State opening

Top sales list state opening

Pakistan

Job Opportunities Pakistan No 1 State Life Insurance Corporation Of Pakistan Boys / Girls in Largest Network Marketing Field Full Time / Part Time Jobs Categories : Student Teacher Doctor Engineer Advocate Property & Car delar Businessman Retired Person & Others State Life Offers For U unlimited income Freedom Career Group Insurance Risk Coverage Secure Family Future Medical Benefit Quick Promotion Hurry Up more detail contact now Saad 0336-5307406 Rawalpindi / Islamabad & Others Share To All Needed Friends

Rs 10.000

See product

Pakistan

Part/Full time jobs in State Life Insurance Corporation Pakistan Rawalpindi Position Vacant of sales represantative Eligibilities: Qualification: Minimum Matric&Above Age: 18 Or Above Male and Female both can apply for this job Army and other Government retired person can also apply Hurry Up For Interview & Selection Contact Now Saad Mobile No 0336-5307406 Rawalpindi / Islamabad & Others

Rs 10.000

See product

Pakistan

State Life Insurance Corporation Of Pakistan Boys / Girls in Largest Network Marketing Field Full Time / Part Time Jobs Student Teacher Doctor Engineer Advocate Property & Car delar Businessman Retired Person & Others State Life Offers For U unlimited income Freedom Career Group Insurance Risk Coverage Secure Family Future Medical Benefit Quick Promotion contact now Saad 0336-5307406 Rawalpindi / Islamabad & Others

Rs 10.000

See product

Pakistan

Part/Full time jobs in State Life Insurance Corporation Pakistan Rawalpindi Position Vacant of sales represantative Eligibilities: Qualification: Minimum Matric&Above Age: 18 Or Above Male and Female both can apply for this job All person can also apply For Interview & Selection Contact Now Saad Mobile No 03365307406 Rawalpindi / Islamabad & Others

Rs 10.000

See product

Pakistan (All cities)

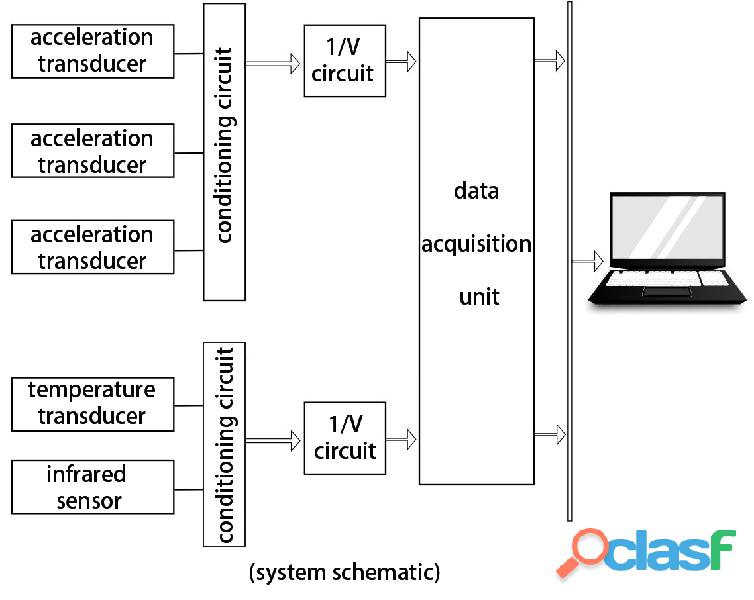

Overview The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection. The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system. The meaning of the system 1. Reduce the amount of tundish slag 2. Improve the purity of molten steel 3. Improve the life of the tundish 4. Reduce sliding nozzle erosion 5. Reduce nozzle blockage 6. Increase continuous pouring heats 7. Reduce the amount of residual steel in the ladle when high-quality steel is casting 8. Improve the yield of molten steel 9. Improve the quality of continuous casting billets In order to improve the purity of the molten steel in the tundish, and improve the quality of the casting billet, especially to improve the quality of the billet in the transition section, and reduce the amount of residual steel in the high-quality ladle, and prolong the life of the tundish lining, and increase the continuous casting heats, it’s necessary to detect and control the slag in the later stage of continuous casting ladle casting. The working principle The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm. The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close the ladle nozzle. The features of the system (1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise. (2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The threshold of slag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such as the sensor service life and sensor usage times. (3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life. (4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm. (5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction. (6) The equipment adopts a modular design. The failure of each module will not affect other parts, which ensure more reliable operation of the system and easy maintenance. (7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag carryover strats, we can choose automatic mode or manual mode. In both modes, the system will give audible and visual alarm signals to remind on-site operators. (8) The system has a powerful database function. Including the comparison function for last two ladles of casting time record, the system automatically stores the running data, and generates a record file every day. (9) The system has the function of automatically controlling the ladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with the ladle slag detection system to automatically control the opening of the ladle nozzle and realize the whole-process control of the liquid level of the molten steel in the tundish. The composition of the system The LAG-S200 slag detection system consists of: vibration detection sensor, pre-signal amplifier, slag detection operation unit, tundish liquid level control unit, on-site operation indication box, and process control cabinet. 1. Vibration detection sensor: It is installed on the robotic arm of the stopper to detect the vibration signal of the whole casting process of the ladle. 2. Pre-signal amplifier: Amplify, convert and transmit the weak vibration signal detected by the vibration detection sensor. 3. Slag detection operation unit: Analyze, judge and discriminate the vibration signal to realize the discrimination of all steel, mixed slag and full slag , and output the slag alarm signal. 4. Tundish liquid level control unit: Accept the control signal of the tundish nozzle and the ladle nozzle, and realize automatic or manual control to the ladle slag according to the requirements. 5. On-site operation instruction box: Provides man-machine exchange for slag alarm indication, fault indication, system activation mode selection, and control mode selection. 6. Process control cabinet, providing power management, displaying man-machine interface and setting management. The parameters of the system 1. The system controls the slag inclusion in molten steel with high precision and closes the nozzle in real time. 2. Improve the quality of steel, reduce defective products, and improve the yield. 3. The yield of molten steel is increased by 0.3%-0.5%. The nozzle can be automatically closed, so that the disadvantage of untimely manual response is overcome and less molten steel remains in the ladle. The threshold value of molten steel (slag threshold) is set by the user within a wide range. 4. No artificial factors are involved, high reliability, good repeatability or consistency. 5. The steelmaking slag does not pass through or rarely flows into the tundish, which increases the service life of the refractory material and the sliding nozzle. 6. Reduce the blockage of the tundish nozzle and increase the number of continuous pouring heats of the tundish.

Rs 200.000

See product

3 photos

Karachi (Sindh)

Dear Sir /Madam We have pleasure to inform you that the system is convenient, reliable and safest .it takes 3 to 5 hours to install the automatic system on your premises we provide 12 months compressive warranty on parts services and we have highly qualified staff ready for discussion and survey at your premises to guide you about your needs for automation & other system in your areas. Product Description: Road Blockers / Rising Kerbs The Automatic Rising Kerb is tough, reliable and un-compromising, providing the perfect solution for prevention of unwanted vehicle access in both manned and unmanned vehicle parking areas. They also provide an excellent deterrent against the most determined intruder. Available in widths of up to 5.0 meters and three heights for varying security levels. Manufactured from welded rectangular hollow section frame and durbar top plate and features an advanced hydraulic power pack to raise and lower the unit smoothly. A state of the art programmable logic controller co-ordinates the hydraulics, access control and traffic light signaling system. An intelligent backup system, fitted as standard, ensures that an emergency lowering facility is operational during any power failure. Specifications: Different types of hydraulic road blockers are available as below: CPV-238 is the standard type of hydraulic road blocker: Length: 2,000 mm Width: 540 mm Lifted Height: 280~380mm CPV-250 is the heavy type of hydraulic road blocker: Length: 2,500mm Width: 720 mm Lifted Height excluding tips: 450mm Lifted Height including tips: 510~530mm. CPV-275 is the high type of hydraulic road blocker: Length: 3,000mm Width: 938mm Lifted Height: 750mm Functions & Features: Strong and durable structure, great capacity of weight bearing; Stable movement, low noise Workable under poor working conditions Adopting low hydraulic pressure driving, with low failure rate, high reliability, and long serving life; Simple and easy maintenance Compatible with other controlling facilities to achieve automatic control; Available with manual operation mode which allows lowering the lifted gate plate back to its horizontal position by manual operation in power failure or malfunction cases. Technical Parameters: Vehicle bearing capacity£º CPV-238 is available for the passing of 70-ton trucks. CPV-250 is available for the passing of middle or small size heavy-duty trucks CPV-275 is available for the passing of 70-ton trucks. System power: 1.5KW/380V Opening time: ¡Ü3S Closing time: ¡Ü4S £¨CPV-275=6S£© Working temperature: -25¡æ--- 65¡æ Storage environment: -10¡æ--- 75¡æ, waterproof, moisture-proof, & dustproof We enclose introduction brochures about for your review and we hope that the information will provide many of the answers to the questions you might have looking forward to your earlier response. Regards, EASY AUTOGATES 021-35163642

Rs 1

See product

Pakistan (All cities)

Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition. The features of the system 1. The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken. 2. The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different segments and different casting speeds. 3. The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed. The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity. 4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient. It has manual, automatic, local and remote control modes. 5. The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux. 6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage. 7. Strong operability, simple and convenient maintenance, and low maintenance cost. 8. It can maintain the even distribution of the flux layer in the mold. The composition of the system The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment. 1. The feeding trolley is the support and walking equipment of the mold flux feeder. The basic equipment of the adding mold flux machine is installed on the feeding trolley. At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position. 2. The feeding bucket is a device for holding mold flux. The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder. The feeding bucket is provided with alarm contact of mold flux level limit.. 3. The swing arm and the feeder motor form a feeding and conveying device. The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor. Then the mold flux can be used for mold distribution. 4. PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates. 5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold. The technical parameter Mold width: 500-2000mm Mold thickness: 100-500mm Type: screw conveying type mold flux feeding machine Heating method: stirring electric heating Arrangement location: on the pouring platform (with its own wheels to move) Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube Molding flux storage tank: 300 L, with material level detection and alarm Control mode: local/remote control, automatic /manual mode Molding flux type: granular flux or powder flux flux adding method: spiral swing adding flux Casting speed interlock: yes Mould size setting: yes Signal transmission: DP/Industrial Ethernet

See product