Temperature instrument

Top sales list temperature instrument

Pakistan (All cities)

Overview: LGK-S107 analog heat source instrument (heating tool) is independently developed and designed by Wuhan CenterRise M&C CO., Ltd. This instrument is a heating and testing equipment used to test the performance of the thermocouples installed in the mold in continuous casting machine. After the installation of the mold breakout prediction thermocouples completed, the analog heat source instrument is used to test these thermocouples before they go online. After the thermocouple is connected to the mold thermocouple detector, the current temperature of each thermocouple point will be displayed. By using our heating device to heat the copper plate point of each thermocouple at a fixed point, the thermocouple will have a synchronous temperature rise and then we can observe the temperature rise curve of the same column of temperature points to see whether the temperature measurement consistency of the column of thermocouples is consistent, so as to judge the overall status of thermocouples installed in the mold. If an abnormal point occurs, it needs to be repaired and replaced, so as to ensure the stable operation of the mold breakout prediction system. The working principle: The heating tool generates high heat by 220v alternating current and the electric heating element. The heat is transmitted to the copper plate of the mold through the copper head to simulate the heat source of molten steel, so that the thermocouples of the mold can sense the temperature change to achieve the purpose of calibrating the temperature measurement system. The composition: Walking trolley mechanism Preloader Pure copper heating contacts PID thermostat High power heating tube high power driver The parameters: Power supply: AC220V 50Hz Total power: 2200W Single point power: 300W Temperature control accuracy: 1°C Temperature control range: 0°C-500°C Common temperature range: 25°C-300°C Heating points: 3 (points can be customized) Heating method: heating tube heating Heating contact material: copper

See product

3 photos

Pakistan

Recirculating chiller for rotary evaporator / small distillation instrument S&A CW-5200 recirculating water chiller is suitable to cool rotary evaporator / small distillation instrument. Its cooling capacity up to 1.4KW and the thermoelectric control in ±0.3℃ precision and temperature control range in 5-35℃. S&A chiller has CE,RoHS and REACH approval. CW-5200 water chiller parameter: Model CW-5200AG CW-5200BG CW-5200DG CW-5200TG CW-5200AH CW-5200AI CW-5200BI CW-5200DI Voltage 220V 220V 110V 220V 220V 220V 220V 110V Frequency 50Hz 60Hz 60Hz 50/60Hz 50Hz 50Hz 60Hz 60Hz Current 2.4~3.1A 2.6~3.3A 4.5~6.5A 2.4~3.3A 2.4~3.1A 2.4~3.1A 2.6~3.3A 4.5~6.5A Compressor power 0.52KW 0.5KW 0.68KW 0.49/0.57KW 0.52KW 0.52KW 0.5KW 0.68KW 0.71HP 0.68HP 0.93HP 0.66/0.77HP 0.71HP 0.71HP 0.68HP 0.93HP Refrigeration capacity 5084Btu/h 4982Btu/h 5186Btu/h 4825/5797Btu/h 5084Btu/h 5084Btu/h 4982Btu/h 5186Btu/h 1.49KW 1.46KW 1.56KW 1.41/1.70KW 1.49KW 1.49KW 1.46KW 1.56KW 1281Kcal/h 1256Kcal/h 1307Kcal/h 1219/1465Kcal/h 1281Kcal/h 1281Kcal/h 1256Kcal/h 1307Kcal/h Refrigerant R-22 / R-134a / R-410a Refrigerant charge 360g 380g 350g 360/380g 360g 360g 380g 350g Precision ±0.3℃ Reducer Capillary Protection Overcurrent protection for compressor, flow alarm, over temperature alarm Pump power 0.03KW 0.05KW 0.1KW Tank capacity 6L Inlet and outlet External Φ10mm brass connector Φ10mm speedy connector Max. lift 10 M 12M 25M Max. flow 10 L/min 13L/min 16 L/min N.W 26 Kgs G.W 29 Kgs Dimension 58 X 29 X 47 cm (L X W X H) Package dimension 70 X 43 X 58 cm (L X W X H) Note: other electric sources can be customized; heating and higher temperature control precision functions are optiona . CONTACT S&A TEL:+86-20-89301885, FAX:+86-20-84309967 SKYPE: teyuchiller Email:marketing@teyu.com.cn Website: http://www.teyuchiller.com

See product

Pakistan (All cities)

Overview The mold is a device that shapes the cast product in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of the mould oscillation deflection detection instrument is to detect the the mould oscillation table’s oscillation frequency, amplitude, deflection rate, phase, oscillation trajectory curve, etc. Through the detection and adjustment of the detection instrument, the mold moves along the outer arc of the continuous casting machine according to the set amplitude, frequency and waveform deflection characteristics. The actual oscillation parameters of the mold oscillation table during the production process and the process parameters of the cast products cannot be effectively known without the data detection of the mold deflection detection instrument, so that the operator cannot adjust the mould’s production process parameters in real time according to the real-time situation of the on-site production. The continuous casting mold deflection detection instrument independently developed by our company is suitable for various molds such as slab, square billet, round billet and shaped billet. The system obtains the process parameters such as actual oscillation holographic parameters and negative slip amount of the oscillation table by effectively detecting the movement of the mold. The technicians can formulate the control strategy of the mould according to these actual parameters, and improve the output and quality of the product within a safe and reliable range. The structure of the instrument Continuous casting mold oscillation and deflection detection instrument is mainly composed of sensor system, sensor signal conditioning circuit, power supply circuit, synchronous data acquisition module, communication cable, and software data analysis system. There are three axial acceleration sensors installed in the mold oscillation and deflection detection instrument, one of which is to detect the vertical oscillation signal (Y axis), and the other two are to detect the horizontal oscillation signal (X and Z axis). The signal obtained by the sensor is processed by the preprocessor and the preprocessing module. The oscillation signal and sensor status signal will be filtered and normalized, sent to the synchronous data collector for digitization and feature extraction, and the data is analyzed and processed by the master computer software to obtain various oscillation parameters and process parameters required by users. The functions of the system 1. Adopting mould oscillation X/Y/Z three-dimensional data acquisition, using high-precision sensor system and high-sensitivity axial accelerometer, comprehensive detection of equipment oscillation state, including: 1) Detect the oscillation frequency of the mold oscillation table 2) Detect the amplitude of the mold oscillation table 3) Detect the deflection rate of oscillation 4) Detect the lateral deflection, longitudinal deflection, phase, and phase difference of the mold oscillation table 5) Three-dimensional display of the oscillation trajectory, and the oscillation table trajectory can be viewed from 6 sides of the oscillation table (X-Y, X-Z, Z-Y) 2. The software system adopts the design of man-machine interactive graphic interface, which can display the mold oscillation state in real time. The software functions include: 1) Real-time data curve display: oscillation waveform, oscillation frequency, signal superposition analysis 2) Single-axis curve display, multi-axis curve display, amplitude, acceleration, three-dimensional graph 3) View historical curve 4) Generate test report 5) Give a warning prompt 6) Spectrum analysis function 7) Long-term storage of data 3. Portable measurement method, which can provide handheld detection equipment with wireless remote transmission, and the operation is simple. 4. Provide an overview of inspection parameters under the full screen, displaying all data including oscillation parameters and process parameters. At the same time, the calculation and display of the oscillation spectrum is completed in real time, which is used to evaluate the frame loss of the waveform , and to determine whether there is a problem with the installation of the oscillation device. 5. Alarm management. Record each alarm data under real-time alarm conditions to analyze the cause of the alarm and evaluate the impact of the alarm on production. 6. Parameter setting. Users can set the ideal oscillation value and normal working range of various steels online. We also can set the alarm limit, and the storage time of the database etc. 7. After charging the device once, it can work continuously for more than four hours. 8. Integrate embedded processing equipment to realize data collection, display, analysis, reporting and other functions. 9. According to the mold characteristics and user requirements, it can be flexibly configured, wich is suitable for all types of molds such as square billets, slabs, round billets and other mold oscillation tables. 10. Support wired and wireless data transmission functions, easy to use. 11. Use the laptop to receive the collected data, can be used for the operation test on site, and can analyze and process the data conveniently. The features of the system 1. The actual oscillation state replaces the ideal oscillation state. The actual oscillation state of the table is used to formulate a control strategy, so that the oscillation table can be used to produce products with more accurate oscillation. 2. Convenient detection method. The equipment can be used for on-site inspection at any time, and the production site can grasp the operating status of the on-site equipment in time, so that we can make production adjustments to the equipment at any time. 3. Efficient working methods and processing platforms. The high-integration equipment developed by embedded technology can work in high temperature and harsh environment. This system can comprehensively detect XYZ three-axis data, and realize real-time data analysis and processing with high-speed data operation and processing platform. 4. Powerful database function. The database adopts the mode of computer automatic management and operator's manual assistance management, and there are tables for recording historical data and alarm data and working parameter setting table of monitoring system inside the database. By adjusting the output range, the best output effect can be obtained.

See product

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

See product

Pakistan

AR807 Temperature Humidity Meter is an instrument used for measuring the moisture content in the atmosphere. Humidity measurement instruments usually rely on measurements of some other quantity such as temperature, pressure, mass or a mechanical or electrical change in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices use changes in electrical capacitance or resistance to measure humidity differences. FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan

AS837 Smart Sensor FEATURES Quickly and conveniently take accurate humidity and temperature readings. It is an ideal humidity&temperature meter instrument with scores of pratical applications for laboratorial, industrial, engineer and professional use. FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan (All cities)

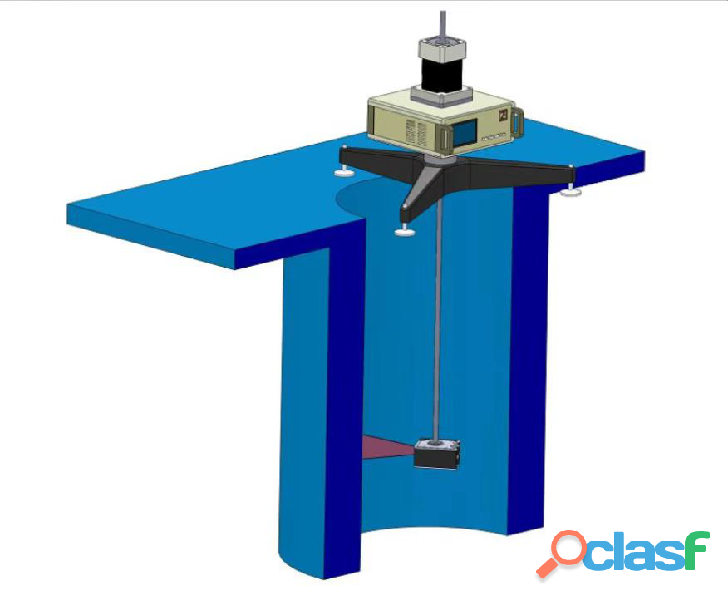

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

See product

Pakistan (All cities)

Overview The handheld roll gap checker is specially used to measure the length between spherical surface, arc surface and plane (or spherical surface). It is specially suitable for the opening adjustment of the roll gap of the metallurgical continuous casters in various specifications, because the roll gap checker has the advantages of high resolution, accurate measurement, stable data and easy to use. Because the opening accuracy of the roll gap checker will directly affect the quality of the casting block, this roll gap checker is an indispensable testing equipment in the continuous casting equipment, which can fully meet the needs of on-site installation testing and use process verification. When the hand-held roll gap meter smoothly passes through the gap between the guide rolls of the continuous casting machine, the upper measuring contact of the hand-held roll gap checker contacts the inner arc roll and the lower measuring contact touches the outer arc roll. The handheld roll gap checker is used in perpendicular to the roll diameter direction, during the pushing process, when the hand-held roll gap meter is in the tangent plane of the upper and lower rolls, the measured value is the smallest at this time, and this value is the roll gap measurement value. The design of the hand-held roll gap gauge ensures that the upper and lower contacts of the roll gap checker can smoothly pass the measured roll along a straight line during measurement. During the measurement process, the roll gap measuring instrument automatically compares the measured values, and displays the minimum measured value on the instrument display interface, which is the current measured roll gap value. The introduction of different types The measuring range of the split hand-held roll gap checker is 180mm - 400mm This hand-held roll gap checker adopts the design that the measuring body and the display instrument are separated. The measuring body can be clamped by an extension rod, which is suitable for online maintenance and measurement of wider slabs, and it is convenient to use the extension rod to send the measuring body into the continuous casting section to measure inside and we can see measurement data on the checker outside. The measuring range of instrument type handheld roll gap checker is 120mm - 400mm This hand-held roll gap meter is light and compact, and it is convenient to carry during maintenance. The measurement value can be seen immediately after measurement, easy to use, and can be equipped with a short measuring rod. It is suitable for the maintenance and measurement of slab online and offline continuous casting sections. It has data printing function, the measurement results can be printed in real time. The measuring range of thin slab hand-held roll gap checker is 60mm - 150mm This handheld roll gap meter is suitable for measuring the roll gap of CSP continuous casting machine and ultra-thin slab continuous casting machine. It is accurate and easy to use. The technical parameters 1. Measuring range of instrument type handheld roll gap checker: 180mm - 400mm (the range can be customized) 2. Measuring range of digital hand-held roll gap checker: 120mm - 400mm (the range can be customized) 3. Measuring range of hand-held thin slab roll checker : 60mm - 150mm (the range can be customized) 4. Measurement accuracy: 0.01mm 5. Working temperature: -25℃~+85℃ 6. Battery capacity: 5000mAh 7. Charger specification: 12V

See product

2 photos

Pakistan

Autoclave Prestige 2100 Classic Brand New Made in UK Demand: Rs.75000/- Seventy Five Thousand only Contact Dr. Fahad Bahria Town Rawalpindi / Islamabad Manufacturer's link: http://www.prestigeautoclaves.com/prestige-classic-2100-electric-autoclave.html Compact and Portable Easy to Operate 18 minute sterilization cycle (23 min total cycle time). Takes only 6 minutes to reach steriziation temperature. Temperature: 121 degrees C Light Weight: Only 11.5 lbs. Cost Effective 9 Liter Capacity Includes Instrument Basket Depressurization valve to reduce cooling time. Light, compact, portable and robust, top loading autoclave. Fast, 11 minute, 126°C sterilizing cycle Simple one step operation starts the automatic cycle. Light sequence indicators show 'Power to Unit' - 'Cycle in Progress' - 'Sterilization in Progress' - 'Cycle is Successful' or 'Cycle has Failed' Interlock system prevents the lid from being removed whilst pressure remains in the vessel. Two stage 'over pressure' protection system incorporating a calibrated Pressure Release Valve and a Gasket Offset Device. Extended life 'green' gasket lasts in excess of 750 cycles. Electronic detectors turn off the power if there is insufficient water. Optional temperature and pressure gauges show internal chamber conditions during the cycle. Thermal fuse (all models) and double pole fuses (not 120v models) protect against overheating and electrical faults. 'TST' indicator strips provide independent verification that the correct combination of temperature, steam and time has been achieved for successful sterilization. For assurance of quality, each autoclave is computer tested and issued with a unique Performance Test Certificate showing that the parameters for successful sterilization are met. BS3970 Pt.4, as certified independently by Eagle Star.

Free

See product

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

See product

Islamabad (Islamabad Capital Territory)

Product Details: It is a Rotating iron. It is not a curling iron. The rotating hot iron is a new styling and straightening Cylinder Iron. The secret to the Rotting iron lies in it is rotating heated polishing cylinder, along with four rows of precision-aligned hair. Here is how it works: when you run the rotating hot iron through your hair, the first set of bristles gently sort and separate your hair strands. Then the rotating heated polishing Rotating cylinder gently glides over your hair, smoothly polishing, straightening, and styling each strand. Finally, the second set of bristles puts the finishing touch on your hair, leaving you with shiny, silky, hair! It's truly Beautiful & amazing! Rotating hot iron uses less heat than traditional hot Instrument, and delivers better results. How? the rotating hot iron's gentle heat in combination with the rotating motion of the polishing cylinder literally polishes your hair strands individually so it doesn't need extreme heat to get amazing result. Your hair will be shinier, bouncier and full of lift and life! Get lift and fullness – right from the root! Get a looks in seconds. Straighten even the roughest, most bristly hair – and still get fullness and style without the stick-straight "flatness" of a flat iron. Do a full style in 9 minutes – and change it again in 3 minutes! Wrap your hair around the rotating polishing cylinder – and get an amazing curl that lasts all day! If you can hold it, you can do it with the rotating hot iron! INSTYLER - ''Hair Styler Heat Up Rotating Hot Iron Styling Tool'' Original Hair Styler - The amazing rotating Hair Styler offers new hair-styling technology that simply makes your old flat iron obsolete. The secret to the Hair Styler lies in its rotating polishing cylinder and four rows of precision-aligned bristles. Original Hair Styler-The Hair Styler is a new hair styling tool that straightens, polishes and styles hair by means of a rotating heated cylinder and brush bristles. This totally new design polishes the hair strands individually, and allows the user to get amazing results that are much better than those they would have gotten using a flat iron, curling iron, or hot tool. The new design delivers great results without an extreme amount of heat or heavy styling products. With the Hair Styler, you don't need a lot of heat to straighten and style your hair! The Hair Styler's unique design actually allows you to use less heat than you are used to, and still get better results than you would with a flat iron or other hot tool. It's a totally new way of thinking about heat and your hair - you don't need the extreme heat to get the results you want. If you decide that you would like more heat, the Hair Styler has three different temperature settings-always start with the lowest temperature setting. Curls, styles and straightens your hair. No more tangles! Simply close the In-Styler over each section of hair and go! Curl or straighten, then gently pull the motorized rotating barrel away to release your perfectly coifed hairdo. Quick and easy to use. Works with every type of hair. “Flat iron” burning, crushed hair and creases are now a thing of the past. The In-Styler adds volume to fine/thin hair, and straightens course, unruly curls with ease, while leaving your hair feeling incredibly smooth and silky. Removes frizz, enhances shine. The unique polishing cylinder enhances shine and minimizes frizz, for beautiful results every time. Computerized heat with three temperature settings and precision aligned bristles give you total control over the styling process. The Hair Styler makes it easy to style your own hair because this new technology gives you smooth, bouncy, and voluminous hair. You can flip it in or out and it works on all types of hair. You will notice it doesn't take as long to style because you don’t have to keep going over the same areas. It also does not leave any odour because it is so gentle and takes less heat. Discover the smart, easy way to get the hairstyle you want, fast.

Rs 4,5

See product

Okara (Punjab)

Product Detail: It is a Rotating iron. It is not a curling iron. The rotating hot iron is a new styling and straightening Cylinder Iron. The secret to the Rotting iron lies in it is rotating heated polishing cylinder, along with four rows of precision-aligned hair. Here is how it works: when you run the rotating hot iron through your hair, the first set of bristles gently sort and separate your hair strands. Then the rotating heated polishing Rotating cylinder gently glides over your hair, smoothly polishing, straightening, and styling each strand. Finally, the second set of bristles puts the finishing touch on your hair, leaving you with shiny, silky, hair! It's truly Beautiful & amazing! Rotating hot iron uses less heat than traditional hot Instrument, and delivers better results. How? the rotating hot iron's gentle heat in combination with the rotating motion of the polishing cylinder literally polishes your hair strands individually so it doesn't need extreme heat to get amazing result. INSTYLER - ''Hair Styler Heat Up Rotating Hot Iron Styling Tool'' Original Hair Styler - The amazing rotating Hair Styler offers new hair-styling technology that simply makes your old flat iron obsolete. The secret to the Hair Styler lies in its rotating polishing cylinder and four rows of precision-aligned bristles. Original Hair Styler-The Hair Styler is a new hair styling tool that straightens, polishes and styles hair by means of a rotating heated cylinder and brush bristles. This totally new design polishes the hair strands individually, and allows the user to get amazing results that are much better than those they would have gotten using a flat iron, curling iron, or hot tool. The new design delivers great results without an extreme amount of heat or heavy styling products. With the Hair Styler, you don't need a lot of heat to straighten and style your hair! The Hair Styler's unique design actually allows you to use less heat than you are used to, and still get better results than you would with a flat iron or other hot tool. It's a totally new way of thinking about heat and your hair - you don't need the extreme heat to get the results you want. If you decide that you would like more heat, the Hair Styler has three different temperature settings-always start with the lowest temperature setting. Curls, styles and straightens your hair. No more tangles! Simply close the In-Styler over each section of hair and go! Curl or straighten, then gently pull the motorized rotating barrel away to release your perfectly coifed hairdo. Quick and easy to use. Works with every type of hair. �Flat iron� burning, crushed hair and creases are now a thing of the past. The In-Styler adds volume to fine/thin hair, and straightens course, unruly curls with ease, while leaving your hair feeling incredibly smooth and silky. Removes frizz, enhances shine. The unique polishing cylinder enhances shine and minimizes frizz, for beautiful results every time. Computerized heat with three temperature settings and precision aligned bristles give you total control over the styling process. The Hair Styler makes it easy to style your own hair because this new technology gives you smooth, bouncy, and voluminous hair. You can flip it in or out and it works on all types of hair. You will notice it doesn't take as long to style because you don�t have to keep going over the same areas. It also does not leave any odour because it is so gentle and takes less heat. Discover the smart, easy way to get the hairstyle you want, fast. We believe in "Best Quality And Best Service" "Customer Satisfaction is our main priority And Goal". Unbelievable price�.� Or kahi nahi�..... Hurry�Offer valid for Limited Period!!!!!! The items are tested before they leave the store. Our goal is to provide best quality goods at best possible prices. OUR MAIN PRIORITY TO KEEP YOU SATISFIED AND HAPPY our request :- Please read everything before buy Order Now : we are just a call away +92-315-1717187 +92-335-8015786 +92-322-4601855 order@msnteleshop.com info@msnteleshop.com

Rs 4

See product

Pakistan

Product Details: It is a Rotating iron. It is not a curling iron. The rotating hot iron is a new styling and straightening Cylinder Iron. The secret to the Rotting iron lies in it is rotating heated polishing cylinder, along with four rows of precision-aligned hair. Here is how it works: when you run the rotating hot iron through your hair, the first set of bristles gently sort and separate your hair strands. Then the rotating heated polishing Rotating cylinder gently glides over your hair, smoothly polishing, straightening, and styling each strand. Finally, the second set of bristles puts the finishing touch on your hair, leaving you with shiny, silky, hair! It's truly Beautiful & amazing! Rotating hot iron uses less heat than traditional hot Instrument, and delivers better results. How? the rotating hot iron's gentle heat in combination with the rotating motion of the polishing cylinder literally polishes your hair strands individually so it doesn't need extreme heat to get amazing result. Your hair will be shinier, bouncier and full of lift and life! Get lift and fullness – right from the root! Get a looks in seconds. Straighten even the roughest, most bristly hair – and still get fullness and style without the stick-straight "flatness" of a flat iron. Do a full style in 9 minutes – and change it again in 3 minutes! Wrap your hair around the rotating polishing cylinder – and get an amazing curl that lasts all day! If you can hold it, you can do it with the rotating hot iron! INSTYLER - ''Hair Styler Heat Up Rotating Hot Iron Styling Tool'' Original Hair Styler - The amazing rotating Hair Styler offers new hair-styling technology that simply makes your old flat iron obsolete. The secret to the Hair Styler lies in its rotating polishing cylinder and four rows of precision-aligned bristles. Original Hair Styler-The Hair Styler is a new hair styling tool that straightens, polishes and styles hair by means of a rotating heated cylinder and brush bristles. This totally new design polishes the hair strands individually, and allows the user to get amazing results that are much better than those they would have gotten using a flat iron, curling iron, or hot tool. The new design delivers great results without an extreme amount of heat or heavy styling products. With the Hair Styler, you don't need a lot of heat to straighten and style your hair! The Hair Styler's unique design actually allows you to use less heat than you are used to, and still get better results than you would with a flat iron or other hot tool. It's a totally new way of thinking about heat and your hair - you don't need the extreme heat to get the results you want. If you decide that you would like more heat, the Hair Styler has three different temperature settings-always start with the lowest temperature setting. Curls, styles and straightens your hair. No more tangles! Simply close the In-Styler over each section of hair and go! Curl or straighten, then gently pull the motorized rotating barrel away to release your perfectly coifed hairdo. Quick and easy to use. Works with every type of hair. “Flat iron” burning, crushed hair and creases are now a thing of the past. The In-Styler adds volume to fine/thin hair, and straightens course, unruly curls with ease, while leaving your hair feeling incredibly smooth and silky. Removes frizz, enhances shine. The unique polishing cylinder enhances shine and minimizes frizz, for beautiful results every time. Computerized heat with three temperature settings and precision aligned bristles give you total control over the styling process. The Hair Styler makes it easy to style your own hair because this new technology gives you smooth, bouncy, and voluminous hair. You can flip it in or out and it works on all types of hair. You will notice it doesn't take as long to style because you don’t have to keep going over the same areas. We believe in "Best Quality And Best Service" "Customer Satisfaction is our main priority And Goal". Unbelievable price….… Or kahi nahi…..... Hurry…Offer valid for Limited Period!!!!!! The items are tested before they leave the store. Our goal is to provide best quality goods at best possible prices. OUR MAIN PRIORITY TO KEEP YOU SATISFIED AND HAPPY our request :- Please read everything before buy Order Now: We are just a call away 03458423444, 03457770439

Rs 4.500

See product

Arifwala (Punjab)

Product Details: It is a Rotating iron. It is not a curling iron. The rotating hot iron is a new styling and straightening Cylinder Iron. The secret to the Rotting iron lies in it is rotating heated polishing cylinder, along with four rows of precision-aligned hair. Here is how it works: when you run the rotating hot iron through your hair, the first set of bristles gently sort and separate your hair strands. Then the rotating heated polishing Rotating cylinder gently glides over your hair, smoothly polishing, straightening, and styling each strand. Finally, the second set of bristles puts the finishing touch on your hair, leaving you with shiny, silky, hair! It's truly Beautiful & amazing! Rotating hot iron uses less heat than traditional hot Instrument, and delivers better results. How? the rotating hot iron's gentle heat in combination with the rotating motion of the polishing cylinder literally polishes your hair strands individually so it doesn't need extreme heat to get amazing result. Your hair will be shinier, bouncier and full of lift and life! Get lift and fullness – right from the root! Get alooks in seconds. Straighten even the roughest, most bristly hair – and still get fullness and style without the stick-straight "flatness" Original Hair Styler - The amazing rotating Hair Styler offers new hair-styling technology that simply makes your old flat iron obsolete. The secret to the Hair Styler lies in its rotating polishing cylinder and four rows of precision-aligned bristles. Original Hair Styler-The Hair Styler is a new hair styling tool that straightens, polishes and styles hair by means of a rotating heated cylinder and brush bristles. This totally new design polishes the hair strands individually, and allows the user to get amazing results that are much better than those they would have gotten using a flat iron, curling iron, or hot tool. The new design delivers great results without an extreme amount of heat or heavy styling products. With the Hair Styler, you don't need a lot of heat to straighten and style your hair! The Hair Styler's unique design actually allows you to use less heat than you are used to, and still get better results than you would with a flat iron or other hot tool. It's a totally new way of thinking about heat and your hair - you don't need the extreme heat to get the results you want. If you decide that you would like more heat, the Hair Styler has three different temperature settings-always start with the lowest temperature setting. Curls, styles and straightens your hair. No more tangles! Simply close the In-Styler over each section of hair and go! Curl or straighten, then gently pull the motorized rotating barrel away to release your perfectly coifed hairdo. Quick and easy to use. Works with every type of hair. “Flat iron” burning, crushed hair and creases are now a thing of the past. The In-Styler adds volume to fine/thin hair, and straightens course, unruly curls with ease, while leaving your hair feeling incredibly smooth and silky. Removes frizz, enhances shine

Rs 4

See product

Pakistan

7701 AZ INSTRUMENT * Measuring range : 0 - 1000 ppm * Accuracy : + / -20% at 0-100pm; + / -15% at 100-500 ppm; ( at 20+ / -5 oC , 50+ / -20% RH) * Power supply : 3 pcs x AAA * Response Time ( T90) : within 60 seconds * Operating humidity : 5~ 99% RH ( no condensation) * Storage condition : -40~ 70oC * Operating temperature : -10~ 60 oC * Meter size : 175 x 47 x 28mm ( LxWxT) * Standard packing includes : Meter, manual, wrist strip, carry pouch in color/ plane box Shipping All Across Pakistan COMPANY: MATRIX ELECTRONICS CONTACT PERSON: FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product