Cart accessories

Top sales list cart accessories

Latest Offers

Pakistan

After a small size Male tri colour beagle smaller than standard size,ideally pocket size or small legged. Must be K.C Registered and come with papers.Ideally Adult or 8months and over.Cash waiting can travel.,

Rs 200,0

See product

Pakistan (All cities)

GoLogica offers complete online training in data modeling that gives professionals the understanding and skills they need to understand data modeling methods. IT specialists, database developers, business analysts, and data analysts who want to become better in creating and managing data structures may benefit from this course. Basic topics covered in the course include entity-relational diagrams (ERDs), data mapping, normalization strategies, and abstract, logical, and physical data modeling. It also covers database design concepts, demonstrating how to build durable, scalable, and effective data models that correspond with business goals. This course, led by industry experts, gives participants practical knowledge through practical assignments, allowing them to apply what they've learned in actual situations. Whether you're new to data modeling or want to improve your existing skills, GoLogica Data Modeling Online Training provides a solid basis for creating and managing successful data models. Enroll in GoLogica Data Modeling Online Training today to obtain the knowledge you need to boost your career in data management and become a certified Data Modeling expert!

Rs 0,0

See product

Pakistan

We have 6 kittens that will be available as pets, they will be ready to leave home on 7 April 2016. There are 3 boys and 3 girls. Silver spotted and Brown spotted. Mum is a gorgeous Silver Marbled F6 and Dad is a stunning tarnish free Silver spotted boy. If you are interested in these babies, please contact me as there is always a great demand for these babies from this pairing. They always make fabulous big kittens and this is probably the last time that these two are paired together due to the age of Oliver. Viewings start at 8 weeks of age after their 1st vaccination when we will require a non-refundable deposit to secure your kitten. We can also early neuter your boys before they leave us, this will be chargeable, please ask us about this. Individual photos will be taken in a few weeks when kittens are weaning. Please note that some of the kittens are in the fuzzies so markings will not clear for a few weeks yet: Beige Collar - Cool Brown Boy Blue Collar - Silver Boy Green Collar - Silver Boy Purple Collar - Brown Girl Yellow Collar - Stunning Cool Brown Girl Pink Collar - Silver Girl

Rs 5.000,0

See product

Pakistan (All cities)

Get the best nail polish services in Hyderabad at Kameleon Salon, from classic manicures to gel finishes.

Free

See product

Pakistan (All cities)

Finding the best tyre shops near me, Sometimes it can be challange, especially when there are so many options available in the markets. Here, you can find a list of the trusted tyre shops where you can get the best deals and services, including new tyres, tyre repairs, or balancing services at affordable prices. Whether you're looking for quality tyres or expert maintenance, these shops offer reliable solutions to meet your needs. https://www.tradebrio.com/exporters/car-tyres.html

Free

See product

Pakistan (All cities)

Jaipur, the Pink City, is not only famous for its architectural splendor but also for its exceptional furniture craftsmanship. If you’re searching for the top furniture manufacturers near you in Jaipur, you’ll find a wealth of options offering a perfect blend of tradition, quality, and modern designs. Why Choose Jaipur Furniture Manufacturers? Expert Craftsmanship: Jaipur’s furniture manufacturers are renowned for their skilled artisans who create intricate designs using time-honored techniques. High-Quality Materials: Most manufacturers use premium woods like teak, sheesham (Indian rosewood), and mango wood, ensuring durability and lasting beauty. Custom Designs: Many offer bespoke furniture tailored to your specific needs and style preferences. Variety: From traditional Rajasthani designs to contemporary and minimalistic styles, there’s something for every taste. Furniture Options Available: Living Room: Elegant sofas, coffee tables, and TV cabinets. Dining Room: Sturdy and stylish dining tables and chairs. Bedroom: Luxurious beds, wardrobes, and dressers. Office Furniture: Ergonomic desks and chairs for a productive workspace. Whether you’re furnishing your home or office, Jaipur’s furniture manufacturers ensure pieces that not only serve practical purposes but also elevate the aesthetics of your space. Explore the top furniture manufacturers near you in Jaipur to find handcrafted masterpieces that reflect the city’s rich heritage and artistic flair. Transform your spaces today with furniture that stands the test of time!

Rs 0,0

See product

Pakistan (All cities)

China Metal Parts Forging OEM Manufacturer Co., Ltd. (https://www.creatorcomponents.com/) was founded in 2000 by a team of experienced professionals in the forging industry. As a Chinese manufacturer, we specialize in providing high-quality carbon steel and alloy steel metal parts and components for a wide variety of industries. We focus on innovation and engineering excellence to ensure that we meet the highest standards of quality and performance. By utilizing advanced technology and state-of-the-art equipment, we produce products that are durable and reliable, meeting the requirements of both domestic and international customers. Quality is a top priority at every stage of our production process. From inspecting raw materials to conducting 100% final product testing, we ensure all products comply with international standards through our thorough quality control system. As a Chinese manufacturer, we offer customized metal parts to cater to the specific needs of industries such as automotive, construction, and energy. We collaborate closely with clients to deliver tailored solutions that align with their business objectives. At China Metal Parts Forging OEM Manufacturer Co., Ltd., we are dedicated to providing innovative, sustainable solutions and excellent customer service, earning the trust of businesses worldwide as a reliable partner.

Free

See product

4 photos

Lahore (Punjab)

Boost your online presence with our expert digital marketing services. We specialize in SEO, PPC, social media management, content creation, and email marketing to drive targeted traffic and maximize ROI. Let us help grow your brand, engage your audience, and achieve measurable results in today’s competitive digital landscape.

Rs 45.000,0

See product

Islamabad (Islamabad Capital Territory)

Marshall Packers and movers in Lahore Pakistan International Packers and movers in Lahore Pakistan Our services House shiftng services Goods transportation Freight forwarding International cargo services International Afghan Transit services International furniture shipping services House shifitng services in Rawalpindi"House shifitng services in Pakistan International cargo services in Islamabad https://marshallpackers.com/services/cargo/

Free

See product

Lahore (Punjab)

SEO Training in Lahore offers comprehensive courses designed to equip individuals with the skills needed to excel in search engine optimization. Whether you're a beginner or looking to enhance your existing knowledge, our training programs cover everything from basic SEO principles to advanced strategies. You will learn keyword research, on-page and off-page optimization, technical SEO, content marketing, and the latest SEO tools and techniques. Our experienced instructors provide hands-on training with real-world examples, ensuring you can apply what you've learned immediately. The course also includes case studies, projects, and practical

Free

See product

2 photos

Pakistan (All cities)

We have the Outboard Boat Engine OXE. Yamaha We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 150.000,0

See product

2 photos

Pakistan (All cities)

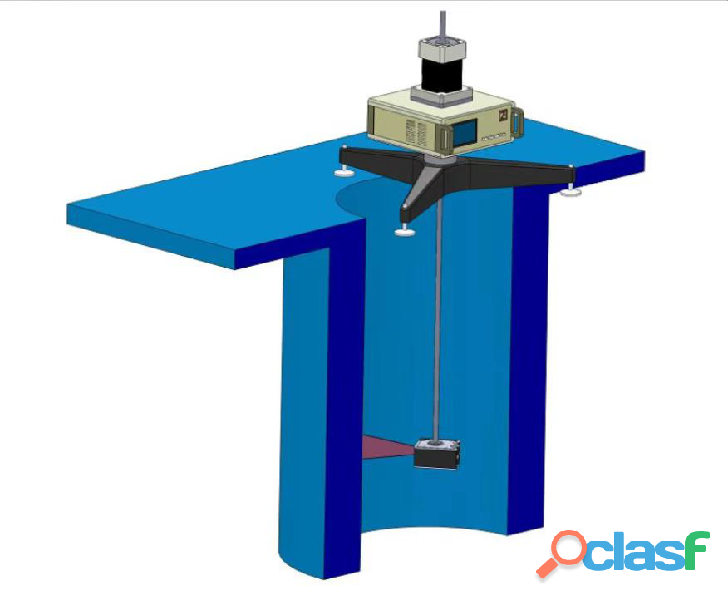

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product

Ahmadpur East (Punjab)

Online Silver Anklet in Jaipur – Chic, Elegant, and Comfortable Step up your accessory game with our gorgeous collection of online silver anklets in Jaipur at thelilacc. Crafted from 925 sterling silver, our anklets are designed to enhance your natural beauty with a perfect blend of sophistication and charm. Whether you prefer a simple design or one with delicate embellishments, our anklets add a graceful touch to any outfit, making them ideal for both everyday wear and special occasions. Why Choose Our Online Silver Anklets in Jaipur? Premium 925 Sterling Silver: Made from high-quality 925 silver, our anklets offer durability and a lasting shine that’s resistant to tarnish. Variety of Styles: From minimalist chic to ornate, detailed designs, our anklets come in a wide range of styles to suit your unique taste. Comfort and Fit: Designed for all-day wear, our anklets are lightweight, comfortable, and easy to adjust for a perfect fit. Perfect for Any Occasion: Whether you're dressing up for a celebration or adding a finishing touch to your daily look, our anklets are versatile enough for any occasion. Convenient Online Shopping: Browse and buy from the comfort of your home, with secure payment options and fast delivery across Jaipur. Shop online silver anklets in Jaipur at thelilacc and bring home the elegance and beauty of finely crafted silver jewelry. Order today and add timeless grace to your style!

Rs 3.541,0

See product

3 photos

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

Rs 0,0

See product