Power locks power steering power windows sellers

Top sales list power locks power steering power windows sellers

Latest Offers

Pakistan (All cities)

" Elevate Your Skin's Radiance at Kameleon Salon Your Premier Skincare Destination in Kokapet. Experience Tailored Treatments, Expert Care, and Revitalizing Solutions for Your Glow" https://www.kameleonsalon.com/skin-services.html

Rs 0,0

See product

Askoley (Northern Areas)

Buy Verified Cash App Accounts https://buy5stareviewer.com/product/buy-verified-cash-app-accounts/ As it acquires clients, verified accounts become essential for businesses and individuals to fully access its features. A verified Cash App account allows you to send, receive, and withdraw substantial amounts of money, making it ideal for entrepreneurs, freelancers, and investors. The verification process ensures that the account is legitimate, reducing the risk of fraud and providing peace of mind for users. Verified Cash App accounts offer several advantages. Firstly, they enable higher transaction limits, allowing users to manage larger sums of money. This is particularly beneficial for businesses that need to process significant payments. Secondly, verified accounts provide enhanced security features, such as two-factor authentication, which helps protect against unauthorized access. Lastly, having a verified account can improve your credibility and trustworthiness when dealing with clients or customers. When purchasing a verified Cash App account, it is crucial to choose a reputable source. Look for sellers who offer guarantees of authenticity and provide excellent customer service. Conduct thorough research and read reviews to ensure you are making a safe and reliable purchase. Contact Info:: Telegram:@BBuy5stareviewer WhatsApp :+1(470) 745-6499 Skype :Buy5stareviewer live:.cid.e4c6455dd0c7f99e Email:buy5stareviewer@gmail.com

Rs 250,0

See product

Multan (Punjab)

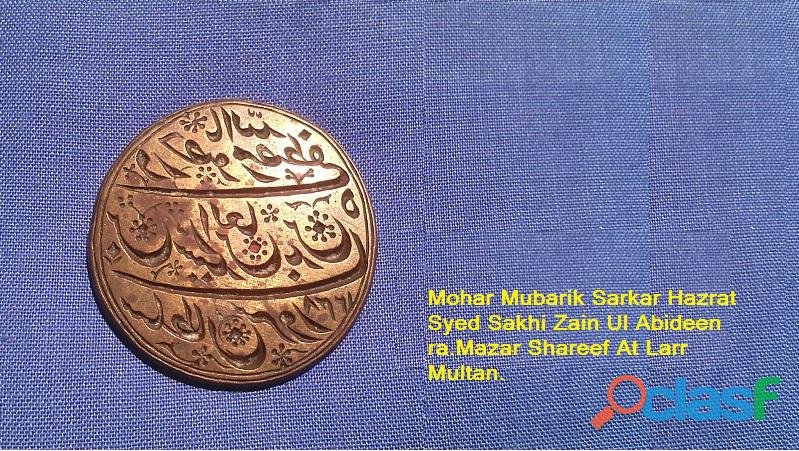

Hazrat Syed Sakhi Zain ul Abideen (RA) migrated from Baghdad to Saudi Arabia and spent 22 years in Madina Munawara.One night, holy Prophet hazrat Mohammad (may peace be upon him) appeared in a dream and instructed him to go to India, convince the people to the right path, preach or spread the teachings of Islam.Obeying the orders of the holy Prophet Hazrat Mohammad (may peace be upon him), the Sufi Saint left Madina Munawara and came to Shahkot. The Sufi saint is the father of a famous Sufi Hazrat Syed Ahmad Sultan, known as Sakhi Sarwar, the bountiful Chief, shrine at Sakhi Sarwar Pakistan. Hazrat syed sakhi Zain ul Abideen (RA) practised austerities and prayers in shahkot, The great renowned Sufi saints paternal genealogy is directly related ten generation up with Ameer ul Momeneen (commander of faithful) Hazrat Imam Ali Ibne Abu Talib R.A, thus he was a direct descendant of the holy Prophet Hazrat Mohammad (may peace be upon him). The name Zain ul Abideen was selected by his father Syed Umar due to the deep love and devotion with Imam Zain ul Abideen (A.S). Specification. Object Name: Seal stamp Description: Syed Zain ul Abideen Shah"Sultan Sarwar" Inscription Script : Arabic Inscription Technique: Engraved Date Period: A D 13th Century 1248 Time period: A D 13th Century Geography: Indian Subcontinent (Central Asia) Culture/period: Islamic Condition: Excellent Relics of the Islamic saints strengthens spiritual beliefs, inspire people and give them comfort in tough times. The holy seal is a precious asset handed down from generation to generation, extremely rare and a genuine masterpiece regarding the sacred relics of the early Islāmic saints.

Rs 100,0

See product

Pakistan (All cities)

Manufacturer's Warranty. Tecno Industries (Reg) اَلحَمْدُ لِله Manufacturers of: SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. (pure copper) Since 1986 Tecno Lazer Pakistan. 0300-9433728 Ring Road, Band Road, Lahore Pakistan. A Servo Stabilizer That Decreases 30 Volts (back-from 250 to 220 & Increases 70 Volts from 150 to 220) (±) 1% {CAN STEP-UP from even low (on-demand)} اَلحَمْدُ لِله Runs your Equipment Even in Low Main Voltage. INFORMATION: 1: ( An Old Transformer / Relay carrying Stabilizer steps down or up after losing or gaining 20-25 Volts While A Servo Stabilizer steps down or up after losing or gaining 1 Volt. (±) 1%) 2: (on-demand) Buck-Boost Transformer Technology add-in 2kVA and above Models. Basically they work on DC Servo Motor Control system. Their efficiency is much better and its output voltage of either 110 or 220 AC or any required voltage, more-over TECNO 3Phase models up-to 500kVA ratings are manufactured against a confirmed order. 1 year warranty with parts. 100% genuine copper winding (GUARANTEED) Specs for (intelligent Voltage Stabilizer): SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. Input Voltage : 150 To 250 AC Output Voltage : 110v & 220v AC (±) 1% Frequency : 45 or 60 Hz Wave Form : Non-distorted Sine-wave Response Time : 25ms / V Efficiency : 95 % Power Factor : 0.95 Relative Humidity : 30% to 80% (without condensation) Temperature Rise : Less Then 50c Control System : DC. Servo Motor Insulation Resistance : More then 3M?? at 500V DC Tested : 1500 V We Manufacture Servo Motor Controlled Automatic Voltage Stabilizer, using Japanese technology, for UPS, Solar, AC Air-Conditioner, Split-Type, Window Type, (LCD/LED TV) Washing Machine, Treadmill, Photocopier Machine. Television, Music System, Refrigerators, Ultra sound Machines, Embroidery Machines, All Sensitive Equipment, Signalling Devices, CNC Machines, Air Conditioning Plants, Telecommunication Networks, Motor Loads, Data Processing Equipment, Bio Medical Equipment, Drives, PLC’s, Induction Heating, Hotels, Defence Application, Industrial Units, Lighting Loads, Residential/ Offices, Farm Houses, R & D Institutions, Mainline Stabilizers, Sophisticated Laboratory Equipment etc. Runs your Appliances Even in Low Main Voltage. وولٹیج سٹیبلائزر Standard Power Ratings Available in Single-Phase & 3-Phase: 500VA, 1kVA, 2kVA, 3kVA, 5kVA, 10kVA, 30kVA. Up-to 500kVA Punjab NWFP, KPK, & All Pakistan Cargo, Feel Free to Call: Rana Naeem Hammad. M.D. Tecno Industries (Pvt) Ltd Lahore. +923009433728

Rs 121,0

See product

11 photos

Pakistan

6 left in total 4 youngsters and one proven pair Youngsters 4000 each all gorgeous pastel colours long tail feathers . All closed rung breeding pair at 4000 pair 4 young plus proven pair 5000

Rs 4.000,0

See product

Pakistan (All cities)

Dev Technosys offers cutting-edge News App Development Services, delivering customized solutions with advanced features like real-time updates and smooth navigation. Our expert team specializes in News App Designing, creating user-friendly and visually appealing interfaces. Get reliable, scalable, and performance-driven News App Solutions tailored to meet your business goals. Visit: https://devtechnosys.com/news-app-development.php

Rs 0,0

See product

Pakistan (All cities)

Overview The handheld roll gap checker is specially used to measure the length between spherical surface, arc surface and plane (or spherical surface). It is specially suitable for the opening adjustment of the roll gap of the metallurgical continuous casters in various specifications, because the roll gap checker has the advantages of high resolution, accurate measurement, stable data and easy to use. Because the opening accuracy of the roll gap checker will directly affect the quality of the casting block, this roll gap checker is an indispensable testing equipment in the continuous casting equipment, which can fully meet the needs of on-site installation testing and use process verification. When the hand-held roll gap meter smoothly passes through the gap between the guide rolls of the continuous casting machine, the upper measuring contact of the hand-held roll gap checker contacts the inner arc roll and the lower measuring contact touches the outer arc roll. The handheld roll gap checker is used in perpendicular to the roll diameter direction, during the pushing process, when the hand-held roll gap meter is in the tangent plane of the upper and lower rolls, the measured value is the smallest at this time, and this value is the roll gap measurement value. The design of the hand-held roll gap gauge ensures that the upper and lower contacts of the roll gap checker can smoothly pass the measured roll along a straight line during measurement. During the measurement process, the roll gap measuring instrument automatically compares the measured values, and displays the minimum measured value on the instrument display interface, which is the current measured roll gap value. The introduction of different types The measuring range of the split hand-held roll gap checker is 180mm - 400mm This hand-held roll gap checker adopts the design that the measuring body and the display instrument are separated. The measuring body can be clamped by an extension rod, which is suitable for online maintenance and measurement of wider slabs, and it is convenient to use the extension rod to send the measuring body into the continuous casting section to measure inside and we can see measurement data on the checker outside. The measuring range of instrument type handheld roll gap checker is 120mm - 400mm This hand-held roll gap meter is light and compact, and it is convenient to carry during maintenance. The measurement value can be seen immediately after measurement, easy to use, and can be equipped with a short measuring rod. It is suitable for the maintenance and measurement of slab online and offline continuous casting sections. It has data printing function, the measurement results can be printed in real time. The measuring range of thin slab hand-held roll gap checker is 60mm - 150mm This handheld roll gap meter is suitable for measuring the roll gap of CSP continuous casting machine and ultra-thin slab continuous casting machine. It is accurate and easy to use. The technical parameters 1. Measuring range of instrument type handheld roll gap checker: 180mm - 400mm (the range can be customized) 2. Measuring range of digital hand-held roll gap checker: 120mm - 400mm (the range can be customized) 3. Measuring range of hand-held thin slab roll checker : 60mm - 150mm (the range can be customized) 4. Measurement accuracy: 0.01mm 5. Working temperature: -25℃~+85℃ 6. Battery capacity: 5000mAh 7. Charger specification: 12V

Rs 0,0

See product

2 photos

Pakistan (All cities)

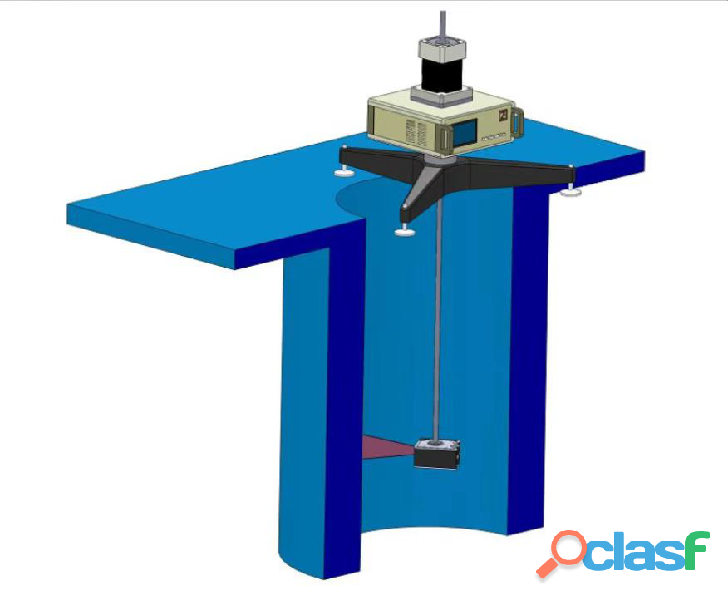

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Bagh (Azad Kashmir)

Eagle Racking India is a leading provider of industrial storage racks in Kanpur, offering high-quality and durable storage solutions for warehouses, factories, and commercial facilities. Our storage racks are designed to maximize space utilization, enhance efficiency, and ensure easy inventory management. We specialize in a wide range of industrial racking systems, including pallet racks, heavy-duty racks, mezzanine racks, and cantilever racks, catering to diverse storage needs. Made from premium-grade steel, our racks are built to withstand heavy loads and provide long-lasting performance. They are designed with customizable shelving options, corrosion-resistant coatings, and high load-bearing capacities to meet industrial requirements Read more: https://eagleracking.com/kanpur/industrial-storage-rack

Rs 0,0

See product

Lahore (Punjab)

SEO Training in Lahore offers comprehensive courses designed to equip individuals with the skills needed to excel in search engine optimization. Whether you're a beginner or looking to enhance your existing knowledge, our training programs cover everything from basic SEO principles to advanced strategies. You will learn keyword research, on-page and off-page optimization, technical SEO, content marketing, and the latest SEO tools and techniques. Our experienced instructors provide hands-on training with real-world examples, ensuring you can apply what you've learned immediately. The course also includes case studies, projects, and practical

Free

See product

2 photos

Pakistan

2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds 2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds .....................2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds

Rs 4.000,0

See product

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

Rs 0,0

See product

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product

Pakistan (All cities)

Effective Bird Deterrence: Strategically designed bird spikes to effectively deter pigeons, sparrows, and other nuisance birds.....

Free

See product

Islamabad (Islamabad Capital Territory)

Marshall Packers and movers in Lahore Pakistan International Packers and movers in Lahore Pakistan Our services House shiftng services Goods transportation Freight forwarding International cargo services International Afghan Transit services International furniture shipping services House shifitng services in Rawalpindi"House shifitng services in Pakistan International cargo services in Islamabad https://marshallpackers.com/services/cargo/

Free

See product

-

Next →