Usb micro usb type c output

Top sales list usb micro usb type c output

Latest Offers

Bagh (Azad Kashmir)

Eagle Racking India is a leading provider of industrial storage racks in Kanpur, offering high-quality and durable storage solutions for warehouses, factories, and commercial facilities. Our storage racks are designed to maximize space utilization, enhance efficiency, and ensure easy inventory management. We specialize in a wide range of industrial racking systems, including pallet racks, heavy-duty racks, mezzanine racks, and cantilever racks, catering to diverse storage needs. Made from premium-grade steel, our racks are built to withstand heavy loads and provide long-lasting performance. They are designed with customizable shelving options, corrosion-resistant coatings, and high load-bearing capacities to meet industrial requirements Read more: https://eagleracking.com/kanpur/industrial-storage-rack

Rs 0,0

See product

Pakistan (All cities)

Kameleon Salon offers top nail polish services in Hyderabad, from classic manicures to trendy gel finishes.

Free

See product

Pakistan (All cities)

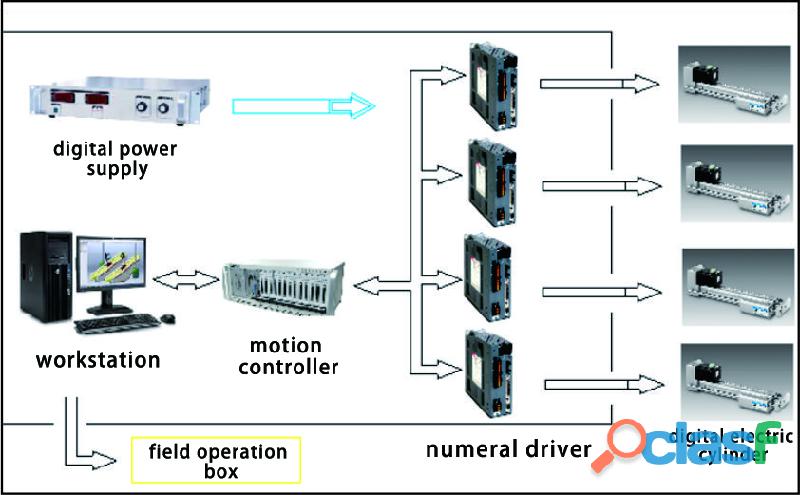

Overview In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting. The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached. During the production process, the adjustment of the mold’s width can be completed without stopping the machine. Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold. Only with adjustment and detection can the online adjustment range of the mold be accurately controlled. Fig 1 Mold online width adjustment system The components of the system Workstation: host system, system width adjustment control, taper detection. On-site operation box: real-time display of the current control status, manual operation to adjust parameters. Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control. On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time. Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment. FIG 2 System block diagram The technical parameters Adjustable range: 0-1250mm (unilateral) Control accuracy: 0.02mm/0.05mm/0.1mm Step resolution: 0.01mm/0.02mm Running speed: 0-10mm/s Power: 3.5KWl 16-bit encoder: 65536 pulses Weight: 25Kg Shell: high-strength aluminum alloy FIG 3 Syetem software interface The functions of the system Realize online width adjustment function Realize the online real-time monitoring function of mold taper Continuous casting production adjustment and non-stop production One-key operation in the main control room, automatic completion High adjustment accuracy and fast speed The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

Rs 0,0

See product

3 photos

Pakistan (All cities)

FutureGenApps is a leading website designing company in Laxmi Nagar. We help businesses to grow online with our expert services such as web design and development, software development, website maintenance, social media marketing, SEO services, and e-commerce websites. Our experts provide a user-friendly and mobile-responsive websites that attract customers and enhance your business. We also maintain your site after it goes live, ensuring you remain stress-free. Whether you're a small start-up or a growing brand, FutureGenApps is here to support your online journey with effective and affordable solutions. Contact FutureGenApps now to get your top-notch website.

Free

See product

2 photos

Rawalpindi (Punjab)

Programmers Lab Training Institute is the best IT training institute for computer short courses in Rawalpindi Islamabad . Our mission is to empower every student with IT skills and knowledge. With a wide array of job oriented computer short courses, we ensure that our students are prepared to succeed in their careers. Our computer short courses include Website Designing Course In Rawalpindi, React-Native course,SEO course, Graphics Designing course, FUll Stack Web Development Course In Rawalpindi Social Media Marketing course, Digital Marketing course, Php course, Sql, Video Editing course, Content Writing course, Basic IT, course ,MS Office Course, and many more short courses.

Rs 0,0

See product

Pakistan (All cities)

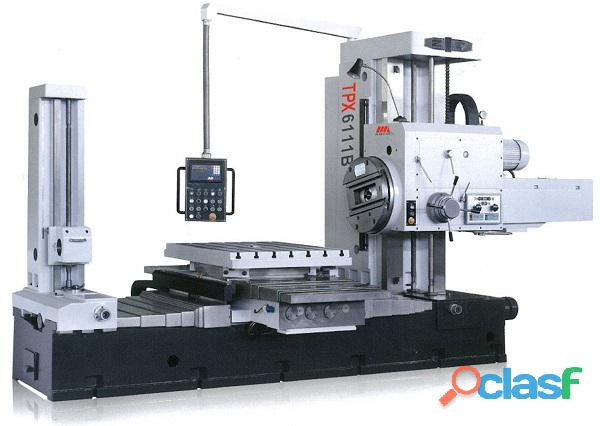

Explore the leading manufacturers of horizontal and vertical boring machines, renowned for their precision engineering, innovative technology, and reliable performance. This guide covers top companies offering high-quality machines for various industries, including construction, mining, and manufacturing. Discover key features, advantages, and the latest trends in boring machine design. Whether you're seeking new or used equipment, find trusted suppliers to meet your project needs with ease. https://www.tradebrio.com/exporters/boring-machine.html

Free

See product

Pakistan (All cities)

We provide best female fitness trainers and best female yoga trainers for women, who wants to stay fit and health from home without going to gym, best ladies gym nearby for housewifes and working women.

Free

See product

3 photos

Pakistan (All cities)

Laser cutting machines have transformed the design and fabrication industries, unlocking a new realm of creative possibilities. With their ability to cut and engrave materials with precision and speed, these machines are not just tools—they are catalysts for innovation. Whether in architecture, fashion, art, or product design, laser cutters have become an essential tool for turning ideas into reality. https://www.tradebrio.com/exporters/laser-cutting-machines.html

Free

See product

Pakistan (All cities)

Finding the best tyre shops near me, Sometimes it can be challange, especially when there are so many options available in the markets. Here, you can find a list of the trusted tyre shops where you can get the best deals and services, including new tyres, tyre repairs, or balancing services at affordable prices. Whether you're looking for quality tyres or expert maintenance, these shops offer reliable solutions to meet your needs. https://www.tradebrio.com/exporters/car-tyres.html

Free

See product

Pakistan (All cities)

Trusted Fence Installation Company in Maryland & Delaware. Explore wood, vinyl, and aluminum fencing solutions for homes and businesses. Call for a free estimate today https://www.fenceanddeckconnection.com/fencing/

Free

See product

Pakistan

One is 7 months old (not sexed); freely flying, like to be out of cage all day, freely flying around. Other one is 5 months old (breeder told male, but not sexed) has already started training; steps on a perch now on demand, wing feathers growing back, likes to be outside cage on his stand.

Rs 4.000,0

See product

Pakistan (All cities)

" Elevate Your Skin's Radiance at Kameleon Salon Your Premier Skincare Destination in Kokapet. Experience Tailored Treatments, Expert Care, and Revitalizing Solutions for Your Glow" https://www.kameleonsalon.com/skin-services.html

Rs 0,0

See product

Sialkot (Punjab)

Feeling intricacies in crafting a CDR application for Engineers Australia’s skills assessment? Do not worry; order CDR Writing Services in Pakistan for Engineers Australia. It is the best-known online writing assistance for CDR applicants in Pakistan. CDRAustralia.Org offers such commendable support to meet aspirants' requirements. The service comprises a complete CDR package from selecting projects to writing career episodes, a summary statement, a CPD statement, and a resume. To guide candidates in framing an EA-acceptable competency assessment report, a brilliant team of professional writers is awaiting. Expert writers offer comprehensive assistance to make the report extraordinary so that it can catch EA’s attention and undergo successful assessment. Hire top experts at CDR Australia and relieve all your writing woes. Hired native writers offer CDR support tailored to your requirements and meet all Engineers Australia standards. If you seek any information regarding the services, contact our experts free of cost by visiting the website. Contact Detail: Website: https://cdraustralia.org/pk/ Mail at: Contact@CDRAustralia.Org WhatsApp: +61-291917405

Rs 2.784.000.000,0

See product

Pakistan (All cities)

Transforming your home into a luxurious haven is an art that requires the perfect blend of style, elegance, and functionality. In Saudi Arabia, cities like Riyadh and Jeddah are home to some of the most exquisite furniture stores where you can find everything you need to create a space that reflects your taste and sophistication. Explore Jonathan Adler Products One of the top names in luxury home decor, Jonathan Adler, offers a stunning array of products that add a touch of glamor to any room. Whether you’re looking for statement pieces like a Jonathan Adler tray, an iconic chair, or a unique vase, these products are designed to stand out. Each item from Jonathan Adler combines bold designs with modern elegance, making them perfect for any luxury interior. Discover the Finest Furniture Stores in Riyadh and Jeddah Riyadh and Jeddah boast a variety of furniture stores that cater to different tastes and preferences. Whether you're searching for classic pieces or contemporary designs, these cities have it all. In furniture stores in Riyadh, you'll find an extensive collection of high-end chairs, sofas, beds, and more. The variety ensures that every piece you choose complements your home’s interior. Similarly, furniture stores in Jeddah offer a rich selection of luxury furniture, from opulent dining chairs to elegant tables and side tables. These stores provide not just furniture but an experience, offering pieces that are not only functional but also works of art

Rs 15.000,0

See product

Pakistan (All cities)

China Metal Parts Forging OEM Manufacturer Co., Ltd. (https://www.creatorcomponents.com/) was founded in 2000 by a team of experienced professionals in the forging industry. As a Chinese manufacturer, we specialize in providing high-quality carbon steel and alloy steel metal parts and components for a wide variety of industries. We focus on innovation and engineering excellence to ensure that we meet the highest standards of quality and performance. By utilizing advanced technology and state-of-the-art equipment, we produce products that are durable and reliable, meeting the requirements of both domestic and international customers. Quality is a top priority at every stage of our production process. From inspecting raw materials to conducting 100% final product testing, we ensure all products comply with international standards through our thorough quality control system. As a Chinese manufacturer, we offer customized metal parts to cater to the specific needs of industries such as automotive, construction, and energy. We collaborate closely with clients to deliver tailored solutions that align with their business objectives. At China Metal Parts Forging OEM Manufacturer Co., Ltd., we are dedicated to providing innovative, sustainable solutions and excellent customer service, earning the trust of businesses worldwide as a reliable partner.

Free

See product

4 photos