Forever lighter

Top sales list forever lighter

Latest Offers

Islamabad (Islamabad Capital Territory)

Starting a bakery business is thrilling, but success requires the proper equipment. The instruments you select will not only help you make high-quality baked items, but will also streamline your operations, increasing your bakery's efficiency and profitability. Here's a list of the basic bakery equipment from the Bakery Machinery Manufacturers, you'll require to get started the Successful Bakery Business. https://www.tradebrio.com/exporters/bakery-machinery.html

Rs 100,0

See product

Karachi (Sindh)

CCTV Market specializes in offering premium CCTV security systems for homes as well as businesses. With over 10+ years of experience and a solid reputation for happy customers, we provide affordable solutions that are customized to meet your security needs. To guarantee you get the highest level of service possible, our knowledgeable staff takes care of everything from CCTV system design and installation to maintenance and repairs. We are your one stop shop for easily CCTV security since we place a high priority on quality in both our goods and services. For dependable and effective CCTV installation and repair, rely on CCTV Market right now.

Rs 150,0

See product

Sialkot (Punjab)

Feeling intricacies in crafting a CDR application for Engineers Australia’s skills assessment? Do not worry; order CDR Writing Services in Pakistan for Engineers Australia. It is the best-known online writing assistance for CDR applicants in Pakistan. CDRAustralia.Org offers such commendable support to meet aspirants' requirements. The service comprises a complete CDR package from selecting projects to writing career episodes, a summary statement, a CPD statement, and a resume. To guide candidates in framing an EA-acceptable competency assessment report, a brilliant team of professional writers is awaiting. Expert writers offer comprehensive assistance to make the report extraordinary so that it can catch EA’s attention and undergo successful assessment. Hire top experts at CDR Australia and relieve all your writing woes. Hired native writers offer CDR support tailored to your requirements and meet all Engineers Australia standards. If you seek any information regarding the services, contact our experts free of cost by visiting the website. Contact Detail: Website: https://cdraustralia.org/pk/ Mail at: Contact@CDRAustralia.Org WhatsApp: +61-291917405

Rs 2.784.000.000,0

See product

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

Rs 0,0

See product

Pakistan (All cities)

Laser cutting machines have transformed the design and fabrication industries, unlocking a new realm of creative possibilities. With their ability to cut and engrave materials with precision and speed, these machines are not just tools—they are catalysts for innovation. Whether in architecture, fashion, art, or product design, laser cutters have become an essential tool for turning ideas into reality. https://www.tradebrio.com/exporters/laser-cutting-machines.html

Free

See product

Pakistan

i have a variety of beautiful, yellow, white, red, yellow/green canaries for sale. male and female. you can get them separately or in pairs! lovely gift for anybody. prices range from £25 and above. offers can be made, when you come to view the birds.

Rs 4.000,0

See product

Pakistan (All cities)

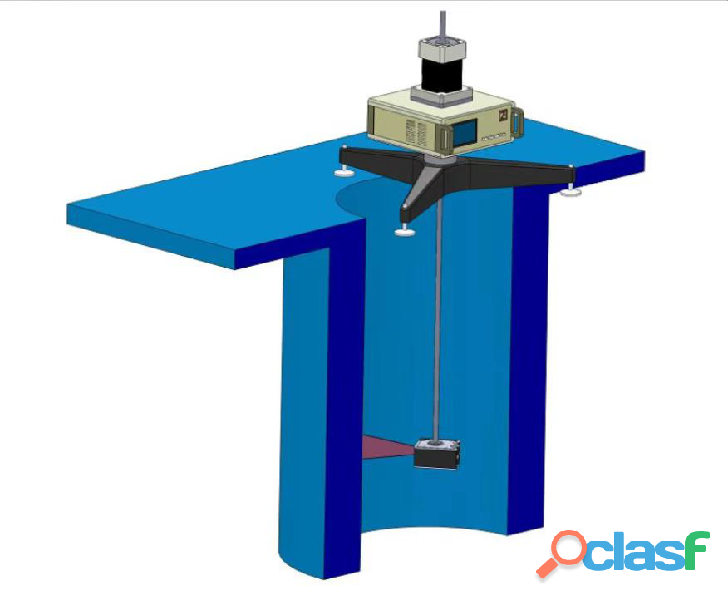

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Pakistan

4 year old male beagle called 'Bizol' who is very sweet a little shy but once settled is very loving and friendly. He is great with other cats and dogs, he would be fine to be rehomed with older children purely as he's a little shy, He is cur....

Rs 200,0

See product

Pakistan

I have available 2 stunning BSH blue kittens. 1 girls and 1 boys. Mum and dad are beautiful blues and are GCCF registered. Mum has a wonderful personality, she is friendly and extremely loving. she has an excellent 4 generations pedigree.

Rs 5.000,0

See product

Pakistan (All cities)

Wedding Cards Manufacturing in Pakistan, Pakistani Wedding Cards, Wedding Cards from Pakistan, Favour Boxes Pakistan, Nikkah Boxes Pakistan, Bid Box Pakistan, Bidh Box Pakistan, Customized Wddding Cards Pakistan, Wedding Cards Lahore, Wedding Cards Pakistan, Acrylic Wedding Cards, Wax Stamp Wedding Cards, Bes Cards https://cardnboxes.com/

Rs 100,0

See product

Pakistan

KC BRITISHPRIDE BRED English Bulldog Hes The son of Britishpride Royal Ascot. available for STUD. HE IS A PROVEN STUD DOG producing quality puppies.

Free

See product

Pakistan

We have 6 kittens that will be available as pets, they will be ready to leave home on 7 April 2016. There are 3 boys and 3 girls. Silver spotted and Brown spotted. Mum is a gorgeous Silver Marbled F6 and Dad is a stunning tarnish free Silver spotted boy. If you are interested in these babies, please contact me as there is always a great demand for these babies from this pairing. They always make fabulous big kittens and this is probably the last time that these two are paired together due to the age of Oliver. Viewings start at 8 weeks of age after their 1st vaccination when we will require a non-refundable deposit to secure your kitten. We can also early neuter your boys before they leave us, this will be chargeable, please ask us about this. Individual photos will be taken in a few weeks when kittens are weaning. Please note that some of the kittens are in the fuzzies so markings will not clear for a few weeks yet: Beige Collar - Cool Brown Boy Blue Collar - Silver Boy Green Collar - Silver Boy Purple Collar - Brown Girl Yellow Collar - Stunning Cool Brown Girl Pink Collar - Silver Girl

Rs 5.000,0

See product

Kandhura (Federally Administered Tribal Areas)

Eagle Racking India is a leading provider of high-quality mezzanine floor in Lucknow, offering cost-effective and space-efficient solutions for warehouses, factories, and commercial establishments. Our mezzanine floors are designed to maximize vertical space utilization, providing an additional floor without the need for expensive building expansions. Constructed with heavy-duty steel and premium-quality materials, our mezzanine floors ensure durability, strength, and safety. They can be customized to meet specific load-bearing capacities and operational requirements, making them ideal for storage, office setups, and retail spaces. Read more: https://eagleracking.com/lucknow/mezzanine-floor

Rs 0,0

See product

Pakistan (All cities)

Dev Technosys offers cutting-edge News App Development Services, delivering customized solutions with advanced features like real-time updates and smooth navigation. Our expert team specializes in News App Designing, creating user-friendly and visually appealing interfaces. Get reliable, scalable, and performance-driven News App Solutions tailored to meet your business goals. Visit: https://devtechnosys.com/news-app-development.php

Rs 0,0

See product

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product