System support executive

Top sales list system support executive

Karachi (Sindh)

Multinational Organization ( WFDSA ).Jo ( SECP or FBR ) Sy Register Hai.For diffrent offices, projects, departments, fields and positions... etc.....,,, SPECIAL PACKAGE FOR STUDENTS (LEARNING and EARNING , FIRST TIME IN PAKISTAN) (3 an 6 hours office work) atractive pakg ( 15,000 to 25,000) IN (morning, noon, evening ) , part time/full time, , male/female we require: , Education,Docotor,Management, trainers, humain resource officers, health care consultants, ETC................. , = Male/Female , Retired Person, House Wives, Teachers, Students,,,,, business men, people of diffrent age, of diffrent qualification and fields...... , everage income 15,000/ to .25,000 (depends on Your Ability) Kindly send your short detaiil @ Name , age , exp , area , edu 03242185777 Via message only

Rs 20

See product

Karachi (Sindh)

Multinational Organization ( WFDSA ).Jo ( SECP or FBR ) Sy Register Hai.For diffrent offices, projects, departments, fields and positions... etc.....,,, SPECIAL PACKAGE FOR STUDENTS (LEARNING and EARNING , FIRST TIME IN PAKISTAN) (3 an 6 hours office work) atractive pakg ( 15,000 to 25,000) IN (morning, noon, evening ) , part time/full time, , male/female we require: , Education,Docotor,Management, trainers, humain resource officers, health care consultants, ETC................. , = Male/Female , Retired Person, House Wives, Teachers, Students,,,,, business men, people of diffrent age, of diffrent qualification and fields...... , everage income 15,000/ to .25,000 (depends on Your Ability) Kindly send your short detaiil @ Name , age , exp , area , edu 03072560364

Rs 28,5

See product

Karachi (Sindh)

Requirement: Qualification: Education: Graduation Documents: CV, Bachelors (Final consolidated mark sheet) & Original NIC Skills: Excellent communication skills and good computer skills Job Type: Full Time. Benefits: Medical + Insurance Others: PF & Overtime ShaikhHanzla.Taimoor@ibexglobal.com

Rs 18.000

See product

Pakistan

Technology Root is a technology marketing and ONE STOP OFFICE SOLUTION company with a committed after sales support team. On site project implementation and after sales support can be provided anywhere in Pakistan. Technology Root is one of the most trusted solution providers of CCTV / Surveillance & Security Solutions, Biometric Attendance System, Metal Detectors, PABX and Fire Security.

See product

Islamabad (Islamabad Capital Territory)

TheDesk Coworking Space offers full furnished executive suites in Islamabad. The suites come with amenities such as; fast internet, reception, parking lot, water, air conditioning system and access to kitchen. For more details and various membership plans, please visit our website: https://thedesk.pk

Rs 75.000

See product

2 photos

Lahore (Punjab)

Support the access contorl function(differet time open the door,people open the door,disassemble the police,Police have no closed the door,the door is opened illegally alarm,door button input,Wired doorbell interface,all the way alarm output,stressalarm,etc.)and attendance functions,Can be equipped with access control software and ground software. Fingerprint Template Capacity:500 Record capacity:30000 Communication:TCP/IP or RS485/RS232 communication Power Supply: Standby current:50mA Working Current:400mA Fingerprint: 2000 Storage:50000 Language: Simplified Chinese Traditional Chinese Enlish .

Rs 22.000

See product

Pakistan (All cities)

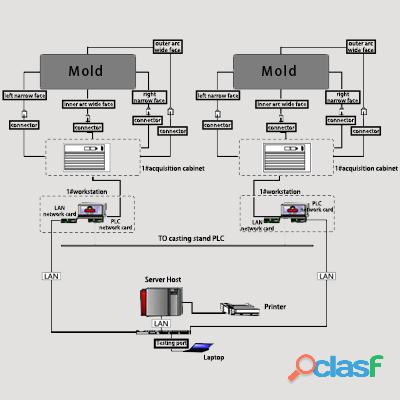

Overview: The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional artificial intelligence and information processing technology to overcome the defects of traditional logic-based prediction models. It has the functions of self-adaptation, self-organization and real-time learning. The breakout prediction system has an optimized industrial network structure. According to the distribution and change rules of the temperature field of the mold, it can track and respond to the breakout process in real time. It can learn and judge by itself, and provide early warning information for on-site operations. It can effectively prevent the occurrence of breakout accidents, greatly reducing the cost and improving the safety factor of continuous casting. The system is suitable for all kinds of continuous casting machines such as square billet, round billet, rectangular billet and slab. Block Diagram of Breakout Prediction System The composition of the system Thermocouple: according to the on-site conditions of the mold, water tank, bolts and mold frame to desgin Front-end acquisition system: Multi-module acquisition chain, industrial Ethernet interface, high-speed embedded processing module Working platform: Real-time display of mold temperature field status, online analysis and prediction of mold breakout Server: Data exchange and storage management, reporting and printing system, with data analysis and self-learning functions The Main technical parameters Data sampling: the sampling frequency of K-type/T-type thermocouple can up to 10HZ Accuracy of temperature measurement: ±0.25℃ Support communication protocol: Industrial Ethernet (TCP/IP),PROFIBUS-DP,CANopen Executive standard: DE0411 Standard Class III/1EC584/IEC1515 Transmission speed: 100M/bps The composition of the software Online monitoring software for breakout prediction Offline query software for breakout prediction Data recovery and self-learning software packages Data acquisition and monitoring software The software package of mold thermal status display The functions of the system Real-time data acquisition, data analysis and judgment Automatic selection of steel grade’s alarm parameters Real-time dynamic picture monitoring Prediction alarm and information display of breakout signs Automatic deceleration after alarm Historical data storage and historical trend graph display Automatic report generation and printing Alarm prediction and pattern recognition of unknown steel grades by neural network Dynamic real-time temperature profile prediction Mould heat flow field display FIG 1:Typical process of mold breakout prediction The features of the system 1. Reasonable design of temperature measurement point and professional protection front-end acquisition system, and complete installation and calibration tool components. 2. The system has strong adaptability and can meet the transformation of various structural continuous casting machines. 3. High-speed data communication, using industrial network to form an independent local area network for each workstation and server. It can realize high-speed data transmission of alarm files, alarm parameters, and other databases. 4. The combination of artificial neural network and intelligent forecasting model improves the alarm accuracy of breakout forecasting. 5. Historical data storage and historical trend graph display, historical reports, historical alarm legend printing, real-time alarm data printing. 6. Provide a local area network interface, which can realize the storage and forwarding of alarm files, and the input and output of offline alarm data. 7. Remote Web browsing can be achieved according to customer needs. 8. Can be seamlessly connected with MES-C220 mould expert system.

Rs 200.000

See product

4 photos

Pakistan (All cities)

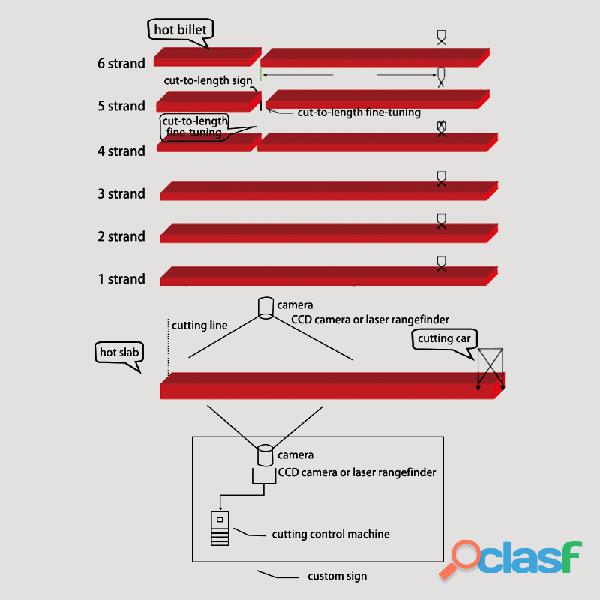

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

See product

Pakistan (All cities)

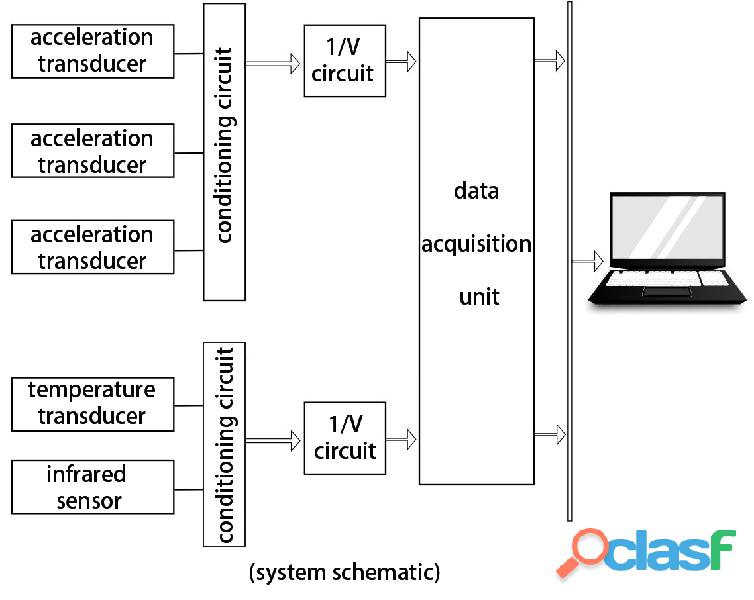

Overview The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection. The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system. The meaning of the system 1. Reduce the amount of tundish slag 2. Improve the purity of molten steel 3. Improve the life of the tundish 4. Reduce sliding nozzle erosion 5. Reduce nozzle blockage 6. Increase continuous pouring heats 7. Reduce the amount of residual steel in the ladle when high-quality steel is casting 8. Improve the yield of molten steel 9. Improve the quality of continuous casting billets In order to improve the purity of the molten steel in the tundish, and improve the quality of the casting billet, especially to improve the quality of the billet in the transition section, and reduce the amount of residual steel in the high-quality ladle, and prolong the life of the tundish lining, and increase the continuous casting heats, it’s necessary to detect and control the slag in the later stage of continuous casting ladle casting. The working principle The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm. The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close the ladle nozzle. The features of the system (1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise. (2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The threshold of slag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such as the sensor service life and sensor usage times. (3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life. (4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm. (5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction. (6) The equipment adopts a modular design. The failure of each module will not affect other parts, which ensure more reliable operation of the system and easy maintenance. (7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag carryover strats, we can choose automatic mode or manual mode. In both modes, the system will give audible and visual alarm signals to remind on-site operators. (8) The system has a powerful database function. Including the comparison function for last two ladles of casting time record, the system automatically stores the running data, and generates a record file every day. (9) The system has the function of automatically controlling the ladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with the ladle slag detection system to automatically control the opening of the ladle nozzle and realize the whole-process control of the liquid level of the molten steel in the tundish. The composition of the system The LAG-S200 slag detection system consists of: vibration detection sensor, pre-signal amplifier, slag detection operation unit, tundish liquid level control unit, on-site operation indication box, and process control cabinet. 1. Vibration detection sensor: It is installed on the robotic arm of the stopper to detect the vibration signal of the whole casting process of the ladle. 2. Pre-signal amplifier: Amplify, convert and transmit the weak vibration signal detected by the vibration detection sensor. 3. Slag detection operation unit: Analyze, judge and discriminate the vibration signal to realize the discrimination of all steel, mixed slag and full slag , and output the slag alarm signal. 4. Tundish liquid level control unit: Accept the control signal of the tundish nozzle and the ladle nozzle, and realize automatic or manual control to the ladle slag according to the requirements. 5. On-site operation instruction box: Provides man-machine exchange for slag alarm indication, fault indication, system activation mode selection, and control mode selection. 6. Process control cabinet, providing power management, displaying man-machine interface and setting management. The parameters of the system 1. The system controls the slag inclusion in molten steel with high precision and closes the nozzle in real time. 2. Improve the quality of steel, reduce defective products, and improve the yield. 3. The yield of molten steel is increased by 0.3%-0.5%. The nozzle can be automatically closed, so that the disadvantage of untimely manual response is overcome and less molten steel remains in the ladle. The threshold value of molten steel (slag threshold) is set by the user within a wide range. 4. No artificial factors are involved, high reliability, good repeatability or consistency. 5. The steelmaking slag does not pass through or rarely flows into the tundish, which increases the service life of the refractory material and the sliding nozzle. 6. Reduce the blockage of the tundish nozzle and increase the number of continuous pouring heats of the tundish.

Rs 200.000

See product

3 photos

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

See product

Lahore (Punjab)

● Anviz technology with optical waterproof fingerprint sensor.Scratch-proof, unbreakable and durable. Well accept all kinds of fingerprints ● BioNano core algorithm platform of high performance and reliability ● New 2011 version algorithm with improved performance on wet and dry fingerprints. Support identification from different angles ● Support multiple languages display. Suitable for local market. ● White backlit keypad with 10 numeric keys and 7 function keys ● Optional RFID/ Mifare/HID card reader ● RS485, Mini USB Slave and TCP/IP for network connection ● Support wiegand26 input/output. ● Direct lock control to open door, door open sensor. ● Optional SC011/SC844 or any other standard access controller for separate type secure access control system ● Unique infrared auto wakeup design ● Time zone and group access control, realtime data transfer monitor ● Standard 2000 fingerprints and 50000 records ● Wall mounted, combine 2-in-1 function for access control and time attendance

Rs 25.000

See product

Lahore (Punjab)

We are currently seeking a Female Coordinator to work with the CEO. To perform this job successfully, an individual must be self-driven and quality-focused. Must have strong initiative, be self-directed, and able to accomplish/perform tasks with minimal direction. Must have excellent communication skills, an interest in technology, and the ability to work effectively under pressure. The company office is located in Gulberg Lahore. Responsibilities: Assist project teams as needed to ensure project success, Work through and resolve issues as needed, Create and modify procedure documentation, user guides and job aids as necessary Must be proficient in English, MS Office tools; such as Outlook, Word, Excel, and PowerPoint, Ability to learn the project process quickly following an orientation, Good understanding of IT solutions & business in general. Excellent IQ and decision support skills. Candidate must be perceived as ambitious, enthusiastic, self-confident, versatile and willing to learn, The candidate will possess excellent interpersonal skills and have the ability to work individually and in a team environment, Can travel outside the station for meetings yes -- OK for recruiters to contact this job advertiser. yes -- Phone calls about this job are ok. no -- Reposting this message elsewhere is NOT OK.

See product

Islamabad (Islamabad Capital Territory)

Dear Sir, We "Al-Fateh International" introducing our self as Engineering Service Provider in Pakistan, kindly find below details for your information. "Al-Fateh International" commenced its operations in 2006, it is one of Pakistan's fastest growing in to integrate Trading/Engineering & Telecom solutions as a strong trading engineering company, AFI provides project development, turnkey solutions, project management support outstanding product offer & country wide distribution network. Moreover AFI adapted to the change and added new products and infrastructure to conform to the industry's international standards. It now provides total multi-model services under a one-window operational concept. SERVICES WORKS • Cell On Wheels (Deployment / Maintenance Works) • Office Networking Solutions & Data Centers • Services for Power Equipment (UPS, Generators, Rectifier, Solar Panels and Cables) • Services for Tower Installation work (BTS / MW Hop) • Site Build Up (New Construction work) • Site Build Up (Sharing Sites) • Manage Services (Operation and Maintenance Services for Existing Building) • Fiber Optic Laying and Termination POWER PRODUCTS • Solar System with Hybrid Charge Controller. • Maintenance Free / VRLA or Gel Batteries (Narada / VISION / FIAMM / SHOTO / YUASA / SACRED SUN) • Solar Based Water Pumping Station (HMA / KSB) • Solar Based Water Geyser • Industrial Online and Line Interactive UPS (APC / RIALLO / EMERSON / DELTA / EATON / ENEL / ELTEK) • Rectifier & DC System for Telecom Equipment (EATON / EMERSON / DELTA / ELTEK) • Automatic Voltage Regulator & Line Conditioner • Battery Testing Kit & Dummy Load Tester • Petrol & Diesel Generator Sets (ALLIED CAT / CUMMINS / STAMFORD / PERKINS) POWER & DATA CABLES • Data & Communication Cables – ( 3M / AYAYA / LEONI / BELDEN / NEWAGE / FAST / PREMIER ) • Networking Cables ( CAT-5 , CAT-6, CAT-7 ) - 3M / AYAYA / DINTEK • Fiber Optic Cables and accessories – ( 3M / PREMIER ) • Feeder Cable, Connectors & Accessories – Brand : LEONI / BELDEN. • Under Ground & Aerial Cables - Brand LEONI / BELDEN • Power & Earthing Cables - Pakistan / FAST / Newage Cables • Under Ground Gel Type Power Cables • HT Conductor Cables SECURITY PRODUCTS • Flip Barriers • Tripod Turnstile • Delta Barriers • Boom Barriers • Kurb Barriers. • Baggage Scanners • Walk Through Gates ( Garatte / CIEA ) • Hand Held Metal Detector ( GARATTE ) • Bollards & Blockers. • Razor Wire & Electric Fencing Solution. TECHNOLOGICAL PRODUCTS • Fire Alarm System ( HONEYWELL / GENT / MORLEY / NOTIFIER ) • Fire Suppression System ( FM200 ) • Access Control System ( Honeywell / BOCSH ) • Public Address System ( BOSH / TOA / AC Audio ) • CCTV Solutions ( Honeywell / BOCSH / Samgsung ) • Queue Management Solution ( Q-Matrix / Local Made ) • Computers & Servers ( IBM / DELL / HP ) • Raised Flooring Solutions ( LINDNER / WIESS ) FABRICATION EXPERTISE • Fabrication works – Telecom Sun Shed • Fabrication works – GSM Antennas Mount • Fabrication works – DB’s & Panels • Fabrication works – Guard Check Post • Fabrication works – ATS / AMF Panel • Fabrication works – Canopies / Fuel tanks • Fabrication works – Cable Ladder and Cable Trays • Fabrication works – Cell on wheel • Fabrication works - Mobile Pumping Solution • Fabrication works - Parking Sheds • Fabrication works - warehouse sheds • Fabrication works - Bill Boards & Signage • Fabrication works - Street Poles & Lights • Fabrication works – Solar Frames & Solar Structure • Fabrication works – Telecom Cabinets & Racks • Fabrication works – Battery Racks • Fabrication works – Generator Trolley Maintaining high professional standards AFI inducts loyalty, integrity & faith as prime obligations in organizational structure with provision of absolute services. AFI handling mega projects nationally. The vision of AFI is shared by its motivated team members who work together to make economy of Pakistan stronger. Regards, Khurram AL-FATEH INTERNATIONAL Suit # 10 | First Floor | G-13/1 | Islamabad (44000) - Pakistan

Free

See product

Karachi (Sindh)

Technical Description: 1. The whole racking system need radio shuttle and forklifts to work together. The radio shuttle is controlled wirelessly by remote to complete storage of goods. Radio shuttle include: Products Feature: 1. Shuttle racking system is a special made racking system for shuttle which based on the structure of Drive- in racking. 2. Depth of this racking system could be 30-60 m, which is much bigger than normal Drive-in racking. 3. Depending on the warehouse structure, the shuttle racking system can be also support for FILO and FIFO. 4. This system doesn’t need the forklift to pick up goods inside the lane, but a shuttle instead. So it has a good safety performance. 5. It is suitable for storing goods of large quantity by small varieties, such as foodã€chemicalã€tobacco industry, it is also the best choice for cold operation storage. http://kfurnitures.com/ http://kfurnitures.com/product/shuttle-racking-system/

Rs 60.000

See product

2 photos

Rawalpindi (Punjab)

Introduction to School Assignments Management System: School Assignments Management System, in short SAMS, is a web application that will help to manage students' assignments in any school. This software will have the ability to send notifications to teachers and parents via an internal messaging system. This software will have the following 3 access levels. Admin Teacher Student Each level has limited access except Admin. However, Admin can grant some extra permission to any account. For example, Admin can give permission to any teacher to delete students. By default, the teacher will not have permission to delete the user. Software Modules:- Following module is available is School Management System:- 1- Main Dashboard (Whole software’s status at a glance) 2- Student Registration (Manage students data and control the access level of parents and students) 3- Manage Teachers (Manage teachers data and their access levels) 4- Classes Management (Manage classes/sections) 5- Settings Module (Setting of whole software will be there) 6- Logs Module (Logs of every important entries and users activity) 7- Reminders Module (Reminders for important tasks) 8- Notification Module (Notifications for Teachers and Students Alert Box) 9- Assignments (Teacher will upload assignments and after completing that assignment, the students will reupload that assignment) 10- Permission Module (Module for set Permissions for software users) 11- Address book (Contacts of important persons) 12- Profile (update profile of logged in user) Note: Custome Modification can be made Free Installation for first time Free 3 Months updates and support.

See product

-

Next →