Water camping tent free

Top sales list water camping tent free

Latest Offers

Pakistan (All cities)

We have the Outboard Boat Engine OXE. Yamaha We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 150.000,0

See product

2 photos

Pakistan (All cities)

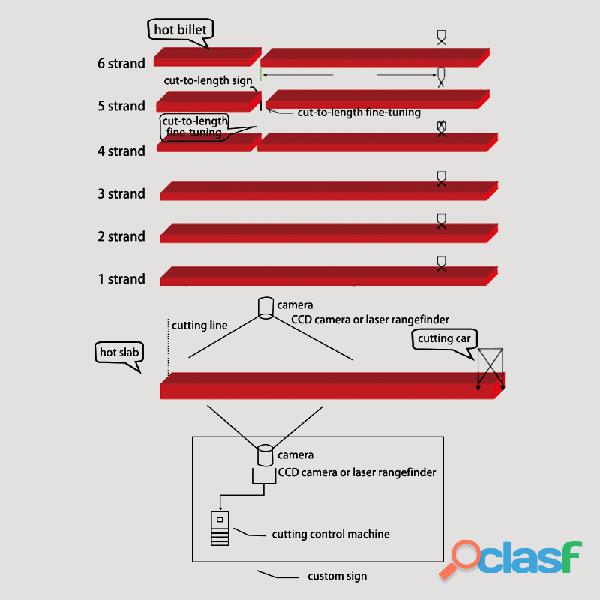

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

Rs 0,0

See product

Pakistan (All cities)

Overview In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline deviation. The measurement of the strand condition monitor Roll gap value: By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed. It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster. Arc condition of guide roller : Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guided roller. Guided roller rotation: It is possible to know whether each guided roller can rotate freely by measuring. Water spray pressure: The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal. The main components of the strand condition monitor 1. The main body of the strand condition monitor used to measure the continuous casting sector 2. The connecting chain between strand condition monitor and dummy bar 3. The storage rack chain of strand condition monitor 4. Battery charger: 24V 5A 5. Calibration equipment 6. Remote control 7. Laptop 8. Printer 9. Data communication cable The technical parameter 1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements) 2. The measurement accuracy of roll gap: 0.01mm 3. The arc measurement range: ±80° 4. The arc measurement accuracy: 0.01° 5. The spray measurement range: 0-10 6. The spray measurement accuracy: ±1 7. The battery usage times: 3 times

Rs 0,0

See product

Pakistan (All cities)

The Veritable Calfskin store bring another Superstar Outfit Fur B-26 Shearling Aircraft Cowhide Coat. This Coat has been made by genuine quality Calfskin and has jazzy Fur Straight Style Collar https://aajacketmaker.com/product/b-26-shearling-fur-jacket/

Rs 70.000,0

See product

Pakistan (All cities)

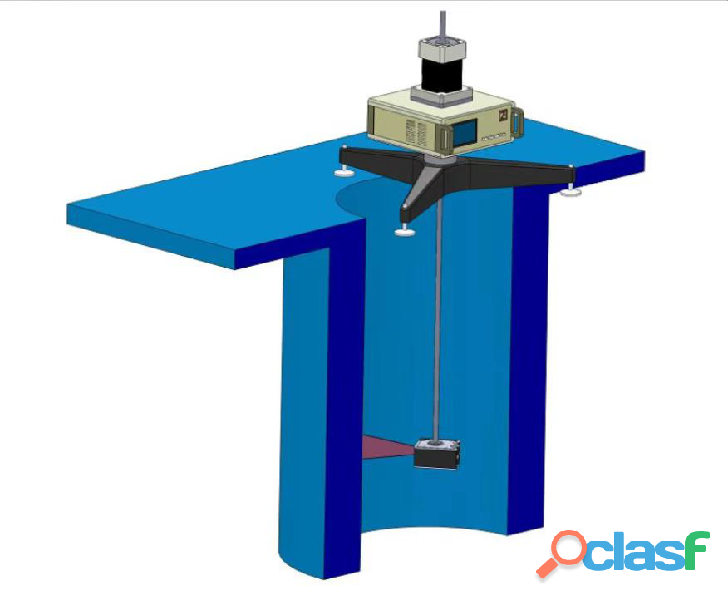

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Lahore (Punjab)

Apple Hair Color Price In Pakistan - Quickon.pk Apple Hair Color Price In Pakistan is a hair dye product designed to provide vibrant, long-lasting color while maintaining the health and integrity of your hair. This product is formulated to offer rich, natural-looking color with the added benefits of conditioning and nourishing ingredients. What is Apple Hair Color Price In Pakistan? Apple Hair Color Price In Pakistan is a professional-quality hair dye that offers a wide range of shades to suit different hair types and preferences. The formula is enriched with conditioning agents and natural extracts that help protect and nourish the hair during the coloring process. It is designed to deliver vibrant, long-lasting color with a natural finish. https://quickon.pk/product/apple-hair-color-price-in-pakistanhttps://quickon.pk/product/feg-plus-hair-growth-sprayhttps://quickon.pk/product/sardar-jee-hair-color-gel-price-in-pakistan

Rs 3.500,0

See product

Pakistan (All cities)

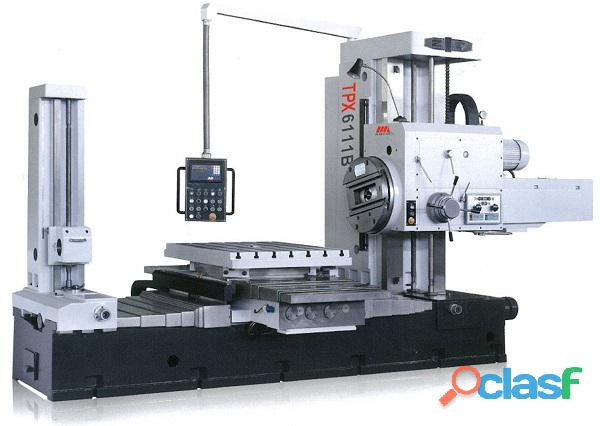

Explore the leading manufacturers of horizontal and vertical boring machines, renowned for their precision engineering, innovative technology, and reliable performance. This guide covers top companies offering high-quality machines for various industries, including construction, mining, and manufacturing. Discover key features, advantages, and the latest trends in boring machine design. Whether you're seeking new or used equipment, find trusted suppliers to meet your project needs with ease. https://www.tradebrio.com/exporters/boring-machine.html

Free

See product

Pakistan (All cities)

Buy Verified Cash App Accounts As it acquires clients, checked accounts become fundamental for organizations and people to completely get to its highlights. A checked money application account permits you to send, get, and pull out a lot of cash, making it ideal for business people, consultants, and financial backers. Purchasing a confirmed money application account has turned into a pattern now, with numerous suppliers offering this help at a sensible cost. In any case, it means quite a bit to purchase from a confided in source to stay away from tricks or fake records. You will learn the fundamentals of purchasing verified cash app accounts and everything else you need to know before making a purchase in this article.

Free

See product

Pakistan (All cities)

Buy the best herbal supplements & medications in USA online at affordable price. Get free delivery across all states. Order Now!

Rs 30.650,0

See product

Lahore (Punjab)

Drive your dreams, rent with ease! With easy online booking and flexible rental options, you can confidently hit the road. https://www.rafaycars.com/

Rs 1.200,0

See product

3 photos

Pakistan

due to a change in personal circumstances and a increase in work hours i am unfortunatly having to look for a new home for my four year old female beagle, jessie. Jessie has been spayed and is a member of the family it has been a very difficu....

Rs 200,0

See product

Pakistan (All cities)

Overview: In the steelmaking production process, the ladle is the key equipment for holding molten steel, secondary refining, and continuous pouring. In a modern steelmaking plant, refractory materials are required for converters, refining, and ladles. In the steelmaking process, ladle is the main equipment for using and consuming refractory materials. Improving the service life of ladles and reducing refractory consumption is the key technology for steelmaking plants to save costs and reduce energy consumption for green production. In order to ensure the orderly operation of the ladle, save the consumption of refractory materials, prolong the service life of the ladle, and ensure the safe operation of the ladle, Wuhan CenterRise M&C Engineering CO. developed and launched the LDT-N200 integrated management system for the ladle. Introduction: LDT-N200 ladle integrated management system integrates LDT-L200 ladle lining thickness gauge, TBP-S300 ladle, tundish baking temperature and leakage monitoring system, RFD -C100 metallurgical electronic positioning system, and also integrates SQL Server database and NeuralWare (American computer software company) neural network software NeuralWorks to realize intelligent and optimized management of ladles. LDT-L200 ladle lining thickness gauge uses a laser area array scanning sensor to accurately measure the real-time thickness of the ladle lining, calculate the lining loss, and predict the service life of the ladle. TBP-S300 ladle, tundish baking temperature and leakage monitoring system uses infrared thermal imaging camera and embedded armor wire system to comprehensively monitor and prevent ladle leakage. RFD-C100 metallurgical electronic positioning system installs RFID electronic tags on all ladles to realize full-time and full-space ladle positioning and tracking. LDT-S200 ladle optimization control and analysis software, based on SQL Server database, B/S network structure, realizes online management of ladles, and adopts BP neural network system to realize intelligent optimization control of ladles. LDT-N200 ladle integrated management system can realize ladle age management based on ladle lining data and neural network algorithm, safety process control of ladle turnover and use, full-time tracking management of steelmaking production and full-space tracking management of ladle use and provide optimal control and management of steelmaking production and ladle maintenance. Comprehensive ladle measurement and monitoring, ladle positioning and management, and data management and optimization enable the LDT-N200 ladle integrated management system to fully realize ladle entire process management, optimize the service life of ladles, and comprehensively reduce the cost of refractory materials. The features: Using a lining thickness gauge to measure the thickness of the ladle lining Using infrared thermal imaging camera/embedded armor wire to realize ladle leakage detection Using RFID/number plate recognition to realize the location management of ladles Ladle age management system based on overall tracking Overall (full-time full-space) ladle management system based on database Provide overall production scheduling data Using neural network to predict ladle service life based on big data Ladle Optimal Scheduling System based on database and ladle service life Increase the service life of ladle by 12%-20% Reduce the use of refractory materials more than 15% Realize orderly management of ladle baking Realize full space and full time domain control Reduce the costs of ladle management and maintenance Improve the efficiency of ladle turnover operation

Rs 0,0

See product

Lahore (Punjab)

Boost your online presence with our expert digital marketing services. We specialize in SEO, PPC, social media management, content creation, and email marketing to drive targeted traffic and maximize ROI. Let us help grow your brand, engage your audience, and achieve measurable results in today’s competitive digital landscape.

Rs 45.000,0

See product

Kandhura (Federally Administered Tribal Areas)

Eagle Racking India is a leading provider of high-quality mezzanine floor in Lucknow, offering cost-effective and space-efficient solutions for warehouses, factories, and commercial establishments. Our mezzanine floors are designed to maximize vertical space utilization, providing an additional floor without the need for expensive building expansions. Constructed with heavy-duty steel and premium-quality materials, our mezzanine floors ensure durability, strength, and safety. They can be customized to meet specific load-bearing capacities and operational requirements, making them ideal for storage, office setups, and retail spaces. Read more: https://eagleracking.com/lucknow/mezzanine-floor

Rs 0,0

See product

Karachi (Sindh)

CCTV Market specializes in offering premium CCTV security systems for homes as well as businesses. With over 10+ years of experience and a solid reputation for happy customers, we provide affordable solutions that are customized to meet your security needs. To guarantee you get the highest level of service possible, our knowledgeable staff takes care of everything from CCTV system design and installation to maintenance and repairs. We are your one stop shop for easily CCTV security since we place a high priority on quality in both our goods and services. For dependable and effective CCTV installation and repair, rely on CCTV Market right now.

Rs 150,0

See product