Huawei y511 white complete

Top sales list huawei y511 white complete

Latest Offers

Pakistan

After a small size Male tri colour beagle smaller than standard size,ideally pocket size or small legged. Must be K.C Registered and come with papers.Ideally Adult or 8months and over.Cash waiting can travel.,

Rs 200,0

See product

Pakistan

4 year old male beagle called 'Bizol' who is very sweet a little shy but once settled is very loving and friendly. He is great with other cats and dogs, he would be fine to be rehomed with older children purely as he's a little shy, He is cur....

Rs 200,0

See product

Pakistan (All cities)

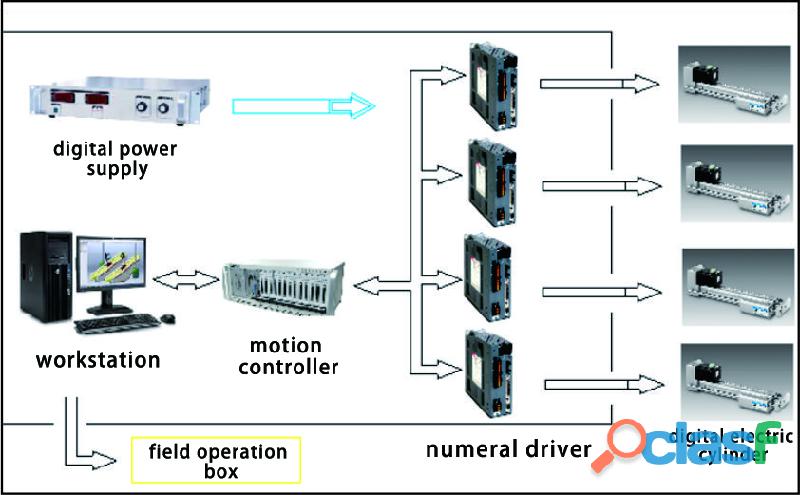

Overview In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting. The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached. During the production process, the adjustment of the mold’s width can be completed without stopping the machine. Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold. Only with adjustment and detection can the online adjustment range of the mold be accurately controlled. Fig 1 Mold online width adjustment system The components of the system Workstation: host system, system width adjustment control, taper detection. On-site operation box: real-time display of the current control status, manual operation to adjust parameters. Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control. On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time. Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment. FIG 2 System block diagram The technical parameters Adjustable range: 0-1250mm (unilateral) Control accuracy: 0.02mm/0.05mm/0.1mm Step resolution: 0.01mm/0.02mm Running speed: 0-10mm/s Power: 3.5KWl 16-bit encoder: 65536 pulses Weight: 25Kg Shell: high-strength aluminum alloy FIG 3 Syetem software interface The functions of the system Realize online width adjustment function Realize the online real-time monitoring function of mold taper Continuous casting production adjustment and non-stop production One-key operation in the main control room, automatic completion High adjustment accuracy and fast speed The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

Rs 0,0

See product

3 photos

Pakistan

2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds 2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds .....................2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds

Rs 4.000,0

See product

Pakistan (All cities)

Finding the best tyre shops near me, Sometimes it can be challange, especially when there are so many options available in the markets. Here, you can find a list of the trusted tyre shops where you can get the best deals and services, including new tyres, tyre repairs, or balancing services at affordable prices. Whether you're looking for quality tyres or expert maintenance, these shops offer reliable solutions to meet your needs. https://www.tradebrio.com/exporters/car-tyres.html

Free

See product

Pakistan (All cities)

Overview: LGK-S107 analog heat source instrument (heating tool) is independently developed and designed by Wuhan CenterRise M&C CO., Ltd. This instrument is a heating and testing equipment used to test the performance of the thermocouples installed in the mold in continuous casting machine. After the installation of the mold breakout prediction thermocouples completed, the analog heat source instrument is used to test these thermocouples before they go online. After the thermocouple is connected to the mold thermocouple detector, the current temperature of each thermocouple point will be displayed. By using our heating device to heat the copper plate point of each thermocouple at a fixed point, the thermocouple will have a synchronous temperature rise and then we can observe the temperature rise curve of the same column of temperature points to see whether the temperature measurement consistency of the column of thermocouples is consistent, so as to judge the overall status of thermocouples installed in the mold. If an abnormal point occurs, it needs to be repaired and replaced, so as to ensure the stable operation of the mold breakout prediction system. The working principle: The heating tool generates high heat by 220v alternating current and the electric heating element. The heat is transmitted to the copper plate of the mold through the copper head to simulate the heat source of molten steel, so that the thermocouples of the mold can sense the temperature change to achieve the purpose of calibrating the temperature measurement system. The composition: Walking trolley mechanism Preloader Pure copper heating contacts PID thermostat High power heating tube high power driver The parameters: Power supply: AC220V 50Hz Total power: 2200W Single point power: 300W Temperature control accuracy: 1°C Temperature control range: 0°C-500°C Common temperature range: 25°C-300°C Heating points: 3 (points can be customized) Heating method: heating tube heating Heating contact material: copper

Rs 0,0

See product

3 photos

Sialkot (Punjab)

Feeling intricacies in crafting a CDR application for Engineers Australia’s skills assessment? Do not worry; order CDR Writing Services in Pakistan for Engineers Australia. It is the best-known online writing assistance for CDR applicants in Pakistan. CDRAustralia.Org offers such commendable support to meet aspirants' requirements. The service comprises a complete CDR package from selecting projects to writing career episodes, a summary statement, a CPD statement, and a resume. To guide candidates in framing an EA-acceptable competency assessment report, a brilliant team of professional writers is awaiting. Expert writers offer comprehensive assistance to make the report extraordinary so that it can catch EA’s attention and undergo successful assessment. Hire top experts at CDR Australia and relieve all your writing woes. Hired native writers offer CDR support tailored to your requirements and meet all Engineers Australia standards. If you seek any information regarding the services, contact our experts free of cost by visiting the website. Contact Detail: Website: https://cdraustralia.org/pk/ Mail at: Contact@CDRAustralia.Org WhatsApp: +61-291917405

Rs 2.784.000.000,0

See product

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

Rs 0,0

See product

Pakistan

Our amazing litter was born on 18th of December mum is stunning tri colour and dad is a lemon and white tri both pedigrees dad has five generations blood line with his papers to prove. We have a litter of 9 chunky playful pups all wormed and....

Rs 200,0

See product

Pakistan

THE AMAZING HUGO & BOSS ARE LOOKING FOR THEIR FOREVER HOME. BOTH BOYS ARE LILAC IN COLOUR BUT ARE CARRIERS OF TAN POINTS WHICH IS THE AT GENE,DNA IS dd/bb/AT. PUPS ARE REALLY SHORT AND COBBY. GREAT CONFIRMATION, THE BEST WAY TO DESCRIBE THESE....

Rs 200,0

See product

Lahore (Punjab)

SEO Training in Lahore offers comprehensive courses designed to equip individuals with the skills needed to excel in search engine optimization. Whether you're a beginner or looking to enhance your existing knowledge, our training programs cover everything from basic SEO principles to advanced strategies. You will learn keyword research, on-page and off-page optimization, technical SEO, content marketing, and the latest SEO tools and techniques. Our experienced instructors provide hands-on training with real-world examples, ensuring you can apply what you've learned immediately. The course also includes case studies, projects, and practical

Free

See product

2 photos

Pakistan (All cities)

Buy the best herbal supplements & medications in USA online at affordable price. Get free delivery across all states. Order Now!

Rs 30.650,0

See product

Pakistan (All cities)

Topper Smart Bidet Tiolet Seat Co., Ltd. (https://www.mfrsbidet.com/) is a professional and experienced smart toilet & bidet manufacturer and supplier, specializing in diversifying our bidet products to suit a range of different needs. We are capable of providing toilet bidets, bidet attachments, bidet seats, toilet seat covers, bidet sprayers, portable bidets and other bidet fittings, and offering practical and personalized sanitary solutions for our customers. Over the years, we have been consistent in supplying high-quality products and thoughtful services. Every stage in the production is guided and supervised by skilled professionals and our quality control systems. Our bidet products all meet tangible and intangible requirements in terms of quality and safety. From the design and development of products to the user experience, we are never slackening our effort, and still trying our best to improve your life quality. Convenience, comfort and superior quality are the ideas we want to convey through our bidets and services. In the future, we will continue to strengthen our capability of design and innovation to better satisfy the demands of the market and create the best home life experience for customers. If you're interested in our bidets, please visit https://www.mfrsbidet.com/.

Rs 200,0

See product

6 photos

Pakistan

KC BRITISHPRIDE BRED English Bulldog Hes The son of Britishpride Royal Ascot. available for STUD. HE IS A PROVEN STUD DOG producing quality puppies.

Free

See product

Pakistan (All cities)

We have the Outboard Boat Engine OXE. Yamaha We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 150.000,0

See product

2 photos