Tune automatic guitar

Top sales list tune automatic guitar

Latest Offers

Bagh (Azad Kashmir)

Eagle Racking India is a leading provider of industrial storage racks in Kanpur, offering high-quality and durable storage solutions for warehouses, factories, and commercial facilities. Our storage racks are designed to maximize space utilization, enhance efficiency, and ensure easy inventory management. We specialize in a wide range of industrial racking systems, including pallet racks, heavy-duty racks, mezzanine racks, and cantilever racks, catering to diverse storage needs. Made from premium-grade steel, our racks are built to withstand heavy loads and provide long-lasting performance. They are designed with customizable shelving options, corrosion-resistant coatings, and high load-bearing capacities to meet industrial requirements Read more: https://eagleracking.com/kanpur/industrial-storage-rack

Rs 0,0

See product

Pakistan

KC BRITISHPRIDE BRED English Bulldog Hes The son of Britishpride Royal Ascot. available for STUD. HE IS A PROVEN STUD DOG producing quality puppies.

Free

See product

Gujranwala (Punjab)

I am a professional logo designer with 4 years of experience, specializing in creating unique and memorable brand identities. My expertise lies in designing logos that effectively communicate your brand’s values and vision. Over the years, I’ve worked with various industries, delivering tailored designs that stand out. I prioritize client satisfaction by ensuring clear communication and timely delivery. My design process is detail-oriented, combining creativity and strategy to create impactful logos. Whether you’re launching a new business or rebranding, I can help elevate your visual presence. Let’s collaborate to bring your ideas to life!

Rs 999,0

See product

Lahore (Punjab)

Apple Hair Color Price In Pakistan - Quickon.pk Apple Hair Color Price In Pakistan is a hair dye product designed to provide vibrant, long-lasting color while maintaining the health and integrity of your hair. This product is formulated to offer rich, natural-looking color with the added benefits of conditioning and nourishing ingredients. What is Apple Hair Color Price In Pakistan? Apple Hair Color Price In Pakistan is a professional-quality hair dye that offers a wide range of shades to suit different hair types and preferences. The formula is enriched with conditioning agents and natural extracts that help protect and nourish the hair during the coloring process. It is designed to deliver vibrant, long-lasting color with a natural finish. https://quickon.pk/product/apple-hair-color-price-in-pakistanhttps://quickon.pk/product/feg-plus-hair-growth-sprayhttps://quickon.pk/product/sardar-jee-hair-color-gel-price-in-pakistan

Rs 3.500,0

See product

Pakistan (All cities)

Buy the best herbal supplements & medications in USA online at affordable price. Get free delivery across all states. Order Now!

Rs 30.650,0

See product

Rawalpindi (Punjab)

Discover a curated selection of stylish, handcrafted handbags and clutches at Baglore.com. Each piece is meticulously designed to blend traditional artistry with contemporary flair, offering timeless elegance for every occasion. Whether you need a chic clutch for a special event or a practical yet stylish handbag for everyday use, our collection provides the perfect accessory. Explore Baglore.com now and elevate your fashion statement with unique, high-quality handcrafted bags.

Rs 3.800,0

See product

16 photos

Pakistan (All cities)

The Veritable Calfskin store bring another Superstar Outfit Fur B-26 Shearling Aircraft Cowhide Coat. This Coat has been made by genuine quality Calfskin and has jazzy Fur Straight Style Collar https://aajacketmaker.com/product/b-26-shearling-fur-jacket/

Rs 70.000,0

See product

Pakistan (All cities)

Transforming your home into a luxurious haven is an art that requires the perfect blend of style, elegance, and functionality. In Saudi Arabia, cities like Riyadh and Jeddah are home to some of the most exquisite furniture stores where you can find everything you need to create a space that reflects your taste and sophistication. Explore Jonathan Adler Products One of the top names in luxury home decor, Jonathan Adler, offers a stunning array of products that add a touch of glamor to any room. Whether you’re looking for statement pieces like a Jonathan Adler tray, an iconic chair, or a unique vase, these products are designed to stand out. Each item from Jonathan Adler combines bold designs with modern elegance, making them perfect for any luxury interior. Discover the Finest Furniture Stores in Riyadh and Jeddah Riyadh and Jeddah boast a variety of furniture stores that cater to different tastes and preferences. Whether you're searching for classic pieces or contemporary designs, these cities have it all. In furniture stores in Riyadh, you'll find an extensive collection of high-end chairs, sofas, beds, and more. The variety ensures that every piece you choose complements your home’s interior. Similarly, furniture stores in Jeddah offer a rich selection of luxury furniture, from opulent dining chairs to elegant tables and side tables. These stores provide not just furniture but an experience, offering pieces that are not only functional but also works of art

Rs 15.000,0

See product

Pakistan (All cities)

We provide best female fitness trainers and best female yoga trainers for women, who wants to stay fit and health from home without going to gym, best ladies gym nearby for housewifes and working women.

Free

See product

3 photos

Pakistan

Stunning Tri-Colour Pedigree Puppies for Sale. Only 3 girls left. Born 8th January and ready to re-home 4th March. These puppies have been home bred and reared within a family home. Mother can be seen with puppies and is from Chantryland an....Beautiful litter of chunky beagle puppies. Lemon and white & Tri in colour. Boys and girls available. They have gorgeous long floppy ears and cheeky personalities. They are ready now for there forever loving homes. Mum is a tri colo....We have for sale 4 wonderful beagle puppies they r good with kids other pets they r all up to date with wormed & flees & vacation they also comes with a dog lead good home only

Rs 200,0

See product

Pakistan (All cities)

Jaipur, the Pink City, is not only famous for its architectural splendor but also for its exceptional furniture craftsmanship. If you’re searching for the top furniture manufacturers near you in Jaipur, you’ll find a wealth of options offering a perfect blend of tradition, quality, and modern designs. Why Choose Jaipur Furniture Manufacturers? Expert Craftsmanship: Jaipur’s furniture manufacturers are renowned for their skilled artisans who create intricate designs using time-honored techniques. High-Quality Materials: Most manufacturers use premium woods like teak, sheesham (Indian rosewood), and mango wood, ensuring durability and lasting beauty. Custom Designs: Many offer bespoke furniture tailored to your specific needs and style preferences. Variety: From traditional Rajasthani designs to contemporary and minimalistic styles, there’s something for every taste. Furniture Options Available: Living Room: Elegant sofas, coffee tables, and TV cabinets. Dining Room: Sturdy and stylish dining tables and chairs. Bedroom: Luxurious beds, wardrobes, and dressers. Office Furniture: Ergonomic desks and chairs for a productive workspace. Whether you’re furnishing your home or office, Jaipur’s furniture manufacturers ensure pieces that not only serve practical purposes but also elevate the aesthetics of your space. Explore the top furniture manufacturers near you in Jaipur to find handcrafted masterpieces that reflect the city’s rich heritage and artistic flair. Transform your spaces today with furniture that stands the test of time!

Rs 0,0

See product

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product

Pakistan (All cities)

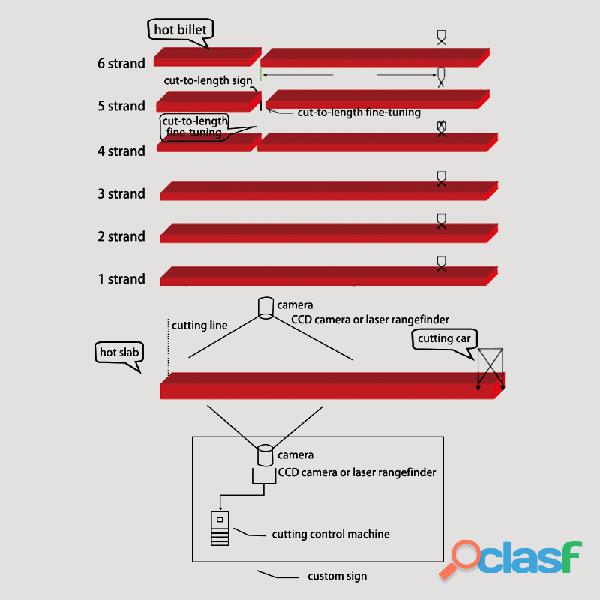

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

Rs 0,0

See product

Pakistan

4 year old male beagle called 'Bizol' who is very sweet a little shy but once settled is very loving and friendly. He is great with other cats and dogs, he would be fine to be rehomed with older children purely as he's a little shy, He is cur....

Rs 200,0

See product

Pakistan (All cities)

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

Rs 0,0

See product