Processing time

Top sales list processing time

Rahimyar Khan (Punjab)

This is the Cloaked link. If you need a uncloaked link let me know. It is not good to put more than one tracker in a link. makes it load slow. If possible to use mine that is good. if not let me know Here is an ad if you have to you can shorten the ad. If you check out the link you will get a great idea about this link. I been doing this about 3 weeks without advertising hardly at all and made $325 Not bad for a one time pay of $25.. In your line of work this would be great for someone with the resources you have. Just do me a favor if you decide to join use my link. Thanks David Cozart If you need anything Let me know. Let s fill up your PayPal with UNLIMITED instant $25 payments paid directly into your PayPal Account daily! We are loving this Job.. You will too! Promise! Earn $25 for EVERY email you process... Process Just 1 email a day = $750 A Month! 8 emails a day,That s $200 a day =$6,000 per Month.. Get Instant LIFETIME Access HERE Join Now. Yours in Success, David C.

Rs 9

See product

Pakistan

processing time one month Complete guidance for Students and Visit Visa For More Information please Contact us... Smart Way Consultants

See product

Pakistan

processing time 1 month se b kam For More Information please Contact us... Smart Way Consultants Pay our consultancy after visa

See product

Islamabad (Islamabad Capital Territory)

processing time maximum Every Category visa available on cheap rates For More Information please Contact us... Smart Way Consultants

Rs 9

See product

Islamabad (Islamabad Capital Territory)

We arrange Russian Visa Invitation / Sponsorship leading to Work & Settlement in St. Petersburg Russia, Guaranteed & Challenging as compared to other Consultants & Agents with Lowest Cost up to visa. St. Petersburg is the Second largest City of Russia having multiclass businesses and Working Opportunities for Foreigners from working to Settlement in a rich cultural & bright Future. We have local representatives in Russia who will Guide you until your complete satisfaction & settlement. Type 1: Russian Language Course, 1 Year (Extendable Visa) Expenses: Invitation & Admission Fee: 970 $ Advance: 200 $ Embassy + Attestation+ NOC Fee: 380 $ Consultancy Fee: 200 UD $ Total Cost: 1550 US $ (155000 PKR) Processing Time: 3 to 5 Weeks Required Documents: Minimum Education Matric + Passport Copy + 1 Pic Transfer Facility from Russia to the fallowing Countries on done basis option is available: 1) Germany 2) Finland 3) Denmark 4) Norway 5) Lithuania 6) Estonia Type 2: Work Permit (3 Years, extendable) Expenses: Invitation Fee: 1000 $ (Advance) Embassy + Processing + Consultancy Fee: 3500 $ Total Cost: 4500 $ (450,000 (PKR) Processing Time: 2 to 3 Months Required Documents: Passport Copy + 1 Type 3: Tourist Visa (Non extendable) Expenses: Invitation Fee: 800 $ Advance: 200$ Embassy + Processing Fee: 200 $ Total Cost: 800 $ (80,000 (PKR) Processing Time: 2 to 3 Weeks Required Documents: Passport Copy + 1 Pic Solutions Consulting (Pvt) Ltd. Office # 5 Ground Floor, Westend Plaza I &T Center Sector G-11/1 Islamabad Pakistan.

Rs 1.350

See product

Karachi (Sindh)

Are you eager to STUDY ABROAD? Study in USA! Guaranteed Admission Scholarships Available! Fastest processing time Study in Germany! No tuition Fee Job Search Visa after Studies Study in Canada! Guaranteed Admission With/Without IELTS Study in Malaysia! Guaranteed Admission 99.99% visa success ratio Reach us NOW! Ocean1 Private Limited(Overseas Education Consultant) 107 1st Floor Park Avenue, Opposite Lal Kothi, Main Shahrah e Faisal, Karachi FaceBook: Ocean Education Consultant Skype: oceanconsultant Linkedin: Ocean1 Education Consultant Email: processing@ocean.net.pk

See product

Karachi (Sindh)

STUDY IN USA! 80+ Panel Universities Available Guaranteed Admission! High Visa Success Ratio! 5 Years Multiple Visa! Fastest Processing time! Reach us Now! 03324535322 www.ocean.net.pk

See product

Pakistan

2 month processing time no IELTS tution fee on arrival part time job accommodation will be provided by college for more information please contact us.....

See product

Lahore (Punjab)

Study in Abroad / Schengen countries / Cyprus * Minimum Education Matric * All Program Graduations/ Masters/Phd or also diploma / degree program * No IELTS for Hungary/Cyprus/ or Sweden( Engineering Or Diploma Program ) * Ielts require for Germany/Holland/Sweden * Maximum processing time 2 months

Rs 1.000

See product

Muzaffargarth (Punjab)

Pay our consultancy after visa No Ielts No Personal bank statement Processing time 6 week Get 16 to 18 CAD$ for 1 h working Get PR after Study Acomodation free After Study get scholarship on 50% For More Information please Contact us... Smart Way Consultants

See product

Pakistan

in malaysia earning 45 to 50 thousand pkr minimum qualification required processing time maximum 1 month 1 year valid visa ( extendable ) for more information please contact us ......

See product

Pakistan

Pay our consultancy after visa No Ielts No Personal bank statement Processing time 6 week Get PR after Study Acomodation free After Study get scholarship on 50% For More Information please Contact us...

See product

Pakistan

Pay our consultancy after visa No Ielts No Personal bank statement Processing time 6 week Get PR after Study Acomodation free

See product

Pakistan

1- Admission in Foreign College/Universities 2- Student Visa 3- Visa Files 4- Visit Visa For UK, Europe, Australia, Canada, USA 5- Hotel Bookings in Foreign Countries 6- Complete guidance for Students and Visit Visa 8- Health & Travel Insurance for Travel & Tourism Pay our consultancy after visa No Ielts No Personal bank statement Processing time 6 week Get 16 to 18 CAD$ for 1 h working Get PR after Study Acomodation free

See product

Pakistan

Pay our consultancy after visa No Ielts No Personal bank statement Processing time 6 week Get 16 to 18 CAD$ for 1 h working Get PR after Study Acomodation free After Study get scholarship on 50% For More Information please Contact us... S W Consultants

See product

Karachi (Sindh)

Get admission in Streamline Universities 100 % Visa success IELTS REQUIREMENT: DIPLOMA:5.5 BAND/ BACHELORS:6 / MASTERS:6.5 free Ielts preparation provided With job , and accommodation assistance Visa processing time is three months. Get admission for next intake in Australian University or college and get 30% discount Book an appointment with us today. Call: 02135631610 03333216011 E-mail: imran@streamlinevisa.com/ zainab@streamlinevisa.com Website:http://www.streamlinevisa.com Facebook:http://www.facebook.com/streamlinevisaconsultants Skype: streamline consultants

See product

Karachi (Sindh)

Guaranteed Admission in USA! 5 YEARS MULTIPLE VISA* Fastest Processing time! Reach Now! www.ocean.net.pk 03324535322

See product

Pakistan

"Job In Dubai " Field: Sales/marketing (Mineral water) Salary: 2000 (derhams) Processing time: 40 days Medical Transport further info: Mohammad Hamza

See product

Karachi (Sindh)

Philippine visit visa available processing time 15 working days documents required. 1. Valid passport 6 months 2. Return ticket with hotel booking 3. Bank statement 2lacs+ - foreign affairs attested 4. Police character certificate - foreign affairs attested 5. 9 pictures please call for further details - only for serious clients

See product

Pakistan

USA 05 Years Multiple Business Visa / Visit Visas Done Basis....!!! USA 05 years Multiple visa Single or Your Family. Interview in optional language (Urdu,English). Processing time 30 days. Refusal Cases may also apply . Only Serious Travels Agents and Visa Consultants Can Contact me. Our Services Charges you may Contact Us. Email: visawali_sarkar@yahoo.com Mob:03102617034

See product

Pakistan (All cities)

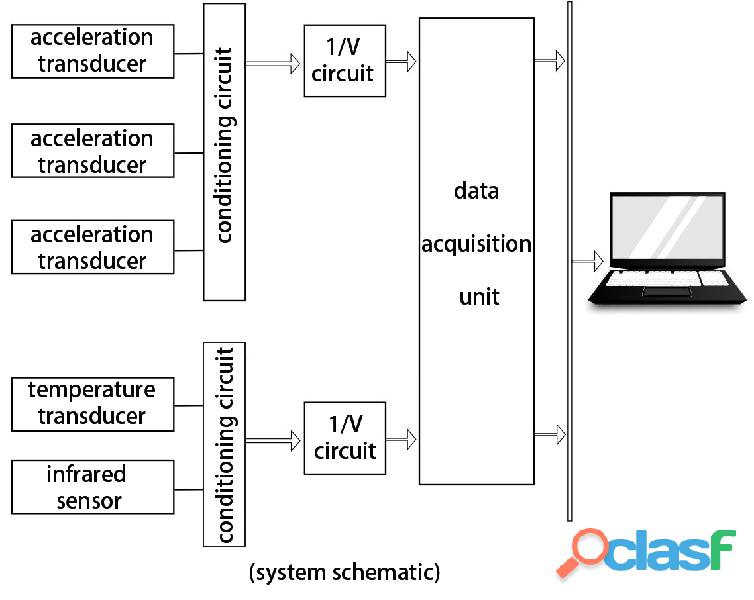

Overview The mold is a device that shapes the cast product in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of the mould oscillation deflection detection instrument is to detect the the mould oscillation table’s oscillation frequency, amplitude, deflection rate, phase, oscillation trajectory curve, etc. Through the detection and adjustment of the detection instrument, the mold moves along the outer arc of the continuous casting machine according to the set amplitude, frequency and waveform deflection characteristics. The actual oscillation parameters of the mold oscillation table during the production process and the process parameters of the cast products cannot be effectively known without the data detection of the mold deflection detection instrument, so that the operator cannot adjust the mould’s production process parameters in real time according to the real-time situation of the on-site production. The continuous casting mold deflection detection instrument independently developed by our company is suitable for various molds such as slab, square billet, round billet and shaped billet. The system obtains the process parameters such as actual oscillation holographic parameters and negative slip amount of the oscillation table by effectively detecting the movement of the mold. The technicians can formulate the control strategy of the mould according to these actual parameters, and improve the output and quality of the product within a safe and reliable range. The structure of the instrument Continuous casting mold oscillation and deflection detection instrument is mainly composed of sensor system, sensor signal conditioning circuit, power supply circuit, synchronous data acquisition module, communication cable, and software data analysis system. There are three axial acceleration sensors installed in the mold oscillation and deflection detection instrument, one of which is to detect the vertical oscillation signal (Y axis), and the other two are to detect the horizontal oscillation signal (X and Z axis). The signal obtained by the sensor is processed by the preprocessor and the preprocessing module. The oscillation signal and sensor status signal will be filtered and normalized, sent to the synchronous data collector for digitization and feature extraction, and the data is analyzed and processed by the master computer software to obtain various oscillation parameters and process parameters required by users. The functions of the system 1. Adopting mould oscillation X/Y/Z three-dimensional data acquisition, using high-precision sensor system and high-sensitivity axial accelerometer, comprehensive detection of equipment oscillation state, including: 1) Detect the oscillation frequency of the mold oscillation table 2) Detect the amplitude of the mold oscillation table 3) Detect the deflection rate of oscillation 4) Detect the lateral deflection, longitudinal deflection, phase, and phase difference of the mold oscillation table 5) Three-dimensional display of the oscillation trajectory, and the oscillation table trajectory can be viewed from 6 sides of the oscillation table (X-Y, X-Z, Z-Y) 2. The software system adopts the design of man-machine interactive graphic interface, which can display the mold oscillation state in real time. The software functions include: 1) Real-time data curve display: oscillation waveform, oscillation frequency, signal superposition analysis 2) Single-axis curve display, multi-axis curve display, amplitude, acceleration, three-dimensional graph 3) View historical curve 4) Generate test report 5) Give a warning prompt 6) Spectrum analysis function 7) Long-term storage of data 3. Portable measurement method, which can provide handheld detection equipment with wireless remote transmission, and the operation is simple. 4. Provide an overview of inspection parameters under the full screen, displaying all data including oscillation parameters and process parameters. At the same time, the calculation and display of the oscillation spectrum is completed in real time, which is used to evaluate the frame loss of the waveform , and to determine whether there is a problem with the installation of the oscillation device. 5. Alarm management. Record each alarm data under real-time alarm conditions to analyze the cause of the alarm and evaluate the impact of the alarm on production. 6. Parameter setting. Users can set the ideal oscillation value and normal working range of various steels online. We also can set the alarm limit, and the storage time of the database etc. 7. After charging the device once, it can work continuously for more than four hours. 8. Integrate embedded processing equipment to realize data collection, display, analysis, reporting and other functions. 9. According to the mold characteristics and user requirements, it can be flexibly configured, wich is suitable for all types of molds such as square billets, slabs, round billets and other mold oscillation tables. 10. Support wired and wireless data transmission functions, easy to use. 11. Use the laptop to receive the collected data, can be used for the operation test on site, and can analyze and process the data conveniently. The features of the system 1. The actual oscillation state replaces the ideal oscillation state. The actual oscillation state of the table is used to formulate a control strategy, so that the oscillation table can be used to produce products with more accurate oscillation. 2. Convenient detection method. The equipment can be used for on-site inspection at any time, and the production site can grasp the operating status of the on-site equipment in time, so that we can make production adjustments to the equipment at any time. 3. Efficient working methods and processing platforms. The high-integration equipment developed by embedded technology can work in high temperature and harsh environment. This system can comprehensively detect XYZ three-axis data, and realize real-time data analysis and processing with high-speed data operation and processing platform. 4. Powerful database function. The database adopts the mode of computer automatic management and operator's manual assistance management, and there are tables for recording historical data and alarm data and working parameter setting table of monitoring system inside the database. By adjusting the output range, the best output effect can be obtained.

See product

Pakistan (All cities)

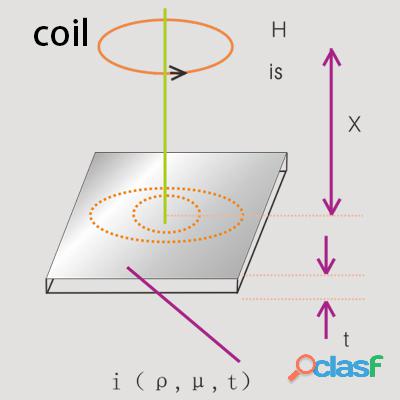

Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting. The molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet. The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows: The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm. At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%. It means that the level fluctuation directly affects the surface quality of the casting billet. The principle of the system The eddy current type molten steel level gauge is the key to the system. The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time 0.10s), high detection accuracy (±05mm), and large measurement range (0-150mm). The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer. The system has the advantages of simple operation and no radiation protection problems. The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform. The sensor is cooled by compressed air during use. The principle is shown in the figure A high-frequency exciting winding is installed above the molten steel surface of the mold. The high-frequency magnetic field generated by the high-frequency exciting winding induces eddy currents on the molten steel surface to form a magnetic field. The magnetic field generated by the induced eddy current is in the opposite direction to the magnetic field generated by the high-frequency exciting winding, which changes the impedance of the high-frequency exciting winding. Under the condition that the winding material and structure, steel grade, temperature remain unchanged, the coil impedance change only has a single-value function relationship with the height of the molten steel level. As long as the impedance change of the high-frequency winding is detected, the change of the molten steel level in the mold can be converted. The components of the system Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper. The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level. 1 Eddy current sensor; 2 mold level gauge; 3 control computer; 4 On-site operation display control panel; 5 digital actuator; The control principle of the system The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation. The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc. In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include: 1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper 2. The influence of the weight change of molten steel in the tundish on the control system 3. The influence of the change of the casting speed of the continuous casting machine on the control system 4. The influence of the mold width change (the mold width is adjustable) on the control system 5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge The function and software implementation In order to overcome these disturbances, the mold level control strategy adopts PID control. And on the basis of PID control, self-adaptive correction and feedforward control are introduced to form an advanced control system. The level control is the main loop, and there is a proportional gain of the main loop controller. According to the self-adaptive correction of the mold width change and feedforward compensation of casting speed, so as to further reduce and eliminate liquid level fluctuations caused by mold width adjustment and casting speed changes. In order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates lightly. And the system will choose a shorter intergrating time when molten steel level fluctuates greatly. Thereby, the fluctuation of the controlled object caused by the frequent action of the stopper rod is suppressed. In the signal processing of molten steel level gauge, an appropriate filtering link is added and the vibration frequency synchronous filter is used for filtering processing, which can overcome the interference of mold vibration frequency and amplitude variation.

Rs 200.000

See product

3 photos

Pakistan (All cities)

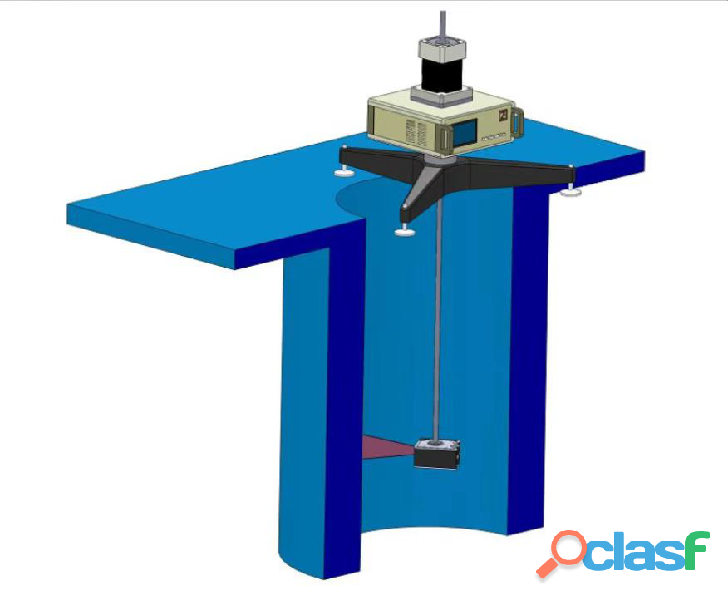

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

See product

Pakistan (All cities)

Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area. The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process. MOC-K100 mould oscillation online monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel. The meaning of the system 1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality. 2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance. 3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair. 4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident. 5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product. 6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed. The functions of the system (1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data including oscillation parameters and process parameters. (2) Time domain waveform: This function mainly displays the oscillation waveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elements of oscillation of each measuring point in real time. (3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and the oscillation difference of each channel can be calculated and displayed intuitively. (4) FFT: This functional module completes the calculation and display of the oscillation spectrum in real time. It is used to evaluate the waveform distortion of the entire oscillation table and to determine whether there is a problem with the installation of the oscillation device. (5) Bar graph: The oscillation of each measuring point is indicated by a bar graph of peak value and sensor gap voltage, which is more intuitive. (6) Trend: After starting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings for different steels under the oscillation conditions. The parameters of the system 1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged 2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes) 3. Sensitivity: 1000mV/g 4. Frequency range: 0.04~10HZ 5. Frequency accuracy: ±0.01 Hz 6. Amplitude accuracy: 0.005mm 7. Transmission mode: wired digital transmission, wireless transmission 8. Host: 3U standard rack, handheld device 9. Sensor power supply: 24V.DC 10. Host power supply: 220V.AC/50Hz Mold oscillation curve The structure of the system The main components of the continuous casting mould online oscillation detection system are: 1. Three-dimensional oscillation measurement sensor 2. Handheld oscillation sensor calibrator 3. Dedicated signal connection cable 4. Preamplifier 5. Operation processing unit 6. Graphic display terminal 7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components 8. Control cabinet

Rs 200.000

See product

3 photos

Pakistan

We offer visa advisory & visa processing service to individual and corporate clients. We are trained to deal with each matter with sensitivity and discretion whilst providing impartial and practical solutions without compromising the quality of our services. We keep up to date with the often complex and frequently changing within visa rules and regulations. • WE PRIDE OURSELVES OF BEING A REPUTABLE & HIGH SUCCESS RATIO. We are; • Highly Committed and Professional • Up-to-date in Visa Laws, Rules and Legislation • Reliable and Professional Service Tailored to Meet the Needs of Individual Clients and Businesses • Providing the Best Possible solution in the Quickest Possible Time Without Any Stress or Burden On Our Clients. • Fast and Prompt in Visa Processing • High Visa Application Success Rate Why Us! • 14 Years Experience • Lowest Rate • Free Visa Assessment • Fast & Prompt Processing • Family Discount • No Hidden Cost • Personal Attention to Every Client • We Deliver What We Promise • Save Your Time and Money • Reputable, Reliable & Responsive Contact: 021-32416765 0300-8244520 info@dynamictravels.com.pk Thanking you Dynamic Travel Services

Rs 20

See product

Pakistan

From Mr Colin Roger, Flat 1, Woolmer House, Upper Clapton Road, London E5 8SU. Alan Sugar London Home. Greetings To You In Jesus Name. Our Names Are Mr Colin Roger, and I Am 43 years old, i Am Currently in United Kingdom ,Am a Business Man Here in Manchester UK, While My wife And Kids Are In UK here. My Family Carey Are Currently Living In The Next City.; We live In a Five Bedroom flat And Has Three Bathroom One Room For You And a Bath Room House In Address : Flat 1, Woolmer House, Upper Clapton Road, London E5 8SU. Alan Sugar London Home.. And We Have 2 kids Jason And Cristine They Are Between The Ages Of ( 2-Years And 5-Years Old ) . Jason ( 2-Yrs Old ) likes To Go The Parks Once A Week And We Would like You To Take Him Just To Have Fun . Cristine Is 5 yrs Old And Love To Meet People.. My Wife Jane Is Now In Switzerland , She Is On a Business Trip My Kids Are Leaving With Me And Sister But She Is Going Back To Her Husband Soon. We Are Christians , Also We Are God Fearing Family When You Get To Our Home , You Will Know More About Us ... I WANT TO EMPLOY THE SERVICES OF A NANNY /HOUSEKEEPER/ WORKER/DRIVER, AT MY HOME IN LONDON.I AM OFFERING AS SALARY 500 BRITISH POUNDS WEEKLY OR EQUIVALENT 3,600 POUNDS STERLING MONTHLY WITH FREE APARTMENT FOR ONLY THREE YEARS,INCLUDING YOUR WEEKLY ALLOWANCE 150POUNDS FOR OVER TIME . SALARY/WAGES ARE BELOW: AU PAIR/NANNY: £3,000 Monthly (weekly allowance £400) DRIVER: £2,200 Monthly (weekly allowance £600) CHEF: £1,500 Monthly (weekly allowance £120) HOUSE SITTER: £2,800 Monthly (weekly allowance £300) *Your performance will be reviewed periodically and we shall make an adjustments to your salary as it sees fit. Additional hours (Overtime) will be paid at a rate that we may agree between ourselves from time to time. it equivalent to ( 2,600poundsMontly ) START Date and Period of Employment: *You are expected to resume duty as soon as you arrive here. * You are expected to be a good and reliable worker. TRAVEL PROCESSING EXPENSES: *You are expected to shoulder Half Of the processing for your visa and other necessary legal documents needed for your arrival. *The host family is ready to shoulder 50% percent part of your travel fee for your convenience ACCOMMODATION/FEEDING: You shall have a big room, huge, and has a double bed, with sitting area and TV/DVD/Video/Hifi. There is also a wireless broadband internet in the house!! Do well to send us your references or resume, and we would get in touch with them. We shall discuss travel arrangements in due course of which I would be of generous assistance to you. VACATION: *Vacation and holidays: This is allowed after 2month DISCIPLINE: Reasons which could give rise to disciplinary measures are as follows: (1 Causing a disruptive influence in the HOME is prohibited. (2) Job incompetence is not allowed. (3) Conduct during or outside working hours prejudicial to my interests.. (4) Unreliability in time keeping or attendance. (5) Failure to comply with our reasonable instructions or procedures. (6) Theft or other dishonest offenses will be dealt with. (7) Drunkenness not allowed. (8) Illegal drug taking prohibited. (9) Child abuse or neglect highly prohibited. NOTE: That any Activities of improper conduct will also be our concern too, you will be highly required to be of your best behavior (in or outside) as you work for us to protect our good name. *IF YOU ARE INTERESTED TO WORK IN MY HOME ,THEN YOU CAN SEND YOUR RESUME OR C-V TO MY E-MAIL CONTACT ADDRESS : COLINROGER2013@YAHOO.COM , COLINROGER17@YAHOO.COM , COLINROGER17@GMAIL.COM WITH YOUR PHOTO AS WELL. *Contact Information Ad Listed from Mr Colin Roger. Email Us at : Colinroger17@yahoo.com, Colinroger17@gmail.com Or You Can Give a Call On My Private Number +4470-3197-2964 God Bless U .

Rs 3,40

See product

Bagh (Azad Kashmir)

ICTE International College of Technical Education. Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-8736681, 0311-5193625, 0092-335-4176949 Food safety refers to routines in the preparation, handling and storage of food meant to prevent foodborne illness and injury. From farm to factory to fork, food products may encounter any number of health hazards during their journey through the supply chain.foodborne diseases. Most of the time, the food handler is the one who intervenes as the vehicle of transmission of these diseases, so it is important that we take into account the great role we play in prevention. The training of food handlers is mandatory and will allow you to obtain a certificate that will accredit you as a food handler, allowing you to work in the food industry. Although it is not mandatory, it is recommended to renew the certificate every 4 years, and to be updated according to the job. Then, the company itself should offer a specific training in its sector. A food handler is anyone who, through their work activity, has direct contact with food during any of its phases until it reaches the final consumer. This includes: preparation, manufacture, processing, packaging, storage, transport, distribution, sale, supply and service. This training course will enable you to perform food handling functions, and you should be responsible with this information, as the health of many consumers depends on you.According to the World Health Organization (WHO), health is a complete state of physical, mental and social well-being, and not just the absence of physical discomfort or illness. So what is food hygiene? It is the group of measures needed to ensure food safety from farm to table, that is, from the moment they are obtained until they reach the final consumer. Therefore, we define food-borne disease as any disease caused by consuming contaminated food. It is important to maintain good food hygiene, as it will lead not only to a safer handling of food, but also to a good reputation for the company, increased customer satisfaction, and we will also avoid possible penalties from health authorities.FOOD CONTAMINATION. TYPES OF CONTAMINANTS AND HAZARDS. What is food contamination? A contaminant or a food hazard is any foreign agent to the food that is capable of producing a negative effect on the health of the consumer.According to their origin the hazards are classified into: Physics: bones, crystals, personal effects, etc. Chemicals: toxic substances, cleaning products, etc. Biological: living beings such as insects, rodents, birds, microorganisms, etc. The main food contamination sources are: The environment Pests: living beings. Utensils and premises: poor hygiene. Garbage. The food handler himself: due to lack of hygiene. Other foods: this is very important, as we are talking about cross-Contamination (transfer of contaminants from one food to another). It can be given by mixing raw and cooked foods, or using the same utensils for different foods.Microorganisms act as a source of infection or food hazard. But what are microorganisms? They are also called germs or microbes and are living beings so small that they are invisible to the human eye. Let’s list them according to the harm they can cause: Beneficial: they are used for food processing. Disruptive: they «warn» us of their presence, since they change the odour, colour, flavour and normal texture of the food. Patogens: These are the most dangerous because at first glance they do not change the food properties. They are mainly responsible for food-borne diseases. What do they need to live? Nutrients: food. Water. Heat. Acidity: as acidity increases, they become less contaminated by bacteria.. Oxygen: some bacteria live on oxygen (most of them), but others also grow without it. Time: the more time passes, the more they multiply and the greater the risk. The most frequent symptoms are general discomfort, vomiting, diarrhea and abdominal pain. But the most dangerous ones can cause serious injuries and even death. What food is more dangerous or likely to become contaminated? Those that pose a MAJOR RISK are: Minced meat. Fresh fish, shellfish and molluscs. Raw products. Fowl and Poultry. Egg-based dishes (use of raw eggs is prohibited). Pastry or bakery goods (especially those containing cream). The maximum time a food retains all its organoleptic, nutritional and health properties is called shelf life. The most frequent and traditional conservation systems used are: By cooling: refrigeration (Between 0º and 5ºC), freezing (less than -18ºC). The COLD CHAIN (or cool chain) must be maintained always. It consists of maintaining the cold (refrigeration or freezing) throughout the entire process through which the food passes: production, transport, reception, storage, sale to the consumer. If the correct temperature is not maintained during the whole process, the food will suffer IRREVERSIBLE consequences. By heating: microorganisms are destroyed by heat. The most popular methods are: pasteurization, cooking, sterilization and ultra-pasteurization. Removing part of the water from the food: drying, salting, curing, sugaring, smoking. Others: pickling, use of preservatives. ICTE International College of Technical Education. Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-8736681, 0311-5193625, 0092-335-4176949

Rs 123

See product

Pakistan (All cities)

Overview The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection. The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system. The meaning of the system 1. Reduce the amount of tundish slag 2. Improve the purity of molten steel 3. Improve the life of the tundish 4. Reduce sliding nozzle erosion 5. Reduce nozzle blockage 6. Increase continuous pouring heats 7. Reduce the amount of residual steel in the ladle when high-quality steel is casting 8. Improve the yield of molten steel 9. Improve the quality of continuous casting billets In order to improve the purity of the molten steel in the tundish, and improve the quality of the casting billet, especially to improve the quality of the billet in the transition section, and reduce the amount of residual steel in the high-quality ladle, and prolong the life of the tundish lining, and increase the continuous casting heats, it’s necessary to detect and control the slag in the later stage of continuous casting ladle casting. The working principle The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm. The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close the ladle nozzle. The features of the system (1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise. (2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The threshold of slag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such as the sensor service life and sensor usage times. (3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life. (4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm. (5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction. (6) The equipment adopts a modular design. The failure of each module will not affect other parts, which ensure more reliable operation of the system and easy maintenance. (7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag carryover strats, we can choose automatic mode or manual mode. In both modes, the system will give audible and visual alarm signals to remind on-site operators. (8) The system has a powerful database function. Including the comparison function for last two ladles of casting time record, the system automatically stores the running data, and generates a record file every day. (9) The system has the function of automatically controlling the ladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with the ladle slag detection system to automatically control the opening of the ladle nozzle and realize the whole-process control of the liquid level of the molten steel in the tundish. The composition of the system The LAG-S200 slag detection system consists of: vibration detection sensor, pre-signal amplifier, slag detection operation unit, tundish liquid level control unit, on-site operation indication box, and process control cabinet. 1. Vibration detection sensor: It is installed on the robotic arm of the stopper to detect the vibration signal of the whole casting process of the ladle. 2. Pre-signal amplifier: Amplify, convert and transmit the weak vibration signal detected by the vibration detection sensor. 3. Slag detection operation unit: Analyze, judge and discriminate the vibration signal to realize the discrimination of all steel, mixed slag and full slag , and output the slag alarm signal. 4. Tundish liquid level control unit: Accept the control signal of the tundish nozzle and the ladle nozzle, and realize automatic or manual control to the ladle slag according to the requirements. 5. On-site operation instruction box: Provides man-machine exchange for slag alarm indication, fault indication, system activation mode selection, and control mode selection. 6. Process control cabinet, providing power management, displaying man-machine interface and setting management. The parameters of the system 1. The system controls the slag inclusion in molten steel with high precision and closes the nozzle in real time. 2. Improve the quality of steel, reduce defective products, and improve the yield. 3. The yield of molten steel is increased by 0.3%-0.5%. The nozzle can be automatically closed, so that the disadvantage of untimely manual response is overcome and less molten steel remains in the ladle. The threshold value of molten steel (slag threshold) is set by the user within a wide range. 4. No artificial factors are involved, high reliability, good repeatability or consistency. 5. The steelmaking slag does not pass through or rarely flows into the tundish, which increases the service life of the refractory material and the sliding nozzle. 6. Reduce the blockage of the tundish nozzle and increase the number of continuous pouring heats of the tundish.

Rs 200.000

See product

3 photos

Bagh (Azad Kashmir)

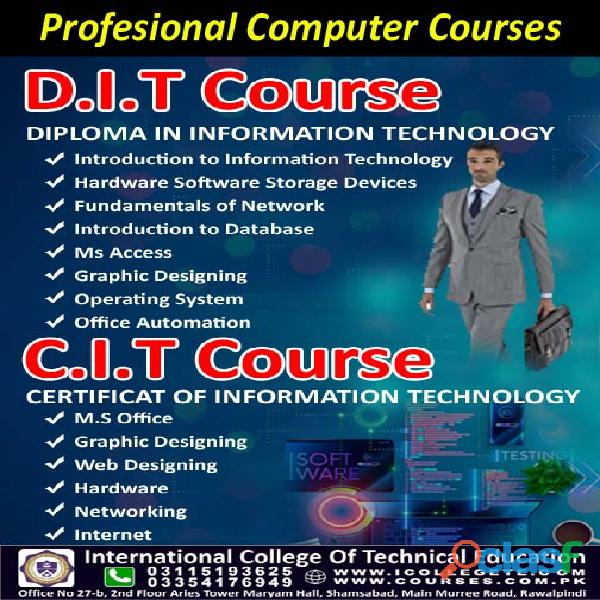

ICTE International College of Technical Education. Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-8736681, 0311-5193625, 0092-335-4176949 DIT - Diploma in Information Technology related to analysis, programming, computer organization, data management, systems development, computer communications, and professional practice and systems principles. The demand for information technology (IT) professionals has grown rapidly in the last decade. This main objective is to equipping students with the technical knowledge required for an IT environment and also developing skills in understanding IT applications in various corporate businesses and banking sectors.Well 'programme intended to develop high quality information technology manpower to meet the needs of industry and educational institutions as well as prepare candidates for advanced study in the field of information technology and computer science. Career Options The range of Information Technology expands to diverse areas such as hardware and software, telecommunication and multimedia to name few. After gaining diploma Information Technology, Students are able to seek a career in the Information Technology industry to evolve technology solutions meeting the business as well as information requirements of the organizations.You will learn a broad spectrum of technical skills in computing and information technology, with emphasis on website design, software development, database design, operating systems and networking. The Diploma of Information Technology combines core subjects and electives: ... web design and development/Students will learn about technical theory, networking, programming, and computer hardware. Depending on the specific major, students may also learn about database management, systems analysis, computer circuitry, website development, and IT management.DIT or Diploma in Information Technology is a three-year diploma course. Candidates pursuing Diploma in Electronic Engineering are taught electrical components telecommunication, signal processing, control systems, electric power control, radio engineering.Diploma in Information Technology is a Diploma level Information Technology course. Information Technology is the acquisition, processing, storage and dissemination of vocal, pictorial, textual and numerical information by a microelectronics-based combination of computing and telecommunications. In India, the various institute provides this course but its duration (regarding this course duration is one year) is not same which differs place to place. Regarding minimum time to complete the diploma is also not same. This diploma course may also be offered by some certain institutes on a part-time basis and its syllabus is divided into three semesters.Diploma in Information Technology is a Diploma level Information Technology course. Information Technology is the acquisition, processing, storage and dissemination of vocal, pictorial, textual and numerical information by a microelectronics-based combination of computing and telecommunications. Work-Sheets Docs-Word Slides-PowerPoint Forms, Database Operating System Basic Concepts of Accounts Maintaining Ledgers, Cash Book Balance Sheet, Profit & Loss Financial Accounting (Tally) C Language, C++ Language, Foxpro HTML, Java Script FRONT PAGE Access Complete Internet Photo Editing Softwares Computer Fundamentals Basics of Computer Hardware Software Installation Virus Protection & Scanning http://www.icollegete.com/course/dit-course-in-pakistan/ http://www.icollegete.com/course/dit-course-in-rawalpindi/ http://www.icollegete.com/course/diploma-information-technology-dit-course-in-rawalpindi-pakistan/

Rs 123

See product

Lahore (Punjab)

Rs: 250,000 Call 0323-4804460 Apollo 9 is most selling model of Novadex Medical Systems because of its ergonomic design, large lcd display and state-of-the-art features and resolutions. Enriched digital beam former and fast process makes this scanner highly efficient in professional ultrasonography. Technical Specification B,M,2B,B/M,4B Gray scale 256 15”LCD monitor Display 2-11 Mhz Tranducer frequency Wide-angle imaging Panoramic focusing technology Rolling M technology 300mm scanning depth Image Processing Cloud processing technology 8-segment TGC Dynamic range M Soften Noise suppression Image enhancement Gray Map Colorize Map Tissue Specific Imaging Left/right reverse Up/down reverse 334 frame cine loop memory 2 USB ports: Pan zoom Tissue Harmonic Imaging Measurement & Calculations Distance, angle, area, volume, trace length, distance ratio Distance, time, slope, HR 2 active transducer connector ports Video,2 USB ports,1 networking port,1 power inlet,1 equipotential terminal AC 100-240V 50/60HZ EXTENDED WARRANTEE: So far now it has been analyzed that some ultrasound scanners have poor probe quality and many probes stop working

Free

See product

-

Next →