Turbo internal storage

Top sales list turbo internal storage

Lahore (Punjab)

Quran scan Pen (Digital Pen religious text) is normal among Muslims as for listening or reciting or learning Holy Koran any time, any place; with intrinsic speaker and headphones. The most partaking a region of Koran ReadPen device is that it starts the Recitation from where you want, by inform the device on any Surah/Ayah of the Holy Koran (included in Gift Packing). Product choices Smart vogue Point the Pen on Ayah/Surah/Word of your different (only the written Koran included) and start listning Complete Holy Qur�an in voices of eighteen notable Reciters Beautifull written Holy Koran (Othmanic Style). Option to store Qari/Reciter Audio, Dua, Adhan, Nasheed (File format: MP3) as nonmandatory at intervals the pen via USB cable Also embody Koran Tafseer Clear and loud sound with intrinsic speakers and phone Beautiful Pen with beatutifull Gift Packing Includes pretty written Holy Koran Internal Li-Ion Chargable Battery Sahih Bukhari (Arabic) Book with Audio Multilingual lexicon Book with Audio Product Specifications 4 GB non-volatile storage PC affiliation. USB permits the user to connect with the laptop computer User-friendly designed, high-quality voice TF Card Support Earphone jack Internal Li-Ion reversible battery Additional Books The packing comes with further new specialy designed little books. Please whereas ordering mention them so as that the books ar incldued at intervals the packing and conjointly the device is pre-loaded with the connected audio. Qaida Noorania Sahih Bukhari (Arabic) wordbook Hajj Book 24 Koran Translations Azerbaijani Bengali Bosnian Chinese Dari English French German Gujrati Indonesian Kazkh Kurdish Malayalam Malaysian Marathi Persian Phasto Portuguese Russian Spanish Tamil Turkish Urdu Uzbek Qari assortment Ali Abdul Rahman Al Huzaifi Abdul Basit �Abd us-Samad Mishary bin Rashid Al-Afasy Ahmad Al Ajamy Salaah Al Budair Mohammed Al-Alim Al-Dokhail Sa�ad Al-Ghamdi M

Rs 4.500

See product

Hangu (Khyber Pakhtunkhwa)

ICTE International College of Technical Education Pvt. Ltd Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-6122937, 0311-5193625, 0092-335-4176949 Hybrid and electric vehicle technology course provides students to the knowledge of hybrid and electric vehicles, and also teaches the principles of operation of vehicles. In this course, students learn technical drawing and design program. The aim of this course is to introduce students to power train.Hybrid electric vehicles are powered by an internal combustion engine and an electric motor, which uses energy stored in batteries. A hybrid electric vehicle cannot be plugged in to charge the battery. Instead, the battery is charged through regenerative braking and by the internal combustion engine.There are three main types of hybrid vehicle; full hybrids, mild hybrids and plug-in hybrids. A full hybrid (FHEV) can run on just the combustion engine (i.e. diesel/petrol), the electric engine (i.e. power from batteries), or a combination. The Toyota Prius is the most commonly known example of this.The main advantages of a hybrid electric motor include comparatively less gas usage and reduced CO2 emission than traditional gas or diesel-engine car or SUV. The most recent types of plug-in hybrid electric-hybrid cars are the most effective green automobiles, featuring a much-improved eco-friendly engine.The light vehicle industry is facing a shortage of engineering talent needed to retool for the use of electric drives as the primary source of motive power. Help fill that gap with Michigan Tech’s Hybrid Electric Vehicle (HEV) curriculum. The coursework provides advanced knowledge and hands-on labs in the design, analysis, control, calibration, and operating characteristics of HEVs. Whether you are a graduate or undergraduate student, you can integrate any number of these courses into your degree. Another flexible option: simply take courses as a non-degree seeking student.Hybrid vehicle technologies such as powertrains provide new opportunities to achieve better trade-offs in vehicle designs. These technologies can lead to improvements in driving performance and fuel economy. This online module presents an introduction to the current status of hybrid vehicles and basic technologies, along with an in-depth discussion about the control and design of split hybrid electric vehicles. SYLLABUS 1 .Introduction of hybrid vehicles History of hybrid vehicles types of system architectures of hybrid vehicles series hybrid parallel hybrid vehicle series –parallel hybrid vehicle complex hybrid vehicle characteristics and difference of HEV and PHEV reasons behind development of HEV and different national fuel standards power electronic in HEV buck boost converter three phase inverter Live transmission explanation of Toyota prius testing standards of HEV and PHEV (AIS Standards) Battery Chemistry, Efficiency, Definition & its Parameters Types of batteries – Pb Acid, Li-Po & Metal Air Architecture- Cells, Modules & Packs Battery Charging & Discharging Cycles Use of Batteries in Hybrid Powertrain Battery Modelling & Management System(BMS) Alternative Energy Storage – Photovoltaic cells, Super-Capacitors, Fuel Cell Demonstration Sessions-on experience on Battery Packs and BMS. Electric Motors , Generators & Power Electronics Electric Motors- AC/DC Motors/ Generators Brushed DC Motor/ Brushless DC Motor- Torque Characteristics Synchronous and Asynchronous AC Motor- Torque Characteristics Reluctance Machines, Actuators & Capacitors DC-AC & AC-DC Convertors Practical design and calculation session on batteries and motors.

Rs 123

See product

Pakistan (All cities)

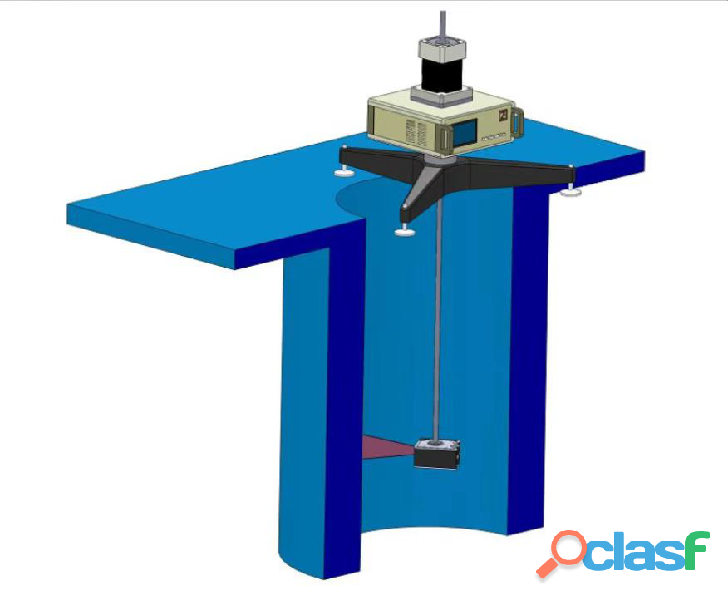

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

See product

Pakistan (All cities)

Overview In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline deviation. The measurement of the strand condition monitor Roll gap value: By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed. It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster. Arc condition of guide roller : Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guided roller. Guided roller rotation: It is possible to know whether each guided roller can rotate freely by measuring. Water spray pressure: The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal. The main components of the strand condition monitor 1. The main body of the strand condition monitor used to measure the continuous casting sector 2. The connecting chain between strand condition monitor and dummy bar 3. The storage rack chain of strand condition monitor 4. Battery charger: 24V 5A 5. Calibration equipment 6. Remote control 7. Laptop 8. Printer 9. Data communication cable The technical parameter 1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements) 2. The measurement accuracy of roll gap: 0.01mm 3. The arc measurement range: ±80° 4. The arc measurement accuracy: 0.01° 5. The spray measurement range: 0-10 6. The spray measurement accuracy: ±1 7. The battery usage times: 3 times

See product