Steel cupboard standard

Top sales list steel cupboard standard

Buner (Khyber Pakhtunkhwa)

Plate flange, thread flange, blind flange, slip-on flange Weld-neck flange, lap-joint flange etc 1 stainless flange and carbon steel flange cast flange 2 Standard: ISO ASME, ANSI. API, JIS, JPI. DIN. UNI. BS. AS etc 3 Size: DN150-DN100 4 Pressure: PN150-PN1500 5 Surface treatment: Transparent/yellow/black anti-rust paint transparent oil 6 Package: Wooden case with standard seaworthy package 7 Primary advantage: High-temperature and high-pressure ressistant Special and irregular steel flange available as your customization.

Rs 21

See product

Lahore (Punjab)

We wish to introduce ourselves (PAK-Standard Glass & Aluminum LTD.) as a leading Aluminum and glass fabrication company based at Lahore since 2001. Since 2001 our multiple range of products in Aluminum, glass add beauty and glamour of Plazas, Hotels, farm houses, resorts, bungalows, all kind of residential and commercial complex, showrooms & town planers. Our company specializes in ALUMINUM single glazed and double glazed windows, doors, Shop fronts, curtain wall, Aluminum cladding, Aluminum dome structure, GLASS All kind of local and imported glass, curtain wall glass, Bend glass, Double glazed glass, Glass stairs, Glass domes, Glass shower cabins, Glass designing, glass flooring, Tempered glass STAINLESS STEEL PRODUCTS Stainless steel railing, stainless steel domes, steel wire railing and steel plus glass railing stainless steel doors for (pharmaceutical companies) BLIND PRODUCT Best quality Roller blinds, Mini blinds, Vertical blinds, Bamboo blinds Wooden blinds etc. We are well equipped with necessary infrastructure and fully trained work force striving to build a strong long term relation without esteemed customers . All our products exclusively designed by our in House designers and best makers. Please feel free to keep in touch with us about any of your project related requirements/queries. We would like to offer our service to you. Our supervisor will contact you for further discussion at a time convenient to you. We trust you will please confirm your order and give us an opportunity to serve you to the best of our capability. Our company specializes Glass and aluminum fabrication and installation as well as providing the repairing services.There is a professional team of engineers working within our company. During our existence in market we did not receive any negative feedback from our customers. We look forward to a wonderful relationship together and success for all concerned. Regards Amjad Ali 03214496148l Office & Display Mnawan bank stop bata pure Lahore.

Rs 350

See product

Jamrud (Federally Administered Tribal Areas)

Size Seamless: From 1/2" to 24" Welded: From 24" to 96"( or as customer requirements) Angle 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Thickness SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH80., SCH100, SCH120, SCH140, SCH160, XXS Standard ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO Material Carbon steel(ASTM A234WPB, , A234WPC, A420WPL6.

Rs 1

See product

Lahore (Punjab)

Orthodontic Pliers Ahaf Surgico manufacturing of Dental Instruments, Dental Implants Tools, Surgical Instruments, of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification.

Rs 5

See product

Lahore (Punjab)

Aspirating Dental Syringe, Ahaf Surgico manufacturing of Dental Instruments, Dental Implants Tools, Surgical Instruments, of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification.

Rs 5

See product

Lahore (Punjab)

Dental Sterilization Cassette Rack Tray Box Ahaf Surgico Manufacturing Of High Quality Latest CNC made Dental Implants Instruments, Dental Implant Tools Kits, Surgical Instruments of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification. E-Mail: Sales@ahafsurgico.com Whatsapp: 0092-3116960642 Website: www.ahafsurgico.com

Rs 5

See product

Lahore (Punjab)

DENTAL AUTOMATIC CROWN REMOVER SET Ahaf Surgico Manufacturing Of High Quality Latest CNC made Dental Implants Instruments, Dental Implant Tools Kits, Surgical Instruments of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification. E-Mail: Sales@ahafsurgico.com Whatsapp: 0092-3116960642 Website: www.ahafsurgico.com

Rs 5

See product

Lahore (Punjab)

Dental Root Elevator Instruments Ahaf Surgico Manufacturing Dental Surgical Instruments of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification. E-Mail: Sales@ahafsurgico.com Whatsapp: 0092-3116960642 Website: www.ahafsurgico.com

Rs 5

See product

Lahore (Punjab)

Instruments Sterilization Trays Ahaf Surgico feel much pleasure in introducing our selves to your esteemed house as one of the prominent self-manufacturers of Dental Instruments, Dental Implants Tools, Orthodontic Instruments, of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification.

Rs 1

See product

Hyderabad (Sindh)

Sinus Lift Osteotome Kit Dental Implant Sinus Lift Placement of Dental Implant into healed site using ridge expansion (Osteotomes). Osteotomes used in sequential manner to enlarge site, preserving bone, only one bur used for initial site marking. Xenograft (Bioss by Geislitch) used to 'plump' site to improve soft tissue contour.Ahaf Surgico Manufacturing Of High Quality Latest CNC made Dental Implants Instruments, Dental Implant Tools Kits, Surgical Instruments of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification.

Rs 10

See product

Pakistan (All cities)

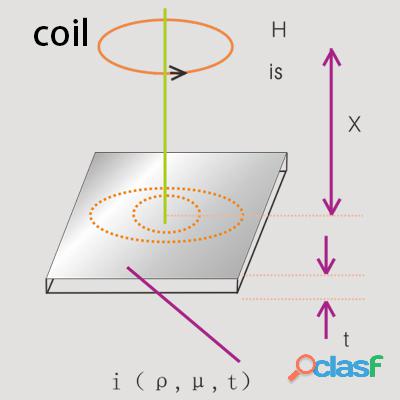

Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting. The molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet. The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows: The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm. At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%. It means that the level fluctuation directly affects the surface quality of the casting billet. The principle of the system The eddy current type molten steel level gauge is the key to the system. The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time 0.10s), high detection accuracy (±05mm), and large measurement range (0-150mm). The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer. The system has the advantages of simple operation and no radiation protection problems. The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform. The sensor is cooled by compressed air during use. The principle is shown in the figure A high-frequency exciting winding is installed above the molten steel surface of the mold. The high-frequency magnetic field generated by the high-frequency exciting winding induces eddy currents on the molten steel surface to form a magnetic field. The magnetic field generated by the induced eddy current is in the opposite direction to the magnetic field generated by the high-frequency exciting winding, which changes the impedance of the high-frequency exciting winding. Under the condition that the winding material and structure, steel grade, temperature remain unchanged, the coil impedance change only has a single-value function relationship with the height of the molten steel level. As long as the impedance change of the high-frequency winding is detected, the change of the molten steel level in the mold can be converted. The components of the system Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper. The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level. 1 Eddy current sensor; 2 mold level gauge; 3 control computer; 4 On-site operation display control panel; 5 digital actuator; The control principle of the system The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation. The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc. In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include: 1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper 2. The influence of the weight change of molten steel in the tundish on the control system 3. The influence of the change of the casting speed of the continuous casting machine on the control system 4. The influence of the mold width change (the mold width is adjustable) on the control system 5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge The function and software implementation In order to overcome these disturbances, the mold level control strategy adopts PID control. And on the basis of PID control, self-adaptive correction and feedforward control are introduced to form an advanced control system. The level control is the main loop, and there is a proportional gain of the main loop controller. According to the self-adaptive correction of the mold width change and feedforward compensation of casting speed, so as to further reduce and eliminate liquid level fluctuations caused by mold width adjustment and casting speed changes. In order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates lightly. And the system will choose a shorter intergrating time when molten steel level fluctuates greatly. Thereby, the fluctuation of the controlled object caused by the frequent action of the stopper rod is suppressed. In the signal processing of molten steel level gauge, an appropriate filtering link is added and the vibration frequency synchronous filter is used for filtering processing, which can overcome the interference of mold vibration frequency and amplitude variation.

Rs 200.000

See product

3 photos

Pakistan

AMF500 Series is a wafer type electromagnetic flowmeter ideal for conductive liquids. It comes in sizes from 25 to 200 mm. AMF500 is widely used for tap-water, waste water, food & beverage, pulp & paper and many other industrial fluid. AMF500 Series electromagnetic flowmeter could be used in compact or separate model with AMC Series converter of electromagnetic flowmeter. FEATURES Light and compact version Flow Velocity range: 0-12 m/s, precise in low flow applications It comes any flanges such as ANSI, DIN, JIS... etc Excellent for high pressure application Protection class: IP68 available; sensor submersible FEP Liner is suitable for vacuum tube High accuracy of +/-0.4% value of reading (or+/-0.2% value of reading) With Forward / Reverse flowrate measurement function SPECIFICATION Pipe Size:25,32,40,50,65,80,100,125,150,200mm Measuring Range: Velocity 0-0.25 m/s min. 0-12 m/s max. Material: Measuring Tube: Stainless Steel 304 Coil Housing: Carbon Steel (standard) Stainless Steel 304(Option) Stainless Steel 316(Option) Liner: FEP Protection: IP 68 IP68(Submersible) Temperature: 40 to +180 Deg.C Max. Pressure: 16 Kg/cm2 (standard) 40 Kg/cm2(option)

See product

Pakistan (All cities)

Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area. The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process. MOC-K100 mould oscillation online monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel. The meaning of the system 1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality. 2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance. 3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair. 4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident. 5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product. 6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed. The functions of the system (1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data including oscillation parameters and process parameters. (2) Time domain waveform: This function mainly displays the oscillation waveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elements of oscillation of each measuring point in real time. (3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and the oscillation difference of each channel can be calculated and displayed intuitively. (4) FFT: This functional module completes the calculation and display of the oscillation spectrum in real time. It is used to evaluate the waveform distortion of the entire oscillation table and to determine whether there is a problem with the installation of the oscillation device. (5) Bar graph: The oscillation of each measuring point is indicated by a bar graph of peak value and sensor gap voltage, which is more intuitive. (6) Trend: After starting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings for different steels under the oscillation conditions. The parameters of the system 1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged 2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes) 3. Sensitivity: 1000mV/g 4. Frequency range: 0.04~10HZ 5. Frequency accuracy: ±0.01 Hz 6. Amplitude accuracy: 0.005mm 7. Transmission mode: wired digital transmission, wireless transmission 8. Host: 3U standard rack, handheld device 9. Sensor power supply: 24V.DC 10. Host power supply: 220V.AC/50Hz Mold oscillation curve The structure of the system The main components of the continuous casting mould online oscillation detection system are: 1. Three-dimensional oscillation measurement sensor 2. Handheld oscillation sensor calibrator 3. Dedicated signal connection cable 4. Preamplifier 5. Operation processing unit 6. Graphic display terminal 7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components 8. Control cabinet

Rs 200.000

See product

3 photos

Sialkot (Punjab)

ZEE-6254 Diode Side Pumped Laser Marking Machine Typical Applications: Laser marking of metal & non-metal materials and products: Stainless steel, Surgical Instruments, Titanium Instruments, Laptop Copper parts, Aluminum alloy, Acrylic Sheet, Ceramics,Plastics, Organics, Thermo-Eastover rubbers, Paper, Bearing, Gear, Detonator. Electronic industry: i phone ipod Capacitor, Inductor, Oscillator, PCB, IC, Connector, Control panel, Electronics’ instruments. Others: Cosmetics, Food package, Bottle, Gift, Advertisement & Sign Crafts, Craft & Gift making and anything you wish to be mark. 1. Marking Head It consists of beam expander, galvanometers & drivers, scan mirrors and f-theta lens. Its marking field and marking resolution depend on the f-theta lens, which are 110x110mm and 0.02mm, respectively in our standard configuration. Typical features include high marking speed, high resolution and high stability. 2. Diode-pumped CW Laser Including beam expander with mount, output coupler with mount, laser diode module, rear mirror with mount, Q-switch, red-dot pointer, aperture, rail base and some mechanical parts. No vibration caused by flowing water so that the laser beam quality and pointing performance are more stable. Electric-to-optical conversion efficiency is high and the operation time of the lamp is elongated. The sealing is very good and there is no water leakage for long time use. The base of the laser head is designed well and there is no re-alignment of laser resonator mirrors required after replacing laser diode module or laser resonator mirrors. The laser has first-pulse compression function and the laser pulse peak power is more consistent. Thus the marking quality is much better since the marked lines are also uniform. 3. Computer and Marking Software Our marking software can create various objects such as sequential numbering, barcodes, Data Matrix, texts, simple geometrical objects (such as line, rectangle, round-corner rectangle, polygon, circle, ellipse, etc) and complex graphic objects input via PLT & BMP files. It also can mark on the flying or rotary objects. It is developed for working under WINDOWS 2000/XP and shares the standard Windows visual interface. It has a few I/O ports to link with customer’s production line. 4. Cooling Circulation System All the surface contacting the water are stainless steel or engineering plastics. A water flow switch is used to alarm if there are less water flow or no water flow. Foreign design and manufacturing techniques, strict quality control, and excellent management make sure that our products are highly quality, highly reliable and highly durable. 5. Manually-adjustable XYZ-axis Stage The manually-adjustable stage XYZ-axis stage has the 3 axle adjustment of XYZ-110x150x300mm. Its top plate is 350x270mm with and 9 x13 array of mounting screws M6 spacing at 25mm. Its maximum loading is about 20kg. We also can design a stage according to customer’s requirements. for more details plz call us.

Rs 1.250.000

See product

Pakistan (All cities)

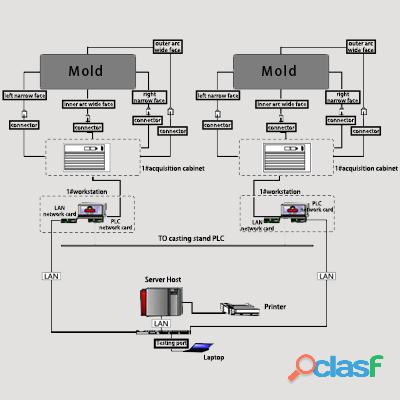

Overview: The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional artificial intelligence and information processing technology to overcome the defects of traditional logic-based prediction models. It has the functions of self-adaptation, self-organization and real-time learning. The breakout prediction system has an optimized industrial network structure. According to the distribution and change rules of the temperature field of the mold, it can track and respond to the breakout process in real time. It can learn and judge by itself, and provide early warning information for on-site operations. It can effectively prevent the occurrence of breakout accidents, greatly reducing the cost and improving the safety factor of continuous casting. The system is suitable for all kinds of continuous casting machines such as square billet, round billet, rectangular billet and slab. Block Diagram of Breakout Prediction System The composition of the system Thermocouple: according to the on-site conditions of the mold, water tank, bolts and mold frame to desgin Front-end acquisition system: Multi-module acquisition chain, industrial Ethernet interface, high-speed embedded processing module Working platform: Real-time display of mold temperature field status, online analysis and prediction of mold breakout Server: Data exchange and storage management, reporting and printing system, with data analysis and self-learning functions The Main technical parameters Data sampling: the sampling frequency of K-type/T-type thermocouple can up to 10HZ Accuracy of temperature measurement: ±0.25℃ Support communication protocol: Industrial Ethernet (TCP/IP),PROFIBUS-DP,CANopen Executive standard: DE0411 Standard Class III/1EC584/IEC1515 Transmission speed: 100M/bps The composition of the software Online monitoring software for breakout prediction Offline query software for breakout prediction Data recovery and self-learning software packages Data acquisition and monitoring software The software package of mold thermal status display The functions of the system Real-time data acquisition, data analysis and judgment Automatic selection of steel grade’s alarm parameters Real-time dynamic picture monitoring Prediction alarm and information display of breakout signs Automatic deceleration after alarm Historical data storage and historical trend graph display Automatic report generation and printing Alarm prediction and pattern recognition of unknown steel grades by neural network Dynamic real-time temperature profile prediction Mould heat flow field display FIG 1:Typical process of mold breakout prediction The features of the system 1. Reasonable design of temperature measurement point and professional protection front-end acquisition system, and complete installation and calibration tool components. 2. The system has strong adaptability and can meet the transformation of various structural continuous casting machines. 3. High-speed data communication, using industrial network to form an independent local area network for each workstation and server. It can realize high-speed data transmission of alarm files, alarm parameters, and other databases. 4. The combination of artificial neural network and intelligent forecasting model improves the alarm accuracy of breakout forecasting. 5. Historical data storage and historical trend graph display, historical reports, historical alarm legend printing, real-time alarm data printing. 6. Provide a local area network interface, which can realize the storage and forwarding of alarm files, and the input and output of offline alarm data. 7. Remote Web browsing can be achieved according to customer needs. 8. Can be seamlessly connected with MES-C220 mould expert system.

Rs 200.000

See product

4 photos