Automatic steel

Top sales list automatic steel

Pakistan

Fragrance Automatic Function For Best Pleasant Environment Fresh Aire has been fragrance and deodorizing offices since 1995! This business was built around a belief that business owners and managers want to make the best initial impression as their customers walk through their doors coupled with a pleasant, desirable work environment for their employees. Whether you have a lot of foot traffic in a retail space or a few employees in a professional office or small production facility, we have a fragrance that will work for you. We are dealing on • ZZ PAFF Plus - Perfumed Insecticide Citrus Insect Killer & Specially Mosquito Killer Made in Spain • Automatic air fresher dispenser (Made in Malaysia) • Fresco original (Made in Malaysia) • Hand soap Liquid dispenser (Made in Malaysia) • Hand Liquid soap Dispenser (stainless steel) • Sanitize dispenser (Made in Taiwan) • Hand sanitize (Malaysia) • Fresco aerosol (Made in Malaysia) • Soap liquid (Anti Bectria) (Made in Malaysia) • Hand dryer (Made in Taiwan) • Tissue Box • Tissue Paper ( all kinds) • Fresh Aire sticks ( for Dinnig Table , and Vehicles ) • 2,3,4 Visitor’s chairs ( Steel body) • • Ozonator Machine for 100% pure water (for you and your family Health) • We are also working on your home and office garden renovation and decoration. It is easy to get started! We invite you to try our service! If you like it: 1- We provide the equipment 2- We have no contracts to sign 3- We do not charge for installation 4- Discounts are available to customers who want maximum areas fragrance Thank you for the giving time. Call us today! Cell#. 0312-1494343 & Land Line #. 042-36286116

Rs 1,20

See product

Pakistan

Fragrance Automatic Function For Best Pleasant Environment Fresh Aire has been fragrance and deodorizing offices since 1995! This business was built around a belief that business owners and managers want to make the best initial impression as their customers walk through their doors coupled with a pleasant, desirable work environment for their employees. Whether you have a lot of foot traffic in a retail space or a few employees in a professional office or small production facility, we have a fragrance that will work for you. We are dealing on • ZZ PAFF Plus - Perfumed Insecticide Citrus Insect Killer & Specially Mosquito Killer Made in Spain • Automatic air fresher dispenser (Made in Malaysia) • Fresco original (Made in Malaysia) • Hand soap Liquid dispenser (Made in Malaysia) • Hand Liquid soap Dispenser (stainless steel) • Sanitize dispenser (Made in Taiwan) • Hand sanitize (Malaysia) • Fresco aerosol (Made in Malaysia) • Soap liquid (Anti Bectria) (Made in Malaysia) • Hand dryer (Made in Taiwan) • Tissue Box • Tissue Paper ( all kinds) • Fresh Aire sticks ( for Dinnig Table , and Vehicles ) • 2,3,4 Visitor’s chairs ( Steel body) • • Ozonator Machine for 100% pure water (for you and your family Health) • We are also working on your home and office garden renovation and decoration. It is easy to get started! We invite you to try our service! If you like it: 1- We provide the equipment 2- We have no contracts to sign 3- We do not charge for installation 4- Discounts are available to customers who want maximum areas fragrance Thank you for the giving time. Call us today! Cell#. 0312-1494343 & Land Line #. 042-36286116

See product

Lahore (Punjab)

The Automatic Doors Company for Automatic Doors and Security Systems has been established since Year 2010 offering a quality bespoke. Service. Our business strives to achieve optional accessories focusing closely on customer needs, to maintain and expand our product leadership and delivery value. Even demanding customers appreciate the high level of innovation and the outstanding quality of our products. we have proven to offer an excellent service planning for installation, testing and commissioning. We can assure fully satisfactory operation of our entire product range. Specializing in manufacturing, design and installation of residential and commercial buildings Automatic sliding Swing Door, Sliding swing Gate, Parking Barriers, security gates, Structure Shade, Road blocker and tyre killers, E-Tag Parking Solutions. Also offering Rolling Shutter, Aluminum Roller Shutter, Insulated sectional door, fire doors, wooden/ metal security Door and windows, Optional Door accessories and stainless steel railings. ADC (Automatic Door Company) PAKISTAN 90B-4 Main Canal Road Gulberg IV Lahore. Pakistan 54600 Web: www.adc.com.pk Email: farhan@adc.com.pk a.farhan@outlook.com Phone: +92-42-35759593-4 Mobile: +92-321-3000222

See product

Lahore (Punjab)

The Automatic Doors Company for Automatic Doors and Security Systems has been established since Year 2010 offering a quality bespoke. Service. Our business strives to achieve optional accessories focusing closely on customer needs, to maintain and expand our product leadership and delivery value. Even demanding customers appreciate the high level of innovation and the outstanding quality of our products. we have proven to offer an excellent service planning for installation, testing and commissioning. We can assure fully satisfactory operation of our entire product range. Specializing in manufacturing, design and installation of residential and commercial buildings Automatic sliding Swing Door, Sliding swing Gate, Parking Barriers, security gates, Structure Shade, Road blocker and tyre killers, E-Tag Parking Solutions. Also offering Rolling Shutter, Aluminum Roller Shutter, Insulated sectional door, fire doors, wooden/ metal security Door and windows, Optional Door accessories and stainless steel railings. https://www.facebook.com/AdcPakistan/ ADC (Automatic Door Company) 90B-4 Main Canal Road Gulberg II Lahore. Pakistan 54600 Phone: +92-42-35759593-4 Mobile: +92-321-3000222

See product

Rawalpindi (Punjab)

We are manufacturer & supplier of residential and commercial buildings automatic sliding Swing Door, Sliding swing Gate, Parking Barriers, security gates, road blocker and tyre killer, E-Tag Parking Solutions. Also offering Rolling Shutter, aluminium roller Shutter, insulated sectional door, fire doors wooden metal security Door and windows, Option Door accessories and stainless steel railings. Automatic Swing Gate Automatic Sliding Gate Automatic Glass Door Automatic Shutter System Motorize gates Malaysian Auto gates Nice Italy Swing Sliding Gates 90B-4 Main Canal Road Gulberg IV Lahore. Pakistan 54600 Web: www.adc.com.pk Email: farhan@adc.com.pk a.farhan@outlook.com Phone: +92-42-35759593-4 Mobile: +92-321-3000222

See product

Pakistan (All cities)

Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition. The features of the system 1. The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken. 2. The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different segments and different casting speeds. 3. The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed. The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity. 4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient. It has manual, automatic, local and remote control modes. 5. The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux. 6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage. 7. Strong operability, simple and convenient maintenance, and low maintenance cost. 8. It can maintain the even distribution of the flux layer in the mold. The composition of the system The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment. 1. The feeding trolley is the support and walking equipment of the mold flux feeder. The basic equipment of the adding mold flux machine is installed on the feeding trolley. At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position. 2. The feeding bucket is a device for holding mold flux. The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder. The feeding bucket is provided with alarm contact of mold flux level limit.. 3. The swing arm and the feeder motor form a feeding and conveying device. The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor. Then the mold flux can be used for mold distribution. 4. PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates. 5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold. The technical parameter Mold width: 500-2000mm Mold thickness: 100-500mm Type: screw conveying type mold flux feeding machine Heating method: stirring electric heating Arrangement location: on the pouring platform (with its own wheels to move) Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube Molding flux storage tank: 300 L, with material level detection and alarm Control mode: local/remote control, automatic /manual mode Molding flux type: granular flux or powder flux flux adding method: spiral swing adding flux Casting speed interlock: yes Mould size setting: yes Signal transmission: DP/Industrial Ethernet

See product

Pakistan (All cities)

Overview The WGS-L200 Laser Slab/ Plate Steel Width Measuring System adopts the principle of double laser triangulation reflection to process the online measurement of the steel plate on the roller bed, and combines the high-speed digital signal processing technology and programming software to process the signal correspondingly, and displays the relevant data and measurement curve, so as to realize the accurate control for steelmaking process during the production. The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The measuring principle of the system The WGS-L200 Laser Slab/Plate Steel Width Measuring System is mainly composed of computing processing software and hardware systems such as testing equipment, computing equipment. The hardware system consists of 2 sets of laser triangulation rangefinding system, on-site signal acquisition and transmission system, operation unit, host analysis and control alarm system, etc. The software of WGS-L200 laser slab/ plate steel width measuring system mainly includes data acquisition and analysis, alarm software and data visualization operation software in the host system. The data analysis system analyzes and converts the data transmitted by the signal acquisition and analysis system into the visual data of the main control room, and completes the width measurement monitoring work in the slab production operation through the set alarm threshold. The features of the system 1. Using the principle of laser triangulation reflection, it is very suitable for dynamic measurement, and the dynamic measurement accuracy is high. 2. Non-contact type, namely, the laser rangefinding sensor is installed on the upper and lower sides of the strip conveying guide groove, and the width measurement device is not in direct contact with the strip. 3. Continuous and fast sampling measurement, the sampling frequency is 300Hz-2000Hz. The measurement frequency can be set freely to realize high-speed width detection. 4. It can effectively identify and compensate the beating, inclination, side deflection and profile of the tested plate; 5. Excellent mathematical model realizes accurate width detection of the bad profile; 6. The software interface is good, powerful, easy to operate and maintenance-free; 7. The software has self-diagnosis function; 8. Full digital detection, automatic calibration system; 9. High measurement accuracy and fast response; 10. Using optical fiber signal transmission; 11. Quality control alarm; The technical parameters Measuring distance: 0.5-0.8m (according to the on-site environment) Resolution: ±0.1mm Repeatability: 0.2mm Measurement output frequency: 100-3KHz Laser class: 2 (IEC60825-1:2014) Protection class: IP65 Communication method: TCP/IP communication

See product

Lahore (Punjab)

Long And Regular Box Filling Facilities - Stainless Steel Gears Machine - Mixer Tank 700 Litter Non Magnetic Stainless Steel - Storage Tank 700 Litter Non Magnetic Stainless Steel - Shifting Pump Non Magnetic Stainless Steel - Junction Tank 150 Litter Non Magnetic Stainless Steel - Side Sealer, - 20 ft 1/2 inch Non Magnetic Stainless Steel Pipe - 6 Trays Aluminum- -contact 03349858228

Rs 700

See product

Lahore (Punjab)

DENTAL AUTOMATIC CROWN REMOVER SET Ahaf Surgico Manufacturing Of High Quality Latest CNC made Dental Implants Instruments, Dental Implant Tools Kits, Surgical Instruments of all kinds. We provide instruments Stainless Steel AISI Standard 400 series,300 Series, Japanese, French, High Carbon of Pakistani Stainless steel in high quality. all products get ISO 9001-2008 CE Mark SCCI SIMAP Certification. E-Mail: Sales@ahafsurgico.com Whatsapp: 0092-3116960642 Website: www.ahafsurgico.com

Rs 5

See product

Pakistan (All cities)

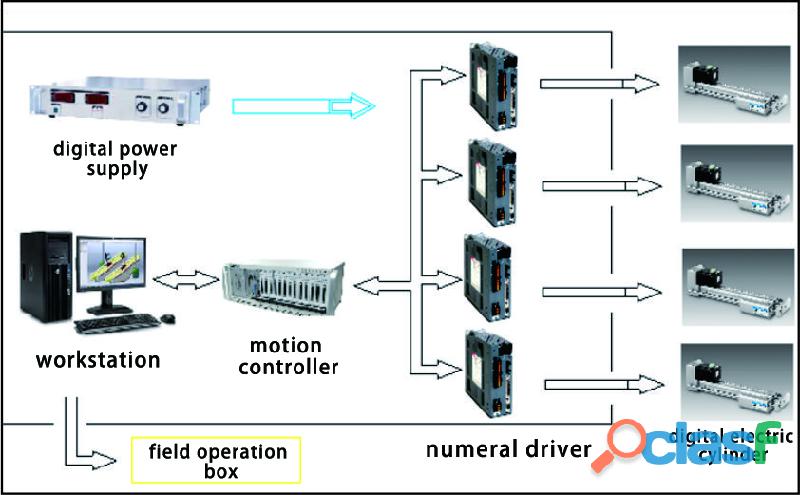

Overview In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting. The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached. During the production process, the adjustment of the mold’s width can be completed without stopping the machine. Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold. Only with adjustment and detection can the online adjustment range of the mold be accurately controlled. Fig 1 Mold online width adjustment system The components of the system Workstation: host system, system width adjustment control, taper detection. On-site operation box: real-time display of the current control status, manual operation to adjust parameters. Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control. On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time. Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment. FIG 2 System block diagram The technical parameters Adjustable range: 0-1250mm (unilateral) Control accuracy: 0.02mm/0.05mm/0.1mm Step resolution: 0.01mm/0.02mm Running speed: 0-10mm/s Power: 3.5KWl 16-bit encoder: 65536 pulses Weight: 25Kg Shell: high-strength aluminum alloy FIG 3 Syetem software interface The functions of the system Realize online width adjustment function Realize the online real-time monitoring function of mold taper Continuous casting production adjustment and non-stop production One-key operation in the main control room, automatic completion High adjustment accuracy and fast speed The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

See product

3 photos

Pakistan (All cities)

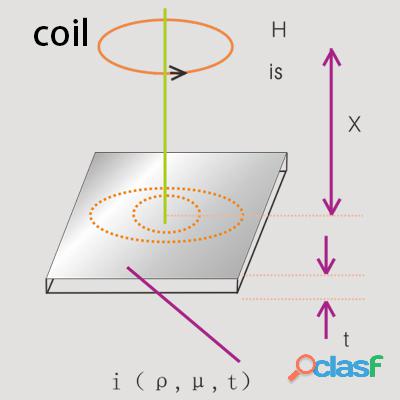

Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting. The molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet. The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows: The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm. At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%. It means that the level fluctuation directly affects the surface quality of the casting billet. The principle of the system The eddy current type molten steel level gauge is the key to the system. The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time 0.10s), high detection accuracy (±05mm), and large measurement range (0-150mm). The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer. The system has the advantages of simple operation and no radiation protection problems. The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform. The sensor is cooled by compressed air during use. The principle is shown in the figure A high-frequency exciting winding is installed above the molten steel surface of the mold. The high-frequency magnetic field generated by the high-frequency exciting winding induces eddy currents on the molten steel surface to form a magnetic field. The magnetic field generated by the induced eddy current is in the opposite direction to the magnetic field generated by the high-frequency exciting winding, which changes the impedance of the high-frequency exciting winding. Under the condition that the winding material and structure, steel grade, temperature remain unchanged, the coil impedance change only has a single-value function relationship with the height of the molten steel level. As long as the impedance change of the high-frequency winding is detected, the change of the molten steel level in the mold can be converted. The components of the system Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper. The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level. 1 Eddy current sensor; 2 mold level gauge; 3 control computer; 4 On-site operation display control panel; 5 digital actuator; The control principle of the system The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation. The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc. In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include: 1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper 2. The influence of the weight change of molten steel in the tundish on the control system 3. The influence of the change of the casting speed of the continuous casting machine on the control system 4. The influence of the mold width change (the mold width is adjustable) on the control system 5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge The function and software implementation In order to overcome these disturbances, the mold level control strategy adopts PID control. And on the basis of PID control, self-adaptive correction and feedforward control are introduced to form an advanced control system. The level control is the main loop, and there is a proportional gain of the main loop controller. According to the self-adaptive correction of the mold width change and feedforward compensation of casting speed, so as to further reduce and eliminate liquid level fluctuations caused by mold width adjustment and casting speed changes. In order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates lightly. And the system will choose a shorter intergrating time when molten steel level fluctuates greatly. Thereby, the fluctuation of the controlled object caused by the frequent action of the stopper rod is suppressed. In the signal processing of molten steel level gauge, an appropriate filtering link is added and the vibration frequency synchronous filter is used for filtering processing, which can overcome the interference of mold vibration frequency and amplitude variation.

Rs 200.000

See product

3 photos

Pakistan (All cities)

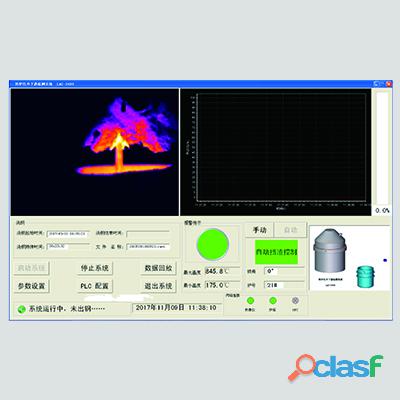

Overview The continuous casting vibration type ladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection. The LAG-S200 continuous casting ladle slag automatic detection system is developed by Wuhan CenterRise M&C Engineering Co., Ltd. after many years of research with many scientific research institutes, and fully combined with the actual situation on site. It has a real field application value as a continuous casting ladle slag automatic detection system. The meaning of the system 1. Reduce the amount of tundish slag 2. Improve the purity of molten steel 3. Improve the life of the tundish 4. Reduce sliding nozzle erosion 5. Reduce nozzle blockage 6. Increase continuous pouring heats 7. Reduce the amount of residual steel in the ladle when high-quality steel is casting 8. Improve the yield of molten steel 9. Improve the quality of continuous casting billets In order to improve the purity of the molten steel in the tundish, and improve the quality of the casting billet, especially to improve the quality of the billet in the transition section, and reduce the amount of residual steel in the high-quality ladle, and prolong the life of the tundish lining, and increase the continuous casting heats, it’s necessary to detect and control the slag in the later stage of continuous casting ladle casting. The working principle The LAG-S200 continuous casting ladle slag automatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through the long nozzle and pours into the tundish, the molten steel impacts the wall of the long nozzle and causes the vibration of the mechanical operating arm used to support the long nozzle. Since the specific gravity of the steelmaking slag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmaking slag appears when the molten steel is about to be all poured. At this time, due to the high viscosity and poor fluidity of light steelmaking slag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel. The system mainly monitors the ladle slag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm. The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close the ladle nozzle. The features of the system (1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise. (2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The threshold of slag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such as the sensor service life and sensor usage times. (3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life. (4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracy of slag alarm. (5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction. (6) The equipment adopts a modular design. The failure of each module will not affect other parts, which ensure more reliable operation of the system and easy maintenance. (7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag carryover strats, we can choose automatic mode or manual mode. In both modes, the system will give audible and visual alarm signals to remind on-site operators. (8) The system has a powerful database function. Including the comparison function for last two ladles of casting time record, the system automatically stores the running data, and generates a record file every day. (9) The system has the function of automatically controlling the ladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with the ladle slag detection system to automatically control the opening of the ladle nozzle and realize the whole-process control of the liquid level of the molten steel in the tundish. The composition of the system The LAG-S200 slag detection system consists of: vibration detection sensor, pre-signal amplifier, slag detection operation unit, tundish liquid level control unit, on-site operation indication box, and process control cabinet. 1. Vibration detection sensor: It is installed on the robotic arm of the stopper to detect the vibration signal of the whole casting process of the ladle. 2. Pre-signal amplifier: Amplify, convert and transmit the weak vibration signal detected by the vibration detection sensor. 3. Slag detection operation unit: Analyze, judge and discriminate the vibration signal to realize the discrimination of all steel, mixed slag and full slag , and output the slag alarm signal. 4. Tundish liquid level control unit: Accept the control signal of the tundish nozzle and the ladle nozzle, and realize automatic or manual control to the ladle slag according to the requirements. 5. On-site operation instruction box: Provides man-machine exchange for slag alarm indication, fault indication, system activation mode selection, and control mode selection. 6. Process control cabinet, providing power management, displaying man-machine interface and setting management. The parameters of the system 1. The system controls the slag inclusion in molten steel with high precision and closes the nozzle in real time. 2. Improve the quality of steel, reduce defective products, and improve the yield. 3. The yield of molten steel is increased by 0.3%-0.5%. The nozzle can be automatically closed, so that the disadvantage of untimely manual response is overcome and less molten steel remains in the ladle. The threshold value of molten steel (slag threshold) is set by the user within a wide range. 4. No artificial factors are involved, high reliability, good repeatability or consistency. 5. The steelmaking slag does not pass through or rarely flows into the tundish, which increases the service life of the refractory material and the sliding nozzle. 6. Reduce the blockage of the tundish nozzle and increase the number of continuous pouring heats of the tundish.

Rs 200.000

See product

3 photos

Pakistan (All cities)

Overview The system realizes the fixed-length measurement of the width, thickness and length of the continuously cast product through machine vision and laser rangefinding system. The measured data is transmitted to the host system through the optical fiber. The host system calculates the weight of each billet according to different steel grades and specific gravity, so that we can realize the fixed length measurement and fixed weight control of the cast products and the precise control of the steelmaking process in the production process. After cutting the billets by fixed weight and length, the fixed weight cut-to-length system is checked by the online weighing measurement system, so as to give feedback to the fixed length model of control system. The slab number (automatic checking) can also be automatically identified online by using machine vision, and the weight and slab number can be automatically stored in the local database for use in the production and management system. The measuring principle of the system On the upper surface of the billet, a set of linear CCD cameras and a laser rangefinding instrument are respectively installed. Through machine vision and laser correction, we can achieve precise measurement of the cast products’ shape. Through accurate cast products’ shape monitoring, the billet thermal expansion coefficient of cast products and cast products’ density at the current temperature, we can obtain the quality of the billet. At the same time, we can achieve high-precision quality cut-to-length , namely, fixed-weight and fixed-length. The system can be matched with the weight detection and calibration system. The system adopts the online barrier-free hidden integral roller table weighing method for continuous casting products, and connects its weighing data into the intelligent control model. The model and steel billet weighing system, and the fixed weight cut-to-length system realize the closed-loop control of the system model, and optimize the fixed weight accuracy through automatic signal collection. The features of the equipment The cutting control technology for fixed-length and fixed-weight of cast products is a concrete manifestation of the lean production management of steel products. In the era of high-quality competition of steel products, only high-end intelligent technology and management can reduce costs, improve quality and market competitiveness. 1. Data management can be carried out according to shifts, pouring times, days, weeks, months, etc., as well as data management according to specifications, production capacity, quality, etc. 2. Each stream can send out signals such as pre-clamping, clamping, cutting, roll-up, roll-down and return of the cutting car according to the user's requirements. 3. The detection and cutting precision is high, the controllable length sizing accuracy is ±1mm, and the quality sizing accuracy is more than 1.5‰. 4. It is not sensitive to other high-intensity light interference, and overcomes the influence of light sources such as sunlight and arc welding. 5. The monitor displays the running status of the current hot billet in real time and displays the corresponding parameters. 6. Laser rangefinding and CCD machine vision are used to calculate the weight of the cast products and optimize the cutting to length. 7. Historical cutting data is automatically stored, and the system can set rules for historical data. 8. Support the free transformation of fixed length, and a variety of operation modes are available for the operator to choose. 9. Adopt advanced high temperature laser measurement and high pixel linear CCD technology. 10. The system provides abundant interfaces, which can communicate with the PLC control. 11. Applicable to all kinds of continuous casting machine flame cutting system. 12. Provide automatic, upper and manual cutting control. The main technical requirements 1. Width range of the inspected cast product: 120~2000 mm 2. Length range of the inspected cast product: 1000~20000 mm 3. Thickness range of the inspected cast product: 35~400 mm 4. Steel billet moving speed: 3.5 m/s 5. Billet running speed: 6.5m/min 6. Temperature of the measured steel billet: 0~850 °C 7. Measurement accuracy: width ±0.2mm thickness ±0.2mm length ±0.2mm 8. Fixed weight accuracy: 0.8‰ (temperature model verification) 9. Quality inspection check: 1‰

See product

Pakistan (All cities)

Overview: Mold powder is mainly used in the continuous casting and steelmaking process, evenly sprinkled on the molten steel surface in the mold to lubricate, keep warm, prevent oxidation and absorb non-metallic inclusions. Mold powder is an indispensable auxiliary production material in the production process. In the process of evenly distributing the mold powder to the molten steel surface of the mold, the amount of mold powder should be controlled, and the thickness of the mold powder should be within a certain range. If the coverage thickness of the mold flux is too thin, it will cause no heat preservation, oxidation of molten steel, inclusions, cracks, large drawing resistance, steel leakage, etc. At the same time, the coverage thickness of mold flux should not be too thick, they can’t melt in time with too much mold powder, if the molten steel is churning, it is easy to get the mold powder into molten steel at this time, resulting in mold leakage. Therefore, the amount of mold powder must be controlled within a reasonable range. The detection and control of mold flux thickness is very important, especially for the steel plants which are strict with the steelmaking production process. The detection principle: The mold flux detection system developed by Wuhan CenterRise M&C Engineering CO., Ltd. uses the laser triangular sensor fixedly installed above the mold to obtain the height h1 by scanning the upper surface layer of mold flux with high-precision laser triangulation. When the laser measuring head is placed each time, the height h3 of the upper nozzle of the mold will be marked, and the system through the PLC system which is connected to the continuous casting machine through the network to introduce the height h1 of the mold liquid level. Through the calculation of three heights, we can get the thickness of mold powder H = 900-h1-(h3-h2)mm (900mm is the depth of mold). The features: The system adopts a high-precision laser triangulation distance meter, which can measure the thickness of the mold flux with high speed and high precision, and the accuracy can reach 1mm. The equipment is easy to install and use. When we are using, the laser rangefinding sensor can be placed directly above the mold without affecting production. The system can be interlocked with the automatic mold powder feeding system to automatically adjust the amount of mold powder, so as to automatically control the amount of mold powder within a reasonable range and realize intelligent automatic mold powder feeding. Non-contact measurement, the system only needs ventilation protection, simple and stable to use. The parameters: Measurement range:0-50mm Temperature measurement range: -20℃-700℃ Equipment installation distance:750mm System measurement accuracy:1mm Laser measurement accuracy: 0.1mm Frequency: 700-2000Hz Cooling method: air-cooled purging Installation method: rail sliding installation, can be slid out during maintenance Storage period: data can be stored for more than 2 years Communication method: Industrial Ethernet or Profibus-DP

Rs 200.000

See product

2 photos

Rawalpindi (Punjab)

A Civil Engineering Laboratory Technician carries out a wide range of sampling and testing of civil construction materials, both in the laboratory and in the field. Civil technology is the field of drafting, cartography, traffic technology and the analysis of construction materials to support construction, engineering, and architecture for roads, bridges and other public structures. Materials testing,Construction Laboratory Technicians are responsible for sample collection and test specimen preparation in order to perform various tests of construction materials including sand, cement, bitumen, aggregate, soil, brick, asphalt and concrete blocks. They generally work under strict supervision of senior technicians, civil engineers or project managers in laboratories (laboratory technician) or at construction sites (field technician). Skills The ability to learn specific, practical techniques and apply this knowledge to solve technical problems. Good hand-eye coordination, to use technical equipment with accuracy. The ability to maintain and calibrate technical equipment. Time management skills to work on several different projects at once. Flexibility for working with and providing support to a number of people. Atterberg Limits 1) Liquid Limit Test Set (with all accessories) 2) Plastic Limit Test Set (with all accessories) 3) Shrinkage Limit Test Set (with all accessories) Sand Equivalent Test 1) Sand Equivalent Test Set (with all accessories) 2) Stock Solution 3) Soundness Sieves 4) Steel Bowl Large 5) Sodium Sulphate 1KG Bottle 6) Distalled Water Unit Weight &Specific Gravity Test for Coarse & Fine Aggregate 1) Density Basket 2) Sand Absorption Core & Tamper 3) Unit Weight Mould 6" Dia 4) Unit Weight Mould 8" Dia 5) Pycnometer 25ml 6) Pycnometer 50ml 7) Pycnometer 100ml Abrasion Test for Coarse Aggregate 1) Los Angeles Abrasion Machine with Digital Autometic Stop Panel with 12 Abressive Charges with Receiving Tray with Sieve # 12 Modified Campaction Test 1) Straight Edge 2) Scoop Small 3) Modified Compaction Mould 6 Inch Dia with Hammer 10 Lbs 4) Standard Compaction Mould 4 Inch Dia with Hammer 5.5 Lbs 5) Rubber Mallet 6) Preparation Knife 7) Spatula Large 8) Spatula Small CBR Laboratory Test Complete 1) Additional CBRMould 6" Dia with Base Plate & Collar 2) Filter Screen (Pack of 100) 3) Swell Plate Brass 4) Surcharge Weight (Circular) 5) Surcharge Weight (Slotted) 6) Spacer Disc 7) Tripod Attachment 8) Dial Indicator 9) CBR Loading Press Electric 10) Proving Ring 50KN 11) Soaking Tank 48 x 98 x 24 Field Density Test 1) Sand Cone Apparatus 6" Dia (Cone + Base + Plate + Plastic Bottle) 2) Sand Cone Apparatus 8" Dia (Cone + Base + Plate + Plastic Bottle) 3) Density Sand Bag Per Kg 4) Chisel & Hammer & Spoon , Brush 5) Digital Balance 30Kg x 5gm 6) Speedy Moisture Tester Capacity 6gm with Mechanical Balance with Calcium Carbide Complete in Wooden Box 7) Chisel 8) Hammer Concrete & Cement Test 1) Cylinder Mould Heavy Duty 6" x 12" 2) Cube Mould 6" x 6" x 6" 3) Digital Compression Strength Machine Capacity 2000KN with fitted Digital Display 4) Concrete Capping Compound Per Kg 5) Slump Cone Apparatus (Cone + Base Plate + Tamping Rod) 6) Tamping Rod 7) Curing Tank Heater 8) Calcium Carbide 9) Hydrometer 10) TDS Meter 11) Micrometer 12) PH Meter 13) Schmidth Hammer 14) Wooden Hammer 15) Warning Pot 16) Rubber Gloves 17) Leather Gloves 18) Capping Device 19) Electric Concrete Mixture 20) Three Gang Mould 50 x 50 x 50mm 21) Rain Gauge 22) Vicat Apparatus 23) Aashto Book Set 24) ASTM Book Set 25) Asphalt MS 2 26) Laser Gun Thermometer Asphalt Equipments 1) Filter Paper 3000gm 2) Mixing Bowl Steel Large & Medium 3) Extruder 4" & 6" 4) Automatic Marshal Compactor 4" & 6" with fitted Digital Automatic Stop Panel with Hammer 4" & 6" 5) Pavement Core Drill Machine with USA Engine 6) Diamond Core Bit 4" Dia 7) Diamond Core Bit 6" Dia 8) Trichloroethylene 9) GMM Apparatus (Vacumm Desicator + Vacumm Pump) 10) Dial Thermometer 11) Marshall Stability Machine with Proving Ring 28KN 12) Marshall Mould with Collar & Base Plate 6" Dia 13) Marshall Mould with Collar & Base Plate 4" Dia 14) Marshall Breaking Head 6" Dia 15) Marshall Flow Meter 16) Digital Water Bath 17) Marshall Breaking Head 4" Dia 18) Extraction Machine 3000gm 19) Automatic Penetrometer Digital

Rs 123

See product

Pakistan (All cities)

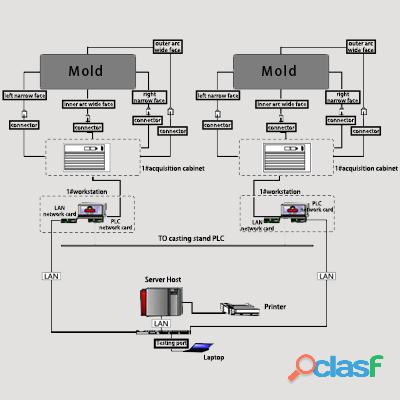

Overview: The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional artificial intelligence and information processing technology to overcome the defects of traditional logic-based prediction models. It has the functions of self-adaptation, self-organization and real-time learning. The breakout prediction system has an optimized industrial network structure. According to the distribution and change rules of the temperature field of the mold, it can track and respond to the breakout process in real time. It can learn and judge by itself, and provide early warning information for on-site operations. It can effectively prevent the occurrence of breakout accidents, greatly reducing the cost and improving the safety factor of continuous casting. The system is suitable for all kinds of continuous casting machines such as square billet, round billet, rectangular billet and slab. Block Diagram of Breakout Prediction System The composition of the system Thermocouple: according to the on-site conditions of the mold, water tank, bolts and mold frame to desgin Front-end acquisition system: Multi-module acquisition chain, industrial Ethernet interface, high-speed embedded processing module Working platform: Real-time display of mold temperature field status, online analysis and prediction of mold breakout Server: Data exchange and storage management, reporting and printing system, with data analysis and self-learning functions The Main technical parameters Data sampling: the sampling frequency of K-type/T-type thermocouple can up to 10HZ Accuracy of temperature measurement: ±0.25℃ Support communication protocol: Industrial Ethernet (TCP/IP),PROFIBUS-DP,CANopen Executive standard: DE0411 Standard Class III/1EC584/IEC1515 Transmission speed: 100M/bps The composition of the software Online monitoring software for breakout prediction Offline query software for breakout prediction Data recovery and self-learning software packages Data acquisition and monitoring software The software package of mold thermal status display The functions of the system Real-time data acquisition, data analysis and judgment Automatic selection of steel grade’s alarm parameters Real-time dynamic picture monitoring Prediction alarm and information display of breakout signs Automatic deceleration after alarm Historical data storage and historical trend graph display Automatic report generation and printing Alarm prediction and pattern recognition of unknown steel grades by neural network Dynamic real-time temperature profile prediction Mould heat flow field display FIG 1:Typical process of mold breakout prediction The features of the system 1. Reasonable design of temperature measurement point and professional protection front-end acquisition system, and complete installation and calibration tool components. 2. The system has strong adaptability and can meet the transformation of various structural continuous casting machines. 3. High-speed data communication, using industrial network to form an independent local area network for each workstation and server. It can realize high-speed data transmission of alarm files, alarm parameters, and other databases. 4. The combination of artificial neural network and intelligent forecasting model improves the alarm accuracy of breakout forecasting. 5. Historical data storage and historical trend graph display, historical reports, historical alarm legend printing, real-time alarm data printing. 6. Provide a local area network interface, which can realize the storage and forwarding of alarm files, and the input and output of offline alarm data. 7. Remote Web browsing can be achieved according to customer needs. 8. Can be seamlessly connected with MES-C220 mould expert system.

Rs 200.000

See product

4 photos

Pakistan (All cities)

Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content. The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal. As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc. The features of thermal imager 1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set. 2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature. 3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily. 4. With hot zone tracking function 5. Equipped with special 7~14um infrared filter lens The technical parameters 1. Temperature measurement range: 200°C ~ 2000°C 2. Temperature measurement accuracy: 2% 3. Detection accuracy and alarm accuracy: ≥98% 4. Resolution: ≥ 0.5℃ 5. Pixels: 640x240PT 6. Band: 7~14um 7. Field of view: 7.5°×5.5° 8. Frame rate: ≥ 25 frames/sec 9. Equipment service life: ≥5 years 10. The normal operation rate of the automatic control system: ≥99%

See product

3 photos

Lahore (Punjab)

Type: Household Sewing Machine Stitch Formation: Chain Stitch Max. Sewing Thickness: 1.8CM Stitch Length: Adjustment Overall Dimensions: 19.5x11.5x21cm Weight: 0.8kgs Condition: New Certification: CE,RoHS Available Color: White Main Material: ABS+Stainless Steel Power Suply: 4 AA batteries or AC/DC adaptor Product Weight: 0.8kgs Product Size: 18x10x20cm Specifications:- manual mini sewing machine 1.Double thread double speed 2.Use hand switch or foot pedal 3.With LED light 4.Portable BM101A Double-thread sewing machine Features: * With Working Light * CE,RoHS Standard. * Double thread, double speed; * Automatic thread rewind; * Sews sleeves; * Use Hand Switch or Foot Pedal to control; * Providing Foot Pedal and Thread Bag in free; * Power Supply:Operated by 4 “AA” batteries or DC adaptor(6V 800mA). * Main Material: ABS & Stainless steel; manual mini sewing machine Specifications * Product Size: 18x10x20cm; * Product Weight: 0.8kgs; Product size: 18x10x20cm(Mini Style)

Rs 3

See product

Karachi (Sindh)

Dear Sir /Madam We have pleasure to inform you that the system is convenient, reliable and safest .it takes 3 to 5 hours to install the automatic system on your premises we provide 12 months compressive warranty on parts services and we have highly qualified staff ready for discussion and survey at your premises to guide you about your needs for automation & other system in your areas. Product Description: Roller Shutter Automation System Entry System sales and repairs rolling steel garage doors, commercial sectional garage doors and commercial operators. Our roll-up doors for the commercial and self-storage markets are made of the highest quality and durability and require low maintenance. We have a complete line of doors and hardware for you, including sectional doors, aluminum / glass doors, rolling steel doors and rolling sheet doors. We enclose introduction brochures about for your review and we hope that the information will provide many of the answers to the questions you might have looking forward to your earlier response. Regards, EASY AUTOGATES 021-35163642

Rs 1

See product

Islamabad (Islamabad Capital Territory)

Heidelberg SM 102 VP Year – 2000 Cpc cp 2000 , Preset Feeder and delivery Steel Plate Feeder and delivery , mechanical & electrical double sheet detection Water cooled press with technotrans chiller ( ink temp. control unit ) Press adjustment via CP 2000 centre , automatic size adjustment SAPC , Al-colour damping system , automatic wash up device for inking rollers and blankets. IN STOCK – IMPORT FROM GERMANY INR 16500000 Heidelberg SM 74-4H Year --- 2013 Cpc cp 2000 , sheet fed control press system Prinect press centre 2 , prinect press centre softare , Preset feeder , colour fast solutions integrated software application Sheet alignment system ,multiple sheet detector SAPC , saphira blanket PRO 200 , Pneumatic wash up blade , power star AP 110 . EXCELLENT RUNNING CONDITION HEIDELBERG SM 74-4H YEAR --- 2007 Four colour Cpc cp 2000 Auto plate Alcolour damping Techno trans refrigeration Auto wash Weko powder spray device Excellent running condition LOCATION - NEW DELHI - 00919868451117

Rs 15.000.000

See product

Pakistan

CSP is a full service general contractor specializing in Residential, commercial, institutional renovation / construction & Security surveillance. We offer traditional general contracting services as well as designing, planning & management services. We provide services including • CIVIL CONSTRUCTION • ELECTRICAL WORKS • MECHANICAL WORKS • FABRICATION • SECURITY SURVEILLANCE Our Services Building Services Building services includes Full design, advisory and Trouble shooting Exercises associated with Building services. Some of the specifically indicated are • Aluminum, Wood & glass work • Building renovation & Construction. • False Ceiling of all type • Window Blinds venation/ Vertical • Tile flooring • Wooden flooring • Building paint & Polish. • Electrical work of all type. • Heating & Cooling system • Roof Waterproofing & Heat insulation. Safety & Security We deal in all kind of Security & Safety Surveillance. • Anti Blast Film / Anti Shatter Film • Safe Heaven Room • Bullet Proof Door, Steel Doors • Bullet Proof/ Metal Automatic Gate • Security Guard Post • Windows Safety Grills • Welded Razor Mesh • Walk through Gates ( Metal detector) • CCTV • Bio metric Access Control Systems • Concrete Barriers • Arms Barriers • Hydraulic Road Blocker • Hesco Gabion Sandbags 215, 2nd Floor, Capital Business Center, F-10 Markaz, Islamabad

See product

Islamabad (Islamabad Capital Territory)

CSP is a full service general contractor specializing in Residential, commercial, institutional renovation / construction & Security surveillance. We offer traditional general contracting services as well as designing, planning & management services. We provide services including • CIVIL CONSTRUCTION • ELECTRICAL WORKS • MECHANICAL WORKS • FABRICATION • SECURITY SURVEILLANCE Building Services Building services includes Full design, advisory and Trouble shooting Exercises associated with Building services. Some of the specifically indicated are • Aluminum, Wood & glass work • Building renovation & Construction • False Ceiling of all type • Window Blinds venation/ Vertical • Tile flooring • Wooden flooring • Building paint & Polish. • Electrical work of all type. • Heating & Cooling system • Roof Waterproofing & Heat insulation. Safety & Security • Anti Blast Film / Anti Shatter Film • Safe Heaven Room • Bullet Proof Door, Steel Doors • Bullet Proof/ Metal Automatic Gate • Security Guard Post • Windows Safety Grills • Welded Razor Mesh • Walk through Gates ( Metal detector) • CCTV • Bio metric Access Control Systems • Concrete Barriers • Arms Barriers • Hydraulic Road Blocker • Hesco Gabion Sandbags 215, 2nd Floor, Capital Business Center, F-10 Markaz, Islamabad Ph: +92 51 2809515-6 Ph: +92 51 2535304 Cell: +92 343 2002000

See product

Islamabad (Islamabad Capital Territory)

CSP is a full service general contractor specializing in Residential, commercial, institutional renovation / construction & Security surveillance. We offer traditional general contracting services as well as designing, planning & management services. We provide services including • CIVIL CONSTRUCTION • ELECTRICAL WORKS • MECHANICAL WORKS • FABRICATION • SECURITY SURVEILLANCE Building Services Building services includes Full design, advisory and Trouble shooting Exercises associated with Building services. Some of the specifically indicated are Aluminum, Wood & glass work Building renovation & Construction. False Ceiling of all type Window Blinds venation/ Vertical Tile flooring Wooden flooring Building paint & Polish. Electrical work of all type. Heating & Cooling system Roof Waterproofing & Heat insulation. Electronic Security CCTV Surveillance System Access Control & time Attendance System Panic Alarm System Fire Alarm System Walk Through Gates and Detectors GSM Alarm System Gate Automation System Under vehicle Surveillance System Mechanical Security Anti-Shatter Film / Blast Film Mesh Fence Bullet Proof Door, Steel Doors Bullet Proof/ Metal Automatic Gate Security Guard Post Windows Safety Grills Razor Wire / Concertina Wire Arms / Boom Barriers Hydraulic Road Blocker Civil Construction Safe Room / Panic room Blast Proof Walls / T-Walls RCC Boundary Walls Sand Walls 215, 2nd Floor, Capital Business Center, F-10 Markaz, Islamabad Ph: +92 51 2809515-6 Ph: +92 51 2535304 Cell: +92 343 2002000

See product

Islamabad (Islamabad Capital Territory)

CSP is a leading provider of integrated security solutions for a diverse range of national clients.In addition, we are committed to providing our customers with more than just security systems and technology. Our Services Electronic Security CCTV Surveillance System Access Control & time Attendance System Panic Alarm System Fire Alarm System Walk Through Gates and Detectors GSM Alarm System Gate Automation System Under vehicle Surveillance System Mechanical Security Anti-Shatter Film / Blast Film Mesh Fence Bullet Proof Door, Steel Doors Bullet Proof/ Metal Automatic Gate Security Guard Post Windows Safety Grills Razor Wire / Concertina Wire Arms / Boom Barriers Hydraulic Road Blocker Civil Construction Safe Room / Panic room Blast Proof Walls / T-Walls RCC Boundary Walls Sand Walls

Rs 9

See product

Islamabad (Islamabad Capital Territory)

CSP is a full service general contractor specializing in Residential, commercial, institutional renovation / construction & Security surveillance. We offer traditional general contracting services as well as designing, planning & management services. We provide services including • CIVIL CONSTRUCTION • ELECTRICAL WORKS • MECHANICAL WORKS • FABRICATION • SECURITY SURVEILLANCE Building Services Building services includes Full design, advisory and Trouble shooting Exercises associated with Building services. Some of the specifically indicated are Aluminum, Wood & glass work Building renovation & Construction. False Ceiling of all type Window Blinds venation/ Vertical Tile flooring Wooden flooring Building paint & Polish. Electrical work of all type. Heating & Cooling system Roof Waterproofing & Heat insulation. Electronic Security CCTV Surveillance System Access Control & time Attendance System Panic Alarm System Fire Alarm System Walk Through Gates and Detectors GSM Alarm System Gate Automation System Under vehicle Surveillance System Mechanical Security Anti-Shatter Film / Blast Film Mesh Fence Bullet Proof Door, Steel Doors Bullet Proof/ Metal Automatic Gate Security Guard Post Windows Safety Grills Razor Wire / Concertina Wire Arms / Boom Barriers Hydraulic Road Blocker Civil Construction Safe Room / Panic room Blast Proof Walls / T-Walls RCC Boundary Walls Sand Walls 215, 2nd Floor, Capital Business Center, F-10 Markaz, Islamabad Ph: +92 51 2809515-6 Fax:+92 51 2809517 Cell:+92 343 2002000

Free

See product

Islamabad (Islamabad Capital Territory)

General Services: Telecom Products & Services. IT Products and Services. Technology implementation Office, Machinery All Kind of FOB Supplies Engineering, Construction Information technology ATS Panel: Breakers Volt Meter Ampere Meter Steel Boxes Automatic Switch Manual Switches Lights, Diode, Connector etc Cookery Services: Cookery Services Cafeteria Services Catering Services Gourmet Services Advisory Services Power Management: Generator Set Generator Filters Industrial Filters etc Spare Parts Machinery Electrical Instrumentation Solar Systems: Complete Solar Systems Solar Cells / Plates Liquid / Dry Batteries Solar Lights Solar Inverter / Combiner Circuits Breaker Service Panel

Free

See product

Karachi (Sindh)

Dear Sir /Madam We have pleasure to inform you that the system is convenient, reliable and safest .it takes 3 to 5 hours to install the automatic system on your premises we provide 12 months compressive warranty on parts services and we have highly qualified staff ready for discussion and survey at your premises to guide you about your needs for automation & other system in your areas. Product Description: Laser Beam Security System Laser Beam Sensor load cell is a steady and toughest production which is made for tough environments. Its construction of high alloy tool steel provides optimum protection under impact loading. By Way of Optical Fencing To Warn Guard / Guest in Remote Hill Station Guest House Thief Bad Intention Person Intrusion so that they can make them self safe before they enter the guest house. We enclose introduction brochures about for your review and we hope that the information will provide many of the answers to the questions you might have looking forward to your earlier response. Regards, EASY AUTOGATES 021-35163642

Rs 1

See product

Karachi (Sindh)

Dear Sir /Madam We have pleasure to inform you that the system is convenient, reliable and safest .it takes 3 to 5 hours to install the automatic system on your premises we provide 12 months compressive warranty on parts services and we have highly qualified staff ready for discussion and survey at your premises to guide you about your needs for automation & other system in your areas. Product Description: Razor Wire Fencing Boundaries Razor Wire Fencing Boundaries are steady and toughest production which is made for tough environments. Its construction of high alloy tool steel provides optimum protection under impact loading. By Way of Optical Fencing To Warn Guard / Guest in Remote Hill Station Guest House Thief Bad Intention Person Interruptions so that they can make them self safe before they enter the Boundary. We enclose introduction brochures about for your review and we hope that the information will provide many of the answers to the questions you might have looking forward to your earlier response. Regards, EASY AUTOGATES 021-35163642

Rs 1

See product

Lahore (Punjab)

We are manufacturer of LV panels Board MCC Lighting panel with automatic on /Off change over distribution board. Distrubution Board in Pakistan. stainless steel ss JB indoor out door for house & industry use Our Email Addres http://www.alfazalengineering.com

Rs 2.500

See product

2 photos

Pakistan (All cities)

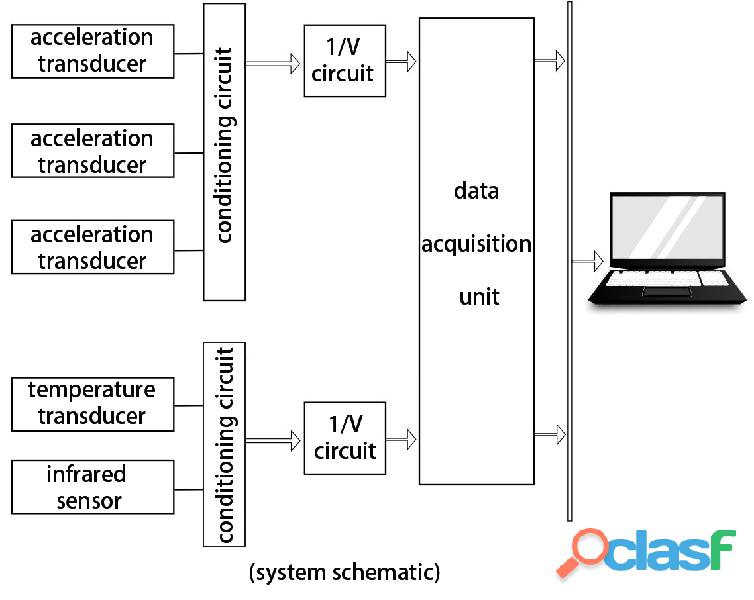

Overview The mold is a device that shapes the cast product in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of the mould oscillation deflection detection instrument is to detect the the mould oscillation table’s oscillation frequency, amplitude, deflection rate, phase, oscillation trajectory curve, etc. Through the detection and adjustment of the detection instrument, the mold moves along the outer arc of the continuous casting machine according to the set amplitude, frequency and waveform deflection characteristics. The actual oscillation parameters of the mold oscillation table during the production process and the process parameters of the cast products cannot be effectively known without the data detection of the mold deflection detection instrument, so that the operator cannot adjust the mould’s production process parameters in real time according to the real-time situation of the on-site production. The continuous casting mold deflection detection instrument independently developed by our company is suitable for various molds such as slab, square billet, round billet and shaped billet. The system obtains the process parameters such as actual oscillation holographic parameters and negative slip amount of the oscillation table by effectively detecting the movement of the mold. The technicians can formulate the control strategy of the mould according to these actual parameters, and improve the output and quality of the product within a safe and reliable range. The structure of the instrument Continuous casting mold oscillation and deflection detection instrument is mainly composed of sensor system, sensor signal conditioning circuit, power supply circuit, synchronous data acquisition module, communication cable, and software data analysis system. There are three axial acceleration sensors installed in the mold oscillation and deflection detection instrument, one of which is to detect the vertical oscillation signal (Y axis), and the other two are to detect the horizontal oscillation signal (X and Z axis). The signal obtained by the sensor is processed by the preprocessor and the preprocessing module. The oscillation signal and sensor status signal will be filtered and normalized, sent to the synchronous data collector for digitization and feature extraction, and the data is analyzed and processed by the master computer software to obtain various oscillation parameters and process parameters required by users. The functions of the system 1. Adopting mould oscillation X/Y/Z three-dimensional data acquisition, using high-precision sensor system and high-sensitivity axial accelerometer, comprehensive detection of equipment oscillation state, including: 1) Detect the oscillation frequency of the mold oscillation table 2) Detect the amplitude of the mold oscillation table 3) Detect the deflection rate of oscillation 4) Detect the lateral deflection, longitudinal deflection, phase, and phase difference of the mold oscillation table 5) Three-dimensional display of the oscillation trajectory, and the oscillation table trajectory can be viewed from 6 sides of the oscillation table (X-Y, X-Z, Z-Y) 2. The software system adopts the design of man-machine interactive graphic interface, which can display the mold oscillation state in real time. The software functions include: 1) Real-time data curve display: oscillation waveform, oscillation frequency, signal superposition analysis 2) Single-axis curve display, multi-axis curve display, amplitude, acceleration, three-dimensional graph 3) View historical curve 4) Generate test report 5) Give a warning prompt 6) Spectrum analysis function 7) Long-term storage of data 3. Portable measurement method, which can provide handheld detection equipment with wireless remote transmission, and the operation is simple. 4. Provide an overview of inspection parameters under the full screen, displaying all data including oscillation parameters and process parameters. At the same time, the calculation and display of the oscillation spectrum is completed in real time, which is used to evaluate the frame loss of the waveform , and to determine whether there is a problem with the installation of the oscillation device. 5. Alarm management. Record each alarm data under real-time alarm conditions to analyze the cause of the alarm and evaluate the impact of the alarm on production. 6. Parameter setting. Users can set the ideal oscillation value and normal working range of various steels online. We also can set the alarm limit, and the storage time of the database etc. 7. After charging the device once, it can work continuously for more than four hours. 8. Integrate embedded processing equipment to realize data collection, display, analysis, reporting and other functions. 9. According to the mold characteristics and user requirements, it can be flexibly configured, wich is suitable for all types of molds such as square billets, slabs, round billets and other mold oscillation tables. 10. Support wired and wireless data transmission functions, easy to use. 11. Use the laptop to receive the collected data, can be used for the operation test on site, and can analyze and process the data conveniently. The features of the system 1. The actual oscillation state replaces the ideal oscillation state. The actual oscillation state of the table is used to formulate a control strategy, so that the oscillation table can be used to produce products with more accurate oscillation. 2. Convenient detection method. The equipment can be used for on-site inspection at any time, and the production site can grasp the operating status of the on-site equipment in time, so that we can make production adjustments to the equipment at any time. 3. Efficient working methods and processing platforms. The high-integration equipment developed by embedded technology can work in high temperature and harsh environment. This system can comprehensively detect XYZ three-axis data, and realize real-time data analysis and processing with high-speed data operation and processing platform. 4. Powerful database function. The database adopts the mode of computer automatic management and operator's manual assistance management, and there are tables for recording historical data and alarm data and working parameter setting table of monitoring system inside the database. By adjusting the output range, the best output effect can be obtained.

See product