Electronic eg cds

Top sales list electronic eg cds

Latest Offers

Pakistan (All cities)

Explore the top 10 CNC machines for small businesses in 2024! This comprehensive guide highlights the best machines for precision, reliability, and affordability, ideal for entrepreneurs, hobbyists, and small manufacturers. Whether you're looking for a versatile CNC mill, router, or laser cutter, find the perfect solution to enhance your production capabilities, improve efficiency, and grow your business. https://www.tradebrio.com/exporters/cnc-machines.html

Free

See product

Pakistan (All cities)

We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 1.000,0

See product

2 photos

Karachi (Sindh)

CCTV Market specializes in offering premium CCTV security systems for homes as well as businesses. With over 10+ years of experience and a solid reputation for happy customers, we provide affordable solutions that are customized to meet your security needs. To guarantee you get the highest level of service possible, our knowledgeable staff takes care of everything from CCTV system design and installation to maintenance and repairs. We are your one stop shop for easily CCTV security since we place a high priority on quality in both our goods and services. For dependable and effective CCTV installation and repair, rely on CCTV Market right now.

Rs 150,0

See product

Pakistan (All cities)

Get professional lawyer app development, lawyer consulting app development, and lawyer finder app development services with Dev Technosys. We create secure, user-friendly legal apps tailored to your needs. Enhance client engagement, manage cases efficiently, and streamline legal services. Contact us today for reliable and innovative legal tech solutions.

Rs 0,0

See product

Pakistan

Top class litter of kc reg Akitas pups. Puppies have a fantastic blood lines and already chunky for their age.The pups have been flead and wormed up to date and are now on solid food. Puppies will be ready to leave for there loving homes

Rs 10.000,0

See product

Pakistan (All cities)

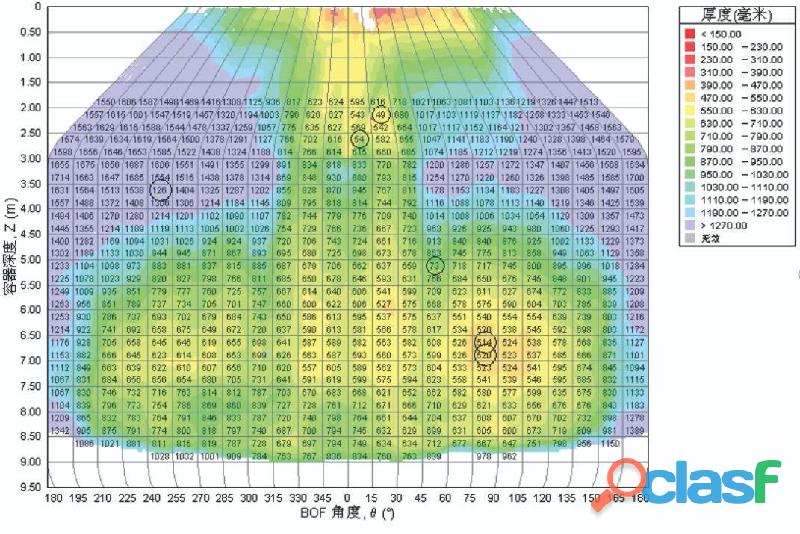

Overview LDT-I200 is a new generation of converter lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the converter, and receives the returned laser light to measure its flight time. Then the system equipment calculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushes the equipment to a certain position on the platform in front of the converter, and the equipment can start to scan and measure the target area of the converter after the equipment performs rapid self-positioning. The Measuring principle The measurement speed of LDT-I200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curve of the entire converter lining can be obtained by combining the measurement data of different positions and angles. During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within 4 minutes, the three-dimensional surface contour of the converter lining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracy up to ±2mm. In order to convert the distance from the internal point of the converter to the thickness gauge into the thickness of the furnace lining at each point, we must know the coordinate relationship between the trolley and the converter. We use the second laser head to position the trolley. When the trolley is pushed to the measurement site, the positioning laser head rotates at high speed to scan the three reflective strips opposite the converter. Through triangulation measurement and calculation, we can calculate the relative position of the trolley to the reflective strips. The coordinates of the reflective strip and the converter are known through mapping, so that the coordinates of the trolley relative to the converter can be accurately obtained. The main components 1. Laser measuring head 2. Wireless communication 3. Battery pack 4. Mobile laser thickness gauge host 5. Converter inclination measurement system 6. Cooling circulation system 7. Positioning auxiliary reflector 8. Laser positioning system The technical indexes Laser reproducibility: ±2mm Laser accuracy: ±2mm Local fastest measurement time: 15s Positioning time: 30s Full image measurement time: 4min The highest measurable lining temperature: 1850℃ Measuring distance: 0.5-25m Actual points are measured per frame: 1500000 points Continuous working time after fully charged: ≥3h Eye-safe laser: Class 1 laser product (doesn't hurt the eyes) The parameters of laser measuring head Measurement principle: According to the flight time and speed of the laser to calculate the distance Laser reproducibility: ±2mm Laser accuracy: ±2mm Scan rate: 2000000 points/second Measuring angle: vertical ±40°, horizontal 360° Maximum measurement temperature: 2200℃ Working temperature: -20℃-80℃ Cooling method: Integrated liquid cooling system, IP64 grade protection Laser wavelength: 1550nm (near infrared)

Rs 0,0

See product

2 photos

Sialkot (Punjab)

Feeling intricacies in crafting a CDR application for Engineers Australia’s skills assessment? Do not worry; order CDR Writing Services in Pakistan for Engineers Australia. It is the best-known online writing assistance for CDR applicants in Pakistan. CDRAustralia.Org offers such commendable support to meet aspirants' requirements. The service comprises a complete CDR package from selecting projects to writing career episodes, a summary statement, a CPD statement, and a resume. To guide candidates in framing an EA-acceptable competency assessment report, a brilliant team of professional writers is awaiting. Expert writers offer comprehensive assistance to make the report extraordinary so that it can catch EA’s attention and undergo successful assessment. Hire top experts at CDR Australia and relieve all your writing woes. Hired native writers offer CDR support tailored to your requirements and meet all Engineers Australia standards. If you seek any information regarding the services, contact our experts free of cost by visiting the website. Contact Detail: Website: https://cdraustralia.org/pk/ Mail at: Contact@CDRAustralia.Org WhatsApp: +61-291917405

Rs 2.784.000.000,0

See product

Pakistan (All cities)

Topper Smart Bidet Tiolet Seat Co., Ltd. (https://www.mfrsbidet.com/) is a professional and experienced smart toilet & bidet manufacturer and supplier, specializing in diversifying our bidet products to suit a range of different needs. We are capable of providing toilet bidets, bidet attachments, bidet seats, toilet seat covers, bidet sprayers, portable bidets and other bidet fittings, and offering practical and personalized sanitary solutions for our customers. Over the years, we have been consistent in supplying high-quality products and thoughtful services. Every stage in the production is guided and supervised by skilled professionals and our quality control systems. Our bidet products all meet tangible and intangible requirements in terms of quality and safety. From the design and development of products to the user experience, we are never slackening our effort, and still trying our best to improve your life quality. Convenience, comfort and superior quality are the ideas we want to convey through our bidets and services. In the future, we will continue to strengthen our capability of design and innovation to better satisfy the demands of the market and create the best home life experience for customers. If you're interested in our bidets, please visit https://www.mfrsbidet.com/.

Rs 200,0

See product

6 photos

Pakistan (All cities)

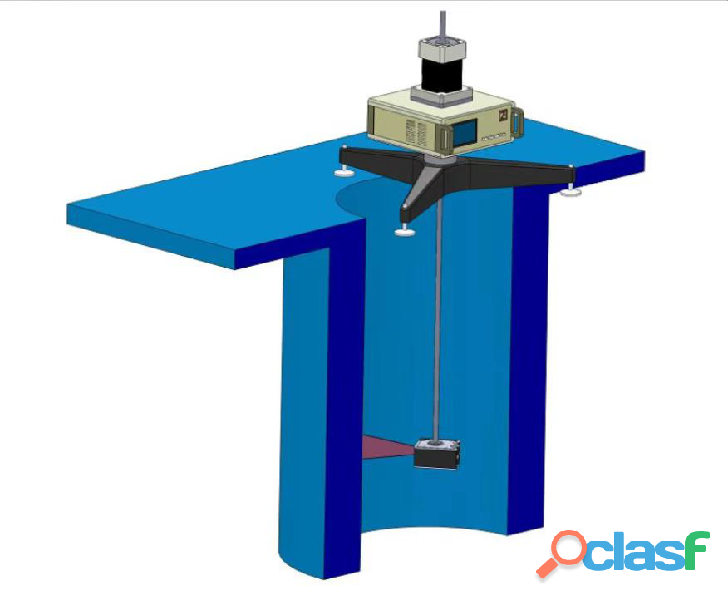

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Lahore (Punjab)

Boost your online presence with our expert digital marketing services. We specialize in SEO, PPC, social media management, content creation, and email marketing to drive targeted traffic and maximize ROI. Let us help grow your brand, engage your audience, and achieve measurable results in today’s competitive digital landscape.

Rs 45.000,0

See product

Pakistan

THE AMAZING HUGO & BOSS ARE LOOKING FOR THEIR FOREVER HOME. BOTH BOYS ARE LILAC IN COLOUR BUT ARE CARRIERS OF TAN POINTS WHICH IS THE AT GENE,DNA IS dd/bb/AT. PUPS ARE REALLY SHORT AND COBBY. GREAT CONFIRMATION, THE BEST WAY TO DESCRIBE THESE....

Rs 200,0

See product

Gujrat (Punjab)

With discreet and reliable surveillance, IonDetective will find out what you want to know. We are professional detectives specializing in obtaining evidence through close observation and time-tested procedures. From cheating spouses to any question or concern that can benefit from being clarified, our company can help bring clear-cut results with total discretion. Our business values honesty, respect, and professionalism; this is exactly why we deserve the truth that you're looking for. Trust us to handle your case with care and precision while keeping the process simple and stress-free. When the truth matters, IonDetective is here to help.

Free

See product

Pakistan (All cities)

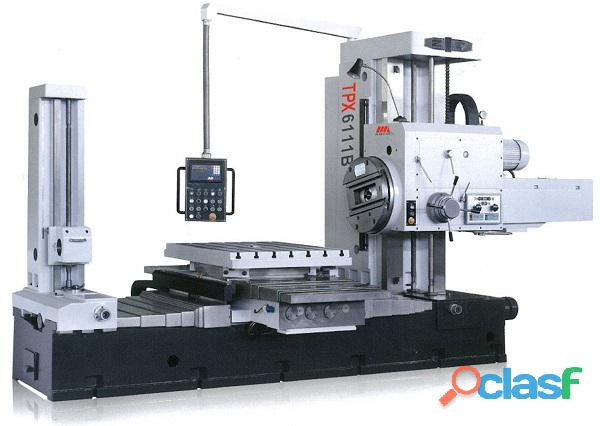

Explore the leading manufacturers of horizontal and vertical boring machines, renowned for their precision engineering, innovative technology, and reliable performance. This guide covers top companies offering high-quality machines for various industries, including construction, mining, and manufacturing. Discover key features, advantages, and the latest trends in boring machine design. Whether you're seeking new or used equipment, find trusted suppliers to meet your project needs with ease. https://www.tradebrio.com/exporters/boring-machine.html

Free

See product

Pakistan (All cities)

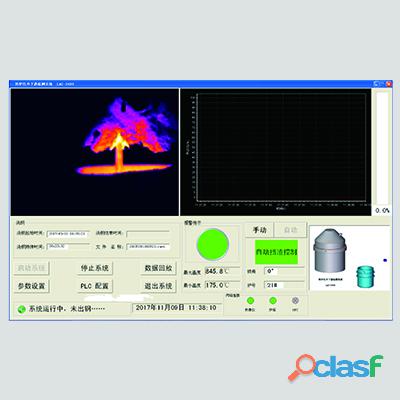

Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content. The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal. As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc. The features of thermal imager 1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set. 2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature. 3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily. 4. With hot zone tracking function 5. Equipped with special 7~14um infrared filter lens The technical parameters 1. Temperature measurement range: 200°C ~ 2000°C 2. Temperature measurement accuracy: 2% 3. Detection accuracy and alarm accuracy: ≥98% 4. Resolution: ≥ 0.5℃ 5. Pixels: 640x240PT 6. Band: 7~14um 7. Field of view: 7.5°×5.5° 8. Frame rate: ≥ 25 frames/sec 9. Equipment service life: ≥5 years 10. The normal operation rate of the automatic control system: ≥99%

Rs 0,0

See product

3 photos

Bela (Balochistan)

Looking for Unique Personalized Gifts in India? Look no further than www.indiaflowersgifts.com! We specialize in crafting one-of-a-kind gifts that are sure to impress your loved ones. From photo frames to customized mugs and cushions, we offer a wide array of options that can be personalized to make your gift stand out. Our service allows you to Send Customized Gifts to India with ease. Simply visit our website, select your favorite item, and personalize it with photos, names, or messages that ignite a special memory. Whether it's a birthday, anniversary, or any special occasion, our gifts are perfect for every celebration. With Personalized Gifts Online Delivery in India, you can have your unique gifts delivered right to the recipient's doorstep. Our reliable delivery network ensures that your gift reaches its destination on time and in perfect condition. Plus, with secure payment options and excellent customer support, shopping with us is a breeze.Source:www.indiaflowersgifts.com/personalized-gifts.asp

Rs 500,0

See product