F10 ful

Top sales list f10 ful

Latest Offers

Pakistan (All cities)

The Veritable Calfskin store bring another Superstar Outfit Fur B-26 Shearling Aircraft Cowhide Coat. This Coat has been made by genuine quality Calfskin and has jazzy Fur Straight Style Collar https://aajacketmaker.com/product/b-26-shearling-fur-jacket/

Rs 70.000,0

See product

Pakistan (All cities)

Overview The mold is a device that shapes the cast product in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of the mould oscillation deflection detection instrument is to detect the the mould oscillation table’s oscillation frequency, amplitude, deflection rate, phase, oscillation trajectory curve, etc. Through the detection and adjustment of the detection instrument, the mold moves along the outer arc of the continuous casting machine according to the set amplitude, frequency and waveform deflection characteristics. The actual oscillation parameters of the mold oscillation table during the production process and the process parameters of the cast products cannot be effectively known without the data detection of the mold deflection detection instrument, so that the operator cannot adjust the mould’s production process parameters in real time according to the real-time situation of the on-site production. The continuous casting mold deflection detection instrument independently developed by our company is suitable for various molds such as slab, square billet, round billet and shaped billet. The system obtains the process parameters such as actual oscillation holographic parameters and negative slip amount of the oscillation table by effectively detecting the movement of the mold. The technicians can formulate the control strategy of the mould according to these actual parameters, and improve the output and quality of the product within a safe and reliable range. The structure of the instrument Continuous casting mold oscillation and deflection detection instrument is mainly composed of sensor system, sensor signal conditioning circuit, power supply circuit, synchronous data acquisition module, communication cable, and software data analysis system. There are three axial acceleration sensors installed in the mold oscillation and deflection detection instrument, one of which is to detect the vertical oscillation signal (Y axis), and the other two are to detect the horizontal oscillation signal (X and Z axis). The signal obtained by the sensor is processed by the preprocessor and the preprocessing module. The oscillation signal and sensor status signal will be filtered and normalized, sent to the synchronous data collector for digitization and feature extraction, and the data is analyzed and processed by the master computer software to obtain various oscillation parameters and process parameters required by users. The functions of the system 1. Adopting mould oscillation X/Y/Z three-dimensional data acquisition, using high-precision sensor system and high-sensitivity axial accelerometer, comprehensive detection of equipment oscillation state, including: 1) Detect the oscillation frequency of the mold oscillation table 2) Detect the amplitude of the mold oscillation table 3) Detect the deflection rate of oscillation 4) Detect the lateral deflection, longitudinal deflection, phase, and phase difference of the mold oscillation table 5) Three-dimensional display of the oscillation trajectory, and the oscillation table trajectory can be viewed from 6 sides of the oscillation table (X-Y, X-Z, Z-Y) 2. The software system adopts the design of man-machine interactive graphic interface, which can display the mold oscillation state in real time. The software functions include: 1) Real-time data curve display: oscillation waveform, oscillation frequency, signal superposition analysis 2) Single-axis curve display, multi-axis curve display, amplitude, acceleration, three-dimensional graph 3) View historical curve 4) Generate test report 5) Give a warning prompt 6) Spectrum analysis function 7) Long-term storage of data 3. Portable measurement method, which can provide handheld detection equipment with wireless remote transmission, and the operation is simple. 4. Provide an overview of inspection parameters under the full screen, displaying all data including oscillation parameters and process parameters. At the same time, the calculation and display of the oscillation spectrum is completed in real time, which is used to evaluate the frame loss of the waveform , and to determine whether there is a problem with the installation of the oscillation device. 5. Alarm management. Record each alarm data under real-time alarm conditions to analyze the cause of the alarm and evaluate the impact of the alarm on production. 6. Parameter setting. Users can set the ideal oscillation value and normal working range of various steels online. We also can set the alarm limit, and the storage time of the database etc. 7. After charging the device once, it can work continuously for more than four hours. 8. Integrate embedded processing equipment to realize data collection, display, analysis, reporting and other functions. 9. According to the mold characteristics and user requirements, it can be flexibly configured, wich is suitable for all types of molds such as square billets, slabs, round billets and other mold oscillation tables. 10. Support wired and wireless data transmission functions, easy to use. 11. Use the laptop to receive the collected data, can be used for the operation test on site, and can analyze and process the data conveniently. The features of the system 1. The actual oscillation state replaces the ideal oscillation state. The actual oscillation state of the table is used to formulate a control strategy, so that the oscillation table can be used to produce products with more accurate oscillation. 2. Convenient detection method. The equipment can be used for on-site inspection at any time, and the production site can grasp the operating status of the on-site equipment in time, so that we can make production adjustments to the equipment at any time. 3. Efficient working methods and processing platforms. The high-integration equipment developed by embedded technology can work in high temperature and harsh environment. This system can comprehensively detect XYZ three-axis data, and realize real-time data analysis and processing with high-speed data operation and processing platform. 4. Powerful database function. The database adopts the mode of computer automatic management and operator's manual assistance management, and there are tables for recording historical data and alarm data and working parameter setting table of monitoring system inside the database. By adjusting the output range, the best output effect can be obtained.

Rs 0,0

See product

Pakistan (All cities)

Wedding Cards Manufacturing in Pakistan, Pakistani Wedding Cards, Wedding Cards from Pakistan, Favour Boxes Pakistan, Nikkah Boxes Pakistan, Bid Box Pakistan, Bidh Box Pakistan, Customized Wddding Cards Pakistan, Wedding Cards Lahore, Wedding Cards Pakistan, Acrylic Wedding Cards, Wax Stamp Wedding Cards, Bes Cards https://cardnboxes.com/

Rs 100,0

See product

Pakistan (All cities)

Get the best nail polish services in Hyderabad at Kameleon Salon, from classic manicures to gel finishes.

Free

See product

Pakistan (All cities)

Overview In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline deviation. The measurement of the strand condition monitor Roll gap value: By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed. It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster. Arc condition of guide roller : Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guided roller. Guided roller rotation: It is possible to know whether each guided roller can rotate freely by measuring. Water spray pressure: The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal. The main components of the strand condition monitor 1. The main body of the strand condition monitor used to measure the continuous casting sector 2. The connecting chain between strand condition monitor and dummy bar 3. The storage rack chain of strand condition monitor 4. Battery charger: 24V 5A 5. Calibration equipment 6. Remote control 7. Laptop 8. Printer 9. Data communication cable The technical parameter 1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements) 2. The measurement accuracy of roll gap: 0.01mm 3. The arc measurement range: ±80° 4. The arc measurement accuracy: 0.01° 5. The spray measurement range: 0-10 6. The spray measurement accuracy: ±1 7. The battery usage times: 3 times

Rs 0,0

See product

Pakistan (All cities)

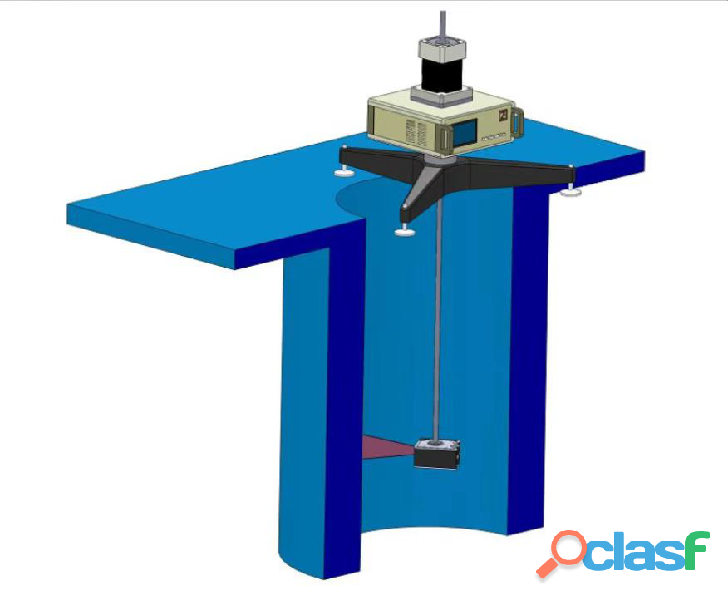

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Multan (Punjab)

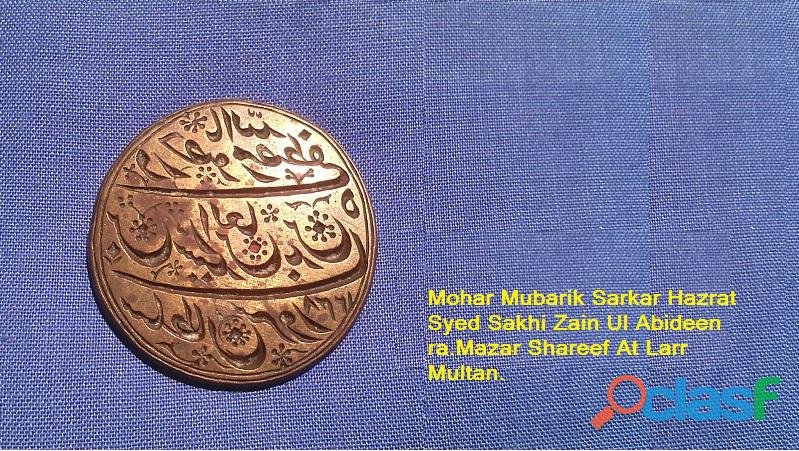

Hazrat Syed Sakhi Zain ul Abideen (RA) migrated from Baghdad to Saudi Arabia and spent 22 years in Madina Munawara.One night, holy Prophet hazrat Mohammad (may peace be upon him) appeared in a dream and instructed him to go to India, convince the people to the right path, preach or spread the teachings of Islam.Obeying the orders of the holy Prophet Hazrat Mohammad (may peace be upon him), the Sufi Saint left Madina Munawara and came to Shahkot. The Sufi saint is the father of a famous Sufi Hazrat Syed Ahmad Sultan, known as Sakhi Sarwar, the bountiful Chief, shrine at Sakhi Sarwar Pakistan. Hazrat syed sakhi Zain ul Abideen (RA) practised austerities and prayers in shahkot, The great renowned Sufi saints paternal genealogy is directly related ten generation up with Ameer ul Momeneen (commander of faithful) Hazrat Imam Ali Ibne Abu Talib R.A, thus he was a direct descendant of the holy Prophet Hazrat Mohammad (may peace be upon him). The name Zain ul Abideen was selected by his father Syed Umar due to the deep love and devotion with Imam Zain ul Abideen (A.S). Specification. Object Name: Seal stamp Description: Syed Zain ul Abideen Shah"Sultan Sarwar" Inscription Script : Arabic Inscription Technique: Engraved Date Period: A D 13th Century 1248 Time period: A D 13th Century Geography: Indian Subcontinent (Central Asia) Culture/period: Islamic Condition: Excellent Relics of the Islamic saints strengthens spiritual beliefs, inspire people and give them comfort in tough times. The holy seal is a precious asset handed down from generation to generation, extremely rare and a genuine masterpiece regarding the sacred relics of the early Islāmic saints.

Rs 100,0

See product

Pakistan

4 year old male beagle called 'Bizol' who is very sweet a little shy but once settled is very loving and friendly. He is great with other cats and dogs, he would be fine to be rehomed with older children purely as he's a little shy, He is cur....

Rs 200,0

See product

Pakistan (All cities)

We are Manufacturer of garden benches. We have wide range of garden and Park benches with weather resistant, Durable and Long lasting. Widely used in Societies, University's, Farm house's. Delivery Available all across Pakistan. Contact us on What's App. [redacted phone number]

Rs 11.000,0

See product

Pakistan (All cities)

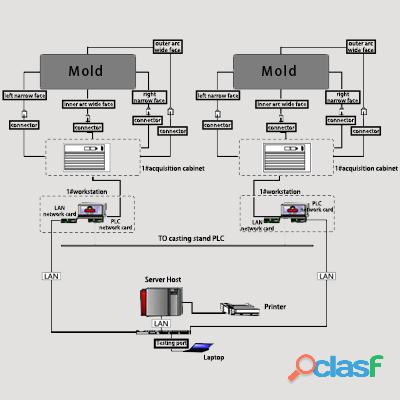

Overview: The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional artificial intelligence and information processing technology to overcome the defects of traditional logic-based prediction models. It has the functions of self-adaptation, self-organization and real-time learning. The breakout prediction system has an optimized industrial network structure. According to the distribution and change rules of the temperature field of the mold, it can track and respond to the breakout process in real time. It can learn and judge by itself, and provide early warning information for on-site operations. It can effectively prevent the occurrence of breakout accidents, greatly reducing the cost and improving the safety factor of continuous casting. The system is suitable for all kinds of continuous casting machines such as square billet, round billet, rectangular billet and slab. Block Diagram of Breakout Prediction System The composition of the system Thermocouple: according to the on-site conditions of the mold, water tank, bolts and mold frame to desgin Front-end acquisition system: Multi-module acquisition chain, industrial Ethernet interface, high-speed embedded processing module Working platform: Real-time display of mold temperature field status, online analysis and prediction of mold breakout Server: Data exchange and storage management, reporting and printing system, with data analysis and self-learning functions The Main technical parameters Data sampling: the sampling frequency of K-type/T-type thermocouple can up to 10HZ Accuracy of temperature measurement: ±0.25℃ Support communication protocol: Industrial Ethernet (TCP/IP),PROFIBUS-DP,CANopen Executive standard: DE0411 Standard Class III/1EC584/IEC1515 Transmission speed: 100M/bps The composition of the software Online monitoring software for breakout prediction Offline query software for breakout prediction Data recovery and self-learning software packages Data acquisition and monitoring software The software package of mold thermal status display The functions of the system Real-time data acquisition, data analysis and judgment Automatic selection of steel grade’s alarm parameters Real-time dynamic picture monitoring Prediction alarm and information display of breakout signs Automatic deceleration after alarm Historical data storage and historical trend graph display Automatic report generation and printing Alarm prediction and pattern recognition of unknown steel grades by neural network Dynamic real-time temperature profile prediction Mould heat flow field display FIG 1:Typical process of mold breakout prediction The features of the system 1. Reasonable design of temperature measurement point and professional protection front-end acquisition system, and complete installation and calibration tool components. 2. The system has strong adaptability and can meet the transformation of various structural continuous casting machines. 3. High-speed data communication, using industrial network to form an independent local area network for each workstation and server. It can realize high-speed data transmission of alarm files, alarm parameters, and other databases. 4. The combination of artificial neural network and intelligent forecasting model improves the alarm accuracy of breakout forecasting. 5. Historical data storage and historical trend graph display, historical reports, historical alarm legend printing, real-time alarm data printing. 6. Provide a local area network interface, which can realize the storage and forwarding of alarm files, and the input and output of offline alarm data. 7. Remote Web browsing can be achieved according to customer needs. 8. Can be seamlessly connected with MES-C220 mould expert system.

Rs 200.000,0

See product

4 photos

Pakistan

Stunning Tri-Colour Pedigree Puppies for Sale. Only 3 girls left. Born 8th January and ready to re-home 4th March. These puppies have been home bred and reared within a family home. Mother can be seen with puppies and is from Chantryland an....Beautiful litter of chunky beagle puppies. Lemon and white & Tri in colour. Boys and girls available. They have gorgeous long floppy ears and cheeky personalities. They are ready now for there forever loving homes. Mum is a tri colo....We have for sale 4 wonderful beagle puppies they r good with kids other pets they r all up to date with wormed & flees & vacation they also comes with a dog lead good home only

Rs 200,0

See product

Pakistan

One is 7 months old (not sexed); freely flying, like to be out of cage all day, freely flying around. Other one is 5 months old (breeder told male, but not sexed) has already started training; steps on a perch now on demand, wing feathers growing back, likes to be outside cage on his stand.

Rs 4.000,0

See product

Pakistan (All cities)

As one of the largest Chinese manufacturers of industrial valves, China Vervo Valve Co., Ltd. offers a wide array of products, including floating ball valves, trunnion ball valves, cast steel gate valves, forged steel gate valves, pressure seal gate valves, cast steel globe valves, forged steel globe valves, cryogenic globe valves, forged steel check valves, swing check valves, dual plate check valves, API 609 butterfly valves, steel plug valves, Y strainers, and more. Our business reaches North America, South America, Europe, Asia, the Middle East, Africa, and Oceania. We manufacture, import, and sell a wide range of industrial valves, including ball, gate, globe, butterfly, check, plug valves, and specialty valve solutions. We look forward to establishing a strong cooperation with you! Visit our website: https://www.vervovalve.com/

Rs 200,0

See product

Pakistan

We have 6 kittens that will be available as pets, they will be ready to leave home on 7 April 2016. There are 3 boys and 3 girls. Silver spotted and Brown spotted. Mum is a gorgeous Silver Marbled F6 and Dad is a stunning tarnish free Silver spotted boy. If you are interested in these babies, please contact me as there is always a great demand for these babies from this pairing. They always make fabulous big kittens and this is probably the last time that these two are paired together due to the age of Oliver. Viewings start at 8 weeks of age after their 1st vaccination when we will require a non-refundable deposit to secure your kitten. We can also early neuter your boys before they leave us, this will be chargeable, please ask us about this. Individual photos will be taken in a few weeks when kittens are weaning. Please note that some of the kittens are in the fuzzies so markings will not clear for a few weeks yet: Beige Collar - Cool Brown Boy Blue Collar - Silver Boy Green Collar - Silver Boy Purple Collar - Brown Girl Yellow Collar - Stunning Cool Brown Girl Pink Collar - Silver Girl

Rs 5.000,0

See product

Lahore (Punjab)

Drive your dreams, rent with ease! With easy online booking and flexible rental options, you can confidently hit the road. https://www.rafaycars.com/

Rs 1.200,0

See product

3 photos