Scientist s

Top sales list scientist s

Latest Offers

Pakistan (All cities)

Artificial Hymen Pills Price in Pakistan What is Artificial Hymen Pills? Artificial Hymen Pills in Pakistan an Artificial Hymen Could Be a Cellulose Compound That is Developed in 2010 in Germany in a Very Laboratory for Microbiology Stuffed With Synthetic Blood That Imitates Human Blood. Artificial Hymen Pills Are Useful for Fake Virginity by Creating a True Hymen. And Imitate the Loss of Blood That Happens on Your First Time. These Pills Are Formulated With 99.9% Natural Ingredients That Are Extracted From Pure Herbs Used for Hundreds of Years in Asia. Of These Ingredients Are Completely Body-safe and Do Not Have Any Side Effects Whatsoever. All You’ve Got to Try is Just Place the Artificial Pills in Pakistan Inside Your Vagina Between 25-30 Minutes Before You Derive Pleasure From Sexual Activity. Artificial Pills Newtelebrands.com the Natural Hymen of a Lady Protects the Vaginal and Its Canal. If You’ve Lost Your Hymen Due to Any Physical Activity. And You’re Worried About Your Dark That You Simply Cannot Bleed at That Point. So Stop Worrying Because There’s a Product That Comes Dead Set Reduce Your Worries, and Provides You Your Virginity Back by Using Pills. These Artificial Hymen Fake Blood Pills Will Influence the Body Heat and Vaginal Moisture and It Will Then Create a Synthetic Membrane That Acts Sort of a Hymen and Tightens the Vaginal Opening. After Successful Penetration of the Male Organ, the Fake Membrane Will Tear Similar to a True Hymen and Discharge a Touch Blood-like Liquid to Finish the Dramatic Effect. How Artificial Hymen Pills Work? Artificial Hymen Pills in Pakistan Usually Fake Virginity, an Artificial Hymen is a Prosthetic Invention for the Aim of Simulating an Intact Hymen in Women. These Pills Contain a Natural Blend. Which After Inserting in the Vagina Properly Temporarily. Giving the Looks of an Intact Hymen and Releasing a Red Liquid That Appears Like Blood When Subjected to Pressure. Artificial Hymen Kit Consists of Two Layers of Cellulose, the Blood Liquid, and Powder. The Factitious Hymen Reacts to Heat and Moisture That is Present Within the Interior of the Vagina. Thus, the Unreal Hymen/hymen Dissolves Inside the Vagina and Exit as a Blood Trail to Substantiate the Virginity. It Has Been Specifically Designed to Offer You the Chance to Introduce One a Minimum of 2 Hours and Half-hour Before Sexual Activity. Make It Easy With the Included Disposable Plastic Tweezers a Finger Deep. During Sexual Activity, It Dissolves Then Completely. And by the Interior Friction of the Penis, the Cellulose Compounds Mix With the Body Fluids. Hymen Flows Down From the Vagina After Sexual Intercourse. Artificial Hymen Pills in Pakistan This Residue is Seen on the Penis and Sheets That Bring the Result to Substantiate Your Virginity at the Specified Moment. The Utilization of Hymen Gel Also Works With the Employment of Condoms. How To Use? Artificial Pills Just Finger Deep and About 1-3 Hours Before the Planned Sexual Activity. The Capsules Contained Fake Blood Therein Which Then Completely Dissolved. During Gender, It Mixes Along With Your Vaginal Secretions and Runs as a Trace of Blood During a Natural Amount. By Tightening the Vaginal Entrance, It Intensifies the Sensation of Virginity. Use It Half-hour – 2 Hours Before the Planned Sexual Issues and Also Confirms Reliably Your Virginity by Artificial Hymen Pills in Pakistan. With Original Blood, Pills Turns Blood Red Together With Moisture and Dissolves Completely. Use 25-30 Minutes Before Sexual Intercourse: Wash Your Hands and Vagina Before Using. Slightly Insert the Synthetic Hymen Into the Vagina. It Will Dissolve Within 20-30 Minutes After Using It. Benefits of Artificial Hymen Pills? Artificial Pills Will Facilitate Your Desire for a Virgin Again Without Undergoing Vaginal Rejuvenation Surgery or Popping Any Dangerous Pills. They Will Facilitate the Reboot of Your Virginity and Feel Young Again. Artificial Pills in Pakistan Facilitates You to Restore Your Hymen to Their Original Position. And Facilitate Your Experience of Sex Sort of a Virgin. The Factitious Hymens Are the Product of Natural Material. Like Synthetic Blood and Cellulose, is Safe for Your Vaginal Health. Lady Secret Cream the Following Are Advantages of Pills Make the Vaginal Path Tighter Make You Bleed at Your Night It Has No Side Effects. It is Non-toxic and Safe No Painful Surgery, Needles, or Anesthesia From Now on Artificial Pills in Pakistan Price Prevent From Doctor’s Visits and Medications You Do Not Need Any Hymenoplasty. It Appears Like the Original Blood 99.9% Harmless, Risk-free Call & Whats App 0300-0085742 | 0330-2828742 The Largest Online Shopping Website: NewTelebrands.Com

Free

See product

Pakistan (All cities)

We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 1.000,0

See product

2 photos

Pakistan (All cities)

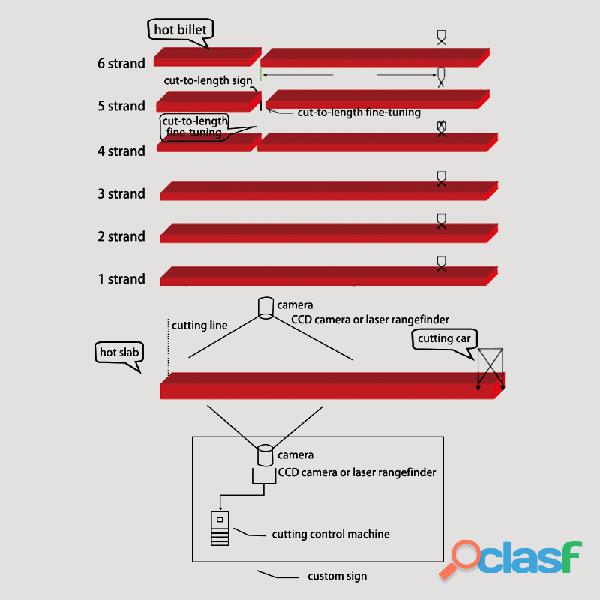

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

Rs 0,0

See product

Pakistan (All cities)

Overview: LGK-S107 analog heat source instrument (heating tool) is independently developed and designed by Wuhan CenterRise M&C CO., Ltd. This instrument is a heating and testing equipment used to test the performance of the thermocouples installed in the mold in continuous casting machine. After the installation of the mold breakout prediction thermocouples completed, the analog heat source instrument is used to test these thermocouples before they go online. After the thermocouple is connected to the mold thermocouple detector, the current temperature of each thermocouple point will be displayed. By using our heating device to heat the copper plate point of each thermocouple at a fixed point, the thermocouple will have a synchronous temperature rise and then we can observe the temperature rise curve of the same column of temperature points to see whether the temperature measurement consistency of the column of thermocouples is consistent, so as to judge the overall status of thermocouples installed in the mold. If an abnormal point occurs, it needs to be repaired and replaced, so as to ensure the stable operation of the mold breakout prediction system. The working principle: The heating tool generates high heat by 220v alternating current and the electric heating element. The heat is transmitted to the copper plate of the mold through the copper head to simulate the heat source of molten steel, so that the thermocouples of the mold can sense the temperature change to achieve the purpose of calibrating the temperature measurement system. The composition: Walking trolley mechanism Preloader Pure copper heating contacts PID thermostat High power heating tube high power driver The parameters: Power supply: AC220V 50Hz Total power: 2200W Single point power: 300W Temperature control accuracy: 1°C Temperature control range: 0°C-500°C Common temperature range: 25°C-300°C Heating points: 3 (points can be customized) Heating method: heating tube heating Heating contact material: copper

Rs 0,0

See product

3 photos

Pakistan (All cities)

Topper Smart Bidet Tiolet Seat Co., Ltd. (https://www.mfrsbidet.com/) is a professional and experienced smart toilet & bidet manufacturer and supplier, specializing in diversifying our bidet products to suit a range of different needs. We are capable of providing toilet bidets, bidet attachments, bidet seats, toilet seat covers, bidet sprayers, portable bidets and other bidet fittings, and offering practical and personalized sanitary solutions for our customers. Over the years, we have been consistent in supplying high-quality products and thoughtful services. Every stage in the production is guided and supervised by skilled professionals and our quality control systems. Our bidet products all meet tangible and intangible requirements in terms of quality and safety. From the design and development of products to the user experience, we are never slackening our effort, and still trying our best to improve your life quality. Convenience, comfort and superior quality are the ideas we want to convey through our bidets and services. In the future, we will continue to strengthen our capability of design and innovation to better satisfy the demands of the market and create the best home life experience for customers. If you're interested in our bidets, please visit https://www.mfrsbidet.com/.

Rs 200,0

See product

6 photos

Pakistan (All cities)

Finding the best tyre shops near me, Sometimes it can be challange, especially when there are so many options available in the markets. Here, you can find a list of the trusted tyre shops where you can get the best deals and services, including new tyres, tyre repairs, or balancing services at affordable prices. Whether you're looking for quality tyres or expert maintenance, these shops offer reliable solutions to meet your needs. https://www.tradebrio.com/exporters/car-tyres.html

Free

See product

Pakistan (All cities)

Himalayan Chef Whole Wheat Flour is a premium quality flour made from 100% whole wheat grains sourced from the fertile lands of Pakistan. Our unbleached and unenriched flour is packed with fiber, protein, and essential nutrients, making it an ideal choice for health-conscious consumers. https://wbm.com.pk/product/whole-wheat-flour-40-lbs-1814-kg-himalayan-chef?srsltid=AfmBOooL_2OymlrRGa_iNHxMLfYjoVR1LhxPTyj5-vkxlZgANSgS57R6

Free

See product

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos

Pakistan

THE AMAZING HUGO & BOSS ARE LOOKING FOR THEIR FOREVER HOME. BOTH BOYS ARE LILAC IN COLOUR BUT ARE CARRIERS OF TAN POINTS WHICH IS THE AT GENE,DNA IS dd/bb/AT. PUPS ARE REALLY SHORT AND COBBY. GREAT CONFIRMATION, THE BEST WAY TO DESCRIBE THESE....

Rs 200,0

See product

Pakistan (All cities)

Buy Verified Cash App Accounts As it acquires clients, checked accounts become fundamental for organizations and people to completely get to its highlights. A checked money application account permits you to send, get, and pull out a lot of cash, making it ideal for business people, consultants, and financial backers. Purchasing a confirmed money application account has turned into a pattern now, with numerous suppliers offering this help at a sensible cost. In any case, it means quite a bit to purchase from a confided in source to stay away from tricks or fake records. You will learn the fundamentals of purchasing verified cash app accounts and everything else you need to know before making a purchase in this article.

Free

See product

Pakistan (All cities)

Effective Bird Deterrence: Strategically designed bird spikes to effectively deter pigeons, sparrows, and other nuisance birds.....

Free

See product

Pakistan (All cities)

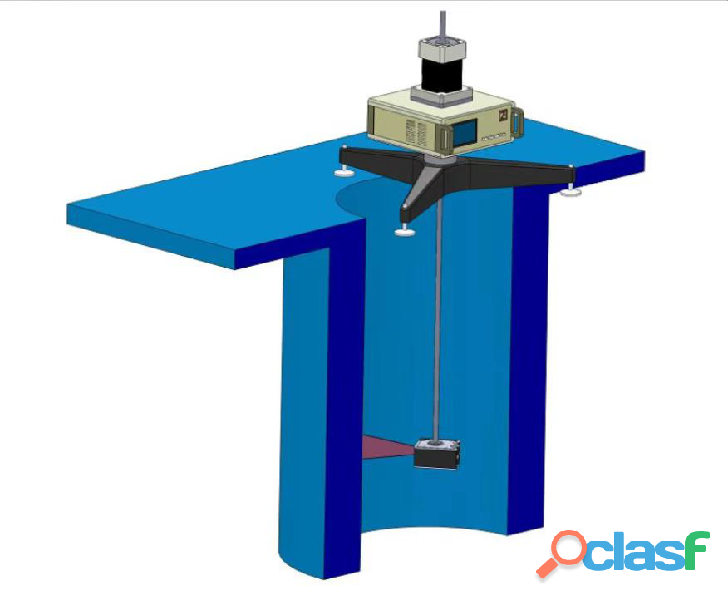

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Pakistan (All cities)

ISO Certification in Kuwait is essential for businesses aiming to improve their credibility, efficiency, and market competitiveness. Achieving ISO Certification in Kuwait offers a standardized management system that supports organizations streamline processes, improve product quality, and ensure customer satisfaction. Additionally, ISO Certification in Kuwait demonstrates a commitment to international best practices, which is crucial in a globalized market. For businesses looking to expand internationally, ISO Certification in Kuwait is a significant advantage, as many clients and countries prefer or require ISO-certified partners. In Kuwait’s growing economy, ISO Certification in Kuwait serves as a key differentiator, fostering trust and reliability among clients and stakeholders. Quality Sistema Certifications & Inspections Pvt. Ltd. is one of the leading Global Organization, providing ISO Certifications, Inspection, Assurance & Auditing Services for industries with competence and transparency to build trust across the global industries. We are a team of highly specialized experts and industry professionals who working towards a sustainable business growth. #ISO 9001 Certification KuwaiT,#ISO Certification in Kuwait #iso 9001,ISO 9001 Certification Kuwait

Free

See product

Gujrat (Punjab)

With discreet and reliable surveillance, IonDetective will find out what you want to know. We are professional detectives specializing in obtaining evidence through close observation and time-tested procedures. From cheating spouses to any question or concern that can benefit from being clarified, our company can help bring clear-cut results with total discretion. Our business values honesty, respect, and professionalism; this is exactly why we deserve the truth that you're looking for. Trust us to handle your case with care and precision while keeping the process simple and stress-free. When the truth matters, IonDetective is here to help.

Free

See product

Pakistan

Kennel Club Assured Breeder. Jimjen George Gently is a proven sire, (daughter & son Crufts qualified), and health tested, for MLS, NCCD, FVll, & IGS, and available at stud, to approved bitches,at small show kennel in Suffolk. 'Reach....Bonnie is a friendly and loving dog who loves attention and is very outgoing. He has been with us since he was 8 months old, but unfortunately he has been fighting with my male cat which causes him stress and anxiety being around the house.....Our amazing litter was born on 18th of December mum is stunning tri colour and dad is a lemon and white tri both pedigrees dad has five generations blood line with his papers to prove. We have a litter of 9 chunky playful pups all wormed and....

Rs 200,0

See product