Claw ring

Top sales list claw ring

Latest Offers

Pakistan

2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds 2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds .....................2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds

Rs 4.000,0

See product

Pakistan (All cities)

We are Manufacturer of garden benches. We have wide range of garden and Park benches with weather resistant, Durable and Long lasting. Widely used in Societies, University's, Farm house's. Delivery Available all across Pakistan. Contact us on What's App. [redacted phone number]

Rs 11.000,0

See product

Pakistan (All cities)

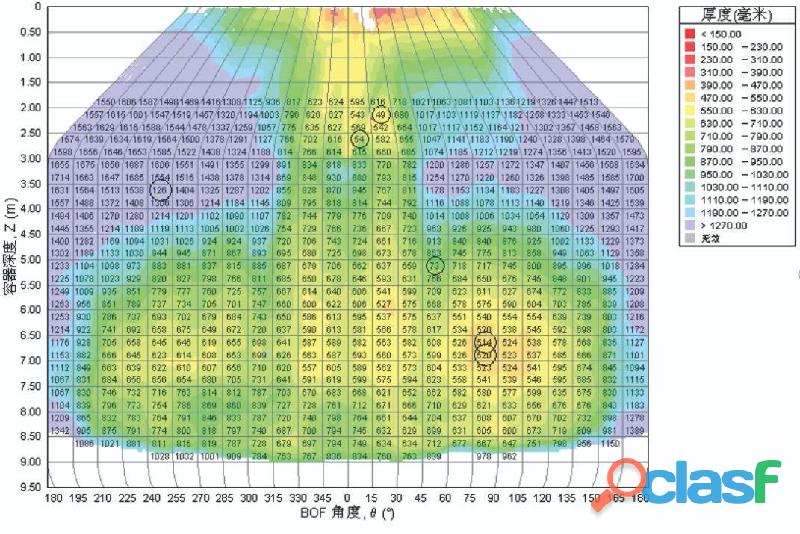

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

Rs 0,0

See product

Pakistan (All cities)

Effective Bird Deterrence: Strategically designed bird spikes to effectively deter pigeons, sparrows, and other nuisance birds.....

Free

See product

Abbottabad (Khyber Pakhtunkhwa)

Looking for the perfect way to Send Birthday Gifts to India? We’ve got you covered with our unique selection of Birthday Gifts! From personalized keepsakes to luxury hampers, there’s something special for everyone. Worried about last-minute orders? Birthday Gift Same Day Delivery in India ensures your gift reaches on time. Explore our curated collection and make birthdays memorable. Shop now to find the ideal gift that says “happy birthday” in the most thoughtful way.

Rs 500,0

See product

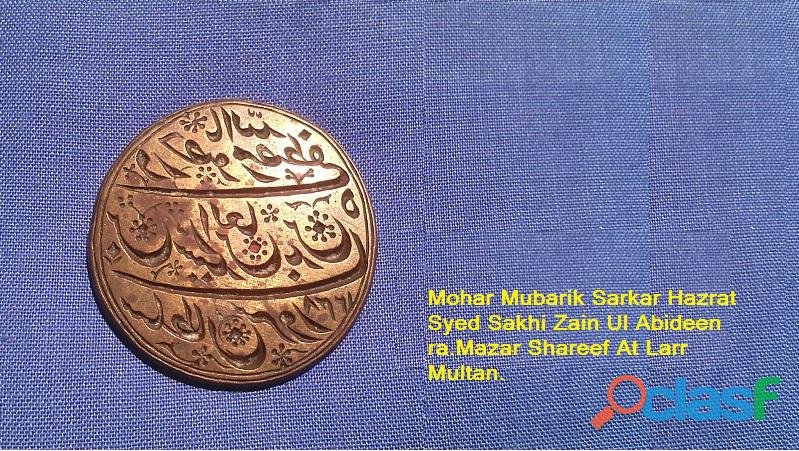

Multan (Punjab)

Hazrat Syed Sakhi Zain ul Abideen (RA) migrated from Baghdad to Saudi Arabia and spent 22 years in Madina Munawara.One night, holy Prophet hazrat Mohammad (may peace be upon him) appeared in a dream and instructed him to go to India, convince the people to the right path, preach or spread the teachings of Islam.Obeying the orders of the holy Prophet Hazrat Mohammad (may peace be upon him), the Sufi Saint left Madina Munawara and came to Shahkot. The Sufi saint is the father of a famous Sufi Hazrat Syed Ahmad Sultan, known as Sakhi Sarwar, the bountiful Chief, shrine at Sakhi Sarwar Pakistan. Hazrat syed sakhi Zain ul Abideen (RA) practised austerities and prayers in shahkot, The great renowned Sufi saints paternal genealogy is directly related ten generation up with Ameer ul Momeneen (commander of faithful) Hazrat Imam Ali Ibne Abu Talib R.A, thus he was a direct descendant of the holy Prophet Hazrat Mohammad (may peace be upon him). The name Zain ul Abideen was selected by his father Syed Umar due to the deep love and devotion with Imam Zain ul Abideen (A.S). Specification. Object Name: Seal stamp Description: Syed Zain ul Abideen Shah"Sultan Sarwar" Inscription Script : Arabic Inscription Technique: Engraved Date Period: A D 13th Century 1248 Time period: A D 13th Century Geography: Indian Subcontinent (Central Asia) Culture/period: Islamic Condition: Excellent Relics of the Islamic saints strengthens spiritual beliefs, inspire people and give them comfort in tough times. The holy seal is a precious asset handed down from generation to generation, extremely rare and a genuine masterpiece regarding the sacred relics of the early Islāmic saints.

Rs 100,0

See product

Lahore (Punjab)

shorthand classes, shorthand speed classes, basic shorthand classes, newspaper dictation, new groups start, morning evening classes, township lahore

Rs 54.770,0

See product

20 photos

Pakistan

due to a change in personal circumstances and a increase in work hours i am unfortunatly having to look for a new home for my four year old female beagle, jessie. Jessie has been spayed and is a member of the family it has been a very difficu....

Rs 200,0

See product

Pakistan (All cities)

The Veritable Calfskin store bring another Superstar Outfit Fur B-26 Shearling Aircraft Cowhide Coat. This Coat has been made by genuine quality Calfskin and has jazzy Fur Straight Style Collar https://aajacketmaker.com/product/b-26-shearling-fur-jacket/

Rs 70.000,0

See product

Pakistan (All cities)

Overview LDT-I200 is a new generation of converter lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the converter, and receives the returned laser light to measure its flight time. Then the system equipment calculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushes the equipment to a certain position on the platform in front of the converter, and the equipment can start to scan and measure the target area of the converter after the equipment performs rapid self-positioning. The Measuring principle The measurement speed of LDT-I200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curve of the entire converter lining can be obtained by combining the measurement data of different positions and angles. During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within 4 minutes, the three-dimensional surface contour of the converter lining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracy up to ±2mm. In order to convert the distance from the internal point of the converter to the thickness gauge into the thickness of the furnace lining at each point, we must know the coordinate relationship between the trolley and the converter. We use the second laser head to position the trolley. When the trolley is pushed to the measurement site, the positioning laser head rotates at high speed to scan the three reflective strips opposite the converter. Through triangulation measurement and calculation, we can calculate the relative position of the trolley to the reflective strips. The coordinates of the reflective strip and the converter are known through mapping, so that the coordinates of the trolley relative to the converter can be accurately obtained. The main components 1. Laser measuring head 2. Wireless communication 3. Battery pack 4. Mobile laser thickness gauge host 5. Converter inclination measurement system 6. Cooling circulation system 7. Positioning auxiliary reflector 8. Laser positioning system The technical indexes Laser reproducibility: ±2mm Laser accuracy: ±2mm Local fastest measurement time: 15s Positioning time: 30s Full image measurement time: 4min The highest measurable lining temperature: 1850℃ Measuring distance: 0.5-25m Actual points are measured per frame: 1500000 points Continuous working time after fully charged: ≥3h Eye-safe laser: Class 1 laser product (doesn't hurt the eyes) The parameters of laser measuring head Measurement principle: According to the flight time and speed of the laser to calculate the distance Laser reproducibility: ±2mm Laser accuracy: ±2mm Scan rate: 2000000 points/second Measuring angle: vertical ±40°, horizontal 360° Maximum measurement temperature: 2200℃ Working temperature: -20℃-80℃ Cooling method: Integrated liquid cooling system, IP64 grade protection Laser wavelength: 1550nm (near infrared)

Rs 0,0

See product

2 photos

Pakistan (All cities)

At Green Build Engineering & Construction Pte. Ltd., we provide specialized engineering solutions designed to meet unique project requirements across various industries. Our expertise and innovative approach allow us to handle complex engineering challenges with precision and efficiency, delivering results that align with your specific goals. multiethnic-professional-construction-engineers-working-with-corporate-colleagues-teamwork-equip_41418-270 Our Offering Services: Custom Design and Fabrication: Tailored engineering solutions for unique structural and mechanical needs. Advanced Equipment Installation: Seamless integration of specialized machinery and systems. Structural Reinforcements: Strengthening existing frameworks to enhance safety and functionality. Prototype Development: Designing and testing prototypes for specialized applications. Consulting and Technical Support: Expert guidance and solutions for complex engineering problems.

Rs 15.613,0

See product

Pakistan (All cities)

Spark your child’s learning journey with Kinder ABC! From fun alphabet adventures to interactive games like tracing, puzzles, and bubble popping, Kinder ABC offers an ad-free, safe space for kids to learn letters, phonics, and more. Download now and make learning fun! Get Kinder ABC on Play Store: https://play.google.com/store/apps/details?id=com.icommunetech.kinderabc Official Website: https://www.icommunetech.com/

Free

See product

3 photos

Pakistan (All cities)

Explore the top 10 CNC machines for small businesses in 2024! This comprehensive guide highlights the best machines for precision, reliability, and affordability, ideal for entrepreneurs, hobbyists, and small manufacturers. Whether you're looking for a versatile CNC mill, router, or laser cutter, find the perfect solution to enhance your production capabilities, improve efficiency, and grow your business. https://www.tradebrio.com/exporters/cnc-machines.html

Free

See product

Pakistan (All cities)

We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 1.000,0

See product

2 photos

Pakistan (All cities)

Overview In order to ensure the quality of the slab, it is necessary to strictly control the performance and various parameters of the CCM’s guide roll within a certain error range. Due to the continuous casting machine (CCM) is large and in a harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. Therefore, it is very important to have a set of equipment that can simulate drawing of steel billet to realize the measurement of CCM’s various parameters and performance. The multifunctional strand condition monitor uses various sensors to realize the measurement of CCM’s roll gap value, the arc value of continuous casting section, the rotation quality of the rolls, and the water spray pressure under the condition of simulating drawing of steel billet. Therefore, the CCM’s quality can be controlled in real time, and it is convenient for the maintenance personnel to analyze the CCM’s measurement results. The problem areas of the casting machine equipment can also be found. If these problems doesn’t be found in time, it will cause the bad quality of CCM’s products, the steel breakout in pouring process, surface and internal cracks and centerline deviation. The measurement of the strand condition monitor Roll gap value: By measuring the distance between a series of inner arc guide rolls and outer arc guide rolls on the CCM’s roller bed. It can be used to set the correct roll gap spacing for each pair of guide rolls in the slab caster. Arc condition of guide roller : Measuring the position between the position of the CCM’s outer arc guide roll and the two adjacent guide rolls and then measuring the deviation compared with the origical position of CCM’s guide roll, we can obtain the arc condition of the outer arc guided roller. Guided roller rotation: It is possible to know whether each guided roller can rotate freely by measuring. Water spray pressure: The operation of the water spray cooling system can be judged by measuring the situation of secondary cooling water spray at different positions of CCM's width direction. Then we can accurately locate whether the water spray at a certain point is normal. The main components of the strand condition monitor 1. The main body of the strand condition monitor used to measure the continuous casting sector 2. The connecting chain between strand condition monitor and dummy bar 3. The storage rack chain of strand condition monitor 4. Battery charger: 24V 5A 5. Calibration equipment 6. Remote control 7. Laptop 8. Printer 9. Data communication cable The technical parameter 1. The measurement range of roll gap: 210mm, 230mm (can be customized according to requirements) 2. The measurement accuracy of roll gap: 0.01mm 3. The arc measurement range: ±80° 4. The arc measurement accuracy: 0.01° 5. The spray measurement range: 0-10 6. The spray measurement accuracy: ±1 7. The battery usage times: 3 times

Rs 0,0

See product