Ups 5fans

Top sales list ups 5fans

Latest Offers

Rawalpindi (Punjab)

Discover a curated selection of stylish, handcrafted handbags and clutches at Baglore.com. Each piece is meticulously designed to blend traditional artistry with contemporary flair, offering timeless elegance for every occasion. Whether you need a chic clutch for a special event or a practical yet stylish handbag for everyday use, our collection provides the perfect accessory. Explore Baglore.com now and elevate your fashion statement with unique, high-quality handcrafted bags.

Rs 3.800,0

See product

16 photos

Pakistan (All cities)

Discover the top 10 servo voltage stabilizers for industrial applications in 2025, engineered to ensure precise voltage regulation and protect sensitive equipment from fluctuations. These high-performance stabilizers improve operational efficiency, reduce downtime, and extend the life of machinery. With advanced features like automatic voltage correction and robust build quality, they are essential for industries looking to maintain optimal power stability and safeguard valuable assets. https://voltsine.in/product/servo-voltage-stabilizer/

Free

See product

Pakistan (All cities)

" Elevate Your Skin's Radiance at Kameleon Salon Your Premier Skincare Destination in Kokapet. Experience Tailored Treatments, Expert Care, and Revitalizing Solutions for Your Glow" https://www.kameleonsalon.com/skin-services.html

Rs 0,0

See product

Pakistan (All cities)

We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 1.000,0

See product

2 photos

Pakistan

I have available 2 stunning BSH blue kittens. 1 girls and 1 boys. Mum and dad are beautiful blues and are GCCF registered. Mum has a wonderful personality, she is friendly and extremely loving. she has an excellent 4 generations pedigree.

Rs 5.000,0

See product

Pakistan (All cities)

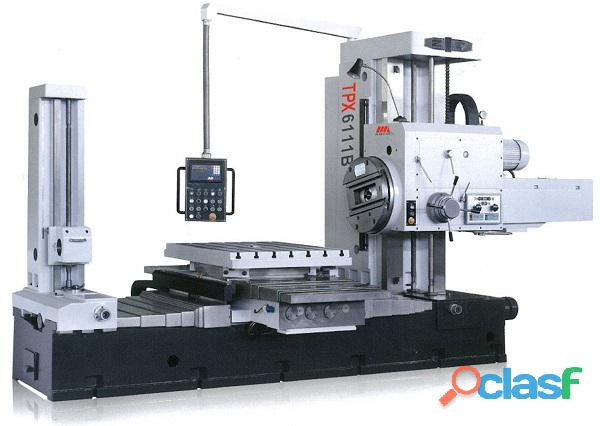

Explore the leading manufacturers of horizontal and vertical boring machines, renowned for their precision engineering, innovative technology, and reliable performance. This guide covers top companies offering high-quality machines for various industries, including construction, mining, and manufacturing. Discover key features, advantages, and the latest trends in boring machine design. Whether you're seeking new or used equipment, find trusted suppliers to meet your project needs with ease. https://www.tradebrio.com/exporters/boring-machine.html

Free

See product

Pakistan

Ready for their new home now pure breed beagles puppies. Both male and females available. They are all tri colour and are use to children. Mum is here to be seen with the puppies. For any further info please feel free to contact me. [Bizarte Beagles] Tri-colour Beagle Puppies male and female available.All Registered,pedigree and come with dew claws removed,free for MLS,NCCD by parentage,fully wormed,fully vaccinated with Contra.... ....

Rs 200,0

See product

Islamabad (Islamabad Capital Territory)

Starting a bakery business is thrilling, but success requires the proper equipment. The instruments you select will not only help you make high-quality baked items, but will also streamline your operations, increasing your bakery's efficiency and profitability. Here's a list of the basic bakery equipment from the Bakery Machinery Manufacturers, you'll require to get started the Successful Bakery Business. https://www.tradebrio.com/exporters/bakery-machinery.html

Rs 100,0

See product

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos

Pakistan (All cities)

Spark your child’s learning journey with Kinder ABC! From fun alphabet adventures to interactive games like tracing, puzzles, and bubble popping, Kinder ABC offers an ad-free, safe space for kids to learn letters, phonics, and more. Download now and make learning fun! Get Kinder ABC on Play Store: https://play.google.com/store/apps/details?id=com.icommunetech.kinderabc Official Website: https://www.icommunetech.com/

Free

See product

3 photos

Pakistan (All cities)

Buy the best herbal supplements & medications in USA online at affordable price. Get free delivery across all states. Order Now!

Rs 30.650,0

See product

Pakistan (All cities)

We have the Outboard Boat Engine OXE. Yamaha We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 150.000,0

See product

2 photos

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

Rs 0,0

See product

Pakistan (All cities)

Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition. The features of the system 1. The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken. 2. The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different segments and different casting speeds. 3. The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed. The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity. 4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient. It has manual, automatic, local and remote control modes. 5. The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux. 6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage. 7. Strong operability, simple and convenient maintenance, and low maintenance cost. 8. It can maintain the even distribution of the flux layer in the mold. The composition of the system The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment. 1. The feeding trolley is the support and walking equipment of the mold flux feeder. The basic equipment of the adding mold flux machine is installed on the feeding trolley. At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position. 2. The feeding bucket is a device for holding mold flux. The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder. The feeding bucket is provided with alarm contact of mold flux level limit.. 3. The swing arm and the feeder motor form a feeding and conveying device. The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor. Then the mold flux can be used for mold distribution. 4. PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates. 5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold. The technical parameter Mold width: 500-2000mm Mold thickness: 100-500mm Type: screw conveying type mold flux feeding machine Heating method: stirring electric heating Arrangement location: on the pouring platform (with its own wheels to move) Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube Molding flux storage tank: 300 L, with material level detection and alarm Control mode: local/remote control, automatic /manual mode Molding flux type: granular flux or powder flux flux adding method: spiral swing adding flux Casting speed interlock: yes Mould size setting: yes Signal transmission: DP/Industrial Ethernet

Rs 0,0

See product

Pakistan

We have 6 kittens that will be available as pets, they will be ready to leave home on 7 April 2016. There are 3 boys and 3 girls. Silver spotted and Brown spotted. Mum is a gorgeous Silver Marbled F6 and Dad is a stunning tarnish free Silver spotted boy. If you are interested in these babies, please contact me as there is always a great demand for these babies from this pairing. They always make fabulous big kittens and this is probably the last time that these two are paired together due to the age of Oliver. Viewings start at 8 weeks of age after their 1st vaccination when we will require a non-refundable deposit to secure your kitten. We can also early neuter your boys before they leave us, this will be chargeable, please ask us about this. Individual photos will be taken in a few weeks when kittens are weaning. Please note that some of the kittens are in the fuzzies so markings will not clear for a few weeks yet: Beige Collar - Cool Brown Boy Blue Collar - Silver Boy Green Collar - Silver Boy Purple Collar - Brown Girl Yellow Collar - Stunning Cool Brown Girl Pink Collar - Silver Girl

Rs 5.000,0

See product