Digital signage displays

Top sales list digital signage displays

Pakistan

A tachometer (RPM gauge) is an instrument measuring the rotation speed of a shaft or disk, as in a motor or other machine. The device usually displays the revolutions per minute (RPM) on a digital displays. Range: 2.5~99999 RPM Shipping All Across Pakistan COMPANY: MATRIX ELECTRONICS CONTACT PERSON: FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan

FEATURES A tachometer (RPM gauge) is an instrument measuring the rotation speed of a shaft or disk, as in a motor or other machine. The device usually displays the revolutions per minute (RPM) on a digital displays. Rotate : 0.5~19999RPM Shipping All Across Pakistan COMPANY: MATRIX ELECTRONICS CONTACT PERSON: FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Karachi (Sindh)

Buy EDM 2347 ESCORT at lowest price in Karachi, Pakistan.No matter from which city you belong to we deliver all over the Pakistan with Reliable courier service and same day shipping with in Karachi premises. Here are the some specs of EDM 2347 Overview: 4½ Digits DMM / Analog-Bar Display Compare Function Relative Offset Function Max/Min Hold Function dB Level Indication Overload Protection Specifications: Displays 4½ Digits & Analog-Bar Displays Basic Accuracy (DC Voltage) +- 0.05% Voltage Measurement Ranges DC:200mV ~1000V (5 ranges) AC:200mV ~ 750V (5 ranges) Current Measurement Ranges DC:200uA~20A (6 ranges) AC:200uA~20A (6 ranges) Resistance Measurement Range 200Ω~20MΩ (6 ranges) Frequency Measurement Range 10Hz~1Mhz dBm Indication -60dBm~+60dBm (600Ω Ref) Other Measurements Compare, Relative, Max, -Hold,Min -Hold Operating Conditions 5~40C, 80% or Less (RH) Input Power AC 220V, 50/60Hz Dimentions 255(W)x100(H)x280(D)mm Weight 1.9 KG (Approx) We Deal In All Kinds Of Electronic Components, Test And Measuring Instruments, Variety Of Multimeters, Clamp meters, temperature guns, Toolkits, Hand Tools, Universal IC Programmers, Etc For more details contact us: Faizan Munir 03002785860 Email: info@matrixelectronic.com Visit Website: www.matrixelectronic.com Address: Matrix Electronic Shop#2, Hassan Center Near Passport Office Saddar Karachi.

See product

Karachi (Sindh)

ADVERTISING & DIGITAL PRINTING Digital Panaflex & Eco-Solvant Printing Digital Textile Printing On Polyester Fabric Out Door Advertising Vehicle Graphics Brand Activation Portable Stand(x-stand, rollup, bridge & table top) Shop Signage Window Graphics Shop Marchandising Inflatables DIGITAL SUBLIMATION TEXTILE PRINTING Ladies Suits T-Shirt Trouser Pillow Curtain Scarf Mug Tea Coaster Bags Caps

See product

Pakistan

Original Fluke 115 Digital Multimeter nominal price The Intelligently Designed Solution for Field Service Technicians With its simple operation, compact design and ease of use, the Fluke 115 True RMS digital multimeter provides the perfect answer for general purpose electrical and electronic test requirements. The Fluke 115 displays True RMS voltage and current readings with 600 count resolution, continuity and capacitance, making it perfect for quick verifications and field service use. For Price Contact Us Shipping All Across Pakistan COMPANY: MATRIX ELECTRONICS CONTACT PERSON: FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan

Bar Graph to display insulation resistance. • Displays the value of external AC voltage along with flashing symbol. • Auto null function to automatically subtract the test lead resistance before displaying the real continuity resistance value. • Trac-Lok mode to conserve battery life on insulation and continuity tests. • Live circuit warning beeper. • Releasing the test button automatically discharges the charges stored in the circuit under test. • Backlight function to view the test results in dimly lit areas. • 200mA continuity measuring current to IEC 61557. • Minimum 1mA current on insulation tests to IEC 61557. Shipping All Across Pakistan COMPANY: MATRIX ELECTRONICS CONTACT PERSON: FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan (All cities)

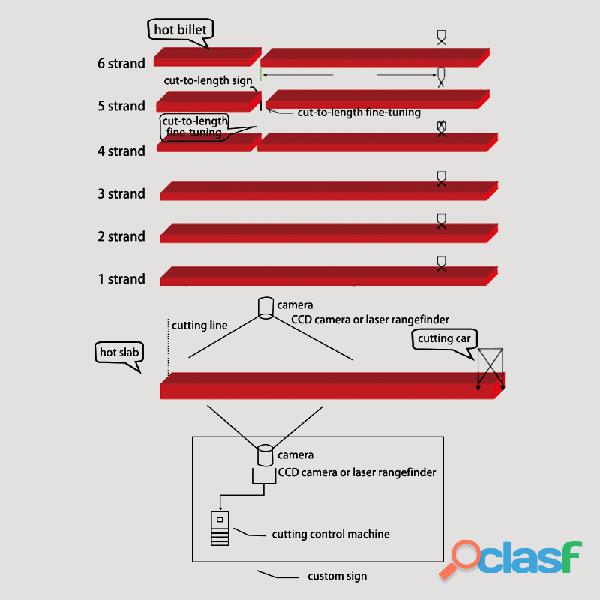

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

See product

Abbottabad (Khyber Pakhtunkhwa)

FRIENDS COMMUNICATION Advertising & Printing Company We Deals in All Kind of Signage Specialized (12) Years of Experience. Maker, Making, Maintenance, Repairing, Repair, Fabrication, Execute, Erection, Installed, Installation, Assemble Fitting, Fitter, Labour, Experience The Difference Innovation Quality Services Warranty, Backup Support, Karachi Lahore Peshawar Islamabad Rawalpindi Kamra Taxila Attock, Chakwal Mirpur Gujranwala Gujarat Jhelum Sialkot Faisalabad, Kharian, Lalamusa, Rawat, Muree, Abbottabad Haripur Naran Kaghan Chitral Okara Sahiwal Khanewal Multan Rahim Yar Khan Bahawalpur Sadiqabad Sargodha Dera Ghazi Khan Flex Sign SMD LED Video, Screen, Digital Pol, Streamer, Poster, Video Animation Signage 3D Acrylic LED Letters Plastic Letter LED Pixel Sign Effect, Digital Billboard, Hoarding, Sites, Golden Steel Alphabet Vinyl Pasting Pollter Cutting, Star, China, Flex Media, Frontlit, Backlit, LED Signboard, MDF, PVC Foam Board, ACM, Aloucbond, ACP, Cladding, Front Fascia, Elevation, Glass, Aluminum Work, Acrylic, Metal, Steel, Wood, Fiber Laser, Cutting, CNC Router, Backlit Customized Design Onyx Acrylic Sheet, UV Direct Flatbed Digital UV Printing, Die Moulding Letters, Alphabet, Vinyl, Plotter Cutting & Pasting, Laser Welding, Pharmacy, Hotel, Hospital,School, College, University, Shop, Office, Restaurant, Plaza, Building, Housing Society, Highway, Motorway, GT Road, Street, Road Sign, 3M, HIP, Diamond Grade Reflective Sheet, Reflector, Sign Board Call More Info Kashif Khan 0 3 2 1 - 4 17 17 00 facebook/friendscommunication1

Rs 599

See product

Pakistan (All cities)

Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area. The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process. MOC-K100 mould oscillation online monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel. The meaning of the system 1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality. 2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance. 3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair. 4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident. 5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product. 6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed. The functions of the system (1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data including oscillation parameters and process parameters. (2) Time domain waveform: This function mainly displays the oscillation waveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elements of oscillation of each measuring point in real time. (3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and the oscillation difference of each channel can be calculated and displayed intuitively. (4) FFT: This functional module completes the calculation and display of the oscillation spectrum in real time. It is used to evaluate the waveform distortion of the entire oscillation table and to determine whether there is a problem with the installation of the oscillation device. (5) Bar graph: The oscillation of each measuring point is indicated by a bar graph of peak value and sensor gap voltage, which is more intuitive. (6) Trend: After starting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings for different steels under the oscillation conditions. The parameters of the system 1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged 2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes) 3. Sensitivity: 1000mV/g 4. Frequency range: 0.04~10HZ 5. Frequency accuracy: ±0.01 Hz 6. Amplitude accuracy: 0.005mm 7. Transmission mode: wired digital transmission, wireless transmission 8. Host: 3U standard rack, handheld device 9. Sensor power supply: 24V.DC 10. Host power supply: 220V.AC/50Hz Mold oscillation curve The structure of the system The main components of the continuous casting mould online oscillation detection system are: 1. Three-dimensional oscillation measurement sensor 2. Handheld oscillation sensor calibrator 3. Dedicated signal connection cable 4. Preamplifier 5. Operation processing unit 6. Graphic display terminal 7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components 8. Control cabinet

Rs 200.000

See product

3 photos

Lahore (Punjab)

(Large Format DIGITAL PRINTING Indoor, Outdoor Signage & Branding) nationwide scope covering all customer segments Services We Offer You . 3D signs • Digital Printing • Shop Fascia • Shop Branding • Vehicle Graphics • Widow Graphics • Pole Signs • Plotter Cutting Signs • Streamers • Campaigns Professionalism and Transparency • We ensure the highest levels of professionalism • We deliver on our promises Client Understanding • Over 12 years of working with Large Scale Companies contact person Muhammad nabeel 0331-4417724

See product

Pakistan

Top performance cost ratio High power density, smallest and compact Aluminum shell, lower EMI The microprocessor(MCU) control Using Encoder to set the voltage and current Four digital volt meter and three digital current meter The current meter displays mA automatically when current belows 1A High efficiency, up to 88% For Price Contact: FAIZAN MUNIR Mobile:0 3002785860 Email : sales @ matrixelectronic . com w w w .matrixelectronic . com Address: Shop#2, Hassan Centre Near Passport Office Saddar karachi

Free

See product

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

See product

Pakistan (All cities)

Overview The handheld roll gap checker is specially used to measure the length between spherical surface, arc surface and plane (or spherical surface). It is specially suitable for the opening adjustment of the roll gap of the metallurgical continuous casters in various specifications, because the roll gap checker has the advantages of high resolution, accurate measurement, stable data and easy to use. Because the opening accuracy of the roll gap checker will directly affect the quality of the casting block, this roll gap checker is an indispensable testing equipment in the continuous casting equipment, which can fully meet the needs of on-site installation testing and use process verification. When the hand-held roll gap meter smoothly passes through the gap between the guide rolls of the continuous casting machine, the upper measuring contact of the hand-held roll gap checker contacts the inner arc roll and the lower measuring contact touches the outer arc roll. The handheld roll gap checker is used in perpendicular to the roll diameter direction, during the pushing process, when the hand-held roll gap meter is in the tangent plane of the upper and lower rolls, the measured value is the smallest at this time, and this value is the roll gap measurement value. The design of the hand-held roll gap gauge ensures that the upper and lower contacts of the roll gap checker can smoothly pass the measured roll along a straight line during measurement. During the measurement process, the roll gap measuring instrument automatically compares the measured values, and displays the minimum measured value on the instrument display interface, which is the current measured roll gap value. The introduction of different types The measuring range of the split hand-held roll gap checker is 180mm - 400mm This hand-held roll gap checker adopts the design that the measuring body and the display instrument are separated. The measuring body can be clamped by an extension rod, which is suitable for online maintenance and measurement of wider slabs, and it is convenient to use the extension rod to send the measuring body into the continuous casting section to measure inside and we can see measurement data on the checker outside. The measuring range of instrument type handheld roll gap checker is 120mm - 400mm This hand-held roll gap meter is light and compact, and it is convenient to carry during maintenance. The measurement value can be seen immediately after measurement, easy to use, and can be equipped with a short measuring rod. It is suitable for the maintenance and measurement of slab online and offline continuous casting sections. It has data printing function, the measurement results can be printed in real time. The measuring range of thin slab hand-held roll gap checker is 60mm - 150mm This handheld roll gap meter is suitable for measuring the roll gap of CSP continuous casting machine and ultra-thin slab continuous casting machine. It is accurate and easy to use. The technical parameters 1. Measuring range of instrument type handheld roll gap checker: 180mm - 400mm (the range can be customized) 2. Measuring range of digital hand-held roll gap checker: 120mm - 400mm (the range can be customized) 3. Measuring range of hand-held thin slab roll checker : 60mm - 150mm (the range can be customized) 4. Measurement accuracy: 0.01mm 5. Working temperature: -25℃~+85℃ 6. Battery capacity: 5000mAh 7. Charger specification: 12V

See product

2 photos