Maple wood baseball bat

Top sales list maple wood baseball bat

Latest Offers

Pakistan

One is 7 months old (not sexed); freely flying, like to be out of cage all day, freely flying around. Other one is 5 months old (breeder told male, but not sexed) has already started training; steps on a perch now on demand, wing feathers growing back, likes to be outside cage on his stand.

Rs 4.000,0

See product

Pakistan

Beautiful lemon and white female beagle pup for sale, 5 months old, fully vaccinated, microchipped, flee'd and wormed. Not kc registered and as she's our pet, mother or father can't be seen. Very playful, energetic and needs a caring family ....

Rs 200,0

See product

Pakistan (All cities)

Wedding Cards Manufacturing in Pakistan, Pakistani Wedding Cards, Wedding Cards from Pakistan, Favour Boxes Pakistan, Nikkah Boxes Pakistan, Bid Box Pakistan, Bidh Box Pakistan, Customized Wddding Cards Pakistan, Wedding Cards Lahore, Wedding Cards Pakistan, Acrylic Wedding Cards, Wax Stamp Wedding Cards, Bes Cards https://cardnboxes.com/

Rs 100,0

See product

Lahore (Punjab)

Drive your dreams, rent with ease! With easy online booking and flexible rental options, you can confidently hit the road. https://www.rafaycars.com/

Rs 1.200,0

See product

3 photos

Pakistan

imported Friesian 4 yr old mare for sale. This filly has been backed a few months ago in Holland just for 2 weeks and then came to the uk. advertised due to her needing more one to one. the most amazing mover and really one to be graded and could do well. sad sale as just overstocked. no bargain hunters need to inquire pls as I won't accept offers price is firm. No novices pls. this mare is not for the pussy due to being a little worried with mounting but will settle quick. extremely low inbreeding only 0.39% her sire is the top stallion Sjouke 453 dam is Katrina who is out of Sierk 326

Rs 50.000,0

See product

Pakistan

Kennel Club Assured Breeder. Jimjen George Gently is a proven sire, (daughter & son Crufts qualified), and health tested, for MLS, NCCD, FVll, & IGS, and available at stud, to approved bitches,at small show kennel in Suffolk. 'Reach....Bonnie is a friendly and loving dog who loves attention and is very outgoing. He has been with us since he was 8 months old, but unfortunately he has been fighting with my male cat which causes him stress and anxiety being around the house.....Our amazing litter was born on 18th of December mum is stunning tri colour and dad is a lemon and white tri both pedigrees dad has five generations blood line with his papers to prove. We have a litter of 9 chunky playful pups all wormed and....

Rs 200,0

See product

Pakistan

Ready for their new home now pure breed beagles puppies. Both male and females available. They are all tri colour and are use to children. Mum is here to be seen with the puppies. For any further info please feel free to contact me. [Bizarte Beagles] Tri-colour Beagle Puppies male and female available.All Registered,pedigree and come with dew claws removed,free for MLS,NCCD by parentage,fully wormed,fully vaccinated with Contra.... ....

Rs 200,0

See product

Pakistan (All cities)

Topper Smart Bidet Tiolet Seat Co., Ltd. (https://www.mfrsbidet.com/) is a professional and experienced smart toilet & bidet manufacturer and supplier, specializing in diversifying our bidet products to suit a range of different needs. We are capable of providing toilet bidets, bidet attachments, bidet seats, toilet seat covers, bidet sprayers, portable bidets and other bidet fittings, and offering practical and personalized sanitary solutions for our customers. Over the years, we have been consistent in supplying high-quality products and thoughtful services. Every stage in the production is guided and supervised by skilled professionals and our quality control systems. Our bidet products all meet tangible and intangible requirements in terms of quality and safety. From the design and development of products to the user experience, we are never slackening our effort, and still trying our best to improve your life quality. Convenience, comfort and superior quality are the ideas we want to convey through our bidets and services. In the future, we will continue to strengthen our capability of design and innovation to better satisfy the demands of the market and create the best home life experience for customers. If you're interested in our bidets, please visit https://www.mfrsbidet.com/.

Rs 200,0

See product

6 photos

Rawalpindi (Punjab)

Discover a curated selection of stylish, handcrafted handbags and clutches at Baglore.com. Each piece is meticulously designed to blend traditional artistry with contemporary flair, offering timeless elegance for every occasion. Whether you need a chic clutch for a special event or a practical yet stylish handbag for everyday use, our collection provides the perfect accessory. Explore Baglore.com now and elevate your fashion statement with unique, high-quality handcrafted bags.

Rs 3.800,0

See product

16 photos

Gujrat (Punjab)

With discreet and reliable surveillance, IonDetective will find out what you want to know. We are professional detectives specializing in obtaining evidence through close observation and time-tested procedures. From cheating spouses to any question or concern that can benefit from being clarified, our company can help bring clear-cut results with total discretion. Our business values honesty, respect, and professionalism; this is exactly why we deserve the truth that you're looking for. Trust us to handle your case with care and precision while keeping the process simple and stress-free. When the truth matters, IonDetective is here to help.

Free

See product

Pakistan (All cities)

GoLogica offers complete online training in data modeling that gives professionals the understanding and skills they need to understand data modeling methods. IT specialists, database developers, business analysts, and data analysts who want to become better in creating and managing data structures may benefit from this course. Basic topics covered in the course include entity-relational diagrams (ERDs), data mapping, normalization strategies, and abstract, logical, and physical data modeling. It also covers database design concepts, demonstrating how to build durable, scalable, and effective data models that correspond with business goals. This course, led by industry experts, gives participants practical knowledge through practical assignments, allowing them to apply what they've learned in actual situations. Whether you're new to data modeling or want to improve your existing skills, GoLogica Data Modeling Online Training provides a solid basis for creating and managing successful data models. Enroll in GoLogica Data Modeling Online Training today to obtain the knowledge you need to boost your career in data management and become a certified Data Modeling expert!

Rs 0,0

See product

Pakistan (All cities)

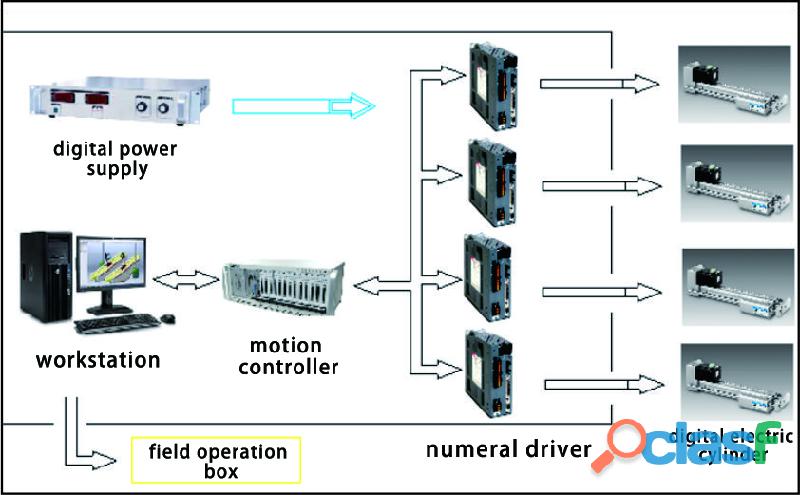

Overview In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting. The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached. During the production process, the adjustment of the mold’s width can be completed without stopping the machine. Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold. Only with adjustment and detection can the online adjustment range of the mold be accurately controlled. Fig 1 Mold online width adjustment system The components of the system Workstation: host system, system width adjustment control, taper detection. On-site operation box: real-time display of the current control status, manual operation to adjust parameters. Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control. On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time. Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment. FIG 2 System block diagram The technical parameters Adjustable range: 0-1250mm (unilateral) Control accuracy: 0.02mm/0.05mm/0.1mm Step resolution: 0.01mm/0.02mm Running speed: 0-10mm/s Power: 3.5KWl 16-bit encoder: 65536 pulses Weight: 25Kg Shell: high-strength aluminum alloy FIG 3 Syetem software interface The functions of the system Realize online width adjustment function Realize the online real-time monitoring function of mold taper Continuous casting production adjustment and non-stop production One-key operation in the main control room, automatic completion High adjustment accuracy and fast speed The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

Rs 0,0

See product

3 photos

Kandhura (Federally Administered Tribal Areas)

Eagle Racking India is a leading provider of high-quality mezzanine floor in Lucknow, offering cost-effective and space-efficient solutions for warehouses, factories, and commercial establishments. Our mezzanine floors are designed to maximize vertical space utilization, providing an additional floor without the need for expensive building expansions. Constructed with heavy-duty steel and premium-quality materials, our mezzanine floors ensure durability, strength, and safety. They can be customized to meet specific load-bearing capacities and operational requirements, making them ideal for storage, office setups, and retail spaces. Read more: https://eagleracking.com/lucknow/mezzanine-floor

Rs 0,0

See product

Pakistan (All cities)

Buy Verified Cash App Accounts As it acquires clients, checked accounts become fundamental for organizations and people to completely get to its highlights. A checked money application account permits you to send, get, and pull out a lot of cash, making it ideal for business people, consultants, and financial backers. Purchasing a confirmed money application account has turned into a pattern now, with numerous suppliers offering this help at a sensible cost. In any case, it means quite a bit to purchase from a confided in source to stay away from tricks or fake records. You will learn the fundamentals of purchasing verified cash app accounts and everything else you need to know before making a purchase in this article.

Free

See product

Pakistan (All cities)

Overview The mold is a device that shapes the cast product in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of the mould oscillation deflection detection instrument is to detect the the mould oscillation table’s oscillation frequency, amplitude, deflection rate, phase, oscillation trajectory curve, etc. Through the detection and adjustment of the detection instrument, the mold moves along the outer arc of the continuous casting machine according to the set amplitude, frequency and waveform deflection characteristics. The actual oscillation parameters of the mold oscillation table during the production process and the process parameters of the cast products cannot be effectively known without the data detection of the mold deflection detection instrument, so that the operator cannot adjust the mould’s production process parameters in real time according to the real-time situation of the on-site production. The continuous casting mold deflection detection instrument independently developed by our company is suitable for various molds such as slab, square billet, round billet and shaped billet. The system obtains the process parameters such as actual oscillation holographic parameters and negative slip amount of the oscillation table by effectively detecting the movement of the mold. The technicians can formulate the control strategy of the mould according to these actual parameters, and improve the output and quality of the product within a safe and reliable range. The structure of the instrument Continuous casting mold oscillation and deflection detection instrument is mainly composed of sensor system, sensor signal conditioning circuit, power supply circuit, synchronous data acquisition module, communication cable, and software data analysis system. There are three axial acceleration sensors installed in the mold oscillation and deflection detection instrument, one of which is to detect the vertical oscillation signal (Y axis), and the other two are to detect the horizontal oscillation signal (X and Z axis). The signal obtained by the sensor is processed by the preprocessor and the preprocessing module. The oscillation signal and sensor status signal will be filtered and normalized, sent to the synchronous data collector for digitization and feature extraction, and the data is analyzed and processed by the master computer software to obtain various oscillation parameters and process parameters required by users. The functions of the system 1. Adopting mould oscillation X/Y/Z three-dimensional data acquisition, using high-precision sensor system and high-sensitivity axial accelerometer, comprehensive detection of equipment oscillation state, including: 1) Detect the oscillation frequency of the mold oscillation table 2) Detect the amplitude of the mold oscillation table 3) Detect the deflection rate of oscillation 4) Detect the lateral deflection, longitudinal deflection, phase, and phase difference of the mold oscillation table 5) Three-dimensional display of the oscillation trajectory, and the oscillation table trajectory can be viewed from 6 sides of the oscillation table (X-Y, X-Z, Z-Y) 2. The software system adopts the design of man-machine interactive graphic interface, which can display the mold oscillation state in real time. The software functions include: 1) Real-time data curve display: oscillation waveform, oscillation frequency, signal superposition analysis 2) Single-axis curve display, multi-axis curve display, amplitude, acceleration, three-dimensional graph 3) View historical curve 4) Generate test report 5) Give a warning prompt 6) Spectrum analysis function 7) Long-term storage of data 3. Portable measurement method, which can provide handheld detection equipment with wireless remote transmission, and the operation is simple. 4. Provide an overview of inspection parameters under the full screen, displaying all data including oscillation parameters and process parameters. At the same time, the calculation and display of the oscillation spectrum is completed in real time, which is used to evaluate the frame loss of the waveform , and to determine whether there is a problem with the installation of the oscillation device. 5. Alarm management. Record each alarm data under real-time alarm conditions to analyze the cause of the alarm and evaluate the impact of the alarm on production. 6. Parameter setting. Users can set the ideal oscillation value and normal working range of various steels online. We also can set the alarm limit, and the storage time of the database etc. 7. After charging the device once, it can work continuously for more than four hours. 8. Integrate embedded processing equipment to realize data collection, display, analysis, reporting and other functions. 9. According to the mold characteristics and user requirements, it can be flexibly configured, wich is suitable for all types of molds such as square billets, slabs, round billets and other mold oscillation tables. 10. Support wired and wireless data transmission functions, easy to use. 11. Use the laptop to receive the collected data, can be used for the operation test on site, and can analyze and process the data conveniently. The features of the system 1. The actual oscillation state replaces the ideal oscillation state. The actual oscillation state of the table is used to formulate a control strategy, so that the oscillation table can be used to produce products with more accurate oscillation. 2. Convenient detection method. The equipment can be used for on-site inspection at any time, and the production site can grasp the operating status of the on-site equipment in time, so that we can make production adjustments to the equipment at any time. 3. Efficient working methods and processing platforms. The high-integration equipment developed by embedded technology can work in high temperature and harsh environment. This system can comprehensively detect XYZ three-axis data, and realize real-time data analysis and processing with high-speed data operation and processing platform. 4. Powerful database function. The database adopts the mode of computer automatic management and operator's manual assistance management, and there are tables for recording historical data and alarm data and working parameter setting table of monitoring system inside the database. By adjusting the output range, the best output effect can be obtained.

Rs 0,0

See product