Measurement

Top sales list measurement

Pakistan (All cities)

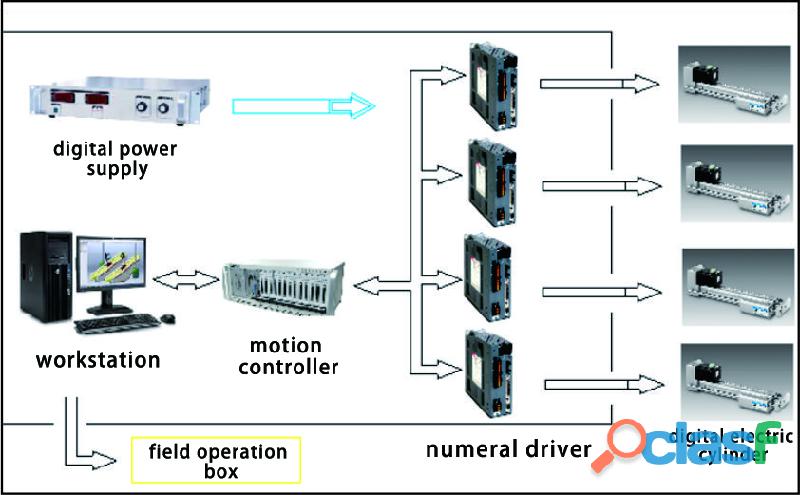

Overview In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting. The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached. During the production process, the adjustment of the mold’s width can be completed without stopping the machine. Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold. Only with adjustment and detection can the online adjustment range of the mold be accurately controlled. Fig 1 Mold online width adjustment system The components of the system Workstation: host system, system width adjustment control, taper detection. On-site operation box: real-time display of the current control status, manual operation to adjust parameters. Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control. On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time. Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment. FIG 2 System block diagram The technical parameters Adjustable range: 0-1250mm (unilateral) Control accuracy: 0.02mm/0.05mm/0.1mm Step resolution: 0.01mm/0.02mm Running speed: 0-10mm/s Power: 3.5KWl 16-bit encoder: 65536 pulses Weight: 25Kg Shell: high-strength aluminum alloy FIG 3 Syetem software interface The functions of the system Realize online width adjustment function Realize the online real-time monitoring function of mold taper Continuous casting production adjustment and non-stop production One-key operation in the main control room, automatic completion High adjustment accuracy and fast speed The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

See product

3 photos

Pakistan

AMF500 Series is a wafer type electromagnetic flowmeter ideal for conductive liquids. It comes in sizes from 25 to 200 mm. AMF500 is widely used for tap-water, waste water, food & beverage, pulp & paper and many other industrial fluid. AMF500 Series electromagnetic flowmeter could be used in compact or separate model with AMC Series converter of electromagnetic flowmeter. FEATURES Light and compact version Flow Velocity range: 0-12 m/s, precise in low flow applications It comes any flanges such as ANSI, DIN, JIS... etc Excellent for high pressure application Protection class: IP68 available; sensor submersible FEP Liner is suitable for vacuum tube High accuracy of +/-0.4% value of reading (or+/-0.2% value of reading) With Forward / Reverse flowrate measurement function SPECIFICATION Pipe Size:25,32,40,50,65,80,100,125,150,200mm Measuring Range: Velocity 0-0.25 m/s min. 0-12 m/s max. Material: Measuring Tube: Stainless Steel 304 Coil Housing: Carbon Steel (standard) Stainless Steel 304(Option) Stainless Steel 316(Option) Liner: FEP Protection: IP 68 IP68(Submersible) Temperature: 40 to +180 Deg.C Max. Pressure: 16 Kg/cm2 (standard) 40 Kg/cm2(option)

See product

Pakistan (All cities)

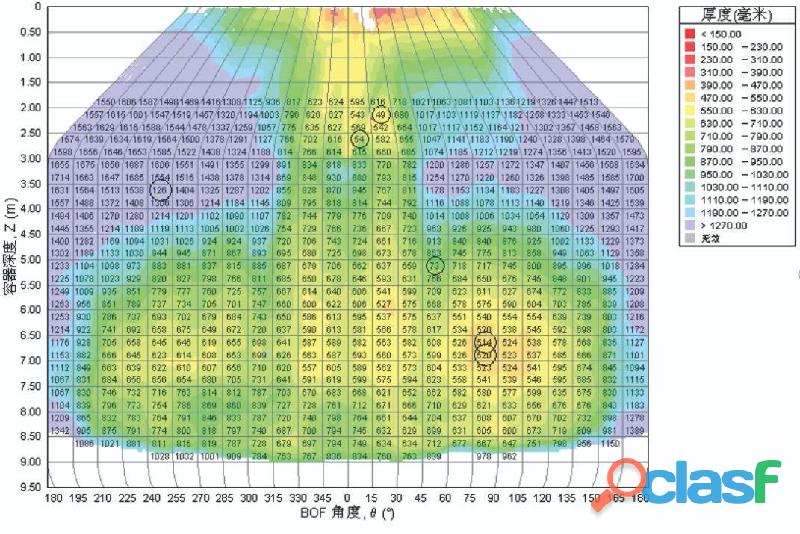

Overview LDT-I200 is a new generation of converter lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the converter, and receives the returned laser light to measure its flight time. Then the system equipment calculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushes the equipment to a certain position on the platform in front of the converter, and the equipment can start to scan and measure the target area of the converter after the equipment performs rapid self-positioning. The Measuring principle The measurement speed of LDT-I200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curve of the entire converter lining can be obtained by combining the measurement data of different positions and angles. During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within 4 minutes, the three-dimensional surface contour of the converter lining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracy up to ±2mm. In order to convert the distance from the internal point of the converter to the thickness gauge into the thickness of the furnace lining at each point, we must know the coordinate relationship between the trolley and the converter. We use the second laser head to position the trolley. When the trolley is pushed to the measurement site, the positioning laser head rotates at high speed to scan the three reflective strips opposite the converter. Through triangulation measurement and calculation, we can calculate the relative position of the trolley to the reflective strips. The coordinates of the reflective strip and the converter are known through mapping, so that the coordinates of the trolley relative to the converter can be accurately obtained. The main components 1. Laser measuring head 2. Wireless communication 3. Battery pack 4. Mobile laser thickness gauge host 5. Converter inclination measurement system 6. Cooling circulation system 7. Positioning auxiliary reflector 8. Laser positioning system The technical indexes Laser reproducibility: ±2mm Laser accuracy: ±2mm Local fastest measurement time: 15s Positioning time: 30s Full image measurement time: 4min The highest measurable lining temperature: 1850℃ Measuring distance: 0.5-25m Actual points are measured per frame: 1500000 points Continuous working time after fully charged: ≥3h Eye-safe laser: Class 1 laser product (doesn't hurt the eyes) The parameters of laser measuring head Measurement principle: According to the flight time and speed of the laser to calculate the distance Laser reproducibility: ±2mm Laser accuracy: ±2mm Scan rate: 2000000 points/second Measuring angle: vertical ±40°, horizontal 360° Maximum measurement temperature: 2200℃ Working temperature: -20℃-80℃ Cooling method: Integrated liquid cooling system, IP64 grade protection Laser wavelength: 1550nm (near infrared)

See product

2 photos

Pakistan (All cities)

Overview The handheld roll gap checker is specially used to measure the length between spherical surface, arc surface and plane (or spherical surface). It is specially suitable for the opening adjustment of the roll gap of the metallurgical continuous casters in various specifications, because the roll gap checker has the advantages of high resolution, accurate measurement, stable data and easy to use. Because the opening accuracy of the roll gap checker will directly affect the quality of the casting block, this roll gap checker is an indispensable testing equipment in the continuous casting equipment, which can fully meet the needs of on-site installation testing and use process verification. When the hand-held roll gap meter smoothly passes through the gap between the guide rolls of the continuous casting machine, the upper measuring contact of the hand-held roll gap checker contacts the inner arc roll and the lower measuring contact touches the outer arc roll. The handheld roll gap checker is used in perpendicular to the roll diameter direction, during the pushing process, when the hand-held roll gap meter is in the tangent plane of the upper and lower rolls, the measured value is the smallest at this time, and this value is the roll gap measurement value. The design of the hand-held roll gap gauge ensures that the upper and lower contacts of the roll gap checker can smoothly pass the measured roll along a straight line during measurement. During the measurement process, the roll gap measuring instrument automatically compares the measured values, and displays the minimum measured value on the instrument display interface, which is the current measured roll gap value. The introduction of different types The measuring range of the split hand-held roll gap checker is 180mm - 400mm This hand-held roll gap checker adopts the design that the measuring body and the display instrument are separated. The measuring body can be clamped by an extension rod, which is suitable for online maintenance and measurement of wider slabs, and it is convenient to use the extension rod to send the measuring body into the continuous casting section to measure inside and we can see measurement data on the checker outside. The measuring range of instrument type handheld roll gap checker is 120mm - 400mm This hand-held roll gap meter is light and compact, and it is convenient to carry during maintenance. The measurement value can be seen immediately after measurement, easy to use, and can be equipped with a short measuring rod. It is suitable for the maintenance and measurement of slab online and offline continuous casting sections. It has data printing function, the measurement results can be printed in real time. The measuring range of thin slab hand-held roll gap checker is 60mm - 150mm This handheld roll gap meter is suitable for measuring the roll gap of CSP continuous casting machine and ultra-thin slab continuous casting machine. It is accurate and easy to use. The technical parameters 1. Measuring range of instrument type handheld roll gap checker: 180mm - 400mm (the range can be customized) 2. Measuring range of digital hand-held roll gap checker: 120mm - 400mm (the range can be customized) 3. Measuring range of hand-held thin slab roll checker : 60mm - 150mm (the range can be customized) 4. Measurement accuracy: 0.01mm 5. Working temperature: -25℃~+85℃ 6. Battery capacity: 5000mAh 7. Charger specification: 12V

See product

2 photos

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

See product

Pakistan (All cities)

Overview In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline deviation. The measurement of the strand condition monitor Roll gap value: By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed. It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster. Arc condition of guide roller : Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guided roller. Guided roller rotation: It is possible to know whether each guided roller can rotate freely by measuring. Water spray pressure: The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal. The main components of the strand condition monitor 1. The main body of the strand condition monitor used to measure the continuous casting sector 2. The connecting chain between strand condition monitor and dummy bar 3. The storage rack chain of strand condition monitor 4. Battery charger: 24V 5A 5. Calibration equipment 6. Remote control 7. Laptop 8. Printer 9. Data communication cable The technical parameter 1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements) 2. The measurement accuracy of roll gap: 0.01mm 3. The arc measurement range: ±80° 4. The arc measurement accuracy: 0.01° 5. The spray measurement range: 0-10 6. The spray measurement accuracy: ±1 7. The battery usage times: 3 times

See product

Pakistan

MS6416 Laser Distance Meter (60 Meter) In Pakistan Assisted laser ray measurements Color Display: Auto Power Off Data Logging: 99 groups Area & Volume Calculation Auxiliary foot level measurement Display Backlight The maximum distance measurement: 60m Distance measurement precision: ±1.5mm Measurement unit options: mm/in/ft Continue measurement function Area measurement function Volume measurement function Pythagorean proposition measurement function: Full mode Add and subtract measurement function Min/Max value Max storage: 99 units Automatic backlight Buttons/Keys sound Laser level: II Laser type: 635nm, 1mW Automatically cut off laser: 20s Automatic shutdown: 150S Brand Mastech Price: 9,500/= Free Delivery All Across the Pakistan Cash on Delivery only for Karachi Customers. More information Contact Us Zain Akram 0 3 0 2 - 2 5 0 5 1 8 3 Email: zaainakram16 at gmail . com

Rs 9.500

See product

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

See product

Pakistan

Now buy Online Laser distance meter n Pakistan, Accurate reading, reliable product. Measuring rang is 80 Meter. The maximum distance measurement: 80m Distance measurement precision: ±1.5mm Measurement unit options: mm/in/ft Continue measurement function Area measurement function Volume measurement function Pythagorean proposition measurement function: Full mode Add and subtract measurement function Min/Max value Max storage: 99 units Automatic backlight Buttons/Keys sound Laser level: II Laser type: 635nm, 1mW Automatically cut off laser: 20s Automatic shutdown: 150S Storage temperature: -20℃-60℃ Working temperature: 0℃~40℃ Storage humidity: Rh85% Battery: 1.5V 3*AAA Weight(including battery):180g Dimension: 120*60*28 mm Safety rating: CE(EMC) RoHS Brand Mastech Price: 10,500/= Free Delivery All Across the Pakistan Cash on Delivery only for Karachi Customers. More information Contact Us Zain Akram 0 3 0 2 - 2 5 0 5 1 8 3 Email: zaainakram16 at gmail . com

Rs 10.500

See product

Pakistan (All cities)

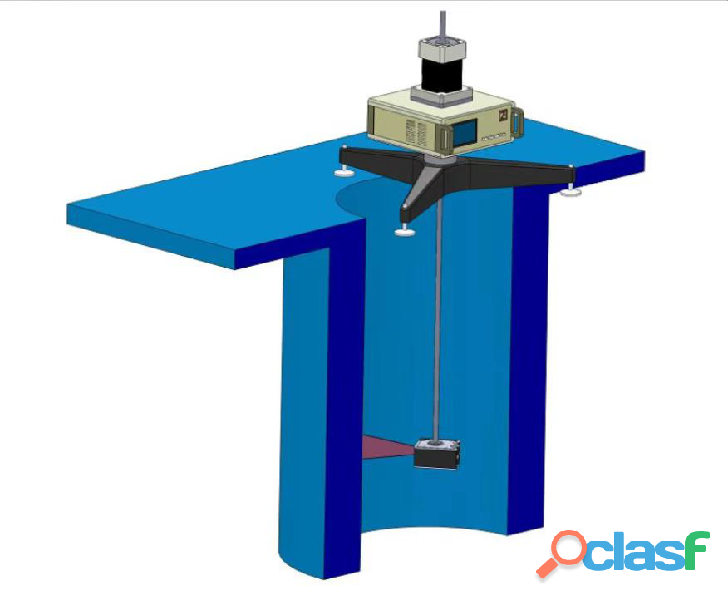

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

See product

Pakistan

Description: SW-150 is a professional hand-held laser range finder, small size, fully functional, accurate measurement, easy to operate, easy one-click to quickly achieve length, area, volume measurement, large-size high-definition LCD with backlight screen display allows you to measure the results at a glance in any environment.This machine is equipped with a unique and indirect measurement modeto meet your measurement needs in different complex environment, easy measurement, easy to improve work efficiency! Dawei deep laser rangefinder is ideal for on-site measurement tool! FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan

Variable - frequency drive (VFD) V & Hz measurement. Lo - Z voltage measurement to drain ghost voltages. Check 3 phase sequence. Voltage harmonic ratio measurement. Smart ohm for ground resistance measurement. Data hold & Auto hold mode. Max/Min/Avg record mode. Relative value display. Frequecy count. (Auto-Range) Temperature type K, J measurement. Capacitance measurement. Data memory & read function. Voltage harmonic ratio General Specifications: Power Source: Single standard 9-volt battery, NEDA 1604, JIS 006P, IEC 6F22. Weight: Approx. 470g Size: 193mm(L)×91mm(W)×53mm(H), (7.6"L×3.6"W×2.1"H) Accessories : Test leads, Battery, Operating Instruction Made in TAIWAN

Rs 14.800

See product

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

See product

Pakistan (All cities)

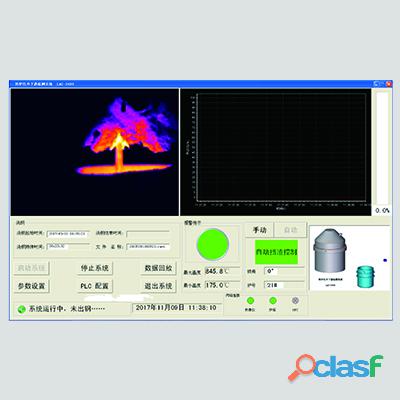

Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content. The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal. As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc. The features of thermal imager 1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set. 2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature. 3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily. 4. With hot zone tracking function 5. Equipped with special 7~14um infrared filter lens The technical parameters 1. Temperature measurement range: 200°C ~ 2000°C 2. Temperature measurement accuracy: 2% 3. Detection accuracy and alarm accuracy: ≥98% 4. Resolution: ≥ 0.5℃ 5. Pixels: 640x240PT 6. Band: 7~14um 7. Field of view: 7.5°×5.5° 8. Frame rate: ≥ 25 frames/sec 9. Equipment service life: ≥5 years 10. The normal operation rate of the automatic control system: ≥99%

See product

3 photos

Pakistan

Features: Dual Display with 6000 counts Jaw size up to ¦µ40mm/1.6 inch Auto Ranging and Manual Ranging DC/AC current measurement up to 1000A Tests AC/DC voltage and current, resistance, capacitance, frequency and duty cycle Relative Measurement Diode 2.7V Continuity Buzzer 50 ohm MAX/MIN Value Measurement Data Hold Display Backlight and Work Light Low Battery Display Auto Power Off True RMS (True Root mean Square Measurement) NCV (Non-Contact Voltage Detector) Inrush (Inrush Current Measurement) USB interface (Windows OS) Technical Specifications: DC Voltage 600mV/6V/60V/600V¡À(0.5% + 3) 1000V¡À(0.8% + 2) AC Voltage 600mV/6V/60V/600V¡À(0.8% + 3) 750V¡À(1% + 4) DC Current 60A/600A/1000A¡À(3.0% + 3) AC Current 60A/600A/1000A¡À(2.5% + 3) Resistance 600¦¸/6k¦¸/60k¦¸/600k¦¸/6M¦¸¡À(1.0% + 3) 60M¦¸¡À(1.5% + 3) Capacitance 6nF/60nF/600nF/6uF/60uF/600uF/6mF/60mF¡À(4.0% + 3) Frequency(From Clamp) 0~10kHz¡À(1.5% + 5) Frequency(AC Voltage) 0~10kHz¡À(1.5% + 5) Logic Frequency 0~60MHz¡À(0.5% + 3) Duty Cycle 10%~90%¡À3.0%

Rs 7.800

See product

Pakistan (All cities)

Overview: Mold powder is mainly used in the continuous casting and steelmaking process, evenly sprinkled on the molten steel surface in the mold to lubricate, keep warm, prevent oxidation and absorb non-metallic inclusions. Mold powder is an indispensable auxiliary production material in the production process. In the process of evenly distributing the mold powder to the molten steel surface of the mold, the amount of mold powder should be controlled, and the thickness of the mold powder should be within a certain range. If the coverage thickness of the mold flux is too thin, it will cause no heat preservation, oxidation of molten steel, inclusions, cracks, large drawing resistance, steel leakage, etc. At the same time, the coverage thickness of mold flux should not be too thick, they can’t melt in time with too much mold powder, if the molten steel is churning, it is easy to get the mold powder into molten steel at this time, resulting in mold leakage. Therefore, the amount of mold powder must be controlled within a reasonable range. The detection and control of mold flux thickness is very important, especially for the steel plants which are strict with the steelmaking production process. The detection principle: The mold flux detection system developed by Wuhan CenterRise M&C Engineering CO., Ltd. uses the laser triangular sensor fixedly installed above the mold to obtain the height h1 by scanning the upper surface layer of mold flux with high-precision laser triangulation. When the laser measuring head is placed each time, the height h3 of the upper nozzle of the mold will be marked, and the system through the PLC system which is connected to the continuous casting machine through the network to introduce the height h1 of the mold liquid level. Through the calculation of three heights, we can get the thickness of mold powder H = 900-h1-(h3-h2)mm (900mm is the depth of mold). The features: The system adopts a high-precision laser triangulation distance meter, which can measure the thickness of the mold flux with high speed and high precision, and the accuracy can reach 1mm. The equipment is easy to install and use. When we are using, the laser rangefinding sensor can be placed directly above the mold without affecting production. The system can be interlocked with the automatic mold powder feeding system to automatically adjust the amount of mold powder, so as to automatically control the amount of mold powder within a reasonable range and realize intelligent automatic mold powder feeding. Non-contact measurement, the system only needs ventilation protection, simple and stable to use. The parameters: Measurement range:0-50mm Temperature measurement range: -20℃-700℃ Equipment installation distance:750mm System measurement accuracy:1mm Laser measurement accuracy: 0.1mm Frequency: 700-2000Hz Cooling method: air-cooled purging Installation method: rail sliding installation, can be slid out during maintenance Storage period: data can be stored for more than 2 years Communication method: Industrial Ethernet or Profibus-DP

Rs 200.000

See product

2 photos

Pakistan (All cities)

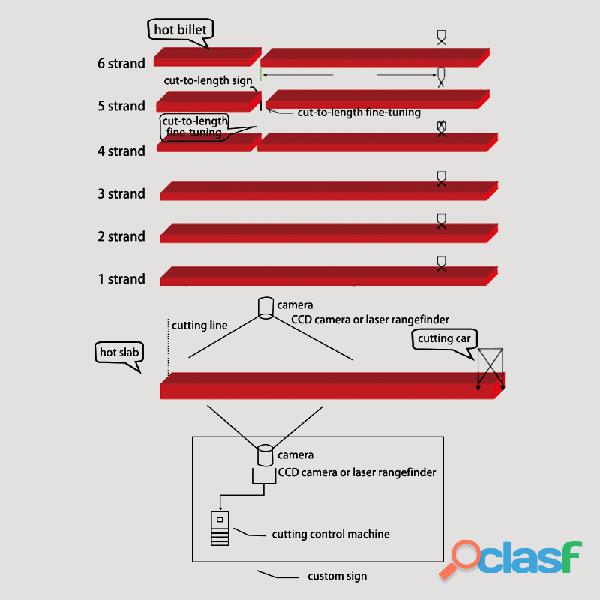

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

See product

Pakistan

Dual Display, 4-digit LCD reading Spectral Sensitivity close to CIE photopic Curve Measuring Levels Ranging 0.01 to 999900 Lux,0.001 to 92927fc, Autoranging 5 step Accurate and Instant response Integral illuminance measurement Luminous intensity measurement Data Hold function Data memory and read function Data logger function Reference value setting for relative or percentage deviation measurement Ripple measurement for STRAY + LIGHT function Time-hold function Point-average function Comparator function Auto power off function RS232 Interface CNS 5119 Class II

Rs 24.000

See product

Pakistan

cash on delievery Dual Display, 4-digit LCD reading Spectral Sensitivity close to CIE photopic Curve Measuring Levels Ranging 0.01 to 999900 Lux,0.001 to 92927fc, Autoranging 5 step Accurate and Instant response Integral illuminance measurement Luminous intensity measurement Data Hold function Data memory and read function Data logger function Reference value setting for relative or percentage deviation measurement Ripple measurement for STRAY + LIGHT function Time-hold function Point-average function Comparator function Auto power off function RS232 Interface CNS 5119 Class II

Rs 24.000

See product

Pakistan

Now available Fluke 365 AC clamp meter in pakistan which has a thin, small jaw with a flexible lead, so gaining access to wires and viewing the display is easier than ever. Features and benefits 200 A AC and DC current measurement with detachable jaw 600 VAC and DC voltage measurement Detachable jaw makes accessing wires and viewing the display easier Built in flashlight/torch allows for easy illumination and identification of wires CAT III 600 V Compact design fits in your hand and can be used while wearing protective equipment State of the art signal processing allows for use in noisy electrical environments while providing stable readings Large, easy to read, backlight display automatically sets the correct measurement range so you do not need to change switch positions while taking a measurement FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Karachi (Sindh)

Buy EDM 2347 ESCORT at lowest price in Karachi, Pakistan.No matter from which city you belong to we deliver all over the Pakistan with Reliable courier service and same day shipping with in Karachi premises. Here are the some specs of EDM 2347 Overview: 4½ Digits DMM / Analog-Bar Display Compare Function Relative Offset Function Max/Min Hold Function dB Level Indication Overload Protection Specifications: Displays 4½ Digits & Analog-Bar Displays Basic Accuracy (DC Voltage) +- 0.05% Voltage Measurement Ranges DC:200mV ~1000V (5 ranges) AC:200mV ~ 750V (5 ranges) Current Measurement Ranges DC:200uA~20A (6 ranges) AC:200uA~20A (6 ranges) Resistance Measurement Range 200Ω~20MΩ (6 ranges) Frequency Measurement Range 10Hz~1Mhz dBm Indication -60dBm~+60dBm (600Ω Ref) Other Measurements Compare, Relative, Max, -Hold,Min -Hold Operating Conditions 5~40C, 80% or Less (RH) Input Power AC 220V, 50/60Hz Dimentions 255(W)x100(H)x280(D)mm Weight 1.9 KG (Approx) We Deal In All Kinds Of Electronic Components, Test And Measuring Instruments, Variety Of Multimeters, Clamp meters, temperature guns, Toolkits, Hand Tools, Universal IC Programmers, Etc For more details contact us: Faizan Munir 03002785860 Email: info@matrixelectronic.com Visit Website: www.matrixelectronic.com Address: Matrix Electronic Shop#2, Hassan Center Near Passport Office Saddar Karachi.

See product

Bahawalnagar (Punjab)

This course will introduced the fundamentals of surveying measurements to provide a broad overview of the surveying instrumentation (Total Station, Digital Level), procedures, measurement corrections and reductions, survey datums, and computations that are required to produce a topographical map or a site plan for engineering and design projects. This course covers three main themes: 1) terrestrial-based survey measurements, 2) space-based positioning (Global Positioning System (GPS)) and surveying (Remote Sensing) techniques, and automated mapping with Geographic Information Systems (GIS) Fundamentals of terrestrial surveying measurements include leveling, distances, and angle measurements to compute Orthometric heights relative to a vertical survey datum and 2-D Cartesian coordinates in a horizontal survey datum for engineering projects.Topics photogrammetry include photography scale, and coordinate computat. This course introduces surveying, civil engineering, and environmental engineering students to basic plane surveying. It goes over fundamental surveying topics like coordinate systems, contouring, an introduction to road planning, and basic surveying equipment and how to use it. Land surveyors are in high demand across a variety of industries, including oil and gas, mining, infrastructure, construction, and civil engineering. Civil engineering is most commonly connected with land surveyor education. This course covers a long-standing need for skilled workers in this industry. Land surveyors are also in high demand in other countries. Students from our institution will receive the study materials. This course introduces students to transportation engineering systems and elementary aspects of civil engineering surveying. The course includes treatment of the following topics in transportation engineering: introduction to transportation systems, pavement design, analysis and modelling techniques for transportation systems, flow theory, scheduling, route planning, demand estimation and economics. Surveying topics include: linear measurement, levelling, theodolite and horizontal and vertical curves. This course requires field training to complete. The institute has all of the required equipment and facilities to provide field training in the surveying sector. Foreign students might also choose to complete this training in their home country. This course program includes extensive field practice in the use of electronic and optical instruments used to measure distances, elevations, and angles from one point to another. electronic laser and DTSA light. Our industry experts, as part of our curriculum committee, review the course outline from time to time and update it based on the latest industry requirements and trends around the world. The main surveying instruments in use around the world are the theodolite, measuring tape, total station, 3D scanners, GPS/GNSS, level and rod. Most instruments screw onto a tripod when in use. Tape measures are often used for measurement of smaller distances. 3D scanners and various forms of aerial imagery are also used.The theodolite is an instrument for the measurement of angles. It uses two separate circles, protractors or alidades to measure angles in the horizontal and the vertical plane. A telescope mounted on trunnions is aligned vertically with the target object. The whole upper section rotates for horizontal alignment. The vertical circle measures the angle that the telescope makes against the vertical, known as the zenith angle. The horizontal circle uses an upper and lower plate. When beginning the survey, the surveyor points the instrument in a known direction (bearing), and clamps the lower plate in place. Civil Surveyor Course Content Introduction Civil Surveyor Classification of survey Principles of survey Chain survey Plotting of chain survey Compass survey Bearing system Drawing Scales Types of scales Leveling Technical terms Purpose of Leveling Plain table survey Methods of plane table survey Adjustment of Levels http://www.icollegete.com/ International College of Technical Education. Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-6122937, 0311-5193625, 0092-335-4176949 http://www.icollegete.com/course/civil-surveyor-practical-training-course-in-rawalpindi-pakistan/

Rs 123

See product

Sialkot (Punjab)

Feature: Easy to clean with slick design To adopt flat switch and without scraggly surface, more easier to clean Credible design, shows battery power Batter power shows through club-shaped chart, which indicated on the LCD screen. Without any operation for 5 minute, it will be turned off automatically. In addition, new Alkali dry cells can be worked for 100hrs continuously. Soft alarm sound can be chosen 3 kinds of tamber, adjustment of volume or without voice. Patients only undertake little test electric current Only go through little current, patients will not feel any ache in a very comfortable treatment. Precise measurement results, irrespective of dry or wet in the root canal Character: Need not to make adjustment automatically, high precise Be use of high integration agglomerate, function all in single integration agglomerate, to realize computerized. It is not necessary to make any adjustment according to different patients. Automatic calibration ensures accuracy and eliminates the effect of changes in temperature, moisture, etc. inside the canal, even during the treatment. With two kinds of different frequency signal, precise measurement results, irrespective of dry or bleeding purulence in the root canal. Precise measurement results, although it's filled with NaCLO2, Physiological Saline, H2O2, Water, etc. Irrespective of kinds of teeth, size of root tip, thickness of root canal file. Exact visualization of the file tip position on Large color display High precise, high contrast Large color display To make position of root canal file the same as indicator bar, adopts large LCD display with exact visualization. Set Shining position of root tip arbitrarily, to as length sign during operation. Can be sterilized by autoclave Dapper root file holder Root canal holder, contrary electrode can be sterilized by autoclave. With dapper holder, it's convenience for dentist during operation. Normally click collect on root canal file to measure, or if root canal file get to the side of holder front Contact point of root canal file is made by high quality metal Specification: Power voltage:DC7.5V(5*DC 1.5V AA Alkali dry cells) Power consumption: below 0.135VA Test Voltage:below AC80mV Test electric current: below 10uA Display: reflex colored LCD display, buzzer Dimensions: W105*D105*H115mm Weigh: about 370g

Free

See product

Pakistan

DHT22 AM2302 Specification: - Brand new and high quality. - Type:AM2302. - Accuracy resolution:0.1. - Humidity range:0-100%RH. - Temperature range:-40~80°C. - Humidity measurement precision:±2%RH. - Temperature measurement precision:±0.5°C. - 4-pin package. - Ultra-low power. - No additional components. - Excellent long-term stability. - All calibration, digital output. - Completely interchangeable. - Long distance signal transmission. - Relative humidity and temperature measurement. Shipping All Across Pakistan COMPANY: MATRIX ELECTRONICS CONTACT PERSON: FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan

CP-100 laser rangefinder is designed for convenient and accurate measurement of distance, area and volume; Measurement range of 0.05~100m, the measurement accuracy up to +/-1.5mm; CP-100 laser rangefinder appearance of small, non-slip soft double injection allows users to have a comfortable sense of holding hands; For Price Contact Us FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan (All cities)

Certeza BM 407 Digital Blood Pressure Monitor Digital BP Apparatus BP Machine Blood Pressure Machine. Digital blood pressure and pulse measurement on arm. For arm circumference of 22-36 cm. Large LCD display. Features • Digital blood pressure and pulse measurement on arm • For arm circumference of 22-36 cm • Large LCD display • WHO classification of hypertension indicator • 120 memory recall function • Irregular Heartbeat Indicator • Average of last 3 readings • One touch automatic operation • 2×60 memory spaces • Medical product • Date and Time Function • Automatic switch off • Signal in case of application error • Low battery indicator • Storage case Specifications • Certeza • Pack Type Single Item • Warranty Yes • Certifications CE. FDA. ISO • Care Label • Health Features Blood pressure and pulse measurement. • Model BM 407 • Warranty Policy EN Cuff is not covered in warranty. Physical damage to machine is not covered in warranty. Do not use sub standard batteries, leakage can damage board which voids warranty. BrightWay Technologies Pvt Ltd. Medical equipment's, Instruments, and Material Providers Company In Pakistan. BRIGHT WAY TECHNOLOGIES (PVT) LTD - Deals In The Sector Of Medical & Dental, I.T Solution & Services, Communication Technologies, Digital Marketing & News.BrightWay Technologies Pvt Ltd Provides All The Solution & Services With Quality Of Work With In Minimum Time & Budget. UAN : +923-111-999-015

Rs 3.150

See product

4 photos

Lahore (Punjab)

Digital Blood Pressure Monitor - Certeza BM 405 - BP Apparatus - BP Machine - Blood Pressure Machine (White & Grey) Digital blood pressure and pulse measurement on arm Universal cuff of 22 – 42 cm Soft cuff material 3rd generation inflation type Features: Digital blood pressure and pulse measurement on arm Universal cuff of 22 – 42 cm Soft cuff material 3rd generation inflation type Large LCD display Irregular heartbeat indicator One-button automatic operation Long-life alkaline batteries Medical product Automatic switch off Signal in case of application error Low battery indicator Optional Adapter Pack Type Single Item Warranty Yes Health Features Blood pressure and pulse measurement. Model BM 405 What’s in the box. 1 x BM 405 - Digital Blood Pressure Monitor - White 4 x AAA batteries 1 x User manual 1 x bag

Rs 2.900

See product

3 photos

Charsadda (Khyber Pakhtunkhwa)

Introduction to civil engineering materials laboratory and design of experiments, with focus on mechanical and physical properties of construction materials; including measurement of strains using mechanical gauges and electrical resistance strain gauges; experiments on metals, aggregates, Portland cement, concrete, asphalt and asphalt mixtures, and wood. A Civil Engineering Laboratory Technician carries out a wide range of sampling and testing of civil construction materials, both in the laboratory and in the field.Civil technology is the field of drafting, cartography, traffic technology and the analysis of construction materials to support construction, engineering, and architecture for roads, bridges and other public structures.Materials testing, measurement of the characteristics and behaviour of such substances as metals, ceramics, or plastics under various conditions. The data thus obtained can be used in specifying the suitability of materials for various applications e.g., building or aircraft construction, machinery, or packaging. A full- or small-scale model of a proposed machine or structure may be tested. Alternatively, investigators may construct mathematical models that utilize knownmaterial characteristics and behaviour to predict capabilities of the structure.Materials like concrete, asphalt and bitumen are used for civil engineeering applications all over the world. Course Outline of Civil Lab Technician Course: 1.Soil Section Testing 2.Concrete Section Objectives Make measurements of behavior of various materials used in Civil Engineering. Provide physical observations to complement concepts learned in 1.030. Introduce experimental procedures and common measurement equipment. Exposure to a variety of established material testing techniques.Analytical engineers may supervise production in factories and elsewhere, determine the causes of a process failure, and test output to maintain quality. They also estimate the time and cost required to complete projects. Supervisory engineers are responsible for major components or entire projects. Engineering analysis involves the application of scientific analytic principles and processes to reveal the properties and state of the system, device or mechanism under study. Engineering analysis proceeds by separating the engineering design into the mechanisms of operation or failure, analyzing or estimating each component of the operation or failure mechanism in isolation, and recombining the components. An engineering technologist is a specialist dedicated to the development, design, and implementation of engineering and technology. Engineering technology education is more of a broad specialized and applied engineering education. Engineering Technologists often work under traditional engineers. However the Engineering Technologist Mobility Forum indicates that an engineering technologist's work should have required the exercise of independent engineering judgment for manufacturing firms, product improvement, design and construction, and government agencies applying engineering principles and technical skills. Engineering technologists also may assume senior management positions in industry or become entrepreneurs. civil lab technician is a professional engineering discipline that deals with the design, construction, and maintenance of the physical and naturally built environment, including works like roads, bridges, canals, dams, and buildings. civil lab technician is traditionally broken into a number of sub-disciplines. It is the second-oldest engineering discipline after military engineering, and it is defined to distinguish non-military engineering from military engineering. civil lab technician takes place in the public sector from municipal through to national governments, and in the private sector from individual homeowners through to international companies. http://www.icollegete.com/ International College of Technical Education. Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-6122937, 0311-5193625, 0092-335-4176949 http://www.icollegete.com/course/civil-lab-technician-course-in-rawalpindi-islamabad-pakistan/

Rs 123

See product

Bahawalpur (Punjab)

A Civil Engineering Laboratory Technician performs a variety of civil construction material sample and testing tasks, both in the lab and out in the field. To assist in the building, engineering, and design of roads, bridges, and other public infrastructure, the discipline of civil technology includes drawing, mapping, traffic technology, and the study of construction materials. Testing of materials is the measuring of the properties and behavior of things like metals, ceramics, or polymers under different circumstances. The information so gathered can be used to indicate whether a material is suitable for use in a variety of applications, such as the construction of buildings or airplanes, machinery, or packaging. It is possible to test a full- or scaled-down model of a proposed machine or building. As an alternative, researchers can use mathematical models that make use of well-known material properties and behavior to forecast the structure’s possibilities. All across the world, applications of civil engineering employ materials like bitumen, asphalt, and concrete. Civil Lab Technician Course Outline Testing the soil section Cement Section Collective Section Roadway Section Asphalt Section Concrete Section Iron Section Construction Laboratory Technicians are responsible for sample collection and test specimen preparation in order to perform various tests of construction materials including sand, cement, bitumen, aggregate, soil, brick, asphalt and concrete blocks. They generally work under strict supervision of senior technicians, civil engineers or project managers in laboratories (laboratory technician) or at construction sites (field technician). Civil Lab Technician Course Content: Soil Section Testing Concrete Section Civil Serveyor Aggregate Section Asphalt Section Bitumen Section Cement Section Steel Section In this lab students become familiar with the field procedures of surveying. This lab course provides students with in-depth knowledge in horizontal measurement, vertical measurement, surveying instrumentation, differential leveling, directional measurement, horizontal control survey, mapping, and geographic information system. http://www.icollegete.com/ International College of Technical Education. Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-6122937, 0311-5193625, 0092-335-4176949 http://www.icollegete.com/course/civil-lab-technician-course-in-rawalpindi-islamabad-pakistan/

Rs 123

See product

Ahmadpur East (Punjab)

ICTE International College of Technical Education Pvt. Ltd Head Office : Office # 27, Second Floor, Maryam Shadi Hall Plaza (Airies Plaza), Shamsabad, Murree Road, Rawalpindi, Pakistan 46000. Email : info@icollegete.com Contact : 051-6122937, 0311-5193625, 0092-335-4176949 A Civil Engineering Laboratory Technician carries out a wide range of sampling and testing of civil construction materials, both in the laboratory and in the field. ... Materials testing, measurement of the characteristics and behaviour of such substances as metals, ceramics, or plastics under various conditions.A Civil Engineering Laboratory Technician carries out a wide range of sampling and testing of civil construction materials, both in the laboratory and in the technology is the field of drafting, cartography, traffic technology and the analysis of construction materials to support construction, engineering, and architecture for roads, bridges and other public testing, measurement of the characteristics and behavior of such substances as metals, ceramics, or plastics under various conditions.Conducts tests of construction materials, prepares sketches and tabulations, and assists in estimating costs in support of civil engineering professionals and engineering technologists. Performing or assisting with field and laboratory tests of soils and construction materials. Providing technical assistance connected with the construction of buildings and other structures, and with surveys or the preparation of survey reports. Ensuring compliance with design specifications, relevant legislation and regulations, and maintenance of desired standards of materials and work. Applying technical knowledge of building and civil engineering principles and practices in order to identify and solve problems arising. Assisting with the preparation of detailed estimates of quantities and costs of materials and labour required for projects, according to the specifications given. Inspecting buildings and structures during and after construction to ensure that they comply with building, grading, zoning and safety laws and approved plans, specifications and standards, as well as with other rules concerning quality and safety. Advising on the installation of fire detectors and sprinkler systems and the use of materials in the construction of buildings and means of transportation to reduce risk of fire and extent of damage and danger if fire occurs. Inspire Institute of Technologies Pakistan (Pvt-Ltd) registered with National Training Bureau and various other prominent technical boards is a common route into this career.Civil Lab Technician Course in Rawalpindi, Civil Lab Technician Practical Training in Rawalpindi, Material Testing Course in Rawalpindi, Civil engineering is one of the oldest engineering disciplines because it deals with constructed environment including planning, designing, and overseeing construction and maintenance of building structures, and facilities, such as roads, railroads, airports, bridges, harbors, channels, dams, irrigation projects. A Civil Engineering Laboratory Technician carries out a wide range of sampling and testing of civil construction materials, both in the laboratory and in the field.Civil technology is the field of drafting, cartography, traffic technology and the analysis of construction materials to support construction, engineering, and architecture for roads, bridges and other public structures.Materials testing, measurement of the characteristics and behaviour of such substances as metals, ceramics, or plastics under various conditions. The data thus obtained can be used in specifying the suitability of materials for various applications e.g., building or aircraft construction, machinery, or packaging. A full- or small-scale model of a proposed machine or structure may be tested. Alternatively, investigators may construct mathematical models that utilize knownmaterial characteristics and behaviour to predict capabilities of the structure.Materials like concrete, asphalt and bitumen are used for civil engineeering applications all over the world. Course Outline of Civil Lab Technician Course: 1. Soil Section Testing 2. Concrete Section 3. Aggregate Section 4. Asphalt Section 5. Bitumen Section 6. Cement Section 7. Steel Section

Rs 123

See product

-

Next →