Qmobile acc box

Top sales list qmobile acc box

Latest Offers

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

Rs 0,0

See product

Pakistan (All cities)

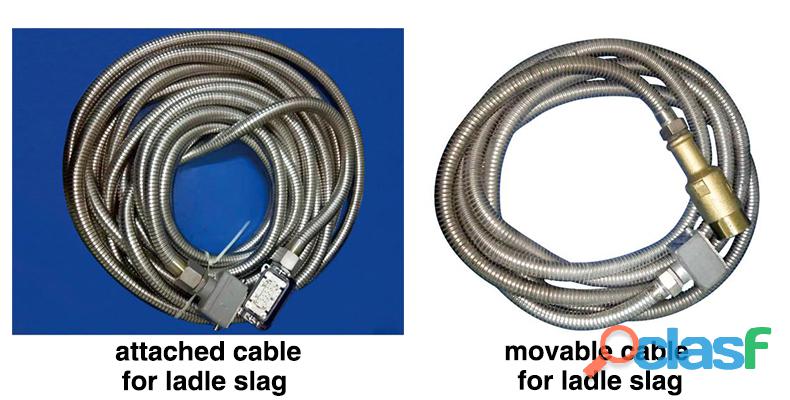

Overview Our company focuses on the production and application of the cables in continuous casting steel production. We have rich on-site usage experience, which provides us with technical guarantees for manufacturing high-quality communication cables. For cables of different applications, we have different protection requirements, such as high temperature resistance, anti-pull, acid and salt spray resistance, slightly positive pressure heavy-duty connector, anti-oil pollution, anti-interference, etc. Common industriaI cable for continuous casting 1. Breakout prediction compensation cable 2. Mold level control cable 3. Mold oscillation cable 4. VUHZ sensor cable 5. Mold width adjustment cable 6. Dynamic lightly depress the cable 7. Fixed cable for ladle slag 8. Movable cable for ladle slag The quality control All our products use proven materials to ensure stable and reliable product quality from the source. The core equipment all adopt imported raw materials. From raw material control to wire harness integrated processing, we ensure the stability and consistency of product quality. The scientific quality management system brings the product quality to a higher level. The program customization Our company has been focusing on the production and processing of wire harness products for many years. We have a professional technical team, which can realize synchronous development and technical docking with customers timely, optimize product design, and provide customers with complete solutions for wire harness products. Widely used: All kinds of wire harnesses produced by our company are widely used in major steel mills across the country, such as SHOUGANG, TISCO, HBIS GROUP, TIANJIN IRON PLANT, BAOGRANG GROUP, etc. The first-class product quality, and has won unanimous praise from domestic and abroad.

Rs 0,0

See product

5 photos

Pakistan (All cities)

Dev Technosys offers cutting-edge News App Development Services, delivering customized solutions with advanced features like real-time updates and smooth navigation. Our expert team specializes in News App Designing, creating user-friendly and visually appealing interfaces. Get reliable, scalable, and performance-driven News App Solutions tailored to meet your business goals. Visit: https://devtechnosys.com/news-app-development.php

Rs 0,0

See product

Pakistan (All cities)

Buy Verified Cash App Accounts As it acquires clients, checked accounts become fundamental for organizations and people to completely get to its highlights. A checked money application account permits you to send, get, and pull out a lot of cash, making it ideal for business people, consultants, and financial backers. Purchasing a confirmed money application account has turned into a pattern now, with numerous suppliers offering this help at a sensible cost. In any case, it means quite a bit to purchase from a confided in source to stay away from tricks or fake records. You will learn the fundamentals of purchasing verified cash app accounts and everything else you need to know before making a purchase in this article.

Free

See product

Pakistan

THE AMAZING HUGO & BOSS ARE LOOKING FOR THEIR FOREVER HOME. BOTH BOYS ARE LILAC IN COLOUR BUT ARE CARRIERS OF TAN POINTS WHICH IS THE AT GENE,DNA IS dd/bb/AT. PUPS ARE REALLY SHORT AND COBBY. GREAT CONFIRMATION, THE BEST WAY TO DESCRIBE THESE....

Rs 200,0

See product

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos

Pakistan (All cities)

As one of the largest Chinese manufacturers of industrial valves, China Vervo Valve Co., Ltd. offers a wide array of products, including floating ball valves, trunnion ball valves, cast steel gate valves, forged steel gate valves, pressure seal gate valves, cast steel globe valves, forged steel globe valves, cryogenic globe valves, forged steel check valves, swing check valves, dual plate check valves, API 609 butterfly valves, steel plug valves, Y strainers, and more. Our business reaches North America, South America, Europe, Asia, the Middle East, Africa, and Oceania. We manufacture, import, and sell a wide range of industrial valves, including ball, gate, globe, butterfly, check, plug valves, and specialty valve solutions. We look forward to establishing a strong cooperation with you! Visit our website: https://www.vervovalve.com/

Rs 200,0

See product

Pakistan (All cities)

Overview In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline deviation. The measurement of the strand condition monitor Roll gap value: By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed. It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster. Arc condition of guide roller : Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guided roller. Guided roller rotation: It is possible to know whether each guided roller can rotate freely by measuring. Water spray pressure: The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal. The main components of the strand condition monitor 1. The main body of the strand condition monitor used to measure the continuous casting sector 2. The connecting chain between strand condition monitor and dummy bar 3. The storage rack chain of strand condition monitor 4. Battery charger: 24V 5A 5. Calibration equipment 6. Remote control 7. Laptop 8. Printer 9. Data communication cable The technical parameter 1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements) 2. The measurement accuracy of roll gap: 0.01mm 3. The arc measurement range: ±80° 4. The arc measurement accuracy: 0.01° 5. The spray measurement range: 0-10 6. The spray measurement accuracy: ±1 7. The battery usage times: 3 times

Rs 0,0

See product

Pakistan (All cities)

Manufacturer's Warranty. Tecno Industries (Reg) اَلحَمْدُ لِله Manufacturers of: SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. (pure copper) Since 1986 Tecno Lazer Pakistan. 0300-9433728 Ring Road, Band Road, Lahore Pakistan. A Servo Stabilizer That Decreases 30 Volts (back-from 250 to 220 & Increases 70 Volts from 150 to 220) (±) 1% {CAN STEP-UP from even low (on-demand)} اَلحَمْدُ لِله Runs your Equipment Even in Low Main Voltage. INFORMATION: 1: ( An Old Transformer / Relay carrying Stabilizer steps down or up after losing or gaining 20-25 Volts While A Servo Stabilizer steps down or up after losing or gaining 1 Volt. (±) 1%) 2: (on-demand) Buck-Boost Transformer Technology add-in 2kVA and above Models. Basically they work on DC Servo Motor Control system. Their efficiency is much better and its output voltage of either 110 or 220 AC or any required voltage, more-over TECNO 3Phase models up-to 500kVA ratings are manufactured against a confirmed order. 1 year warranty with parts. 100% genuine copper winding (GUARANTEED) Specs for (intelligent Voltage Stabilizer): SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. Input Voltage : 150 To 250 AC Output Voltage : 110v & 220v AC (±) 1% Frequency : 45 or 60 Hz Wave Form : Non-distorted Sine-wave Response Time : 25ms / V Efficiency : 95 % Power Factor : 0.95 Relative Humidity : 30% to 80% (without condensation) Temperature Rise : Less Then 50c Control System : DC. Servo Motor Insulation Resistance : More then 3M?? at 500V DC Tested : 1500 V We Manufacture Servo Motor Controlled Automatic Voltage Stabilizer, using Japanese technology, for UPS, Solar, AC Air-Conditioner, Split-Type, Window Type, (LCD/LED TV) Washing Machine, Treadmill, Photocopier Machine. Television, Music System, Refrigerators, Ultra sound Machines, Embroidery Machines, All Sensitive Equipment, Signalling Devices, CNC Machines, Air Conditioning Plants, Telecommunication Networks, Motor Loads, Data Processing Equipment, Bio Medical Equipment, Drives, PLC’s, Induction Heating, Hotels, Defence Application, Industrial Units, Lighting Loads, Residential/ Offices, Farm Houses, R & D Institutions, Mainline Stabilizers, Sophisticated Laboratory Equipment etc. Runs your Appliances Even in Low Main Voltage. وولٹیج سٹیبلائزر Standard Power Ratings Available in Single-Phase & 3-Phase: 500VA, 1kVA, 2kVA, 3kVA, 5kVA, 10kVA, 30kVA. Up-to 500kVA Punjab NWFP, KPK, & All Pakistan Cargo, Feel Free to Call: Rana Naeem Hammad. M.D. Tecno Industries (Pvt) Ltd Lahore. +923009433728

Rs 121,0

See product

11 photos

Islamabad (Islamabad Capital Territory)

In the bustling heart of Delhi, optimizing your workspace is crucial for productivity and employee well-being. Ryan Office System provides premium modular office furniture in Delhi, offering versatile solutions tailored to your unique needs. Our modular designs prioritize flexibility, allowing you to reconfigure your office layout as your business evolves. From sleek workstations and ergonomic chairs to adaptable storage units and collaborative meeting tables, we offer a comprehensive range of furniture to create a dynamic and efficient environment. Why choose Ryan Office System for your modular furniture needs in Delhi? Customization: We understand that every office is different. Our modular systems can be customized to fit your specific space and workflow, ensuring optimal utilization. Quality & Durability: We use high-quality materials and craftsmanship to create furniture that is built to last, providing a long-term investment for your business. Ergonomic Design: We prioritize employee comfort and well-being with ergonomic designs that promote good posture and reduce strain. Space Optimization: Our modular solutions maximize space utilization, creating a more organized and efficient work environment. Professional Aesthetics: We offer a wide range of modern and stylish designs that enhance the professional image of your office. Ryan Office System empowers Delhi businesses to create adaptable and productive workspaces. Our expert team will guide you through the selection and installation process, ensuring a seamless experience. Invest in the future of your office with our premium modular office furniture in Delhi.read more :- https://www.ryanofficesystems.in/delhi/modular-office-furniture

Free

See product

Pakistan (All cities)

FutureGenApps is a leading website designing company in Laxmi Nagar. We help businesses to grow online with our expert services such as web design and development, software development, website maintenance, social media marketing, SEO services, and e-commerce websites. Our experts provide a user-friendly and mobile-responsive websites that attract customers and enhance your business. We also maintain your site after it goes live, ensuring you remain stress-free. Whether you're a small start-up or a growing brand, FutureGenApps is here to support your online journey with effective and affordable solutions. Contact FutureGenApps now to get your top-notch website.

Free

See product

2 photos

Pakistan (All cities)

Spark your child’s learning journey with Kinder ABC! From fun alphabet adventures to interactive games like tracing, puzzles, and bubble popping, Kinder ABC offers an ad-free, safe space for kids to learn letters, phonics, and more. Download now and make learning fun! Get Kinder ABC on Play Store: https://play.google.com/store/apps/details?id=com.icommunetech.kinderabc Official Website: https://www.icommunetech.com/

Free

See product

3 photos

Multan (Punjab)

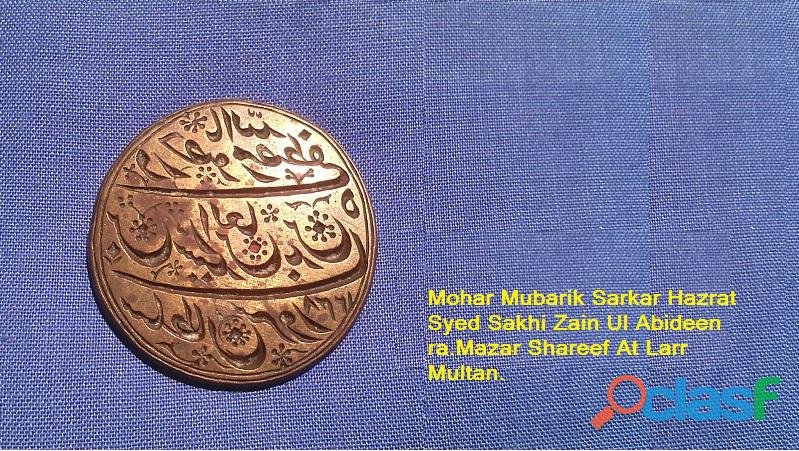

Hazrat Syed Sakhi Zain ul Abideen (RA) migrated from Baghdad to Saudi Arabia and spent 22 years in Madina Munawara.One night, holy Prophet hazrat Mohammad (may peace be upon him) appeared in a dream and instructed him to go to India, convince the people to the right path, preach or spread the teachings of Islam.Obeying the orders of the holy Prophet Hazrat Mohammad (may peace be upon him), the Sufi Saint left Madina Munawara and came to Shahkot. The Sufi saint is the father of a famous Sufi Hazrat Syed Ahmad Sultan, known as Sakhi Sarwar, the bountiful Chief, shrine at Sakhi Sarwar Pakistan. Hazrat syed sakhi Zain ul Abideen (RA) practised austerities and prayers in shahkot, The great renowned Sufi saints paternal genealogy is directly related ten generation up with Ameer ul Momeneen (commander of faithful) Hazrat Imam Ali Ibne Abu Talib R.A, thus he was a direct descendant of the holy Prophet Hazrat Mohammad (may peace be upon him). The name Zain ul Abideen was selected by his father Syed Umar due to the deep love and devotion with Imam Zain ul Abideen (A.S). Specification. Object Name: Seal stamp Description: Syed Zain ul Abideen Shah"Sultan Sarwar" Inscription Script : Arabic Inscription Technique: Engraved Date Period: A D 13th Century 1248 Time period: A D 13th Century Geography: Indian Subcontinent (Central Asia) Culture/period: Islamic Condition: Excellent Relics of the Islamic saints strengthens spiritual beliefs, inspire people and give them comfort in tough times. The holy seal is a precious asset handed down from generation to generation, extremely rare and a genuine masterpiece regarding the sacred relics of the early Islāmic saints.

Rs 100,0

See product

Pakistan (All cities)

ISO Certification in Kuwait is essential for businesses aiming to improve their credibility, efficiency, and market competitiveness. Achieving ISO Certification in Kuwait offers a standardized management system that supports organizations streamline processes, improve product quality, and ensure customer satisfaction. Additionally, ISO Certification in Kuwait demonstrates a commitment to international best practices, which is crucial in a globalized market. For businesses looking to expand internationally, ISO Certification in Kuwait is a significant advantage, as many clients and countries prefer or require ISO-certified partners. In Kuwait’s growing economy, ISO Certification in Kuwait serves as a key differentiator, fostering trust and reliability among clients and stakeholders. Quality Sistema Certifications & Inspections Pvt. Ltd. is one of the leading Global Organization, providing ISO Certifications, Inspection, Assurance & Auditing Services for industries with competence and transparency to build trust across the global industries. We are a team of highly specialized experts and industry professionals who working towards a sustainable business growth. #ISO 9001 Certification KuwaiT,#ISO Certification in Kuwait #iso 9001,ISO 9001 Certification Kuwait

Free

See product

Pakistan (All cities)

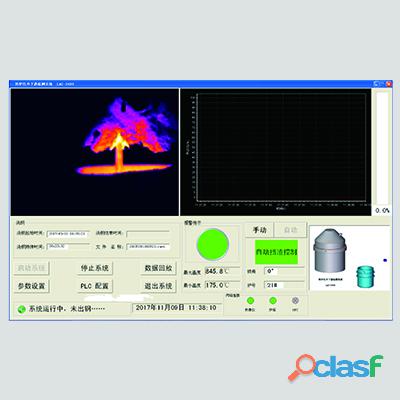

Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content. The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal. As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc. The features of thermal imager 1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set. 2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature. 3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily. 4. With hot zone tracking function 5. Equipped with special 7~14um infrared filter lens The technical parameters 1. Temperature measurement range: 200°C ~ 2000°C 2. Temperature measurement accuracy: 2% 3. Detection accuracy and alarm accuracy: ≥98% 4. Resolution: ≥ 0.5℃ 5. Pixels: 640x240PT 6. Band: 7~14um 7. Field of view: 7.5°×5.5° 8. Frame rate: ≥ 25 frames/sec 9. Equipment service life: ≥5 years 10. The normal operation rate of the automatic control system: ≥99%

Rs 0,0

See product

3 photos