Nec projector lamp picture

Top sales list nec projector lamp picture

Latest Offers

Bagh (Azad Kashmir)

Eagle Racking India is a leading provider of industrial storage racks in Kanpur, offering high-quality and durable storage solutions for warehouses, factories, and commercial facilities. Our storage racks are designed to maximize space utilization, enhance efficiency, and ensure easy inventory management. We specialize in a wide range of industrial racking systems, including pallet racks, heavy-duty racks, mezzanine racks, and cantilever racks, catering to diverse storage needs. Made from premium-grade steel, our racks are built to withstand heavy loads and provide long-lasting performance. They are designed with customizable shelving options, corrosion-resistant coatings, and high load-bearing capacities to meet industrial requirements Read more: https://eagleracking.com/kanpur/industrial-storage-rack

Rs 0,0

See product

Pakistan

I have available 2 stunning BSH blue kittens. 1 girls and 1 boys. Mum and dad are beautiful blues and are GCCF registered. Mum has a wonderful personality, she is friendly and extremely loving. she has an excellent 4 generations pedigree.

Rs 5.000,0

See product

Pakistan (All cities)

Topper Smart Bidet Tiolet Seat Co., Ltd. (https://www.mfrsbidet.com/) is a professional and experienced smart toilet & bidet manufacturer and supplier, specializing in diversifying our bidet products to suit a range of different needs. We are capable of providing toilet bidets, bidet attachments, bidet seats, toilet seat covers, bidet sprayers, portable bidets and other bidet fittings, and offering practical and personalized sanitary solutions for our customers. Over the years, we have been consistent in supplying high-quality products and thoughtful services. Every stage in the production is guided and supervised by skilled professionals and our quality control systems. Our bidet products all meet tangible and intangible requirements in terms of quality and safety. From the design and development of products to the user experience, we are never slackening our effort, and still trying our best to improve your life quality. Convenience, comfort and superior quality are the ideas we want to convey through our bidets and services. In the future, we will continue to strengthen our capability of design and innovation to better satisfy the demands of the market and create the best home life experience for customers. If you're interested in our bidets, please visit https://www.mfrsbidet.com/.

Rs 200,0

See product

6 photos

Lahore (Punjab)

Apple Hair Color Price In Pakistan - Quickon.pk Apple Hair Color Price In Pakistan is a hair dye product designed to provide vibrant, long-lasting color while maintaining the health and integrity of your hair. This product is formulated to offer rich, natural-looking color with the added benefits of conditioning and nourishing ingredients. What is Apple Hair Color Price In Pakistan? Apple Hair Color Price In Pakistan is a professional-quality hair dye that offers a wide range of shades to suit different hair types and preferences. The formula is enriched with conditioning agents and natural extracts that help protect and nourish the hair during the coloring process. It is designed to deliver vibrant, long-lasting color with a natural finish. https://quickon.pk/product/apple-hair-color-price-in-pakistanhttps://quickon.pk/product/feg-plus-hair-growth-sprayhttps://quickon.pk/product/sardar-jee-hair-color-gel-price-in-pakistan

Rs 3.500,0

See product

Pakistan (All cities)

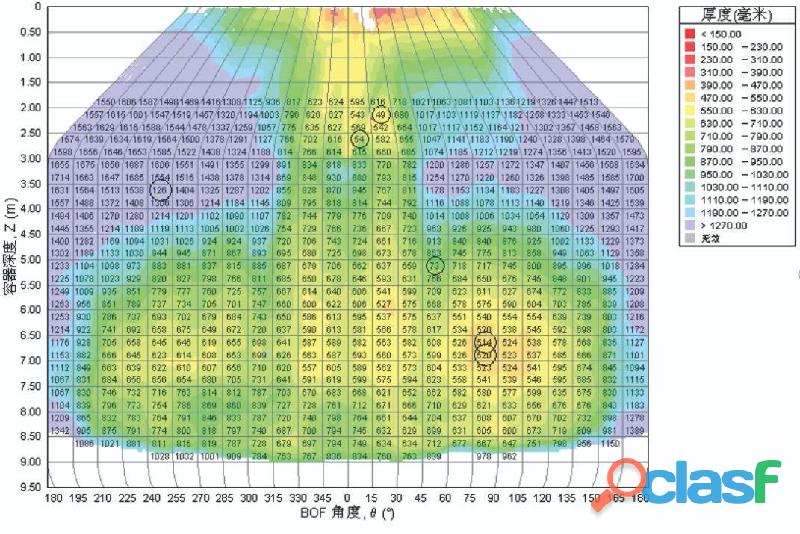

Overview LDT-I200 is a new generation of converter lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the converter, and receives the returned laser light to measure its flight time. Then the system equipment calculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushes the equipment to a certain position on the platform in front of the converter, and the equipment can start to scan and measure the target area of the converter after the equipment performs rapid self-positioning. The Measuring principle The measurement speed of LDT-I200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curve of the entire converter lining can be obtained by combining the measurement data of different positions and angles. During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within 4 minutes, the three-dimensional surface contour of the converter lining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracy up to ±2mm. In order to convert the distance from the internal point of the converter to the thickness gauge into the thickness of the furnace lining at each point, we must know the coordinate relationship between the trolley and the converter. We use the second laser head to position the trolley. When the trolley is pushed to the measurement site, the positioning laser head rotates at high speed to scan the three reflective strips opposite the converter. Through triangulation measurement and calculation, we can calculate the relative position of the trolley to the reflective strips. The coordinates of the reflective strip and the converter are known through mapping, so that the coordinates of the trolley relative to the converter can be accurately obtained. The main components 1. Laser measuring head 2. Wireless communication 3. Battery pack 4. Mobile laser thickness gauge host 5. Converter inclination measurement system 6. Cooling circulation system 7. Positioning auxiliary reflector 8. Laser positioning system The technical indexes Laser reproducibility: ±2mm Laser accuracy: ±2mm Local fastest measurement time: 15s Positioning time: 30s Full image measurement time: 4min The highest measurable lining temperature: 1850℃ Measuring distance: 0.5-25m Actual points are measured per frame: 1500000 points Continuous working time after fully charged: ≥3h Eye-safe laser: Class 1 laser product (doesn't hurt the eyes) The parameters of laser measuring head Measurement principle: According to the flight time and speed of the laser to calculate the distance Laser reproducibility: ±2mm Laser accuracy: ±2mm Scan rate: 2000000 points/second Measuring angle: vertical ±40°, horizontal 360° Maximum measurement temperature: 2200℃ Working temperature: -20℃-80℃ Cooling method: Integrated liquid cooling system, IP64 grade protection Laser wavelength: 1550nm (near infrared)

Rs 0,0

See product

2 photos

Pakistan

i have a variety of beautiful, yellow, white, red, yellow/green canaries for sale. male and female. you can get them separately or in pairs! lovely gift for anybody. prices range from £25 and above. offers can be made, when you come to view the birds.

Rs 4.000,0

See product

Pakistan (All cities)

Spark your child’s learning journey with Kinder ABC! From fun alphabet adventures to interactive games like tracing, puzzles, and bubble popping, Kinder ABC offers an ad-free, safe space for kids to learn letters, phonics, and more. Download now and make learning fun! Get Kinder ABC on Play Store: https://play.google.com/store/apps/details?id=com.icommunetech.kinderabc Official Website: https://www.icommunetech.com/

Free

See product

3 photos

Pakistan (All cities)

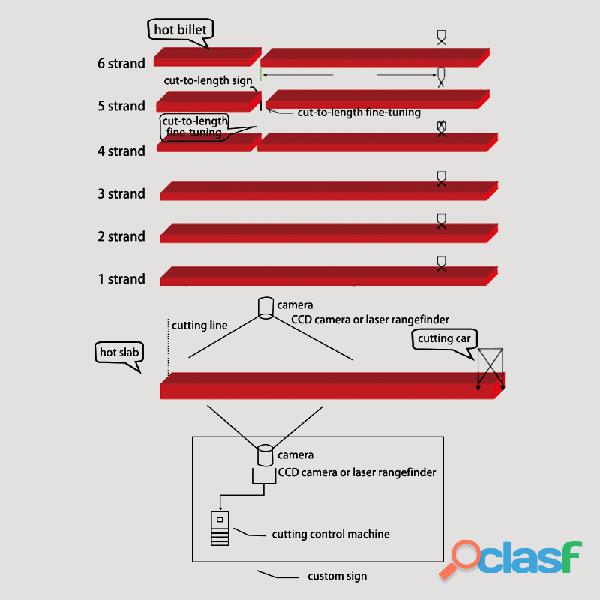

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

Rs 0,0

See product

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

Rs 0,0

See product

Pakistan (All cities)

Laser cutting machines have transformed the design and fabrication industries, unlocking a new realm of creative possibilities. With their ability to cut and engrave materials with precision and speed, these machines are not just tools—they are catalysts for innovation. Whether in architecture, fashion, art, or product design, laser cutters have become an essential tool for turning ideas into reality. https://www.tradebrio.com/exporters/laser-cutting-machines.html

Free

See product

Pakistan (All cities)

As one of the largest Chinese manufacturers of industrial valves, China Vervo Valve Co., Ltd. offers a wide array of products, including floating ball valves, trunnion ball valves, cast steel gate valves, forged steel gate valves, pressure seal gate valves, cast steel globe valves, forged steel globe valves, cryogenic globe valves, forged steel check valves, swing check valves, dual plate check valves, API 609 butterfly valves, steel plug valves, Y strainers, and more. Our business reaches North America, South America, Europe, Asia, the Middle East, Africa, and Oceania. We manufacture, import, and sell a wide range of industrial valves, including ball, gate, globe, butterfly, check, plug valves, and specialty valve solutions. We look forward to establishing a strong cooperation with you! Visit our website: https://www.vervovalve.com/

Rs 200,0

See product

Pakistan (All cities)

" Elevate Your Skin's Radiance at Kameleon Salon Your Premier Skincare Destination in Kokapet. Experience Tailored Treatments, Expert Care, and Revitalizing Solutions for Your Glow" https://www.kameleonsalon.com/skin-services.html

Rs 0,0

See product

Pakistan (All cities)

Buy Verified Cash App Accounts As it acquires clients, checked accounts become fundamental for organizations and people to completely get to its highlights. A checked money application account permits you to send, get, and pull out a lot of cash, making it ideal for business people, consultants, and financial backers. Purchasing a confirmed money application account has turned into a pattern now, with numerous suppliers offering this help at a sensible cost. In any case, it means quite a bit to purchase from a confided in source to stay away from tricks or fake records. You will learn the fundamentals of purchasing verified cash app accounts and everything else you need to know before making a purchase in this article.

Free

See product

Pakistan (All cities)

GoLogica offers complete online training in data modeling that gives professionals the understanding and skills they need to understand data modeling methods. IT specialists, database developers, business analysts, and data analysts who want to become better in creating and managing data structures may benefit from this course. Basic topics covered in the course include entity-relational diagrams (ERDs), data mapping, normalization strategies, and abstract, logical, and physical data modeling. It also covers database design concepts, demonstrating how to build durable, scalable, and effective data models that correspond with business goals. This course, led by industry experts, gives participants practical knowledge through practical assignments, allowing them to apply what they've learned in actual situations. Whether you're new to data modeling or want to improve your existing skills, GoLogica Data Modeling Online Training provides a solid basis for creating and managing successful data models. Enroll in GoLogica Data Modeling Online Training today to obtain the knowledge you need to boost your career in data management and become a certified Data Modeling expert!

Rs 0,0

See product

Gujranwala (Punjab)

I am a professional logo designer with 4 years of experience, specializing in creating unique and memorable brand identities. My expertise lies in designing logos that effectively communicate your brand’s values and vision. Over the years, I’ve worked with various industries, delivering tailored designs that stand out. I prioritize client satisfaction by ensuring clear communication and timely delivery. My design process is detail-oriented, combining creativity and strategy to create impactful logos. Whether you’re launching a new business or rebranding, I can help elevate your visual presence. Let’s collaborate to bring your ideas to life!

Rs 999,0

See product