Instrument calibration

Top sales list instrument calibration

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

See product

Pakistan (All cities)

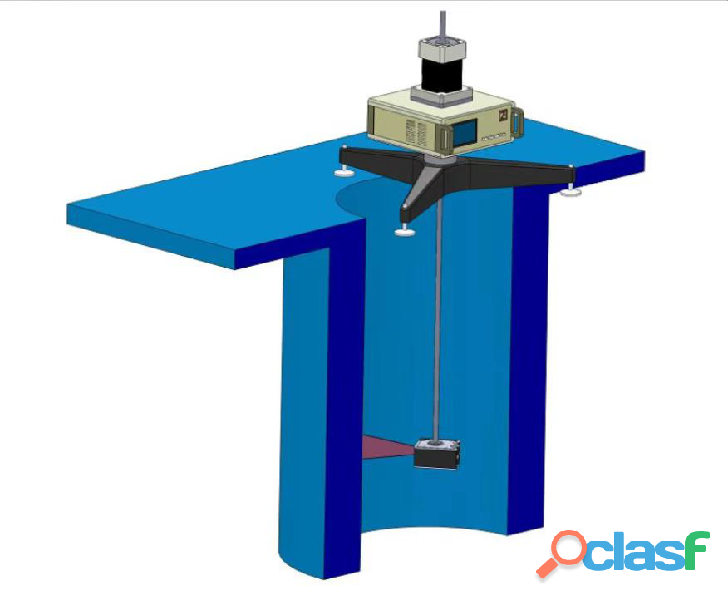

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

See product

Pakistan

NEXIQ 125032 USB Link + Software Diesel Truck Diagnose Full Set Super Truck Scanner Nexiq Feature: Compatible with applications that diagnose engines, transmissions, ABS, instrument panels and more. Reduce reprogramming times with direct USB connection Mixed fleet capabilities with broad protocol support Quick access to vehicle data for maintenance or management reports Quickly attaches to vehicle's diagnostic connector. Easy portability increases flexibility, May be used with desktop PC or laptop. NEXIQ 125032 USB Link packed software and application - Allison (Included!) - Bendix 6.3.8.0 (Included!) - Detroit Diesel DDDL 7.05 ((Included!) - Detroit Diesel DDCT (Included!) - Detroit Diesel Calibration Tool (Included!) - Eaton Service Ranger 3.2 (Included!) - International DLB (Included!) - International ICAP, IPTS, NETS, IPC (Included!) - International Master Diagnostic (Incluided!) - Meritor and Wabco Diagnostics (Included!) - Cummins Insite 7.5 (Included!) - Hino 2.0.3. (Included!) - Caterpillar 2.0.1.0 (Included!) - Perkins EST 2010B (Included!) - V Macks 2.6.12 (Included!) - V Macks Dealer Pro (Included!) - Volvo VCADS 2.35.10 (Included!) - Toyota Techstream for car (Included!) NEXIQ 125032 USB LinkAPI Support • RP1210A, RP1210B • J2534-2 • USB vehicle-to-PC connectivity, NEXIQ USB linke supports Windows xp and windows 7 32-bit and 64-bit and windows CE compliant Not all applications are included. If compatibility confirmation is required, more information is needed, or there are questions about an unlisted application, please contact us, a specialist will help you make the right choice. NEXIQ 125032 Protocol Coverage CAN - J1939/CAN125/CAN250/CAN500/CAN1000 2nd CAN - J1939/CAN125/CAN250/CAN500/CAN1000 J1587/J1708 J1850 J2534 ISO 15765 (Diagnostic CAN) ISO 14230 (KWP2000 over ISO9141) ALDL ATEC 160 (160 baud) NEXIQ supportHeavy-Duty, Light-and Medium-Duty Trucks, CONSTRUCTION EQUIPMENT like (Wheel loader, Articulated Hauler and Excavator), Genset.FREE Heavy-Duty Truck Diagnostic Applications 1, VOLVO TRUCK: FM10, NH565, FH12, FM12, VHD, FH16, FM7, VN, WC, WG, WI, FH565, NH12, FL6, FL7, FL10, FL12, NH525, WX, COMP04, FE, VHD, FH, FM, VM, FM9, F10, F12 , F16, NL10, NL12,VOLVO BUSES: B10B, B10M, B10L, B10R, M10R, B12, B58, B6, B7R, OLYMPIAN, SUPEROLY2,VOLVO BUS:B12B,B12M,B12R,B6R,B7L,B7R,B9L,B9R,B9S,B9TL,PREVH,PREVX, 3,MACK TRUCKS:V-MAC I, V-MAC II, V-MAC III, V-MAC IV, Service Diagnostic 4,VOLVO CONSTRUCTION EQUIPMENT (CE): Wheel loader:L110E, L110F, L120E, L120F, L150E, L150F, L180E, L180F, L220E, L220F, L330E, L350F, L60E, L60F, L70E, L70F, L90E, L90F Articulated Hauler:A25D, A25E, A30D, A30E, A35D, A35E, A40D, A40E, T450D, Excavator:EC135B, EC140B, EC140C, EC160B, EC160C, EC180B, EC180C, EC210B, EC210C, EC235C, EC240B, EC240C, EC290B, EC290C, EC330B, EC330C, EC360B, EC360C, EC460B, EC460C, EC700C, EC700B, EC700C, ECR145C, ECR235C, ECR305C, EW140B, EW140C, EW145B, EW145C, EW160B, EW160C, EW180B, EW180C, EW200B, EW210C, FC2121C, FC2421C, FC2924C, FC3329C, PL4611 Grader:G710B, G720B, G726B, G730B, G740B, G746B, G780B, G930, G940, G946, G960 , G970, G976, G990 5,Navistar:ALL Diamond Logic Builder (DLB) ServiceMaxx 6,International:ALL Intune, MD32, 7,Freightliner:ALL ServiceLink:cascadia,century,columbia,Coronado,classic,FLDSD,4900FA, 4900SA,4900EX. 8,HINO:ENGINE:300SERIES, 500 SERIES, CR03_J08E, CR03_J05D, COMMONRAIL(J05E), J05D_US, J08E_US,P11C, VCS, Hibrid, Inverter, Brake(ABS), AT_45043LE 9,ISUZU_GMC:1996-1999 NPR Diesel and F Series Include, NPR/W 3500, NPR HD/W 4500, This is for 6.0L V-8 Gasoline Engines only, 7.8L 6HK1 Engine Isuzu: NPR, NPR HD, NQR, NRR, FTR, FVR, FXR with 6HK1 LG4 Engine, NPR, NPR HD, NQR, NRR with 5.2L (4HK1) or 3.0L (4JJ1) Diesel engine. 6.0L V-8 Gasoline Engine GM: W3500, W4500, W5500, WT5500, W5500 HD,with 5.2L Diesel Engine Only,T6500, T7500, T8500 nexiqnexiq-11nexiq-9nexiq-8nexiq-7 WE HAVE LAUNCH X431 GDS FOR HEAVY DUTY TRUCK SCANNER AND ALL KIND OF AUTO DIAGNOSTIC SCNANERS WWW.LAUNCHSCAN.COM 00923326886636

See product

Pakistan

NEXIQ 125032 USB Link + Software Diesel Truck Diagnose Full Set Super Truck Scanner Nexiq Feature: Compatible with applications that diagnose engines, transmissions, ABS, instrument panels and more. Reduce reprogramming times with direct USB connection Mixed fleet capabilities with broad protocol support Quick access to vehicle data for maintenance or management reports Quickly attaches to vehicle's diagnostic connector. Easy portability increases flexibility, May be used with desktop PC or laptop. NEXIQ 125032 USB Link packed software and application - Allison (Included!) - Bendix 6.3.8.0 (Included!) - Detroit Diesel DDDL 7.05 ((Included!) - Detroit Diesel DDCT (Included!) - Detroit Diesel Calibration Tool (Included!) - Eaton Service Ranger 3.2 (Included!) - International DLB (Included!) - International ICAP, IPTS, NETS, IPC (Included!) - International Master Diagnostic (Incluided!) - Meritor and Wabco Diagnostics (Included!) - Cummins Insite 7.5 (Included!) - Hino 2.0.3. (Included!) - Caterpillar 2.0.1.0 (Included!) - Perkins EST 2010B (Included!) - V Macks 2.6.12 (Included!) - V Macks Dealer Pro (Included!) - Volvo VCADS 2.35.10 (Included!) - Toyota Techstream for car (Included!) NEXIQ 125032 USB LinkAPI Support • RP1210A, RP1210B • J2534-2 • USB vehicle-to-PC connectivity, NEXIQ USB linke supports Windows xp and windows 7 32-bit and 64-bit and windows CE compliant Not all applications are included. If compatibility confirmation is required, more information is needed, or there are questions about an unlisted application, please contact us, a specialist will help you make the right choice. NEXIQ 125032 Protocol Coverage CAN - J1939/CAN125/CAN250/CAN500/CAN1000 2nd CAN - J1939/CAN125/CAN250/CAN500/CAN1000 J1587/J1708 J1850 J2534 ISO 15765 (Diagnostic CAN) ISO 14230 (KWP2000 over ISO9141) ALDL ATEC 160 (160 baud) NEXIQ supportHeavy-Duty, Light-and Medium-Duty Trucks, CONSTRUCTION EQUIPMENT like (Wheel loader, Articulated Hauler and Excavator), Genset.FREE Heavy-Duty Truck Diagnostic Applications 1, VOLVO TRUCK: FM10, NH565, FH12, FM12, VHD, FH16, FM7, VN, WC, WG, WI, FH565, NH12, FL6, FL7, FL10, FL12, NH525, WX, COMP04, FE, VHD, FH, FM, VM, FM9, F10, F12 , F16, NL10, NL12,VOLVO BUSES: B10B, B10M, B10L, B10R, M10R, B12, B58, B6, B7R, OLYMPIAN, SUPEROLY2,VOLVO BUS:B12B,B12M,B12R,B6R,B7L,B7R,B9L,B9R,B9S,B9TL,PREVH,PREVX, 3,MACK TRUCKS:V-MAC I, V-MAC II, V-MAC III, V-MAC IV, Service Diagnostic 4,VOLVO CONSTRUCTION EQUIPMENT (CE): Wheel loader:L110E, L110F, L120E, L120F, L150E, L150F, L180E, L180F, L220E, L220F, L330E, L350F, L60E, L60F, L70E, L70F, L90E, L90F Articulated Hauler:A25D, A25E, A30D, A30E, A35D, A35E, A40D, A40E, T450D, Excavator:EC135B, EC140B, EC140C, EC160B, EC160C, EC180B, EC180C, EC210B, EC210C, EC235C, EC240B, EC240C, EC290B, EC290C, EC330B, EC330C, EC360B, EC360C, EC460B, EC460C, EC700C, EC700B, EC700C, ECR145C, ECR235C, ECR305C, EW140B, EW140C, EW145B, EW145C, EW160B, EW160C, EW180B, EW180C, EW200B, EW210C, FC2121C, FC2421C, FC2924C, FC3329C, PL4611 Grader:G710B, G720B, G726B, G730B, G740B, G746B, G780B, G930, G940, G946, G960 , G970, G976, G990 5,Navistar:ALL Diamond Logic Builder (DLB) ServiceMaxx 6,International:ALL Intune, MD32, 7,Freightliner:ALL ServiceLink:cascadia,century,columbia,Coronado,classic,FLDSD,4900FA, 4900SA,4900EX. 8,HINO:ENGINE:300SERIES, 500 SERIES, CR03_J08E, CR03_J05D, COMMONRAIL(J05E), J05D_US, J08E_US,P11C, VCS, Hibrid, Inverter, Brake(ABS), AT_45043LE 9,ISUZU_GMC:1996-1999 NPR Diesel and F Series Include, NPR/W 3500, NPR HD/W 4500, This is for 6.0L V-8 Gasoline Engines only, 7.8L 6HK1 Engine Isuzu: NPR, NPR HD, NQR, NRR, FTR, FVR, FXR with 6HK1 LG4 Engine, NPR, NPR HD, NQR, NRR with 5.2L (4HK1) or 3.0L (4JJ1) Diesel engine. 6.0L V-8 Gasoline Engine GM: W3500, W4500, W5500, WT5500, W5500 HD,with 5.2L Diesel Engine Only,T6500, T7500, T8500 nexiqnexiq-11nexiq-9nexiq-8nexiq-7 WWW.LAUNCHSCAN.COM 00923326886636

Rs 70

See product

Pakistan

NEXIQ 125032 USB Link + Software Diesel Truck Diagnose Full Set Super Truck Scanner Nexiq Feature: Compatible with applications that diagnose engines, transmissions, ABS, instrument panels and more. Reduce reprogramming times with direct USB connection Mixed fleet capabilities with broad protocol support Quick access to vehicle data for maintenance or management reports Quickly attaches to vehicle's diagnostic connector. Easy portability increases flexibility, May be used with desktop PC or laptop. NEXIQ 125032 USB Link packed software and application - Allison (Included!) - Bendix 6.3.8.0 (Included!) - Detroit Diesel DDDL 7.05 ((Included!) - Detroit Diesel DDCT (Included!) - Detroit Diesel Calibration Tool (Included!) - Eaton Service Ranger 3.2 (Included!) - International DLB (Included!) - International ICAP, IPTS, NETS, IPC (Included!) - International Master Diagnostic (Incluided!) - Meritor and Wabco Diagnostics (Included!) - Cummins Insite 7.5 (Included!) - Hino 2.0.3. (Included!) - Caterpillar 2.0.1.0 (Included!) - Perkins EST 2010B (Included!) - V Macks 2.6.12 (Included!) - V Macks Dealer Pro (Included!) - Volvo VCADS 2.35.10 (Included!) - Toyota Techstream for car (Included!) NEXIQ 125032 USB LinkAPI Support • RP1210A, RP1210B • J2534-2 • USB vehicle-to-PC connectivity, NEXIQ USB linke supports Windows xp and windows 7 32-bit and 64-bit and windows CE compliant Not all applications are included. If compatibility confirmation is required, more information is needed, or there are questions about an unlisted application, please contact us, a specialist will help you make the right choice. NEXIQ 125032 Protocol Coverage CAN - J1939/CAN125/CAN250/CAN500/CAN1000 2nd CAN - J1939/CAN125/CAN250/CAN500/CAN1000 J1587/J1708 J1850 J2534 ISO 15765 (Diagnostic CAN) ISO 14230 (KWP2000 over ISO9141) ALDL ATEC 160 (160 baud) NEXIQ supportHeavy-Duty, Light-and Medium-Duty Trucks, CONSTRUCTION EQUIPMENT like (Wheel loader, Articulated Hauler and Excavator), Genset.FREE Heavy-Duty Truck Diagnostic Applications 1, VOLVO TRUCK: FM10, NH565, FH12, FM12, VHD, FH16, FM7, VN, WC, WG, WI, FH565, NH12, FL6, FL7, FL10, FL12, NH525, WX, COMP04, FE, VHD, FH, FM, VM, FM9, F10, F12 , F16, NL10, NL12,VOLVO BUSES: B10B, B10M, B10L, B10R, M10R, B12, B58, B6, B7R, OLYMPIAN, SUPEROLY2,VOLVO BUS:B12B,B12M,B12R,B6R,B7L,B7R,B9L,B9R,B9S,B9TL,PREVH,PREVX, 3,MACK TRUCKS:V-MAC I, V-MAC II, V-MAC III, V-MAC IV, Service Diagnostic 4,VOLVO CONSTRUCTION EQUIPMENT (CE): Wheel loader:L110E, L110F, L120E, L120F, L150E, L150F, L180E, L180F, L220E, L220F, L330E, L350F, L60E, L60F, L70E, L70F, L90E, L90F Articulated Hauler:A25D, A25E, A30D, A30E, A35D, A35E, A40D, A40E, T450D, Excavator:EC135B, EC140B, EC140C, EC160B, EC160C, EC180B, EC180C, EC210B, EC210C, EC235C, EC240B, EC240C, EC290B, EC290C, EC330B, EC330C, EC360B, EC360C, EC460B, EC460C, EC700C, EC700B, EC700C, ECR145C, ECR235C, ECR305C, EW140B, EW140C, EW145B, EW145C, EW160B, EW160C, EW180B, EW180C, EW200B, EW210C, FC2121C, FC2421C, FC2924C, FC3329C, PL4611 Grader:G710B, G720B, G726B, G730B, G740B, G746B, G780B, G930, G940, G946, G960 , G970, G976, G990 5,Navistar:ALL Diamond Logic Builder (DLB) ServiceMaxx 6,International:ALL Intune, MD32, 7,Freightliner:ALL ServiceLink:cascadia,century,columbia,Coronado,classic,FLDSD,4900FA, 4900SA,4900EX. 8,HINO:ENGINE:300SERIES, 500 SERIES, CR03_J08E, CR03_J05D, COMMONRAIL(J05E), J05D_US, J08E_US,P11C, VCS, Hibrid, Inverter, Brake(ABS), AT_45043LE 9,ISUZU_GMC:1996-1999 NPR Diesel and F Series Include, NPR/W 3500, NPR HD/W 4500, This is for 6.0L V-8 Gasoline Engines only, 7.8L 6HK1 Engine Isuzu: NPR, NPR HD, NQR, NRR, FTR, FVR, FXR with 6HK1 LG4 Engine, NPR, NPR HD, NQR, NRR with 5.2L (4HK1) or 3.0L (4JJ1) Diesel engine. 6.0L V-8 Gasoline Engine GM: W3500, W4500, W5500, WT5500, W5500 HD,with 5.2L Diesel Engine Only,T6500, T7500, T8500 nexiqnexiq-11nexiq-9nexiq-8nexiq-7 WWW.LAUNCHSCAN.COM 00923326886636

Rs 70

See product

Pakistan

AR807 Temperature Humidity Meter is an instrument used for measuring the moisture content in the atmosphere. Humidity measurement instruments usually rely on measurements of some other quantity such as temperature, pressure, mass or a mechanical or electrical change in a substance as moisture is absorbed. By calibration and calculation, these measured quantities can lead to a measurement of humidity. Modern electronic devices use changes in electrical capacitance or resistance to measure humidity differences. FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

See product