M co engineering

Top sales list m co engineering

Pakistan

if u want construct your Bunglow Home flat farm House or Factory u can contect with us for Best Quality construction work On normal Rates with or without matirial Also Repair mantinance & All kind of paint work of old & new Buildings & Tilles marble fixing & polish for new & old Also furniture polish & Door windows polish contect with us. 03453555390 03142460030 03443100200 03142460040

Free

See product

Faisalabad (Punjab)

Dastgir Engineering offers a full selection of new commercial kitchen equipment from nationally known foodservice manufacturers at best prices. Dastgir Engineering can provide the commercial kitchen equipment you need, at prices you can afford. Find everything to outfit a commercial kitchen, including: Restaurant ranges, convection ovens, Flat grills & broilers Bakery & dough equipment Cookware & kitchen tools Commercial sinks & dishwashers Food processors & dough mixers Wire shelving units Food storage containers Cold Storage Machinery Hotel Equipment & Supplies HVACR Engineers & Contractors Kitchen Equipment & Supplies Commercial Bakery Equipments. Super Market Equipment. Meat Shops For details contact: Kainat Nabi Assistant Marketing Manager Mobile Number: - Dastgir Engineering Co. Lahore.

See product

Pakistan

Dastgir Engineering offers a full selection of new commercial kitchen equipment from nationally known foodservice manufacturers at best prices. Dastgir Engineering can provide the commercial kitchen equipment you need, at prices you can afford. Find everything to outfit a commercial kitchen, including: • Restaurant ranges, convection ovens, • Flat grills & broilers • Bakery & dough equipment • Cookware & kitchen tools • Commercial sinks & dishwashers • Food processors & dough mixers • Wire shelving units • Food storage containers • Cold Storage Machinery • Hotel Equipment & Supplies • HVACR Engineers & Contractors • Kitchen Equipment & Supplies • Commercial Bakery Equipments. • Super Market Equipment. • Meat Shops Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt.

See product

Karachi (Sindh)

Dastgir Engineering offers a full selection of new commercial kitchen equipment from nationally known foodservice manufacturers at best prices. Dastgir Engineering can provide the commercial kitchen equipment you need, at prices you can afford. Find everything to outfit a commercial kitchen, including: • Restaurant ranges, convection ovens, • Flat grills & broilers • Bakery & dough equipment • Cookware & kitchen tools • Commercial sinks & dishwashers • Food processors & dough mixers • Wire shelving units • Food storage containers • Cold Storage Machinery • Hotel Equipment & Supplies • HVACR Engineers & Contractors • Kitchen Equipment & Supplies • Commercial Bakery Equipments. • Super Market Equipment. • Meat Shops Uzma Khan Assistant Marketing Manager Mobile Number: 0322-8628179 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt. www.dastgirengineeering.com

See product

Pakistan

Dastgir Engineering provides best quality equipments for your Restaurant, Café/Bar, Bakeries etc. We deal in the following field: 1) Commercial Kitchen Equipment. 2) Commercial Refrigerator. 3) Commercial Bakery Equipments. 4) Super Market Equipment. 5) Commercial Washing Equipment. 6) Meat Shops. For query you can contact us: Uzma Khan Assistant Marketing Manager Mobile Number: 042-36665202 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt.

Free

See product

Peshawar (Khyber Pakhtunkhwa)

An Individual with three years of Teaching Experience in a Public Sector University; Holding B.E and M.S in Engineering. Offering expertise in the dimension of Engineering Subject, Graduate Record Examination Preparation (Quantitative Only), GRE Local Preparation (Quantitative and Analytical) and Inter Level Mathematics Preparation.

See product

Quetta (Balochistan)

--COOL & COOL--COMPANY-- split ac firdge deep freezer window ac water dispenser all air condition machine automatic washing machine specialized workers etc. Home services or ab bhot si bari companyan B counteract de sakti hain *chiller peelant companies centar dawlance toshiba dealer of Godre kenwood supra york lg samsung hitachi gree haier auto daikin carrier mitsubishi electric mr.slim acson fujitsu actronair anverter V singer and othere company ling and all kind of Home applaience complit Repairing services instalation 24Hr. all karachi Home Service Availebil or ab Karachi k bad A/C Repairing and services Split AC Repairing Engineering Services Office gahr. ya koi B area PURA PAKISTAN Cool & Cool only. 0345-2680093 Electronic and Refrigeration Repaing Service home services 24 hr. Special Offers for New & Old Customers :-) Summer Offers:- Visiting Charges Rs: General A/C Services only Rs: Master A/C Services only Rs: Split A/C Installation only Rs: A/C Gas Charging only Rs: Refrigators Gas charging Rs: Notes: we are using orgiancal Gas U.S.A not in Chain . Contact:-03452680093 Name: hany or ab bhot si COMPANYAN B contract de sakti hain all over karachi

Rs 600

See product

Pakistan (All cities)

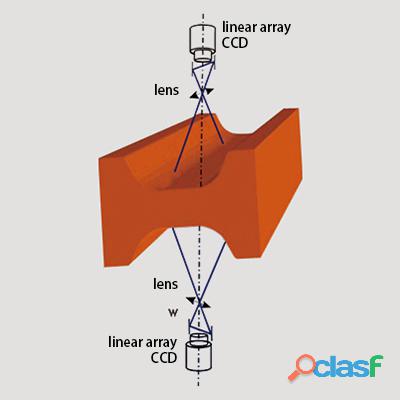

Overview The surface quality inspection of high temperature cast product is of great significance to the repair of cast product’s defects and the hot delivery of hot cast product. The ZSQ-T series of online surface quality inspection equipment for casting billets developed by Wuhan CenterRise M&C Engineering Co., Ltd can detect the defects such as scratches, cracks, holes, pits, edge cracks, edge defects on the surface of the cast products, and meet the customer's requirements for the quality inspection of the surface of the cast product. The principle of the system The ZSQ-T200 online surface quality inspection system for continuously cast products adopts the principle of optical imaging and uses a CCD image sensor to input the surface image of the cast products to be detected into the computer, and then the obtained image is processed by special image processing software to find out whether there is any defect in the image. After the defects in the image are obtained, the obtained defects are classified through a special self-learning system, and finally the requirements of the computer to automatically identify the surface defects of the cast products are achieved. The composition of the system 1. Optical part: The optical part is composed of multiple fixed-focus lenses and linear CCD, which mainly realizes scanning and imaging of the surface of the cast products. 2. Lighting part: The lighting part is composed of a high-brightness LED array and a cylindrical lens, which realizes high-brightness and high-uniformity lighting on the surface of the cast products. 3. Mechanical structure part: The mechanical structure part mainly realizes the adjustment, installation and fixing of the optical part and the lighting part, and consists of the imaging head (optical part), light box (lighting part), bracket and control cabinet. The structure is required to be stable and reliable. 4. Real-time processing: The real-time processing part is completed by the multi-CCD data real-time sampling processing unit (high-speed DSP) independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. 5. Hardware part: The hardware part consists of high-speed storage controller and storage hard disk array, Gigabit InternetMAC controller, Gigabit Ethernet PHY. Rj45, and multiple high-speed workstations. 6. Detection software: The detection software mainly realizes the functions of collection, storage, transmission, processing of CCD scanning images, extraction of defects, analysis of defect characteristics, calculation of defect size and position, storage of defect images, generation of cast product’s surface quality analysis reports. etc.

See product

Pakistan (All cities)

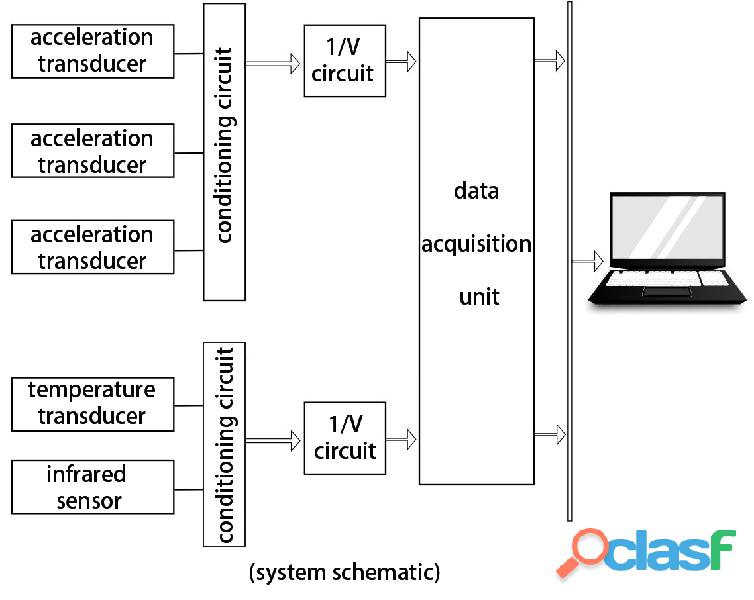

Overview The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection. The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system. The meaning of the system 1. Reduce the amount of tundish slag 2. Improve the purity of molten steel 3. Improve the life of the tundish 4. Reduce sliding nozzle erosion 5. Reduce nozzle blockage 6. Increase continuous pouring heats 7. Reduce the amount of residual steel in the ladle when high-quality steel is casting 8. Improve the yield of molten steel 9. Improve the quality of continuous casting billets In order to improve the purity of the molten steel in the tundish, and improve the quality of the casting billet, especially to improve the quality of the billet in the transition section, and reduce the amount of residual steel in the high-quality ladle, and prolong the life of the tundish lining, and increase the continuous casting heats, it’s necessary to detect and control the slag in the later stage of continuous casting ladle casting. The working principle The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm. The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close the ladle nozzle. The features of the system (1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise. (2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The threshold of slag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such as the sensor service life and sensor usage times. (3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life. (4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm. (5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction. (6) The equipment adopts a modular design. The failure of each module will not affect other parts, which ensure more reliable operation of the system and easy maintenance. (7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag carryover strats, we can choose automatic mode or manual mode. In both modes, the system will give audible and visual alarm signals to remind on-site operators. (8) The system has a powerful database function. Including the comparison function for last two ladles of casting time record, the system automatically stores the running data, and generates a record file every day. (9) The system has the function of automatically controlling the ladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with the ladle slag detection system to automatically control the opening of the ladle nozzle and realize the whole-process control of the liquid level of the molten steel in the tundish. The composition of the system The LAG-S200 slag detection system consists of: vibration detection sensor, pre-signal amplifier, slag detection operation unit, tundish liquid level control unit, on-site operation indication box, and process control cabinet. 1. Vibration detection sensor: It is installed on the robotic arm of the stopper to detect the vibration signal of the whole casting process of the ladle. 2. Pre-signal amplifier: Amplify, convert and transmit the weak vibration signal detected by the vibration detection sensor. 3. Slag detection operation unit: Analyze, judge and discriminate the vibration signal to realize the discrimination of all steel, mixed slag and full slag , and output the slag alarm signal. 4. Tundish liquid level control unit: Accept the control signal of the tundish nozzle and the ladle nozzle, and realize automatic or manual control to the ladle slag according to the requirements. 5. On-site operation instruction box: Provides man-machine exchange for slag alarm indication, fault indication, system activation mode selection, and control mode selection. 6. Process control cabinet, providing power management, displaying man-machine interface and setting management. The parameters of the system 1. The system controls the slag inclusion in molten steel with high precision and closes the nozzle in real time. 2. Improve the quality of steel, reduce defective products, and improve the yield. 3. The yield of molten steel is increased by 0.3%-0.5%. The nozzle can be automatically closed, so that the disadvantage of untimely manual response is overcome and less molten steel remains in the ladle. The threshold value of molten steel (slag threshold) is set by the user within a wide range. 4. No artificial factors are involved, high reliability, good repeatability or consistency. 5. The steelmaking slag does not pass through or rarely flows into the tundish, which increases the service life of the refractory material and the sliding nozzle. 6. Reduce the blockage of the tundish nozzle and increase the number of continuous pouring heats of the tundish.

Rs 200.000

See product

3 photos

Pakistan (All cities)

Overview: Mold powder is mainly used in the continuous casting and steelmaking process, evenly sprinkled on the molten steel surface in the mold to lubricate, keep warm, prevent oxidation and absorb non-metallic inclusions. Mold powder is an indispensable auxiliary production material in the production process. In the process of evenly distributing the mold powder to the molten steel surface of the mold, the amount of mold powder should be controlled, and the thickness of the mold powder should be within a certain range. If the coverage thickness of the mold flux is too thin, it will cause no heat preservation, oxidation of molten steel, inclusions, cracks, large drawing resistance, steel leakage, etc. At the same time, the coverage thickness of mold flux should not be too thick, they can’t melt in time with too much mold powder, if the molten steel is churning, it is easy to get the mold powder into molten steel at this time, resulting in mold leakage. Therefore, the amount of mold powder must be controlled within a reasonable range. The detection and control of mold flux thickness is very important, especially for the steel plants which are strict with the steelmaking production process. The detection principle: The mold flux detection system developed by Wuhan CenterRise M&C Engineering CO., Ltd. uses the laser triangular sensor fixedly installed above the mold to obtain the height h1 by scanning the upper surface layer of mold flux with high-precision laser triangulation. When the laser measuring head is placed each time, the height h3 of the upper nozzle of the mold will be marked, and the system through the PLC system which is connected to the continuous casting machine through the network to introduce the height h1 of the mold liquid level. Through the calculation of three heights, we can get the thickness of mold powder H = 900-h1-(h3-h2)mm (900mm is the depth of mold). The features: The system adopts a high-precision laser triangulation distance meter, which can measure the thickness of the mold flux with high speed and high precision, and the accuracy can reach 1mm. The equipment is easy to install and use. When we are using, the laser rangefinding sensor can be placed directly above the mold without affecting production. The system can be interlocked with the automatic mold powder feeding system to automatically adjust the amount of mold powder, so as to automatically control the amount of mold powder within a reasonable range and realize intelligent automatic mold powder feeding. Non-contact measurement, the system only needs ventilation protection, simple and stable to use. The parameters: Measurement range:0-50mm Temperature measurement range: -20℃-700℃ Equipment installation distance:750mm System measurement accuracy:1mm Laser measurement accuracy: 0.1mm Frequency: 700-2000Hz Cooling method: air-cooled purging Installation method: rail sliding installation, can be slid out during maintenance Storage period: data can be stored for more than 2 years Communication method: Industrial Ethernet or Profibus-DP

Rs 200.000

See product

2 photos

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

See product

Pakistan (All cities)

Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition. The features of the system 1. The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken. 2. The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different segments and different casting speeds. 3. The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed. The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity. 4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient. It has manual, automatic, local and remote control modes. 5. The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux. 6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage. 7. Strong operability, simple and convenient maintenance, and low maintenance cost. 8. It can maintain the even distribution of the flux layer in the mold. The composition of the system The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment. 1. The feeding trolley is the support and walking equipment of the mold flux feeder. The basic equipment of the adding mold flux machine is installed on the feeding trolley. At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position. 2. The feeding bucket is a device for holding mold flux. The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder. The feeding bucket is provided with alarm contact of mold flux level limit.. 3. The swing arm and the feeder motor form a feeding and conveying device. The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor. Then the mold flux can be used for mold distribution. 4. PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates. 5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold. The technical parameter Mold width: 500-2000mm Mold thickness: 100-500mm Type: screw conveying type mold flux feeding machine Heating method: stirring electric heating Arrangement location: on the pouring platform (with its own wheels to move) Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube Molding flux storage tank: 300 L, with material level detection and alarm Control mode: local/remote control, automatic /manual mode Molding flux type: granular flux or powder flux flux adding method: spiral swing adding flux Casting speed interlock: yes Mould size setting: yes Signal transmission: DP/Industrial Ethernet

See product

Pakistan (All cities)

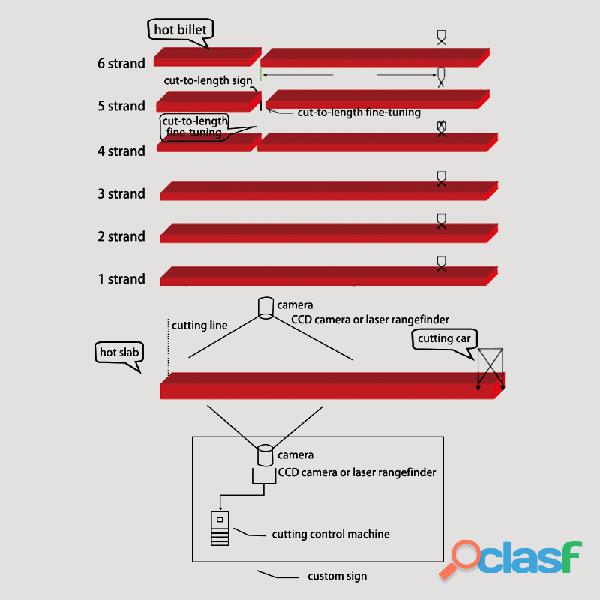

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

See product

Pakistan (All cities)

Overview: In the steelmaking production process, the ladle is the key equipment for holding molten steel, secondary refining, and continuous pouring. In a modern steelmaking plant, refractory materials are required for converters, refining, and ladles. In the steelmaking process, ladle is the main equipment for using and consuming refractory materials. Improving the service life of ladles and reducing refractory consumption is the key technology for steelmaking plants to save costs and reduce energy consumption for green production. In order to ensure the orderly operation of the ladle, save the consumption of refractory materials, prolong the service life of the ladle, and ensure the safe operation of the ladle, Wuhan CenterRise M&C Engineering CO. developed and launched the LDT-N200 integrated management system for the ladle. Introduction: LDT-N200 ladle integrated management system integrates LDT-L200 ladle lining thickness gauge, TBP-S300 ladle, tundish baking temperature and leakage monitoring system, RFD -C100 metallurgical electronic positioning system, and also integrates SQL Server database and NeuralWare (American computer software company) neural network software NeuralWorks to realize intelligent and optimized management of ladles. LDT-L200 ladle lining thickness gauge uses a laser area array scanning sensor to accurately measure the real-time thickness of the ladle lining, calculate the lining loss, and predict the service life of the ladle. TBP-S300 ladle, tundish baking temperature and leakage monitoring system uses infrared thermal imaging camera and embedded armor wire system to comprehensively monitor and prevent ladle leakage. RFD-C100 metallurgical electronic positioning system installs RFID electronic tags on all ladles to realize full-time and full-space ladle positioning and tracking. LDT-S200 ladle optimization control and analysis software, based on SQL Server database, B/S network structure, realizes online management of ladles, and adopts BP neural network system to realize intelligent optimization control of ladles. LDT-N200 ladle integrated management system can realize ladle age management based on ladle lining data and neural network algorithm, safety process control of ladle turnover and use, full-time tracking management of steelmaking production and full-space tracking management of ladle use and provide optimal control and management of steelmaking production and ladle maintenance. Comprehensive ladle measurement and monitoring, ladle positioning and management, and data management and optimization enable the LDT-N200 ladle integrated management system to fully realize ladle entire process management, optimize the service life of ladles, and comprehensively reduce the cost of refractory materials. The features: Using a lining thickness gauge to measure the thickness of the ladle lining Using infrared thermal imaging camera/embedded armor wire to realize ladle leakage detection Using RFID/number plate recognition to realize the location management of ladles Ladle age management system based on overall tracking Overall (full-time full-space) ladle management system based on database Provide overall production scheduling data Using neural network to predict ladle service life based on big data Ladle Optimal Scheduling System based on database and ladle service life Increase the service life of ladle by 12%-20% Reduce the use of refractory materials more than 15% Realize orderly management of ladle baking Realize full space and full time domain control Reduce the costs of ladle management and maintenance Improve the efficiency of ladle turnover operation

See product

Karachi (Sindh)

REALTOP (CHINA) CONCRETE STATIONRY CONCRETE PUMP MODEL HBT-50 Main Technical Parameter for HBT50.10.82RSC Technical ParametersUnit............................HBT50.10.82RSC Max. Theor. Concrete Output (m³/h)...........60 Concrete Pressure (mpa).....................10 Theor. Max. Horizontal Delivery Distance (m)..........750 Theor.Max.VerticalDelivery Distance (m)......180 Main Pump............................................Japanese Kawasaki Cylinder Diameter/Rod D × Stroke(mm).........φ110/70×1200 Concrete Cylinder Bore × Stroke(mm).........φ200×1400 Diesel Engine Power(kw).................................Cummins 82 Rated Rotating Speed(r/m).................................2200 Hopper Capacity(L)................................660 Hopper Height(mm)........................................1400 Oil Tank Capacity(L).....................................500 Hyd raulic Circuit Form.........................................Opened-circuit Delivery Valves Style.........................................S-valved Max. Grain Diameter(mm)Pebble:..........50 Crushed Stone:...................40 Out Dimension(mm)..................5230×2160×2010 Total Weight(kg)...................4350 Regards SHAH OMER M/s Lucky Engineering & Scientific Co Karachi 03219269422 03343669422

Rs 5.800.000

See product

Karachi (Sindh)

Product Description Masalta's floor saws are designed for strength, durability and performance. Whether cutting concrete or asphalt, the reinforced steel box frame design adds strength necessary to reduce vibrations while sawing. Minimizing vibrations enhances the performance of the blade and extends the life of the saw. Features * Super-rigid box frame ensures straight cuts while resisting warping and vibration--prolongs saw life; Extends blade life * Japanese shaft bearings for long service life * Ergonomically designed, height adjustable handles with comfortable grips * Easy crank for raising/lowering cutting depth * Hinged front, lift-up blade guard is designed to provide easy blade replacement * Large water tank provides an optimum flow and volume of water to the blade * Throttle control as standard part Model...........MF20-1 Engine.Air-cooled, 4-cycle,single cylinder Engine Type.......Diesel, Kipor 186 Power Kw(hp)......6.6(9.0) Operation Mass Kg(lb).......216(484) Max.Cutting Depth cm(in....17(6.7) Blade Size cm(in)........35-50(14-20) Depth Adjustment.......Handle Rotation Driving............MSemi-self Propelled Water Tank Capacity L........40. Regards Shah Omer M/s Lucky Engineering & Scientific Co Karachi 03219269422 03343669422 02135312095

Rs 185

See product

Pakistan

No. University Established Campuses Specialization Website 1 Allama Iqbal Open University (AIOU) 1974 General (Large) AIOU 2 COMSATS Institute of Information Technology 2000 Abbottabad, Attock, Sahiwal, Lahore, Vehari, Virtual, Wah Information Technology COMSATS 3 Federal Urdu University 2002 Karachi , Sindh . General (Large) FUUAST 4 Institute of Space Technology (IST) 2002 General IST 5 International Islamic University, Islamabad 1980 General (Large) IIU 6 National University of Modern Languages (NUML) 2000 Faisalabad, Hyderabad, Karachi, Lahore, Multan, Peshawar, Quetta Language NUML 7 National University of Sciences and Technology (Pakistan) (NUST) 1991 Engineering NUST 8 Pakistan Institute of Development Economics (PIDE) 1957 Economics PIDE 9 Pakistan Institute of Engineering and Applied Sciences (PIEAS) 1967 Engineering PIEAS 10 Quaid-i-Azam University 1965 General (Medium) QAU 11 Shaheed Zulfiqar Ali Bhutto Medical University 2013 Medical SZABMU Private Sector[edit] No. University Established Campuses Specialization Website 1 Foundation University, Islamabad 2002 General FUI 2 National University of Computer and Emerging Sciences 2000 Chiniot - Faisalabad, Karachi, Lahore, Peshawar Information Technology NU 3 Muslim Youth University 2015 Islamic MYU 4 Riphah International University 2002 Faisalabad, Lahore General (Medium) Riphah 5 Shifa Tameer-e-Millat University 2012 General STMU Armed Forces[edit] No. University Established Force Campuses Specialization Website 1 Air University (Pakistan Air Force) 2002 Pakistan Air Force Multan Engineering AU 2 Bahria University 2000 Pakistan Navy Karachi, Lahore, Islamabad General (Large) Bahria 3 National Defence University, Pakistan (NDU) 1965 Pakistan Army General (Military) NDU Balochistan[edit] Public Sector[edit] No. University Location Established Campuses Specialization Links 1 Balochistan University of Engineering and Technology Khuzdar 1987 General (Small) BUETK 2 Balochistan University of Information Technology, Engineering and Management Sciences Quetta 2002 Information Technology BUITMS 3 Lasbela University of Agriculture, Water and Marine Sciences Lasbela 2005 General (Medium) LUAWMS 4 Sardar Bahadur Khan Women's University Quetta 2004 General (Small) SBKUW 5 University of Balochistan Quetta 1970 Loralai General (Medium) UoB 6 University of Turbat Turbat 2012 General (Medium) UoT 7 University of Loralai Loralai 2013 General (Small) UoLi Private Sector[edit] No. University Location Established Campuses Specialization Website 1 Al-Hamd Islamic University Quetta 1995 (2005)* Islamabad General (Small) AIU * Granted University Status Khyber Pakhtunkhwa[edit] Public Sector[edit] No. University Location Established Campuses Specialization Website 1 Abdul Wali Khan University Mardan Mardan 2009 General AWKUM 2 Bacha Khan University Charsadda 2012 General BKUC 3 Gomal University Dera Ismail Khan 1974 General GU 4 Hazara University Mansehra 2002 General HU 5 Institute of Management Sciences (Peshawar) (IMS) Peshawar 1995 (2002)* Business IMSciences 6 Islamia College University Peshawar 1913 (2008)* General ICP 7 Khushal Khan Khattak University Karak, Pakistan 2013 General KKKUK 8 Khyber Medical University Peshawar 2007 Medical KMU 9 Kohat University of Science and Technology Kohat 2001 Engineering and Technology KUST 10 Shaheed Benazir Bhutto University, Sheringal Upper Dir 2009 General SBBU 11 Shaheed Benazir Bhutto Women University Peshawar 2012 General SBBWU 12 University of Agriculture, Peshawar Peshawar 1981 Agriculture, Veterinary and Business AUP 13 University of Engineering and Technology, Peshawar Peshawar 1980 Abbottabad, Bannu, Jalozai, Mardan Engineering and Technology UET Peshawar 14 University of FATA Kohat 2013 General none 15 University of Haripur Haripur 2012 General UoH 16 University of Malakand Malakand 2001 General UoM 17 University of Peshawar Peshawar 1950 General UPesh 18 University of Science and Technology (Bannu) Bannu 2005 General USTB 19 University of Swabi Swabi 2013 General UoSwabi 20 University of Swat Saidu Sharif, Swat 2009 General UoSwat Private Sector[edit] Islamia College University Ghulam Ishaq Khan Institute of Engineering Sciences and Technology University of Malakand, Chakdara COMSATS Abbottabad No. University Location Established Campuses Specialization Website 1 Abasyn University Peshawar 2007 Islamabad General Abasyn 2 CECOS University of Information Technology and Emerging Sciences Peshawar 1986 Information Technology CECOS 3 City University of Science and Information Technology, Peshawar Peshawar 2008 Information Technology City University 4 Gandhara University Peshawar 2002 Medical Gandhara 5 Ghulam Ishaq Khan Institute of Engineering Sciences and Technology Topi, Swabi 1988 (1993)* Engineering and Technology GIKI 6 IQRA National University Peshawar 2012 General Iqra Psh 7 Northern University, Nowshera Nowshera 2008 General Northern 8 Preston University (Pakistan) Kohat 1984 Ajman, Islamabad, Lahore, Peshawar General Preston 9 Qurtuba University Peshawar 2001 Peshawar General Qurtuba 10 Sarhad University of Science and Information Technology Peshawar 2001 Science and Technology SUIT Armed Forces[edit] No. University Location Established Force Specialization Website 1 Pakistan Military Academy (PMA) Kakul, Abbotabad 1947 Pakistan Army Training Pakistan Army * Granted University Status Punjab[edit] Public Sector[edit] Ghazi University in D.G.Khan No. University Location Established Campuses Specialization Website 1 Bahauddin Zakariya University Multan 1975 Layyah, Sahiwal General BZU 2 Fatima Jinnah Women University Rawalpindi 1998 General FJWU 3 University of Sargodha Sargodha 2002 Lahore, Gujranwala, Mandi Bahauddin General UoS 4 Ghazi University Dera Ghazi Khan 2012 General Ghazi University 5 Government College University, Faisalabad Faisalabad 1933 (2002)* General GCUF 6 Government College University, Lahore Lahore 1864 General GCU 7 Government College Women University, Faisalabad Faisalabad 2012 General GCWUF 8 Government College Women University, Sialkot Sialkot 2012 General GCWUS 9 Government Sadiq College Women University Bahawalpur 2012 General GSCWU 10 Information Technology University, Lahore Lahore 2012 Information Technology ITU 11 Islamia University Bahawalpur 1975 Bahawalnagar, Rahim Yar Khan General IUB 12 Khawaja Fareed University of Engineering & Information Technology, Rahim Yar Khan Rahim Yar Khan 2014 Engineering none 13 King Edward Medical University Lahore 1860 (2006)* Medical KEMU 14 Kinnaird College for Women University Lahore 1917 General Kinnaird 15 Lahore College for Women University Lahore 1922 Jhang General LCWU 16 Muhammad Nawaz Sharif University of Agriculture Multan 2012 Agriculture MNSUAM 17 National College of Arts (NCA) Lahore 1996 Arts NCA 18 National Textile University Faisalabad 1959 (2002)* Textile Engineering NTU 19 NFC Institute of Engineering and Technology Multan 1985 Engineering NFCIET 20 Pakistan Institute of Fashion and Design Lahore 2010 Fashion PIDF 21 Pir Mehr Ali Shah Arid Agriculture University Rawalpindi 1970 (1994)* Agriculture and Veterinary UAAR 22 University of Agriculture, Faisalabad Faisalabad 1906 (1961)* Burewala, Toba Tek Singh Agriculture and Veterinary UAF 23 University of Education Lahore 2002 Dera Ghazi Khan, Faisalabad, Jauharabad, Multan, Okara, Pakistan, Vehari Education UE 24 University of Engineering and Technology, Lahore Lahore 1921 Faisalabad, Kala Shah Kaku, Rachna College of Engineering and Technology (Gujranwala) Engineering UET 25 University of Engineering and Technology, Taxila Taxila 1975 Chakwal Engineering UET Taxila 26 University of Gujrat Gujrat 2004 Lahore, Sialkot General UoG 27 University of Health Sciences, Lahore Lahore 2002 Medical UHS 28 University of the Punjab Lahore 1882 Gujranwala, Jhelum General PU 29 University of Veterinary and Animal Sciences Lahore 1882 Jhang, Pattoki Veterinary UVAS 30 Virtual University of Pakistan Lahore 2002 Badin, Dera Ghazi Khan, Faisalabad, Ghotki, Gujranwala, Hyderabad, Islamabad, Jhelum, Karachi, Lahore, Multan, Muzaffargarh, Peshawar, Pishin, Pakistan, Rawalpindi, Sahiwal Distance Education VU 31 Women University Multan Multan 2010 General WUM Unrecognized/Newly Established Universities No. University Location Established Specialization Website 1 Muhammad Nawaz Sharif University of Engineering and Technology Multan 2012 Engineering MNSUET 2 University of Engineering and Technology (Rasul) Rasul, Mandi Bahauddin 2014 Engineering UET Rasul 3 University of Jhang Jhang 2015 General none 4 University of Okara Okara 2015 General none 5 University of Sahiwal Sahiwal 2015 General none 6 University of Veterinary and Animal Sciences, Bahawalpur Bahawalpur 2014 Veterinary none Private Sector[edit] 1 University Location Established Campuses Specialization Website 1 Ali Institute of Education Lahore 1992 Education AIE 2 Beaconhouse National University Lahore 2003 General BNU 3 Forman Christian College Lahore 1864 (2005)* General FC College 4 GIFT University Gujranwala 2002 General GIFT 5 Global Institute, Lahore Lahore 1996 General Global 6 Hajvery University Lahore 2002 General Hajvery 7 HITEC University Taxila 2007 Engineering Hitech Uni 8 Imperial College of Business Studies Lahore 1991 General Imperial 9 Institute of Management Sciences, Lahore Lahore 1987 Business Pak-AIMS 10 Institute of Southern Punjab Multan 2010 General USP 11 Lahore Garrison University Lahore 2012 General LGU 12 Lahore Leads University Lahore 2011 General Leads 13 Lahore School of Economics Lahore 1997 Business and Economics Lahore School of Economics 14 Lahore University of Management Sciences (LUMS) Lahore 1984 Business LUMS 15 Minhaj University, Lahore Lahore 2005 General MUL 16 National College of Business Administration and Economics Lahore 1994 Multan Business and Economics NCBAE 17 Nur International University Lahore 2015 General N/A 18 Qarshi University Lahore 2011 General QU 19 The Superior College Lahore 2004 General Superior 20 University of Central Punjab Lahore 2002 General UCP 21 University of Faisalabad Faisalabad 2002 General TUF 22 University of Lahore Lahore 2002 Gujrat, Islamabad, Sargodha General UoL 23 University of Management and Technology, Lahore Lahore 1990 Sialkot Business and Technology UMT 24 University of South Asia (Pakistan) Lahore 2003 General USA 25 University of Wah Wah 2009 General UW * Granted University Status Sindh[edit] Public Sector[edit] Department of Economics, University of Karachi Mehran University, Main Entrance Sir Syed University of Engineering and Technology IQRA University Main Campus Hamdard University No. University Location Established Campuses Specialization Website 1 Benazir Bhutto Shaheed University Karachi 2010 (2007)* General BBSUL 2 Dawood University of Engineering and Technology Karachi 1962 (2007)* Engineering DUET 3 Dow University of Health Sciences Karachi 1945 (2003)* Medical DUHS 4 Gambat Institute of Medical Sciences Khairpur 2012 Medical N/A 5 Institute of Business Administration, Karachi Karachi 1955 Business IBA 6 Jinnah Sindh Medical University Karachi 2012 Medical JSMU 7 Liaquat University of Medical and Health Sciences Jamshoro 1881 (2002)* Medical LUMHS 8 Mehran University of Engineering and Technology Jamshoro 1963 (1977)* Khairpur Engineering MUET 9 NED University of Engineering and Technology Karachi 1921 (1977)* Engineering NEDUET 10 Peoples University of Medical & Health Sciences for Women Nawabshah 2013 Medical PUMHS 11 Quaid-e-Awam University of Engineering, Science and Technology Nawabshah 1974 (1996)* Larkana Engineering QUEST 12 Shah Abdul Latif University Khairpur 1974 (1987)* Shikarpur General SALU 13 Shaheed Benazir Bhutto University, Nawabshah Benazirabad 2010 General SBBUSBA 14 Shaheed Mohtarma Benazir Bhutto Medical University Larkana 2008 Medical SMBBMU 15 Sindh Agriculture University Tandojam 1977 Agriculture and Technology SAU 16 Sindh Madrasatul Islam Karachi 1885 (2012)* General SMIU 17 Sukkur Institute of Business Administration Sukkur 1994 Business and Information Technology IBA-Suk 18 Shaheed Zulfiqar Ali Bhutto University of Law Karachi 2012 Law SZABUL 19 University of Karachi Karachi 1951 General UoK 20 University of Sindh Jamshoro 1947 Badin, Dadu, Pakistan, Mirpur Khas General USindh Unrecognized/Newly Established Universities No. University Location Established Specialization Website 1 Shaheed Benazir Bhutto University of Veterinary and Animal Sciences Karachi 2013 Veterinary SBBUVAS Private Sector[edit] No. University Location Established Campuses Specialization Website 1 Aga Khan University Karachi 1983 Medical AKU 2 Baqai Medical University Karachi 1989 (1996)* Medical Baqai 3 Commeces Institute of Business and Emerging Sciences Karachi 1993 Business Commeces Institute 4 Dadabhoy Institute of Higher Education Karachi 2000 General Dadabhoy 5 DHA Suffa University Karachi 2012 General DSU 6 Greenwich University, Karachi Karachi 1998 General Greenwich University 7 Hamdard University Karachi 1991 Islamabad (Subject to the renewal of NOC in December, 2015.) General Hamdard 8 Habib University Karachi 2009 (2014)* Liberal Arts and Sciences Habib 9 Indus University Karachi 2004 General Indus 10 Indus Valley School of Art and Architecture Karachi 1989 (1994)* Arts and Architecture Indus Valley 11 Institute of Business Management Karachi 1995 Business, Engineering and Technology IoBM 12 Institute of Business & Technology, Karachi Karachi 2001 Business BizTek 13 Iqra University Karachi 1998 (2000)* Islamabad, Quetta General Iqra 14 Isra University Hyderabad 1997 Islamabad, Karachi General Isra 15 Jinnah University for Women Karachi 1998 General JUW 16 Karachi Institute of Economics and Technology Karachi 1997 General PAFKIET 17 Karachi School for Business and Leadership Karachi 2009 (2012)* Business KSBL 18 KASB Institute of Technology Karachi 2011 Business KASBIT 19 Muhammad Ali Jinnah University Karachi 2009 Islamabad Business, Engineering and Technology Jinnah 20 Nazeer Hussain University Karachi 2012 Business NHU 21 Newports Institute of Communications and Economics Karachi 2013 Business Newports 22 Preston Institute of Management Science and Technology Karachi 2001 Business and Technology PIMSATK-Khi 23 Preston University (Pakistan) Karachi 1984 General Preston 24 Shaheed Benazir Bhutto City University Karachi 2013 General SBBCU 25 Shaheed Benazir Bhutto Dewan University Karachi 2013 General none 26 Shaheed Zulfiqar Ali Bhutto Institute of Science and Technology (SZABIST) Karachi 1995 Dubai, Hyderabad, Islamabad, Larkana General SZABIST 27 Sindh Institute of Medical Sciences Karachi 2009 Medical none 28 Sir Syed University of Engineering and Technology Karachi 1993 Engineering SSUET 29 Textile Institute of Pakistan Karachi 1994 (2001)* Textile TIP 30 Ziauddin University Karachi 1995 Medical ZU Unrecognized/Newly Established Universities No. University Location Established Specialization Website 1 Hyderabad Institute of Arts, Science and Technology Hyderabad 2013 Sciences HIAST 2 Qalandar Shahbaz University of Modern Sciences Karachi 2013 Sciences QSUMS 3 University of East Hyderabad 1999 Sciences UoE Armed Forces[edit] No. University Location Established Force Specialization Website 1 Pakistan Naval Academy Karachi 1970 Pakistan Navy Military Pak Navy * Granted University Status Azad Kashmir[edit]Sunny Leone Mirpur University of Science and Technology Public Sector[edit] No. University Location Established Specialization Website 1 Mirpur University of Science and Technology (MUST) Mirpur 1980 (2008)* Engineering and Technology MUST 2 University of Azad Jammu and Kashmir Muzaffarabad 1980 General AJKU 3 University of Management Sciences and Information Technology Kotli 1980 (2014)* General UMSIT 4 University of Poonch Rawalakot 1980 (2012)* General UPR 5 Women University of Azad Jammu and Kashmir, Bagh Bagh, Azad Kashmir 2013 General none Private Sector[edit] No. University Location Established Specialization Website 1 Al-Khair University (The University is restricted for MS/M.Phil/PhD admissions/programs and can only offer admissions up to Masters’ level at its Bhimber campus, AJK, from Fall 2014.) Bhimber 1994 (2011)* General AL-Khair 2 Mohi-ud-Din Islamic University Nerian Sharif 2000 General MIU * Granted University Status Gilgit-Baltistan[edit] Nan Pakistan Academy of Sciences

See product

Pakistan

Dastgir Engineering offers a full selection of new commercial kitchen equipment from nationally known food service manufacturers at best prices. Dastgir Engineering can provide the commercial kitchen equipment you need, at prices you can afford. Find everything to outfit a commercial kitchen, including: • Restaurant ranges, convection ovens, • Flat grills & broilers • Bakery & dough equipment • Cookware & kitchen tools • Commercial sinks & dishwashers • Food processors & dough mixers • Wire shelving units • Food storage containers • Cold Storage Machinery • Hotel Equipment & Supplies • HVACR Engineers & Contractors • Kitchen Equipment & Supplies • Commercial Bakery Equipments. • Super Market Equipment. • Meat Shops For detail contact: Dastgir Engineering Co. Lahore.

See product

Rawalpindi (Punjab)

INSPIRE INSTITUTE OF TECHNOLOGIES www.iitpakistan.com HEALTH AND SAFETY COURSES IN PAKISTAN General Safety Officer Osha Iosh Nebosh Icertosh IADC Rig Pass The field of Health & Safety Management provides a glorious opportunity for a marvelous future worldwide. Those who aim to glow on the horizon of enviable success, feel free to contact us. We, at Inspire Institute Of Technologies - IIT Pakistan offer ICERTOSH, NEBOSH, IOSH, OSHA, IADC RIG PASS, TQM,QC,QA, DISASTER MANAGEMENT, INTERIOR DESIGNING, SAFETY OFFICER, CIVIL & QUANTITY SURVEYOR, WEB DEVELOPMENT, AUTOCAD etc, courses to help you open professional doors for you globally. HSE Engineering diploma NEBOSH IGC IOSH MS Fire Safety Diploma OSHA Oil and Gas Safety Diploma rig Pass Safety IWCF,IADC Certificate Civil Engineering/Quantity Surveyor Diploma Civil Surveyor Qunatinty Survery Primavera Ms Project AutoCAD Advanced Diploma Courses AutoCAD Mechinal AutoCAD 2010 AutoCAD 2D/3D Max IT(Information Technology) and Computer Diploma Courses Basic Computer Ms Office Advanced Certificate Of Information Technology Diploma Of Information Technology PGD IT Graphic Designing A+ Hardware Networking WebDevelopment Diploma Courses Visual Basic PHP & ASP.NET Web Development Web Designing Complete WebSite Development course Java, Java Scripting PHP &MySQL HTML,CSS Web Design Networking Accounting Courses Peachtree Quick Books Tally Eagle Point Sap ERP Oracle Certification Diploma Course Hotel Management and Hospitality Diploma Courses Hotel & Management Diploma Hospitality Management Diploma Spoken English Diploma Courses Spoken English Diploma Courses IELTS & TOEFL TECHNICAL & PROFESSIONAL DIPLOMAS 1 Diploma in health, safety & environment (HSE) 2 Diploma in Safety management 3 Diploma in software engineering 4 Diploma in computer engineering 5 Diploma in information technology 6 Diploma in safety & security management 7 Diploma in engineering (Electrical, M

Rs 9

See product

Pakistan (All cities)

China Metal Parts Forging OEM Manufacturer Co., Ltd. (https://www.creatorcomponents.com/) was founded in 2000 by a team of experienced professionals in the forging industry. As a Chinese manufacturer, we specialize in providing high-quality carbon steel and alloy steel metal parts and components for a wide variety of industries. We focus on innovation and engineering excellence to ensure that we meet the highest standards of quality and performance. By utilizing advanced technology and state-of-the-art equipment, we produce products that are durable and reliable, meeting the requirements of both domestic and international customers. Quality is a top priority at every stage of our production process. From inspecting raw materials to conducting 100% final product testing, we ensure all products comply with international standards through our thorough quality control system. As a Chinese manufacturer, we offer customized metal parts to cater to the specific needs of industries such as automotive, construction, and energy. We collaborate closely with clients to deliver tailored solutions that align with their business objectives. At China Metal Parts Forging OEM Manufacturer Co., Ltd., we are dedicated to providing innovative, sustainable solutions and excellent customer service, earning the trust of businesses worldwide as a reliable partner.

Free

See product

4 photos

Pakistan

Dastgir Engineering provides best quality equipments for your Coffee Shop. For query you can contact us Dastgir Engineering Co. LAHORE. 12-A, Lahore Road, Saddar Cantt.

See product

Pakistan

Dastgir Engineering provides Complete Solution of Hotel, Restaurant, Commercial Refrigeration, Food Machinery, Super Market’s Equipment & Accessories. We deal in the following field: 1. Cold Storage Machinery 2. Hotel Equipment & Supplies 3. HVACR Engineers & Contractors 4. Kitchen Equipment & Supplies 5. Shelving & Racking System 6. Commercial Bakery Equipments. 7. Super Market Equipment. 8. Commercial Washing Equipment. 9. Meat Shops For query you can contact: Uzma Khan Assistant Marketing Managers Mobile Number: 042-36665202 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt.

See product

Pakistan

Dastgir Engineering provides best quality displays for your Bakery. For query you can contact: Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt

See product

Lahore (Punjab)

Dastgir Engineering provides best quality equipments for your Restaurant. For query you can contact: Uzma Khan Assistant Marketing Manager Mobile Number: 0322-8628179 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt.

See product

Pakistan

Dastgir Engineering provides best quality Pizza equipment's for your Fast Food Restaurant. For query you can contact: Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt.

See product

Lahore (Punjab)

Dastgir Engineering provides best quality Glass Door Refrigerator for your Bakery. For query you can contact: Uzma Khan Assistant Marketing Manager Mobile Number: 0322-8628179 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt

See product

Lahore (Punjab)

Dastgir Engineering provides best quality Salad Bar for your Bakery and Restaurant. For query you can contact: Uzma Khan Assistant Marketing Manager Mobile Number: 0322-8628179 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt

See product

Lahore (Punjab)

Dastgir Engineering provides best quality equipments for your Fast Food Restaurant. For query you can contact us: Uzma Khan Assistant Marketing Manager Mobile Number: 0322-8628179 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt.

See product

Lahore (Punjab)

Dastgir Engineering provides best quality equipments for your Restaurant, Café/Bar, Bakeries etc. We deal in the following field: 1) Commercial Kitchen Equipment. 2) Commercial Refrigerator. 3) Commercial Bakery Equipments. 4) Super Market Equipment. 5) Commercial Washing Equipment. 6) Meat Shops. For query you can contact us: Uzma Khan Assistant Marketing Manager Mobile Number: 042-36665202 Dastgir Engineering Co. 12-A, Lahore Road, Saddar Cantt. www.dastgirengineering.com

See product

-

Next →