Gigaset box dual

Top sales list gigaset box dual

Latest Offers

Bela (Balochistan)

Looking for Unique Personalized Gifts in India? Look no further than www.indiaflowersgifts.com! We specialize in crafting one-of-a-kind gifts that are sure to impress your loved ones. From photo frames to customized mugs and cushions, we offer a wide array of options that can be personalized to make your gift stand out. Our service allows you to Send Customized Gifts to India with ease. Simply visit our website, select your favorite item, and personalize it with photos, names, or messages that ignite a special memory. Whether it's a birthday, anniversary, or any special occasion, our gifts are perfect for every celebration. With Personalized Gifts Online Delivery in India, you can have your unique gifts delivered right to the recipient's doorstep. Our reliable delivery network ensures that your gift reaches its destination on time and in perfect condition. Plus, with secure payment options and excellent customer support, shopping with us is a breeze.Source:www.indiaflowersgifts.com/personalized-gifts.asp

Rs 500,0

See product

Pakistan (All cities)

China Metal Parts Forging OEM Manufacturer Co., Ltd. (https://www.creatorcomponents.com/) was founded in 2000 by a team of experienced professionals in the forging industry. As a Chinese manufacturer, we specialize in providing high-quality carbon steel and alloy steel metal parts and components for a wide variety of industries. We focus on innovation and engineering excellence to ensure that we meet the highest standards of quality and performance. By utilizing advanced technology and state-of-the-art equipment, we produce products that are durable and reliable, meeting the requirements of both domestic and international customers. Quality is a top priority at every stage of our production process. From inspecting raw materials to conducting 100% final product testing, we ensure all products comply with international standards through our thorough quality control system. As a Chinese manufacturer, we offer customized metal parts to cater to the specific needs of industries such as automotive, construction, and energy. We collaborate closely with clients to deliver tailored solutions that align with their business objectives. At China Metal Parts Forging OEM Manufacturer Co., Ltd., we are dedicated to providing innovative, sustainable solutions and excellent customer service, earning the trust of businesses worldwide as a reliable partner.

Free

See product

4 photos

Pakistan (All cities)

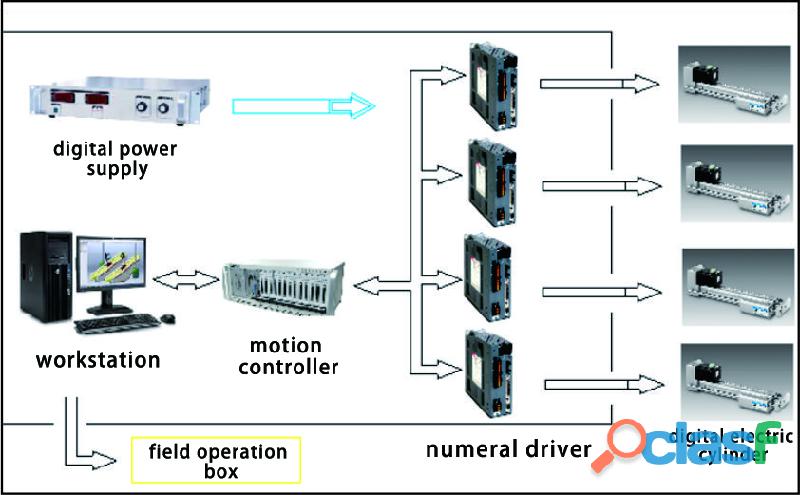

Overview In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting. The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached. During the production process, the adjustment of the mold’s width can be completed without stopping the machine. Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold. Only with adjustment and detection can the online adjustment range of the mold be accurately controlled. Fig 1 Mold online width adjustment system The components of the system Workstation: host system, system width adjustment control, taper detection. On-site operation box: real-time display of the current control status, manual operation to adjust parameters. Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control. On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time. Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment. FIG 2 System block diagram The technical parameters Adjustable range: 0-1250mm (unilateral) Control accuracy: 0.02mm/0.05mm/0.1mm Step resolution: 0.01mm/0.02mm Running speed: 0-10mm/s Power: 3.5KWl 16-bit encoder: 65536 pulses Weight: 25Kg Shell: high-strength aluminum alloy FIG 3 Syetem software interface The functions of the system Realize online width adjustment function Realize the online real-time monitoring function of mold taper Continuous casting production adjustment and non-stop production One-key operation in the main control room, automatic completion High adjustment accuracy and fast speed The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

Rs 0,0

See product

3 photos

Pakistan (All cities)

GoLogica offers complete online training in data modeling that gives professionals the understanding and skills they need to understand data modeling methods. IT specialists, database developers, business analysts, and data analysts who want to become better in creating and managing data structures may benefit from this course. Basic topics covered in the course include entity-relational diagrams (ERDs), data mapping, normalization strategies, and abstract, logical, and physical data modeling. It also covers database design concepts, demonstrating how to build durable, scalable, and effective data models that correspond with business goals. This course, led by industry experts, gives participants practical knowledge through practical assignments, allowing them to apply what they've learned in actual situations. Whether you're new to data modeling or want to improve your existing skills, GoLogica Data Modeling Online Training provides a solid basis for creating and managing successful data models. Enroll in GoLogica Data Modeling Online Training today to obtain the knowledge you need to boost your career in data management and become a certified Data Modeling expert!

Rs 0,0

See product

Askoley (Northern Areas)

Buy Verified Cash App Accounts https://buy5stareviewer.com/product/buy-verified-cash-app-accounts/ As it acquires clients, verified accounts become essential for businesses and individuals to fully access its features. A verified Cash App account allows you to send, receive, and withdraw substantial amounts of money, making it ideal for entrepreneurs, freelancers, and investors. The verification process ensures that the account is legitimate, reducing the risk of fraud and providing peace of mind for users. Verified Cash App accounts offer several advantages. Firstly, they enable higher transaction limits, allowing users to manage larger sums of money. This is particularly beneficial for businesses that need to process significant payments. Secondly, verified accounts provide enhanced security features, such as two-factor authentication, which helps protect against unauthorized access. Lastly, having a verified account can improve your credibility and trustworthiness when dealing with clients or customers. When purchasing a verified Cash App account, it is crucial to choose a reputable source. Look for sellers who offer guarantees of authenticity and provide excellent customer service. Conduct thorough research and read reviews to ensure you are making a safe and reliable purchase. Contact Info:: Telegram:@BBuy5stareviewer WhatsApp :+1(470) 745-6499 Skype :Buy5stareviewer live:.cid.e4c6455dd0c7f99e Email:buy5stareviewer@gmail.com

Rs 250,0

See product

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos

Pakistan (All cities)

Buy the best herbal supplements & medications in USA online at affordable price. Get free delivery across all states. Order Now!

Rs 30.650,0

See product

Pakistan (All cities)

Get the best nail polish services in Hyderabad at Kameleon Salon, from classic manicures to gel finishes.

Free

See product

Pakistan (All cities)

The Energy-Efficient Single Phase Oil Cooled Servo Stabilizer provides reliable voltage stabilization for homes and offices, protecting sensitive electronics and appliances from voltage fluctuations. Featuring an advanced oil cooling system, it ensures efficient heat dissipation and prolonged lifespan. With low energy consumption, it offers cost-effective power protection, making it the ideal solution for stable and uninterrupted electricity flow. https://voltsine.in/product/single-phase-oil-cooled-servo-stabilizer/

Free

See product

Pakistan (All cities)

Laser cutting machines have transformed the design and fabrication industries, unlocking a new realm of creative possibilities. With their ability to cut and engrave materials with precision and speed, these machines are not just tools—they are catalysts for innovation. Whether in architecture, fashion, art, or product design, laser cutters have become an essential tool for turning ideas into reality. https://www.tradebrio.com/exporters/laser-cutting-machines.html

Free

See product

Karachi (Sindh)

CCTV Market specializes in offering premium CCTV security systems for homes as well as businesses. With over 10+ years of experience and a solid reputation for happy customers, we provide affordable solutions that are customized to meet your security needs. To guarantee you get the highest level of service possible, our knowledgeable staff takes care of everything from CCTV system design and installation to maintenance and repairs. We are your one stop shop for easily CCTV security since we place a high priority on quality in both our goods and services. For dependable and effective CCTV installation and repair, rely on CCTV Market right now.

Rs 150,0

See product

Pakistan (All cities)

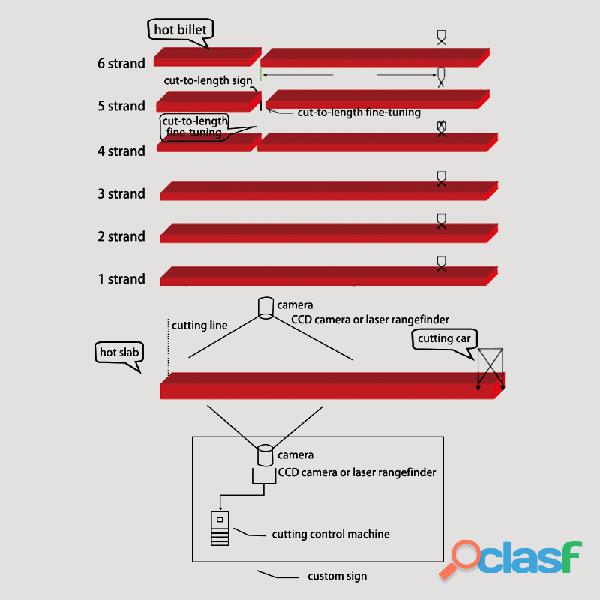

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

Rs 0,0

See product

Pakistan (All cities)

We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 1.000,0

See product

2 photos

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

Rs 0,0

See product

Pakistan (All cities)

ISO Certification in Kuwait is essential for businesses aiming to improve their credibility, efficiency, and market competitiveness. Achieving ISO Certification in Kuwait offers a standardized management system that supports organizations streamline processes, improve product quality, and ensure customer satisfaction. Additionally, ISO Certification in Kuwait demonstrates a commitment to international best practices, which is crucial in a globalized market. For businesses looking to expand internationally, ISO Certification in Kuwait is a significant advantage, as many clients and countries prefer or require ISO-certified partners. In Kuwait’s growing economy, ISO Certification in Kuwait serves as a key differentiator, fostering trust and reliability among clients and stakeholders. Quality Sistema Certifications & Inspections Pvt. Ltd. is one of the leading Global Organization, providing ISO Certifications, Inspection, Assurance & Auditing Services for industries with competence and transparency to build trust across the global industries. We are a team of highly specialized experts and industry professionals who working towards a sustainable business growth. #ISO 9001 Certification KuwaiT,#ISO Certification in Kuwait #iso 9001,ISO 9001 Certification Kuwait

Free

See product