Fresh cutt piece print

Top sales list fresh cutt piece print

Latest Offers

Pakistan (All cities)

Topper Smart Bidet Tiolet Seat Co., Ltd. (https://www.mfrsbidet.com/) is a professional and experienced smart toilet & bidet manufacturer and supplier, specializing in diversifying our bidet products to suit a range of different needs. We are capable of providing toilet bidets, bidet attachments, bidet seats, toilet seat covers, bidet sprayers, portable bidets and other bidet fittings, and offering practical and personalized sanitary solutions for our customers. Over the years, we have been consistent in supplying high-quality products and thoughtful services. Every stage in the production is guided and supervised by skilled professionals and our quality control systems. Our bidet products all meet tangible and intangible requirements in terms of quality and safety. From the design and development of products to the user experience, we are never slackening our effort, and still trying our best to improve your life quality. Convenience, comfort and superior quality are the ideas we want to convey through our bidets and services. In the future, we will continue to strengthen our capability of design and innovation to better satisfy the demands of the market and create the best home life experience for customers. If you're interested in our bidets, please visit https://www.mfrsbidet.com/.

Rs 200,0

See product

6 photos

Kandhura (Federally Administered Tribal Areas)

Eagle Racking India is a leading provider of high-quality mezzanine floor in Lucknow, offering cost-effective and space-efficient solutions for warehouses, factories, and commercial establishments. Our mezzanine floors are designed to maximize vertical space utilization, providing an additional floor without the need for expensive building expansions. Constructed with heavy-duty steel and premium-quality materials, our mezzanine floors ensure durability, strength, and safety. They can be customized to meet specific load-bearing capacities and operational requirements, making them ideal for storage, office setups, and retail spaces. Read more: https://eagleracking.com/lucknow/mezzanine-floor

Rs 0,0

See product

Ahmadpur East (Punjab)

Sunshine Pest Control Pvt. Ltd offers expert waterproofing services to protect your home or business from water damage. We specialize in terrace, basement, and bathroom waterproofing using high-quality materials and proven techniques. Our solutions ensure long-lasting protection against leaks, dampness, and seepage. Choose our reliable services to keep your property dry, safe, and damage-free. Get in touch today for a free site inspection. Visit For More: https://pestcontrolsunshine.com/waterproofing-services/

Free

See product

Lahore (Punjab)

SEO Training in Lahore offers comprehensive courses designed to equip individuals with the skills needed to excel in search engine optimization. Whether you're a beginner or looking to enhance your existing knowledge, our training programs cover everything from basic SEO principles to advanced strategies. You will learn keyword research, on-page and off-page optimization, technical SEO, content marketing, and the latest SEO tools and techniques. Our experienced instructors provide hands-on training with real-world examples, ensuring you can apply what you've learned immediately. The course also includes case studies, projects, and practical

Free

See product

2 photos

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product

Pakistan

Our amazing litter was born on 18th of December mum is stunning tri colour and dad is a lemon and white tri both pedigrees dad has five generations blood line with his papers to prove. We have a litter of 9 chunky playful pups all wormed and....

Rs 200,0

See product

Multan (Punjab)

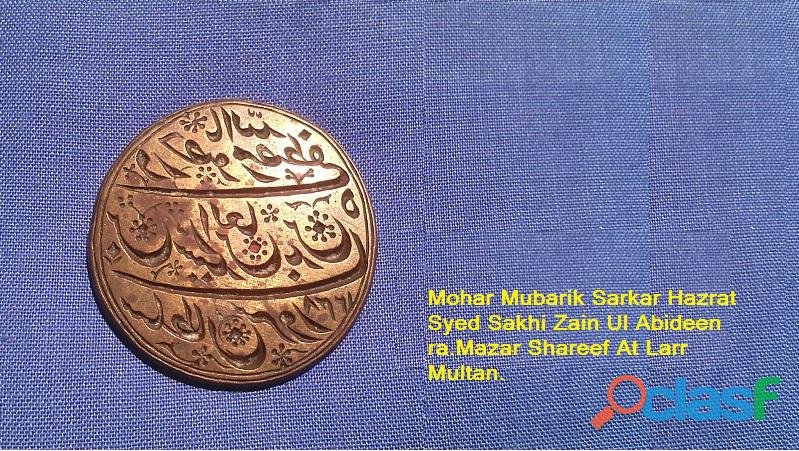

Hazrat Syed Sakhi Zain ul Abideen (RA) migrated from Baghdad to Saudi Arabia and spent 22 years in Madina Munawara.One night, holy Prophet hazrat Mohammad (may peace be upon him) appeared in a dream and instructed him to go to India, convince the people to the right path, preach or spread the teachings of Islam.Obeying the orders of the holy Prophet Hazrat Mohammad (may peace be upon him), the Sufi Saint left Madina Munawara and came to Shahkot. The Sufi saint is the father of a famous Sufi Hazrat Syed Ahmad Sultan, known as Sakhi Sarwar, the bountiful Chief, shrine at Sakhi Sarwar Pakistan. Hazrat syed sakhi Zain ul Abideen (RA) practised austerities and prayers in shahkot, The great renowned Sufi saints paternal genealogy is directly related ten generation up with Ameer ul Momeneen (commander of faithful) Hazrat Imam Ali Ibne Abu Talib R.A, thus he was a direct descendant of the holy Prophet Hazrat Mohammad (may peace be upon him). The name Zain ul Abideen was selected by his father Syed Umar due to the deep love and devotion with Imam Zain ul Abideen (A.S). Specification. Object Name: Seal stamp Description: Syed Zain ul Abideen Shah"Sultan Sarwar" Inscription Script : Arabic Inscription Technique: Engraved Date Period: A D 13th Century 1248 Time period: A D 13th Century Geography: Indian Subcontinent (Central Asia) Culture/period: Islamic Condition: Excellent Relics of the Islamic saints strengthens spiritual beliefs, inspire people and give them comfort in tough times. The holy seal is a precious asset handed down from generation to generation, extremely rare and a genuine masterpiece regarding the sacred relics of the early Islāmic saints.

Rs 100,0

See product

Pakistan (All cities)

We have the Outboard Boat Engine OXE. Yamaha We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 150.000,0

See product

2 photos

Pakistan (All cities)

Laser cutting machines have transformed the design and fabrication industries, unlocking a new realm of creative possibilities. With their ability to cut and engrave materials with precision and speed, these machines are not just tools—they are catalysts for innovation. Whether in architecture, fashion, art, or product design, laser cutters have become an essential tool for turning ideas into reality. https://www.tradebrio.com/exporters/laser-cutting-machines.html

Free

See product

Islamabad (Islamabad Capital Territory)

Starting a bakery business is thrilling, but success requires the proper equipment. The instruments you select will not only help you make high-quality baked items, but will also streamline your operations, increasing your bakery's efficiency and profitability. Here's a list of the basic bakery equipment from the Bakery Machinery Manufacturers, you'll require to get started the Successful Bakery Business. https://www.tradebrio.com/exporters/bakery-machinery.html

Rs 100,0

See product

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

Rs 0,0

See product

Gujrat (Punjab)

Jaipur, a city celebrated for its heritage and craftsmanship, is home to some of the finest Sheesham wood bed manufacturers. Sheesham wood, known for its strength, durability, and stunning natural grain patterns, is the ideal material for crafting high-quality beds that combine functionality with timeless beauty. Why Choose Sheesham Wood Beds? Durability: Sheesham wood is incredibly strong and resistant to wear, ensuring a long-lasting bed. Elegant Design: The rich textures and natural grain of Sheesham add a luxurious and earthy charm to any bedroom. Customizable Options: Jaipur manufacturers offer bespoke designs to suit your space and style preferences, from traditional carved beds to sleek modern styles. Eco-Friendly Choice: Many manufacturers use sustainably sourced Sheesham wood, supporting environmentally responsible practices. Types of Sheesham Wood Beds Available: Standard Beds: Classic designs suitable for any bedroom decor. Storage Beds: Functional beds with built-in storage to maximize space. Platform Beds: Minimalist and contemporary designs for a modern look. Poster Beds: Elegant four-poster beds that bring a royal touch to your space. Customized Beds: Tailored designs to fit specific dimensions and styles. Why Choose Sheesham Wood Bed Manufacturers in Jaipur? Jaipur’s Sheesham wood bed manufacturers are known for their impeccable craftsmanship, attention to detail, and the ability to deliver high-quality products. With a focus on both aesthetics and functionality, they ensure each bed is not only a piece of furniture but also a work of art. Explore the collections from Jaipur’s top Sheesham wood bed manufacturers and bring home a bed that combines luxury, comfort, and durability for a perfect night’s rest.

Rs 54.651,0

See product

2 photos

Pakistan

due to a change in personal circumstances and a increase in work hours i am unfortunatly having to look for a new home for my four year old female beagle, jessie. Jessie has been spayed and is a member of the family it has been a very difficu....

Rs 200,0

See product

Lahore (Punjab)

Apple Hair Color Price In Pakistan - Quickon.pk Apple Hair Color Price In Pakistan is a hair dye product designed to provide vibrant, long-lasting color while maintaining the health and integrity of your hair. This product is formulated to offer rich, natural-looking color with the added benefits of conditioning and nourishing ingredients. What is Apple Hair Color Price In Pakistan? Apple Hair Color Price In Pakistan is a professional-quality hair dye that offers a wide range of shades to suit different hair types and preferences. The formula is enriched with conditioning agents and natural extracts that help protect and nourish the hair during the coloring process. It is designed to deliver vibrant, long-lasting color with a natural finish. https://quickon.pk/product/apple-hair-color-price-in-pakistanhttps://quickon.pk/product/feg-plus-hair-growth-sprayhttps://quickon.pk/product/sardar-jee-hair-color-gel-price-in-pakistan

Rs 3.500,0

See product

Pakistan (All cities)

Overview: In the steelmaking production process, the ladle is the key equipment for holding molten steel, secondary refining, and continuous pouring. In a modern steelmaking plant, refractory materials are required for converters, refining, and ladles. In the steelmaking process, ladle is the main equipment for using and consuming refractory materials. Improving the service life of ladles and reducing refractory consumption is the key technology for steelmaking plants to save costs and reduce energy consumption for green production. In order to ensure the orderly operation of the ladle, save the consumption of refractory materials, prolong the service life of the ladle, and ensure the safe operation of the ladle, Wuhan CenterRise M&C Engineering CO. developed and launched the LDT-N200 integrated management system for the ladle. Introduction: LDT-N200 ladle integrated management system integrates LDT-L200 ladle lining thickness gauge, TBP-S300 ladle, tundish baking temperature and leakage monitoring system, RFD -C100 metallurgical electronic positioning system, and also integrates SQL Server database and NeuralWare (American computer software company) neural network software NeuralWorks to realize intelligent and optimized management of ladles. LDT-L200 ladle lining thickness gauge uses a laser area array scanning sensor to accurately measure the real-time thickness of the ladle lining, calculate the lining loss, and predict the service life of the ladle. TBP-S300 ladle, tundish baking temperature and leakage monitoring system uses infrared thermal imaging camera and embedded armor wire system to comprehensively monitor and prevent ladle leakage. RFD-C100 metallurgical electronic positioning system installs RFID electronic tags on all ladles to realize full-time and full-space ladle positioning and tracking. LDT-S200 ladle optimization control and analysis software, based on SQL Server database, B/S network structure, realizes online management of ladles, and adopts BP neural network system to realize intelligent optimization control of ladles. LDT-N200 ladle integrated management system can realize ladle age management based on ladle lining data and neural network algorithm, safety process control of ladle turnover and use, full-time tracking management of steelmaking production and full-space tracking management of ladle use and provide optimal control and management of steelmaking production and ladle maintenance. Comprehensive ladle measurement and monitoring, ladle positioning and management, and data management and optimization enable the LDT-N200 ladle integrated management system to fully realize ladle entire process management, optimize the service life of ladles, and comprehensively reduce the cost of refractory materials. The features: Using a lining thickness gauge to measure the thickness of the ladle lining Using infrared thermal imaging camera/embedded armor wire to realize ladle leakage detection Using RFID/number plate recognition to realize the location management of ladles Ladle age management system based on overall tracking Overall (full-time full-space) ladle management system based on database Provide overall production scheduling data Using neural network to predict ladle service life based on big data Ladle Optimal Scheduling System based on database and ladle service life Increase the service life of ladle by 12%-20% Reduce the use of refractory materials more than 15% Realize orderly management of ladle baking Realize full space and full time domain control Reduce the costs of ladle management and maintenance Improve the efficiency of ladle turnover operation

Rs 0,0

See product