Cnc machine operator

Top sales list cnc machine operator

Ahmadpur East (Punjab)

1.A new generation embedded DSP control system, total off-line operation, optional between USB connection or USB flash disk loading, with battery provided, reliable power fall safeguard and recovery. 2.Adopting HIWIN linear track imported from Taiwan, the processing durability and stability are beyond your imagination. 3.With professional machine design strategies, individualized processing of stainless steel, iron plate, aluminum plate, copper plate within thickness of 1 mm can be performed by common cutters. 4.2.2KW high-power water-cooling spindle motor; low noise and high efficiency. 5.Unique gantry design, driven by dual motor; more powerful, and more stable. 6.Experienced designers provide with more competitive products, as you choose this equipment, you have obtained a broader scope of business.

Rs 101

See product

Lahore (Punjab)

Plasma cutting machines are suitable for small and large scale manufacturers, artists, and even DIY enthusiasts. Used to cut precise metal shapes, plasma cutting machines can suit the needs of an individual wishing to cut custom metal plates, through to industrial scale business operations needing to quickly and accurately cut hundreds of identical shapes, via either handheld plasma cutting systems or mechanized plasma.(NOTE) all unit include compressor, dryer, oxygen celender, gas cutter head, etc,..

Rs 850.000

See product

Bagh (Azad Kashmir)

S&A water cooler CW-3000 for CNC/Laser Engraver S&A CW-3000 Series is professional cooling machine referring to international, advanced thermolysis cooling system design, suitable for small water-cooled cooling devices requested machinery. Water cooler CW-3000 feature: 1. Specific disconnection alarm security protection. 2. Hermetic type water tank, water is available for a long time used. 3. Real-time temperature monitoring, accurate knowledge of heating devices working condition. 4. Professional air-cooled forced radiator with strong heat dissipating capacity and difficult to be blocked up. 5. Equipped with alarm output port to protect sensitive components quickly. 6. High cost performance, low failure rate. Specfications: CW-3000AG: applied to cool a single 80W CO2 laser tube (emitting rate lower than 60%) CW-3000AH: applied to cool dual 1.5 KW CNC spindles or welding equipment; Voltage:110V-220V Frequency: 50/60Hz Tank capacity:9L Max. lift:10M-70M; Max. flow: 10L/min- 2L/min N.W: 9.5Kgs; G.W: 12Kgs Dimension : 49 X 27 X 38cm (L X W X H) Packing dimension: 59 X 39 X 48cm (L X W X H) CONTACT S&A TE:+86-20-89301885 FAX:+86-20-84309967 SKYPE: teyuchiller Email:marketing@teyuchiller.com Website: http://www.teyuchiller.com

Rs 8.018

See product

Badin (Sindh)

Truepowersolution Online ups| Stabilizer | Isolation Transformer | Line Conditioner | ATM UPS pure sine wave | Solar Hybrid pure sine wave inverter | MPPT Charger | Telecom AVR | Telecom Charger | Industrial UPS - Stabilizer Application Ideal for Ups Bypass Supply. ATM Machine. IT Equipments Data Center & Call Center. CNC Machine. Plastic Molding Machine. Spark Erosion and Wire-Cut Machine. For BTS | RBS Mobile Tower. Communication Equipment Like Radio & TV Transmitters,. Operation Theater, Large X-Ray Machine, Printing Embroidery Machine, Cathy Labs, CT scanner Ultrasound Machine & Other Medical Equipments. Air-Condition Plants, Patrol Pumps, CNG Station Dispensers, computer servers etc. Pakistan Karachi Lahore Islamabad Faisalabad Peshawar

Rs 13.500

See product

Pakistan

Staff Required for Alhani Technical Works looking Office Secretary (Female) Salary:3000 Dhs. Electrical Technician 2000 dhs. Computer + CCTV Operator: 3000 Dhs, Auto Electrician: 2000 Dhs, Spray Painter: 2200 Dhs, Sales Helper: 1800 Dhs, Workshop Helper: 1800 Dhs, Lathe Machine Operator: 2200 Dhs, Gate Keeper:1800 Dhs. Forward profile: dsn.emarati@gmail.com DSN Contractors LLC. UAE

See product

Pakistan (All cities)

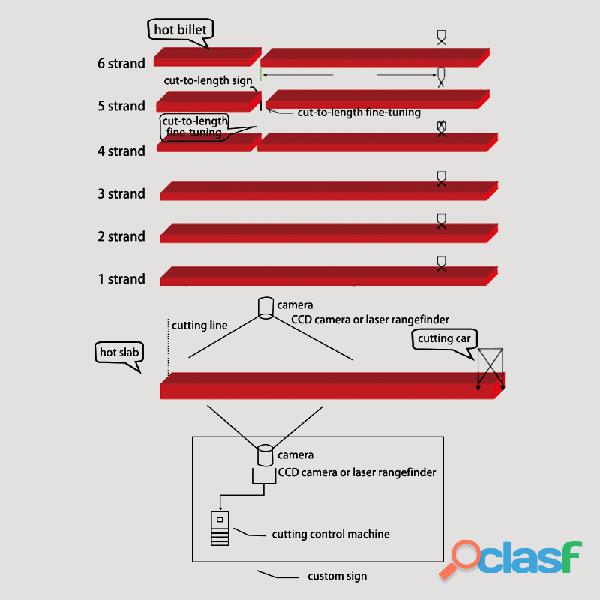

Overview The all-digital non-touching infrared/laser automatic cut-to-length system developed by Wuhan CenterRise M&C Engineering Co., Ltd. is the first digital measurement, digital transmission, digital positioning and digital control technology in China. It is suitable for the primary and secondary cutting of continuously cast product of square billets, rectangular billets, slabs, round billets and shaped billets. It can automatically cut 1-24 strands billets to length at the same time, and display the casting speed and running status of each billet. The system has high measurement and control accuracy and strong anti-interference ability, which improves the output and quality of the cast products and reduces the labor intensity of the operator. The whole system has the advantages of low investment, simple installation, debugging and operation, and basically maintenance free. No need to change the original production equipment, a major breakthrough in the automatic cut-to-length cutting method, and it is also an important part of the continuous casting process, which has been highly praised by experts and manufacturers. Digital infrared cutting to length can also provide high-definition solutions, so that the measurement error is ±2mm, and the system can support 4 strands high-definition CCD image measurement. The features of the system 1. The system adopts advanced digital image processing technology (non-touching type) to identify the length of hot billet online, automatically controls the flame cutting machine to cut the hot billet to a certain length, detects and displays the running status and casting speed, and collects the image information of the moving billet from a long distance through an infrared camera. 2. The computer processes the image information by pattern recognition program, forms the operation information and converts it into the electrical signal of the specified format, so that the hot billet can be cut by the actuator. The system can cut the 1-24 strands to length at the same time with an infrared camera. 3. A schematic diagram of the overall layout and working principle of the system is shown in Figure 1. Fig 1 The functions of the system 1. Applicable to all kinds of continuous casting machine flame cutting system. 2. Adopt advanced digital image pickup technology. 3. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 4. The system provides abundant interfaces, which can communicate with with the PLC. 5. The fixed-length parameters and data can be directly modified by the secondary system to optimize the fixed-length cutting. 6. Historical cutting data is automatically stored, and the system can set rules for historical data. 7. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 8. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 9. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 10. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 11. Provide automatic, manual cutting control. 12. The detection and cutting precision is high, and the controllable precision is ±5mm. The extension of the system The system can install 1 to 8 cameras. Generally, when one camera cannot meet the requirements, the system can be equipped with 2 to 8 cameras. The camera can be fixed inside and outside the operating room perpendicular to the roller line, and the setting height is generally 3-5 meters, so that the camera can clearly and completely capture the image of the moving billet. High-definition line scan cameras can also be provided to perform high-precision positioning of each strand of cast products. Line scan cameras are used to support up to 12 strand systems, which ensures that the center of the viewing angle, the billet head, and the fixed-length mark are vertical to improve the cutting and fixed-length accuracy. The technical parameters 1.Numbers of caster stands: maximum 24 strands 2.Cutting method: flame cutting 3.Matching casting speed: ≤6.5m/s 4.Temperature range of billets: 1000℃ 5.Measurement accuracy: ±5mm 6.Cut-to-length range: 3-18m 7.Signal transmission: TCP/IP 8.Number of signals: pre-cut, cut

See product

Pakistan (All cities)

Overview The mold is a device that shapes the cast product in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of the mould oscillation deflection detection instrument is to detect the the mould oscillation table’s oscillation frequency, amplitude, deflection rate, phase, oscillation trajectory curve, etc. Through the detection and adjustment of the detection instrument, the mold moves along the outer arc of the continuous casting machine according to the set amplitude, frequency and waveform deflection characteristics. The actual oscillation parameters of the mold oscillation table during the production process and the process parameters of the cast products cannot be effectively known without the data detection of the mold deflection detection instrument, so that the operator cannot adjust the mould’s production process parameters in real time according to the real-time situation of the on-site production. The continuous casting mold deflection detection instrument independently developed by our company is suitable for various molds such as slab, square billet, round billet and shaped billet. The system obtains the process parameters such as actual oscillation holographic parameters and negative slip amount of the oscillation table by effectively detecting the movement of the mold. The technicians can formulate the control strategy of the mould according to these actual parameters, and improve the output and quality of the product within a safe and reliable range. The structure of the instrument Continuous casting mold oscillation and deflection detection instrument is mainly composed of sensor system, sensor signal conditioning circuit, power supply circuit, synchronous data acquisition module, communication cable, and software data analysis system. There are three axial acceleration sensors installed in the mold oscillation and deflection detection instrument, one of which is to detect the vertical oscillation signal (Y axis), and the other two are to detect the horizontal oscillation signal (X and Z axis). The signal obtained by the sensor is processed by the preprocessor and the preprocessing module. The oscillation signal and sensor status signal will be filtered and normalized, sent to the synchronous data collector for digitization and feature extraction, and the data is analyzed and processed by the master computer software to obtain various oscillation parameters and process parameters required by users. The functions of the system 1. Adopting mould oscillation X/Y/Z three-dimensional data acquisition, using high-precision sensor system and high-sensitivity axial accelerometer, comprehensive detection of equipment oscillation state, including: 1) Detect the oscillation frequency of the mold oscillation table 2) Detect the amplitude of the mold oscillation table 3) Detect the deflection rate of oscillation 4) Detect the lateral deflection, longitudinal deflection, phase, and phase difference of the mold oscillation table 5) Three-dimensional display of the oscillation trajectory, and the oscillation table trajectory can be viewed from 6 sides of the oscillation table (X-Y, X-Z, Z-Y) 2. The software system adopts the design of man-machine interactive graphic interface, which can display the mold oscillation state in real time. The software functions include: 1) Real-time data curve display: oscillation waveform, oscillation frequency, signal superposition analysis 2) Single-axis curve display, multi-axis curve display, amplitude, acceleration, three-dimensional graph 3) View historical curve 4) Generate test report 5) Give a warning prompt 6) Spectrum analysis function 7) Long-term storage of data 3. Portable measurement method, which can provide handheld detection equipment with wireless remote transmission, and the operation is simple. 4. Provide an overview of inspection parameters under the full screen, displaying all data including oscillation parameters and process parameters. At the same time, the calculation and display of the oscillation spectrum is completed in real time, which is used to evaluate the frame loss of the waveform , and to determine whether there is a problem with the installation of the oscillation device. 5. Alarm management. Record each alarm data under real-time alarm conditions to analyze the cause of the alarm and evaluate the impact of the alarm on production. 6. Parameter setting. Users can set the ideal oscillation value and normal working range of various steels online. We also can set the alarm limit, and the storage time of the database etc. 7. After charging the device once, it can work continuously for more than four hours. 8. Integrate embedded processing equipment to realize data collection, display, analysis, reporting and other functions. 9. According to the mold characteristics and user requirements, it can be flexibly configured, wich is suitable for all types of molds such as square billets, slabs, round billets and other mold oscillation tables. 10. Support wired and wireless data transmission functions, easy to use. 11. Use the laptop to receive the collected data, can be used for the operation test on site, and can analyze and process the data conveniently. The features of the system 1. The actual oscillation state replaces the ideal oscillation state. The actual oscillation state of the table is used to formulate a control strategy, so that the oscillation table can be used to produce products with more accurate oscillation. 2. Convenient detection method. The equipment can be used for on-site inspection at any time, and the production site can grasp the operating status of the on-site equipment in time, so that we can make production adjustments to the equipment at any time. 3. Efficient working methods and processing platforms. The high-integration equipment developed by embedded technology can work in high temperature and harsh environment. This system can comprehensively detect XYZ three-axis data, and realize real-time data analysis and processing with high-speed data operation and processing platform. 4. Powerful database function. The database adopts the mode of computer automatic management and operator's manual assistance management, and there are tables for recording historical data and alarm data and working parameter setting table of monitoring system inside the database. By adjusting the output range, the best output effect can be obtained.

See product

Pakistan (All cities)

Manufacturer's Warranty. Tecno Industries (Reg) اَلحَمْدُ لِله Manufacturers of: SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. (pure copper) Since 1986 Tecno Lazer Pakistan. 0300-9433728 Ring Road, Band Road, Lahore Pakistan. A Servo Stabilizer That Decreases 30 Volts (back-from 250 to 220 & Increases 70 Volts from 150 to 220) (±) 1% {CAN STEP-UP from even low (on-demand)} اَلحَمْدُ لِله Runs your Equipment Even in Low Main Voltage. INFORMATION: 1: ( An Old Transformer / Relay carrying Stabilizer steps down or up after losing or gaining 20-25 Volts While A Servo Stabilizer steps down or up after losing or gaining 1 Volt. (±) 1%) 2: (on-demand) Buck-Boost Transformer Technology add-in 2kVA and above Models. Basically they work on DC Servo Motor Control system. Their efficiency is much better and its output voltage of either 110 or 220 AC or any required voltage, more-over TECNO 3Phase models up-to 500kVA ratings are manufactured against a confirmed order. 1 year warranty with parts. 100% genuine copper winding (GUARANTEED) Specs for (intelligent Voltage Stabilizer): SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. Input Voltage : 150 To 250 AC Output Voltage : 110v & 220v AC (±) 1% Frequency : 45 or 60 Hz Wave Form : Non-distorted Sine-wave Response Time : 25ms / V Efficiency : 95 % Power Factor : 0.95 Relative Humidity : 30% to 80% (without condensation) Temperature Rise : Less Then 50c Control System : DC. Servo Motor Insulation Resistance : More then 3M?? at 500V DC Tested : 1500 V We Manufacture Servo Motor Controlled Automatic Voltage Stabilizer, using Japanese technology, for UPS, Solar, AC Air-Conditioner, Split-Type, Window Type, (LCD/LED TV) Washing Machine, Treadmill, Photocopier Machine. Television, Music System, Refrigerators, Ultra sound Machines, Embroidery Machines, All Sensitive Equipment, Signalling Devices, CNC Machines, Air Conditioning Plants, Telecommunication Networks, Motor Loads, Data Processing Equipment, Bio Medical Equipment, Drives, PLC’s, Induction Heating, Hotels, Defence Application, Industrial Units, Lighting Loads, Residential/ Offices, Farm Houses, R & D Institutions, Mainline Stabilizers, Sophisticated Laboratory Equipment etc. Runs your Appliances Even in Low Main Voltage. وولٹیج سٹیبلائزر Standard Power Ratings Available in Single-Phase & 3-Phase: 500VA, 1kVA, 2kVA, 3kVA, 5kVA, 10kVA, 30kVA. Up-to 500kVA Punjab NWFP, KPK, & All Pakistan Cargo, Feel Free to Call: Rana Naeem Hammad. M.D. Tecno Industries (Pvt) Ltd Lahore. +923009433728

Rs 121

See product

11 photos

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

See product

Pakistan (All cities)

Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area. The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process. MOC-K100 mould oscillation online monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel. The meaning of the system 1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality. 2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance. 3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair. 4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident. 5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product. 6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed. The functions of the system (1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data including oscillation parameters and process parameters. (2) Time domain waveform: This function mainly displays the oscillation waveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elements of oscillation of each measuring point in real time. (3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and the oscillation difference of each channel can be calculated and displayed intuitively. (4) FFT: This functional module completes the calculation and display of the oscillation spectrum in real time. It is used to evaluate the waveform distortion of the entire oscillation table and to determine whether there is a problem with the installation of the oscillation device. (5) Bar graph: The oscillation of each measuring point is indicated by a bar graph of peak value and sensor gap voltage, which is more intuitive. (6) Trend: After starting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings for different steels under the oscillation conditions. The parameters of the system 1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged 2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes) 3. Sensitivity: 1000mV/g 4. Frequency range: 0.04~10HZ 5. Frequency accuracy: ±0.01 Hz 6. Amplitude accuracy: 0.005mm 7. Transmission mode: wired digital transmission, wireless transmission 8. Host: 3U standard rack, handheld device 9. Sensor power supply: 24V.DC 10. Host power supply: 220V.AC/50Hz Mold oscillation curve The structure of the system The main components of the continuous casting mould online oscillation detection system are: 1. Three-dimensional oscillation measurement sensor 2. Handheld oscillation sensor calibrator 3. Dedicated signal connection cable 4. Preamplifier 5. Operation processing unit 6. Graphic display terminal 7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components 8. Control cabinet

Rs 200.000

See product

3 photos

Mirpur (Azad Kashmir)

The Bachelor of Science in Electro-Mechanical Technology (BSEMT) is designed to teach students the theory and application of a broad range of electrical, mechanical, computer, control and instrumentation technologies the students' knowledge and skills in the design, construction, operation and use of robot.Help engineers design, develop, test, and manufacture industrial machinery, consumer products, and other equipment. Assist in product tests — by setting up instrumentation for auto crash tests.This program is designed to prepare students for employment in the field of mechanical design and drafting, with an in-depth course of study in the technological aspects of the design profession.Accurately and efficiently create 2D and 3D production drawings using CAD technology. Use traditional machine tools and computer numerical control technology (CNC) to manufacture production parts following industry standards and safety protocols. Use knowledge of production tools and equipment, mechanical part design, production planning and work flow methods, and quality assurance tools and techniques, to perform design calculations and evaluate and resolve engineering design and manufacturing issues. Create professional technical written documents and effectively communicate technical information to appropriate audiences. Demonstrate professional responsibility: work effectively as a member of a project team; meet deadlines; show respect for coworkers; provide stewardship of resources, equipment and facilities.Mechanical Technology is a hands-on curriculum that provides an in-depth course of study in the technological aspects of the mechanical design profession. Students are exposed to the current technology used in industry and prepared for careers in the field of mechanical design and technology.This course general introduction to engineering materials used in design and manufacturing. Topics include mechanical, physical, and chemical properties of ferrous and non-ferrous metals, plastics, ceramics, glass, and composites. The course will cover material sources, formation and production. Emphasis is on material selection for mechanical design purposes based on material properties and manufacturability. The course will cover different aspects of material testing and field trips to local material testing labs as permitted.Today's engineering and technology fields and the multifaceted role of the technologist will be explored. Orientation to student services, academic policies, stress management, science study skills, time management, and other college survival skills will be presented. Additional topics of study include applied mathematics, use of scientific calculators, teamwork and problem solving skills in the classroom and laboratory, and an introduction to the physical units and dimensions encountered in the technologies.is course is the culmination of the previous and concurrent course required for the Mechanical Technology Program. Students will be assigned a problem and asked to provide a solution. Most of the necessary information will be provided but some may require the students to do some research, such as a search on the internet. The project will incorporate drawing/design, analysis and manufacturing knowledge. The students may be asked to produce a scaled model prototype. The students will present their results in a short presentation to invited faculty, Advisory Board members and other invited guests. Prerequisite: MET 104, MET 205, MAT 152, PHY 119. Co-requisite.

Rs 25

See product

4 photos

Karachi (Sindh)

Single Drum Vibratory Roller MSR58 The MSR58 single drum road roller is lightweight and highly maneuverable. It is designed for the compaction of asphalt and various granular mediums. Aside from its landscaping applications, the roller can also be utilized for maintenance jobs around small work sites such as bridges and footpaths. The Masalta MSR58 is fundamentally different from conventional chain or belt driven rollers on the market. Our single drum road roller is outfitted with a fully featured hydraulic drive system that combines hydraulic pump and motors to power both mechanical movement and vibration output. Periodical fine tuning allows the machine to perform efficiently and consistently. Features 1. The reversing safeguard and Deadman control system are designed for operator safety. 2. Easily accessible controls allow for convenient operation. 3. The height-adjustable handle is ergonomically designed and simplifies the transport process. 4. Self-cleaning scrapers effectively prevent the dirt buildup. 5. The beveled drum edge eliminates surface markings. 6. Side clearance allow for a close pavement approach, enabling easy navigation around walls, curbs, and other obstacles. 7. The compact body of the single drum road roller allows it to maneuvers easily in confined areas. 8. Thick drum shells increase its potential service life. 9. The removable water tank has a large capacity and possesses anti-corrosion properties. 10. A built-in cooling fan operates continuously and extends the potential service life of onboard components. Model............MSR58H Engine ..........Type Honda G×160 Power Kw(hp).........4.0(5..5) Weight Kg(lb).......185(408) Drum Diameter mm(in)....580×Φ400(23×Φ16) Static Linear Force N/cm....10 Centrifugal Force kN.......28.5 Frequency vpm(Hz)...........4560(76) Travel Speed km/h...........0-1.5 Water tank Capacity...... L15 Regards SHAH OMER Lucky Engg 0321-9269422 03343669422 02135312095

Rs 490

See product

Badin (Sindh)

kig5007Sai Engineering focusing on Diesel Generator Set supplying. Our team is expert in repairing all types of generators including Cummins, Ashok Leyland, Kirlosker, Mahindra, MWM, Perkins, Sudhir, Volvo 5 kva to 5000 kva are repaired with the guarantee. Our team personnel conduct exhaustive inspection of the generators by making use of advanced testing technology. The experts thoroughly analyse and rate every component of machine, from the engine to hydraulics, from tiny washers to operator's manual. There are more than 100 checkpoints which the quality experts check before they include the used generator in the inventory. Ensure trouble free operation for long period, the used generators we provide are assured for excellent performance. Bhavnagar, Gujarat. info@saidieselgenerator.com Mr.Mahesh mo.9879304079 www.saidieselgenerator.com

Free

See product

Karachi (Sindh)

Description Support Upto 4 Lines & 32 Extensions, Built in UPS, Built in CLI, Built In OGM, Full Privacy, Highly Reliable, Music on Hold, No Console Needed Set Any Extension To Operator, GSM Device Support Power Supply 1 Year Warranty of System Also Avaliable In Just Rs 31,999/- Also Provide Audio/Video Door Phone, CCTV HD Cameras, Fire Alarm System & Fire Extinguisher, Time Attendance Machine.

Rs 31.999

See product