Completely mint

Top sales list completely mint

Latest Offers

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product

Pakistan (All cities)

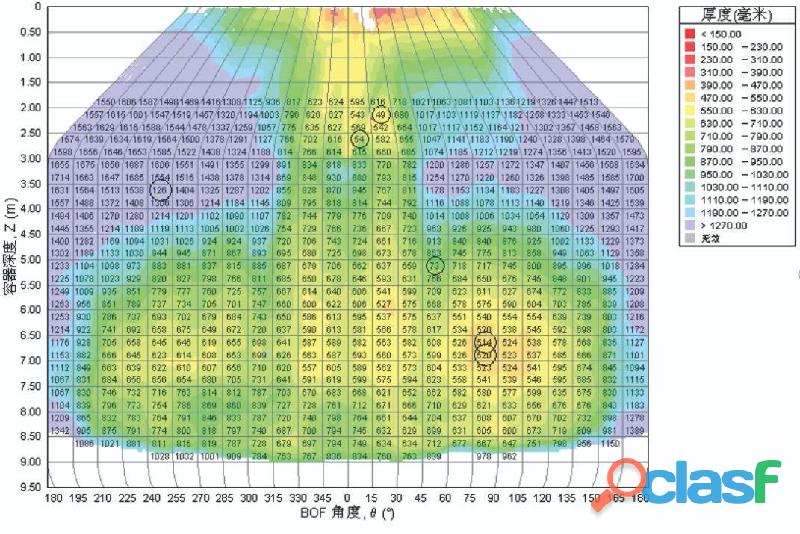

Overview LDT-I200 is a new generation of converter lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the converter, and receives the returned laser light to measure its flight time. Then the system equipment calculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushes the equipment to a certain position on the platform in front of the converter, and the equipment can start to scan and measure the target area of the converter after the equipment performs rapid self-positioning. The Measuring principle The measurement speed of LDT-I200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curve of the entire converter lining can be obtained by combining the measurement data of different positions and angles. During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within 4 minutes, the three-dimensional surface contour of the converter lining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracy up to ±2mm. In order to convert the distance from the internal point of the converter to the thickness gauge into the thickness of the furnace lining at each point, we must know the coordinate relationship between the trolley and the converter. We use the second laser head to position the trolley. When the trolley is pushed to the measurement site, the positioning laser head rotates at high speed to scan the three reflective strips opposite the converter. Through triangulation measurement and calculation, we can calculate the relative position of the trolley to the reflective strips. The coordinates of the reflective strip and the converter are known through mapping, so that the coordinates of the trolley relative to the converter can be accurately obtained. The main components 1. Laser measuring head 2. Wireless communication 3. Battery pack 4. Mobile laser thickness gauge host 5. Converter inclination measurement system 6. Cooling circulation system 7. Positioning auxiliary reflector 8. Laser positioning system The technical indexes Laser reproducibility: ±2mm Laser accuracy: ±2mm Local fastest measurement time: 15s Positioning time: 30s Full image measurement time: 4min The highest measurable lining temperature: 1850℃ Measuring distance: 0.5-25m Actual points are measured per frame: 1500000 points Continuous working time after fully charged: ≥3h Eye-safe laser: Class 1 laser product (doesn't hurt the eyes) The parameters of laser measuring head Measurement principle: According to the flight time and speed of the laser to calculate the distance Laser reproducibility: ±2mm Laser accuracy: ±2mm Scan rate: 2000000 points/second Measuring angle: vertical ±40°, horizontal 360° Maximum measurement temperature: 2200℃ Working temperature: -20℃-80℃ Cooling method: Integrated liquid cooling system, IP64 grade protection Laser wavelength: 1550nm (near infrared)

Rs 0,0

See product

2 photos

Pakistan (All cities)

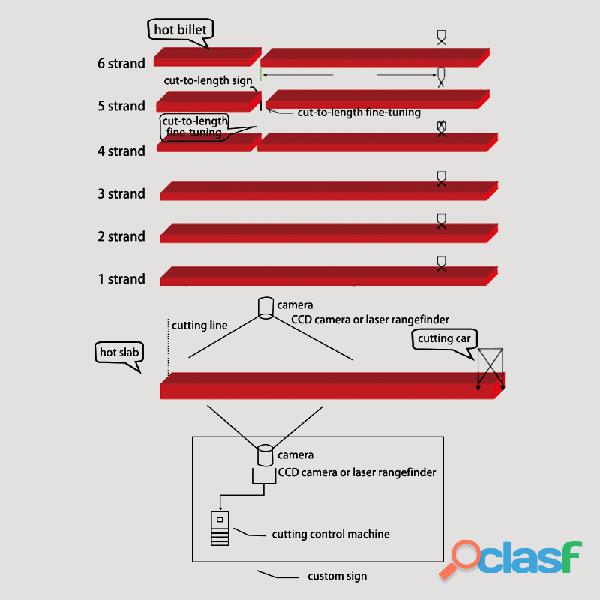

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

Rs 0,0

See product

Pakistan

Unfortunately have to sell my Chinese water dragons and I need to down size on my reptile room these 2 are extremely friendly and love to come out and roam full working vivarium vivarium is large as you can see in images so need a van to come remove and 2 or 3 people to carry down stairs please contact me on [telephone removed]

Rs 50.000,0

See product

Pakistan (All cities)

Protect your valuable machinery and equipment from voltage fluctuations with our reliable servo voltage stabilizer. Designed to maintain a consistent and stable voltage supply, it ensures optimal performance and extends the lifespan of your devices. Ideal for both industrial and commercial applications, our stabilizer provides superior protection against power surges, ensuring your machines run smoothly and efficiently. Trust our advanced technology for enhanced safety and reliability in every operation. https://voltsine.in/product/servo-voltage-stabilizer/

Free

See product

Pakistan (All cities)

As one of the largest Chinese manufacturers of industrial valves, China Vervo Valve Co., Ltd. offers a wide array of products, including floating ball valves, trunnion ball valves, cast steel gate valves, forged steel gate valves, pressure seal gate valves, cast steel globe valves, forged steel globe valves, cryogenic globe valves, forged steel check valves, swing check valves, dual plate check valves, API 609 butterfly valves, steel plug valves, Y strainers, and more. Our business reaches North America, South America, Europe, Asia, the Middle East, Africa, and Oceania. We manufacture, import, and sell a wide range of industrial valves, including ball, gate, globe, butterfly, check, plug valves, and specialty valve solutions. We look forward to establishing a strong cooperation with you! Visit our website: https://www.vervovalve.com/

Rs 200,0

See product

Pakistan (All cities)

Dev Technosys offers cutting-edge News App Development Services, delivering customized solutions with advanced features like real-time updates and smooth navigation. Our expert team specializes in News App Designing, creating user-friendly and visually appealing interfaces. Get reliable, scalable, and performance-driven News App Solutions tailored to meet your business goals. Visit: https://devtechnosys.com/news-app-development.php

Rs 0,0

See product

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

Rs 0,0

See product

Islamabad (Islamabad Capital Territory)

In the bustling heart of Delhi, optimizing your workspace is crucial for productivity and employee well-being. Ryan Office System provides premium modular office furniture in Delhi, offering versatile solutions tailored to your unique needs. Our modular designs prioritize flexibility, allowing you to reconfigure your office layout as your business evolves. From sleek workstations and ergonomic chairs to adaptable storage units and collaborative meeting tables, we offer a comprehensive range of furniture to create a dynamic and efficient environment. Why choose Ryan Office System for your modular furniture needs in Delhi? Customization: We understand that every office is different. Our modular systems can be customized to fit your specific space and workflow, ensuring optimal utilization. Quality & Durability: We use high-quality materials and craftsmanship to create furniture that is built to last, providing a long-term investment for your business. Ergonomic Design: We prioritize employee comfort and well-being with ergonomic designs that promote good posture and reduce strain. Space Optimization: Our modular solutions maximize space utilization, creating a more organized and efficient work environment. Professional Aesthetics: We offer a wide range of modern and stylish designs that enhance the professional image of your office. Ryan Office System empowers Delhi businesses to create adaptable and productive workspaces. Our expert team will guide you through the selection and installation process, ensuring a seamless experience. Invest in the future of your office with our premium modular office furniture in Delhi.read more :- https://www.ryanofficesystems.in/delhi/modular-office-furniture

Free

See product

Pakistan (All cities)

We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 1.000,0

See product

2 photos

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos

Pakistan

KC BRITISHPRIDE BRED English Bulldog Hes The son of Britishpride Royal Ascot. available for STUD. HE IS A PROVEN STUD DOG producing quality puppies.

Free

See product

Lahore (Punjab)

Drive your dreams, rent with ease! With easy online booking and flexible rental options, you can confidently hit the road. https://www.rafaycars.com/

Rs 1.200,0

See product

3 photos

Pakistan

Kennel Club Assured Breeder. Jimjen George Gently is a proven sire, (daughter & son Crufts qualified), and health tested, for MLS, NCCD, FVll, & IGS, and available at stud, to approved bitches,at small show kennel in Suffolk. 'Reach....Bonnie is a friendly and loving dog who loves attention and is very outgoing. He has been with us since he was 8 months old, but unfortunately he has been fighting with my male cat which causes him stress and anxiety being around the house.....Our amazing litter was born on 18th of December mum is stunning tri colour and dad is a lemon and white tri both pedigrees dad has five generations blood line with his papers to prove. We have a litter of 9 chunky playful pups all wormed and....

Rs 200,0

See product

Pakistan (All cities)

Trusted Fence Installation Company in Maryland & Delaware. Explore wood, vinyl, and aluminum fencing solutions for homes and businesses. Call for a free estimate today https://www.fenceanddeckconnection.com/fencing/

Free

See product