, avoid excessive heat styling, and protect your hair from direct sunlight. For more details: WhatsApp: +923001819306 Website: quickon.pk Product Link: https://quickon.pk/ https://quickon.pk/product/apple-hair-color-price-in-pakistan https://quickon.pk/product/luvvel-hair-darkening-shampoo-price-in-pakistan https://quickon.pk/product/navratna-oil-price-in-pakistan https://quickon.pk/product/german-hair-color-gel https://quickon.pk/product/zinc-shampoo-price-in-pakistan https://quickon.pk/product/catherine-slimming-tea https://quickon.pk/product/lichen-hair-color-gel

Rs 3.500,0

See product

Pakistan (All cities)

As one of the largest Chinese manufacturers of industrial valves, China Vervo Valve Co., Ltd. offers a wide array of products, including floating ball valves, trunnion ball valves, cast steel gate valves, forged steel gate valves, pressure seal gate valves, cast steel globe valves, forged steel globe valves, cryogenic globe valves, forged steel check valves, swing check valves, dual plate check valves, API 609 butterfly valves, steel plug valves, Y strainers, and more. Our business reaches North America, South America, Europe, Asia, the Middle East, Africa, and Oceania. We manufacture, import, and sell a wide range of industrial valves, including ball, gate, globe, butterfly, check, plug valves, and specialty valve solutions. We look forward to establishing a strong cooperation with you! Visit our website: https://www.vervovalve.com/

Rs 200,0

See product

Islamabad (Islamabad Capital Territory)

Starting a bakery business is thrilling, but success requires the proper equipment. The instruments you select will not only help you make high-quality baked items, but will also streamline your operations, increasing your bakery's efficiency and profitability. Here's a list of the basic bakery equipment from the Bakery Machinery Manufacturers, you'll require to get started the Successful Bakery Business. https://www.tradebrio.com/exporters/bakery-machinery.html

Rs 100,0

See product

Pakistan (All cities)

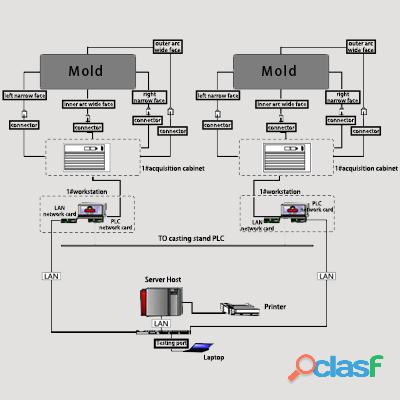

Overview: The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional artificial intelligence and information processing technology to overcome the defects of traditional logic-based prediction models. It has the functions of self-adaptation, self-organization and real-time learning. The breakout prediction system has an optimized industrial network structure. According to the distribution and change rules of the temperature field of the mold, it can track and respond to the breakout process in real time. It can learn and judge by itself, and provide early warning information for on-site operations. It can effectively prevent the occurrence of breakout accidents, greatly reducing the cost and improving the safety factor of continuous casting. The system is suitable for all kinds of continuous casting machines such as square billet, round billet, rectangular billet and slab. Block Diagram of Breakout Prediction System The composition of the system Thermocouple: according to the on-site conditions of the mold, water tank, bolts and mold frame to desgin Front-end acquisition system: Multi-module acquisition chain, industrial Ethernet interface, high-speed embedded processing module Working platform: Real-time display of mold temperature field status, online analysis and prediction of mold breakout Server: Data exchange and storage management, reporting and printing system, with data analysis and self-learning functions The Main technical parameters Data sampling: the sampling frequency of K-type/T-type thermocouple can up to 10HZ Accuracy of temperature measurement: ±0.25℃ Support communication protocol: Industrial Ethernet (TCP/IP),PROFIBUS-DP,CANopen Executive standard: DE0411 Standard Class III/1EC584/IEC1515 Transmission speed: 100M/bps The composition of the software Online monitoring software for breakout prediction Offline query software for breakout prediction Data recovery and self-learning software packages Data acquisition and monitoring software The software package of mold thermal status display The functions of the system Real-time data acquisition, data analysis and judgment Automatic selection of steel grade’s alarm parameters Real-time dynamic picture monitoring Prediction alarm and information display of breakout signs Automatic deceleration after alarm Historical data storage and historical trend graph display Automatic report generation and printing Alarm prediction and pattern recognition of unknown steel grades by neural network Dynamic real-time temperature profile prediction Mould heat flow field display FIG 1:Typical process of mold breakout prediction The features of the system 1. Reasonable design of temperature measurement point and professional protection front-end acquisition system, and complete installation and calibration tool components. 2. The system has strong adaptability and can meet the transformation of various structural continuous casting machines. 3. High-speed data communication, using industrial network to form an independent local area network for each workstation and server. It can realize high-speed data transmission of alarm files, alarm parameters, and other databases. 4. The combination of artificial neural network and intelligent forecasting model improves the alarm accuracy of breakout forecasting. 5. Historical data storage and historical trend graph display, historical reports, historical alarm legend printing, real-time alarm data printing. 6. Provide a local area network interface, which can realize the storage and forwarding of alarm files, and the input and output of offline alarm data. 7. Remote Web browsing can be achieved according to customer needs. 8. Can be seamlessly connected with MES-C220 mould expert system.

Rs 200.000,0

See product

4 photos

Pakistan

We have 6 kittens that will be available as pets, they will be ready to leave home on 7 April 2016. There are 3 boys and 3 girls. Silver spotted and Brown spotted. Mum is a gorgeous Silver Marbled F6 and Dad is a stunning tarnish free Silver spotted boy. If you are interested in these babies, please contact me as there is always a great demand for these babies from this pairing. They always make fabulous big kittens and this is probably the last time that these two are paired together due to the age of Oliver. Viewings start at 8 weeks of age after their 1st vaccination when we will require a non-refundable deposit to secure your kitten. We can also early neuter your boys before they leave us, this will be chargeable, please ask us about this. Individual photos will be taken in a few weeks when kittens are weaning. Please note that some of the kittens are in the fuzzies so markings will not clear for a few weeks yet: Beige Collar - Cool Brown Boy Blue Collar - Silver Boy Green Collar - Silver Boy Purple Collar - Brown Girl Yellow Collar - Stunning Cool Brown Girl Pink Collar - Silver Girl

Rs 5.000,0

See product