Jerman months

Top sales list jerman months

Latest Offers

Lahore (Punjab)

Apple Hair Color Price In Pakistan - Quickon.pk Apple Hair Color Price In Pakistan is a hair dye product designed to provide vibrant, long-lasting color while maintaining the health and integrity of your hair. This product is formulated to offer rich, natural-looking color with the added benefits of conditioning and nourishing ingredients. What is Apple Hair Color Price In Pakistan? Apple Hair Color Price In Pakistan is a professional-quality hair dye that offers a wide range of shades to suit different hair types and preferences. The formula is enriched with conditioning agents and natural extracts that help protect and nourish the hair during the coloring process. It is designed to deliver vibrant, long-lasting color with a natural finish. https://quickon.pk/product/apple-hair-color-price-in-pakistanhttps://quickon.pk/product/feg-plus-hair-growth-sprayhttps://quickon.pk/product/sardar-jee-hair-color-gel-price-in-pakistan

Rs 3.500,0

See product

Pakistan (All cities)

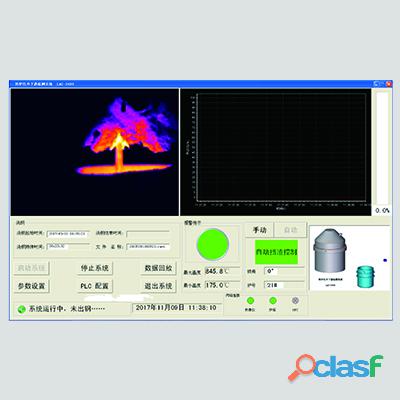

Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content. The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal. As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc. The features of thermal imager 1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set. 2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature. 3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily. 4. With hot zone tracking function 5. Equipped with special 7~14um infrared filter lens The technical parameters 1. Temperature measurement range: 200°C ~ 2000°C 2. Temperature measurement accuracy: 2% 3. Detection accuracy and alarm accuracy: ≥98% 4. Resolution: ≥ 0.5℃ 5. Pixels: 640x240PT 6. Band: 7~14um 7. Field of view: 7.5°×5.5° 8. Frame rate: ≥ 25 frames/sec 9. Equipment service life: ≥5 years 10. The normal operation rate of the automatic control system: ≥99%

Rs 0,0

See product

3 photos

Rawalpindi (Punjab)

Discover a curated selection of stylish, handcrafted handbags and clutches at Baglore.com. Each piece is meticulously designed to blend traditional artistry with contemporary flair, offering timeless elegance for every occasion. Whether you need a chic clutch for a special event or a practical yet stylish handbag for everyday use, our collection provides the perfect accessory. Explore Baglore.com now and elevate your fashion statement with unique, high-quality handcrafted bags.

Rs 3.800,0

See product

16 photos

Pakistan (All cities)

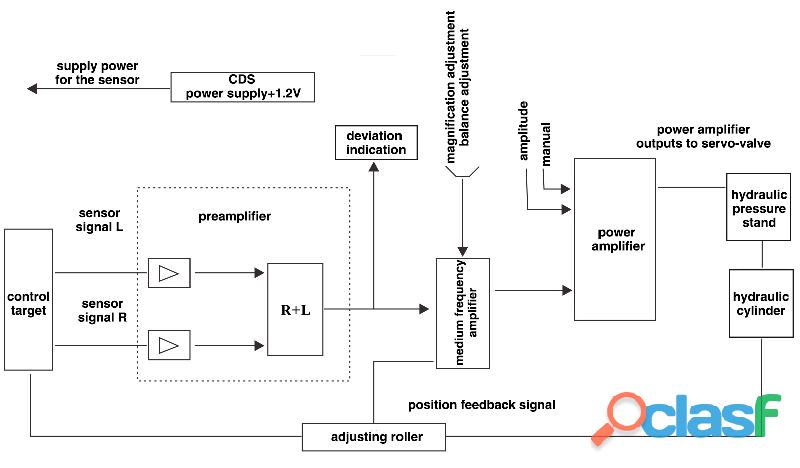

The composition of the system The photoelectric strip automatic center position control system is mainly composed of sensors, amplifiers, PLC controllers, hydraulic control and other parts. System composition block diagram The main technical parameters 1. Detection width: 300-2800mm 2. Detection light source: 220VAC. (100VAC) 30W. High frequency white light works continuously 3. Photodetector: precision die-casting components, time constant 20ms 4. Maximum working voltage: 50VDC 5. Distance from receiver to emitter: 300-1000mm 6. Operating temperature: 0℃-60℃ 7. Resolution: 0.5mm 8. Linearity: ±1%F.S (after linearization) 9. Repeatability error: △R1%, F.S 10. Servo-valve working signal: ±10V 11. Rated pressure (oil pressure): 4.5Mpa 12. Rated flow: 30L/min 13. Symmetry: 10%

Rs 0,0

See product

2 photos

Pakistan (All cities)

Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area. The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process. MOC-K100 mould oscillation online monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel. The meaning of the system 1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality. 2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance. 3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair. 4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident. 5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product. 6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed. The functions of the system (1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data including oscillation parameters and process parameters. (2) Time domain waveform: This function mainly displays the oscillation waveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elements of oscillation of each measuring point in real time. (3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and the oscillation difference of each channel can be calculated and displayed intuitively. (4) FFT: This functional module completes the calculation and display of the oscillation spectrum in real time. It is used to evaluate the waveform distortion of the entire oscillation table and to determine whether there is a problem with the installation of the oscillation device. (5) Bar graph: The oscillation of each measuring point is indicated by a bar graph of peak value and sensor gap voltage, which is more intuitive. (6) Trend: After starting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings for different steels under the oscillation conditions. The parameters of the system 1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged 2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes) 3. Sensitivity: 1000mV/g 4. Frequency range: 0.04~10HZ 5. Frequency accuracy: ±0.01 Hz 6. Amplitude accuracy: 0.005mm 7. Transmission mode: wired digital transmission, wireless transmission 8. Host: 3U standard rack, handheld device 9. Sensor power supply: 24V.DC 10. Host power supply: 220V.AC/50Hz Mold oscillation curve The structure of the system The main components of the continuous casting mould online oscillation detection system are: 1. Three-dimensional oscillation measurement sensor 2. Handheld oscillation sensor calibrator 3. Dedicated signal connection cable 4. Preamplifier 5. Operation processing unit 6. Graphic display terminal 7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components 8. Control cabinet

Rs 200.000,0

See product

3 photos

Pakistan

I have available 2 stunning BSH blue kittens. 1 girls and 1 boys. Mum and dad are beautiful blues and are GCCF registered. Mum has a wonderful personality, she is friendly and extremely loving. she has an excellent 4 generations pedigree.

Rs 5.000,0

See product

Pakistan (All cities)

At Green Build Engineering & Construction Pte. Ltd., we provide specialized engineering solutions designed to meet unique project requirements across various industries. Our expertise and innovative approach allow us to handle complex engineering challenges with precision and efficiency, delivering results that align with your specific goals. multiethnic-professional-construction-engineers-working-with-corporate-colleagues-teamwork-equip_41418-270 Our Offering Services: Custom Design and Fabrication: Tailored engineering solutions for unique structural and mechanical needs. Advanced Equipment Installation: Seamless integration of specialized machinery and systems. Structural Reinforcements: Strengthening existing frameworks to enhance safety and functionality. Prototype Development: Designing and testing prototypes for specialized applications. Consulting and Technical Support: Expert guidance and solutions for complex engineering problems.

Rs 15.613,0

See product

Pakistan (All cities)

ALUMINIUM USED BEVERAGE CANS SCRAP LOOSE BALED OF UK ORIGIN. Available quantity 500mt Minimum Order acceptable 25MT Will be loaded in a 40ft high cube container Weight per container will be approx 25 mt. Origin: United Kingdom Details Item Aluminium scrap UBC Attechment : 3% Purity: 97.9% Minimum Density : 14 Pounds Per Cubic ft (225 kg/m3) Smooth Surface Tight Tolerances aluminum scrap Easy control and operation Fast melting Discontinuous melting with scrap High efficiency Stable working structure Packaging & Delivery Packaging Detail: it comes in bales, or according to the customer demand. Delivery Detail : Within 21-25 working days after order confirmed A maximum of 3% of impurities to be considered.this is just an outer limited Specification: Aluminium UBC Beverage Cans Chemical Composition: Si: 0.2 – 0.6%, Fe: 0.35%, Cu: 0.1%, Mn: 0.1%, Mg: 0.45 – 0.9%, Cr: 0.1%, Zn: 0.1% Standard Conforming to: (C11000 (ETP) Content 99.90%) Origin: United Kingdom/ Europe Packing: In Bundles Quantity: 25MTS and up to 300 MT per month Shipment: 40FT Container for more details contact us via email at baicuscrapmetalltd@gmail.com or whatsapp +447918 245841

Rs 300,0

See product

2 photos

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

Rs 0,0

See product

Pakistan (All cities)

Overview In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline deviation. The measurement of the strand condition monitor Roll gap value: By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed. It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster. Arc condition of guide roller : Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guided roller. Guided roller rotation: It is possible to know whether each guided roller can rotate freely by measuring. Water spray pressure: The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal. The main components of the strand condition monitor 1. The main body of the strand condition monitor used to measure the continuous casting sector 2. The connecting chain between strand condition monitor and dummy bar 3. The storage rack chain of strand condition monitor 4. Battery charger: 24V 5A 5. Calibration equipment 6. Remote control 7. Laptop 8. Printer 9. Data communication cable The technical parameter 1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements) 2. The measurement accuracy of roll gap: 0.01mm 3. The arc measurement range: ±80° 4. The arc measurement accuracy: 0.01° 5. The spray measurement range: 0-10 6. The spray measurement accuracy: ±1 7. The battery usage times: 3 times

Rs 0,0

See product

Gujranwala (Punjab)

I am a professional logo designer with 4 years of experience, specializing in creating unique and memorable brand identities. My expertise lies in designing logos that effectively communicate your brand’s values and vision. Over the years, I’ve worked with various industries, delivering tailored designs that stand out. I prioritize client satisfaction by ensuring clear communication and timely delivery. My design process is detail-oriented, combining creativity and strategy to create impactful logos. Whether you’re launching a new business or rebranding, I can help elevate your visual presence. Let’s collaborate to bring your ideas to life!

Rs 999,0

See product

Pakistan

KC BRITISHPRIDE BRED English Bulldog Hes The son of Britishpride Royal Ascot. available for STUD. HE IS A PROVEN STUD DOG producing quality puppies.

Free

See product

Pakistan

Stunning Tri-Colour Pedigree Puppies for Sale. Only 3 girls left. Born 8th January and ready to re-home 4th March. These puppies have been home bred and reared within a family home. Mother can be seen with puppies and is from Chantryland an....Beautiful litter of chunky beagle puppies. Lemon and white & Tri in colour. Boys and girls available. They have gorgeous long floppy ears and cheeky personalities. They are ready now for there forever loving homes. Mum is a tri colo....We have for sale 4 wonderful beagle puppies they r good with kids other pets they r all up to date with wormed & flees & vacation they also comes with a dog lead good home only

Rs 200,0

See product

Pakistan (All cities)

We have the Outboard Boat Engine OXE. Yamaha We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 150.000,0

See product

2 photos

Gujrat (Punjab)

Jaipur, a city celebrated for its heritage and craftsmanship, is home to some of the finest Sheesham wood bed manufacturers. Sheesham wood, known for its strength, durability, and stunning natural grain patterns, is the ideal material for crafting high-quality beds that combine functionality with timeless beauty. Why Choose Sheesham Wood Beds? Durability: Sheesham wood is incredibly strong and resistant to wear, ensuring a long-lasting bed. Elegant Design: The rich textures and natural grain of Sheesham add a luxurious and earthy charm to any bedroom. Customizable Options: Jaipur manufacturers offer bespoke designs to suit your space and style preferences, from traditional carved beds to sleek modern styles. Eco-Friendly Choice: Many manufacturers use sustainably sourced Sheesham wood, supporting environmentally responsible practices. Types of Sheesham Wood Beds Available: Standard Beds: Classic designs suitable for any bedroom decor. Storage Beds: Functional beds with built-in storage to maximize space. Platform Beds: Minimalist and contemporary designs for a modern look. Poster Beds: Elegant four-poster beds that bring a royal touch to your space. Customized Beds: Tailored designs to fit specific dimensions and styles. Why Choose Sheesham Wood Bed Manufacturers in Jaipur? Jaipur’s Sheesham wood bed manufacturers are known for their impeccable craftsmanship, attention to detail, and the ability to deliver high-quality products. With a focus on both aesthetics and functionality, they ensure each bed is not only a piece of furniture but also a work of art. Explore the collections from Jaipur’s top Sheesham wood bed manufacturers and bring home a bed that combines luxury, comfort, and durability for a perfect night’s rest.

Rs 54.651,0

See product

2 photos