Apple ipod 3g 8gb

Top sales list apple ipod 3g 8gb

Latest Offers

Pakistan (All cities)

The Veritable Calfskin store bring another Superstar Outfit Fur B-26 Shearling Aircraft Cowhide Coat. This Coat has been made by genuine quality Calfskin and has jazzy Fur Straight Style Collar https://aajacketmaker.com/product/b-26-shearling-fur-jacket/

Rs 70.000,0

See product

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product

Abbottabad (Khyber Pakhtunkhwa)

Looking for the perfect way to Send Birthday Gifts to India? We’ve got you covered with our unique selection of Birthday Gifts! From personalized keepsakes to luxury hampers, there’s something special for everyone. Worried about last-minute orders? Birthday Gift Same Day Delivery in India ensures your gift reaches on time. Explore our curated collection and make birthdays memorable. Shop now to find the ideal gift that says “happy birthday” in the most thoughtful way.

Rs 500,0

See product

Bagh (Azad Kashmir)

Eagle Racking India is a leading provider of industrial storage racks in Kanpur, offering high-quality and durable storage solutions for warehouses, factories, and commercial facilities. Our storage racks are designed to maximize space utilization, enhance efficiency, and ensure easy inventory management. We specialize in a wide range of industrial racking systems, including pallet racks, heavy-duty racks, mezzanine racks, and cantilever racks, catering to diverse storage needs. Made from premium-grade steel, our racks are built to withstand heavy loads and provide long-lasting performance. They are designed with customizable shelving options, corrosion-resistant coatings, and high load-bearing capacities to meet industrial requirements Read more: https://eagleracking.com/kanpur/industrial-storage-rack

Rs 0,0

See product

Pakistan (All cities)

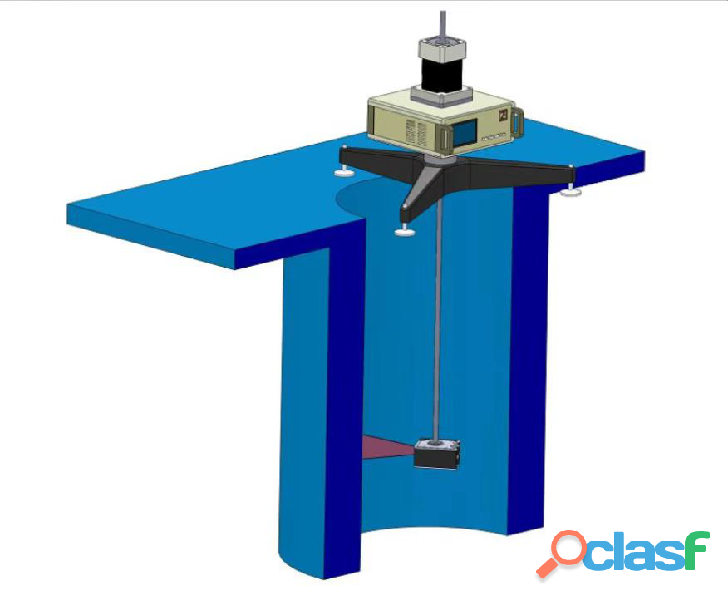

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Lahore (Punjab)

Apple Hair Color Price In Pakistan - Quickon.pk Apple Hair Color Price In Pakistan is a hair dye product designed to provide vibrant, long-lasting color while maintaining the health and integrity of your hair. This product is formulated to offer rich, natural-looking color with the added benefits of conditioning and nourishing ingredients. What is Apple Hair Color Price In Pakistan? Apple Hair Color Price In Pakistan is a professional-quality hair dye that offers a wide range of shades to suit different hair types and preferences. The formula is enriched with conditioning agents and natural extracts that help protect and nourish the hair during the coloring process. It is designed to deliver vibrant, long-lasting color with a natural finish. https://quickon.pk/product/apple-hair-color-price-in-pakistanhttps://quickon.pk/product/feg-plus-hair-growth-sprayhttps://quickon.pk/product/sardar-jee-hair-color-gel-price-in-pakistan

Rs 3.500,0

See product

Pakistan

Beautiful lemon and white female beagle pup for sale, 5 months old, fully vaccinated, microchipped, flee'd and wormed. Not kc registered and as she's our pet, mother or father can't be seen. Very playful, energetic and needs a caring family ....

Rs 200,0

See product

Pakistan

2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds 2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds .....................2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds

Rs 4.000,0

See product

Pakistan (All cities)

Artificial Hymen Pills Price in Pakistan What is Artificial Hymen Pills? Artificial Hymen Pills in Pakistan an Artificial Hymen Could Be a Cellulose Compound That is Developed in 2010 in Germany in a Very Laboratory for Microbiology Stuffed With Synthetic Blood That Imitates Human Blood. Artificial Hymen Pills Are Useful for Fake Virginity by Creating a True Hymen. And Imitate the Loss of Blood That Happens on Your First Time. These Pills Are Formulated With 99.9% Natural Ingredients That Are Extracted From Pure Herbs Used for Hundreds of Years in Asia. Of These Ingredients Are Completely Body-safe and Do Not Have Any Side Effects Whatsoever. All You’ve Got to Try is Just Place the Artificial Pills in Pakistan Inside Your Vagina Between 25-30 Minutes Before You Derive Pleasure From Sexual Activity. Artificial Pills Newtelebrands.com the Natural Hymen of a Lady Protects the Vaginal and Its Canal. If You’ve Lost Your Hymen Due to Any Physical Activity. And You’re Worried About Your Dark That You Simply Cannot Bleed at That Point. So Stop Worrying Because There’s a Product That Comes Dead Set Reduce Your Worries, and Provides You Your Virginity Back by Using Pills. These Artificial Hymen Fake Blood Pills Will Influence the Body Heat and Vaginal Moisture and It Will Then Create a Synthetic Membrane That Acts Sort of a Hymen and Tightens the Vaginal Opening. After Successful Penetration of the Male Organ, the Fake Membrane Will Tear Similar to a True Hymen and Discharge a Touch Blood-like Liquid to Finish the Dramatic Effect. How Artificial Hymen Pills Work? Artificial Hymen Pills in Pakistan Usually Fake Virginity, an Artificial Hymen is a Prosthetic Invention for the Aim of Simulating an Intact Hymen in Women. These Pills Contain a Natural Blend. Which After Inserting in the Vagina Properly Temporarily. Giving the Looks of an Intact Hymen and Releasing a Red Liquid That Appears Like Blood When Subjected to Pressure. Artificial Hymen Kit Consists of Two Layers of Cellulose, the Blood Liquid, and Powder. The Factitious Hymen Reacts to Heat and Moisture That is Present Within the Interior of the Vagina. Thus, the Unreal Hymen/hymen Dissolves Inside the Vagina and Exit as a Blood Trail to Substantiate the Virginity. It Has Been Specifically Designed to Offer You the Chance to Introduce One a Minimum of 2 Hours and Half-hour Before Sexual Activity. Make It Easy With the Included Disposable Plastic Tweezers a Finger Deep. During Sexual Activity, It Dissolves Then Completely. And by the Interior Friction of the Penis, the Cellulose Compounds Mix With the Body Fluids. Hymen Flows Down From the Vagina After Sexual Intercourse. Artificial Hymen Pills in Pakistan This Residue is Seen on the Penis and Sheets That Bring the Result to Substantiate Your Virginity at the Specified Moment. The Utilization of Hymen Gel Also Works With the Employment of Condoms. How To Use? Artificial Pills Just Finger Deep and About 1-3 Hours Before the Planned Sexual Activity. The Capsules Contained Fake Blood Therein Which Then Completely Dissolved. During Gender, It Mixes Along With Your Vaginal Secretions and Runs as a Trace of Blood During a Natural Amount. By Tightening the Vaginal Entrance, It Intensifies the Sensation of Virginity. Use It Half-hour – 2 Hours Before the Planned Sexual Issues and Also Confirms Reliably Your Virginity by Artificial Hymen Pills in Pakistan. With Original Blood, Pills Turns Blood Red Together With Moisture and Dissolves Completely. Use 25-30 Minutes Before Sexual Intercourse: Wash Your Hands and Vagina Before Using. Slightly Insert the Synthetic Hymen Into the Vagina. It Will Dissolve Within 20-30 Minutes After Using It. Benefits of Artificial Hymen Pills? Artificial Pills Will Facilitate Your Desire for a Virgin Again Without Undergoing Vaginal Rejuvenation Surgery or Popping Any Dangerous Pills. They Will Facilitate the Reboot of Your Virginity and Feel Young Again. Artificial Pills in Pakistan Facilitates You to Restore Your Hymen to Their Original Position. And Facilitate Your Experience of Sex Sort of a Virgin. The Factitious Hymens Are the Product of Natural Material. Like Synthetic Blood and Cellulose, is Safe for Your Vaginal Health. Lady Secret Cream the Following Are Advantages of Pills Make the Vaginal Path Tighter Make You Bleed at Your Night It Has No Side Effects. It is Non-toxic and Safe No Painful Surgery, Needles, or Anesthesia From Now on Artificial Pills in Pakistan Price Prevent From Doctor’s Visits and Medications You Do Not Need Any Hymenoplasty. It Appears Like the Original Blood 99.9% Harmless, Risk-free Call & Whats App 0300-0085742 | 0330-2828742 The Largest Online Shopping Website: NewTelebrands.Com

Free

See product

Pakistan (All cities)

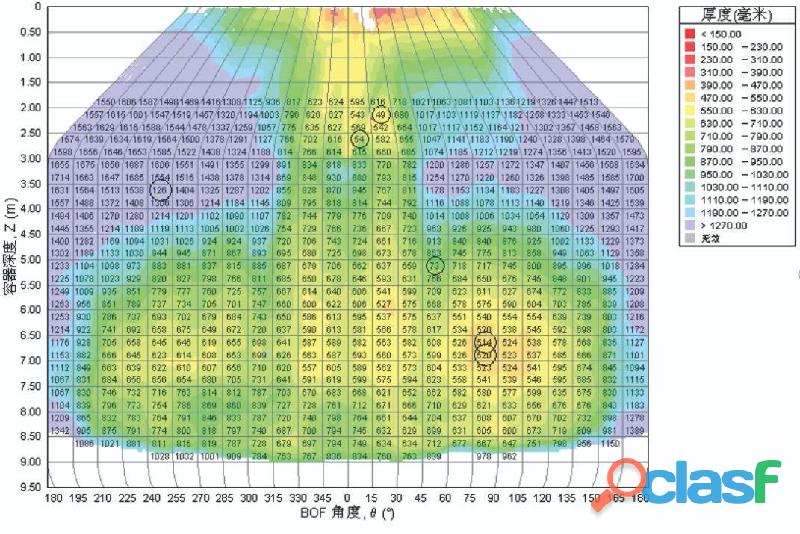

Overview LDT-I200 is a new generation of converter lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the converter, and receives the returned laser light to measure its flight time. Then the system equipment calculates the distance between the equipment and the target point according to the transmission speed of the laser. During measurement, the user pushes the equipment to a certain position on the platform in front of the converter, and the equipment can start to scan and measure the target area of the converter after the equipment performs rapid self-positioning. The Measuring principle The measurement speed of LDT-I200 can reach up to 2,000,000 points per second, and each scan can obtain distance data of more than 1.5 million points. The actual surface curve of the entire converter lining can be obtained by combining the measurement data of different positions and angles. During the measurement, the laser head of the equipment rotates at a certain step angle to rapidly change the angle of the pulsed laser beam. Within 4 minutes, the three-dimensional surface contour of the converter lining can be formed, and the thickness information of the furnace lining can be obtained through coordinate conversion calculation. The measurement accuracy up to ±2mm. In order to convert the distance from the internal point of the converter to the thickness gauge into the thickness of the furnace lining at each point, we must know the coordinate relationship between the trolley and the converter. We use the second laser head to position the trolley. When the trolley is pushed to the measurement site, the positioning laser head rotates at high speed to scan the three reflective strips opposite the converter. Through triangulation measurement and calculation, we can calculate the relative position of the trolley to the reflective strips. The coordinates of the reflective strip and the converter are known through mapping, so that the coordinates of the trolley relative to the converter can be accurately obtained. The main components 1. Laser measuring head 2. Wireless communication 3. Battery pack 4. Mobile laser thickness gauge host 5. Converter inclination measurement system 6. Cooling circulation system 7. Positioning auxiliary reflector 8. Laser positioning system The technical indexes Laser reproducibility: ±2mm Laser accuracy: ±2mm Local fastest measurement time: 15s Positioning time: 30s Full image measurement time: 4min The highest measurable lining temperature: 1850℃ Measuring distance: 0.5-25m Actual points are measured per frame: 1500000 points Continuous working time after fully charged: ≥3h Eye-safe laser: Class 1 laser product (doesn't hurt the eyes) The parameters of laser measuring head Measurement principle: According to the flight time and speed of the laser to calculate the distance Laser reproducibility: ±2mm Laser accuracy: ±2mm Scan rate: 2000000 points/second Measuring angle: vertical ±40°, horizontal 360° Maximum measurement temperature: 2200℃ Working temperature: -20℃-80℃ Cooling method: Integrated liquid cooling system, IP64 grade protection Laser wavelength: 1550nm (near infrared)

Rs 0,0

See product

2 photos

Pakistan (All cities)

Laser cutting machines have transformed the design and fabrication industries, unlocking a new realm of creative possibilities. With their ability to cut and engrave materials with precision and speed, these machines are not just tools—they are catalysts for innovation. Whether in architecture, fashion, art, or product design, laser cutters have become an essential tool for turning ideas into reality. https://www.tradebrio.com/exporters/laser-cutting-machines.html

Free

See product

Rawalpindi (Punjab)

Discover a curated selection of stylish, handcrafted handbags and clutches at Baglore.com. Each piece is meticulously designed to blend traditional artistry with contemporary flair, offering timeless elegance for every occasion. Whether you need a chic clutch for a special event or a practical yet stylish handbag for everyday use, our collection provides the perfect accessory. Explore Baglore.com now and elevate your fashion statement with unique, high-quality handcrafted bags.

Rs 3.800,0

See product

16 photos

Pakistan (All cities)

Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According to different steel grades, casting speed, vibration and other process parameters, then the system can analyze and calculate the accurate mold flux addition amount through intelligent software. Then the system sends out signals to control the mold flux addition process and mold flux addition amount, and designs appropriate nozzles and propellers according to the fluidity of molten steel in the mold and the ductility of mold flux. After the system setting is completed, there is no manual intervention is required. It completely replaces the whole process of manual addition of mold flux, and realizes the automation of mold flux addition. The features of the system 1. The system automatically controls the amount, process and time of adding mold flux according to the process requirements of automatic mold flux addition, so as to maintain the physical state of the mold flux and prevent it from being broken. 2. The user can match different parameters according to actual needs, so as to change the length of the mold flux feeding time and the amount of mold flux, which can suit for the use of different segments and different casting speeds. 3. The casting speed signal is used and the amount of adding mold flux can be automatically adjusted according to the casting speed. The mold flux can be added timely and evenly, which can improve the quality of the billet and reduce labor intensity. 4. The time is controlled by PLC, no manual intervention is required. The adjustment is very convenient. It has manual, automatic, local and remote control modes. 5. The system has reliable performance and simple structure, and can be adapted to powder and granular mold flux. 6. It has a special anti-blocking nozzle and backflushing design to overcome the phenomenon of pipeline blockage. 7. Strong operability, simple and convenient maintenance, and low maintenance cost. 8. It can maintain the even distribution of the flux layer in the mold. The composition of the system The system consists of feeding trolley, feeding bucket, swing arm and feeder motor, swing arm transmission device, PLC and control equipment. 1. The feeding trolley is the support and walking equipment of the mold flux feeder. The basic equipment of the adding mold flux machine is installed on the feeding trolley. At the same time, the trolley can easily make the mold flux feeder walk to the working position or the parking position. 2. The feeding bucket is a device for holding mold flux. The mold flux is pre-filled in the feeding bucket and is evenly output through the feeder. The feeding bucket is provided with alarm contact of mold flux level limit.. 3. The swing arm and the feeder motor form a feeding and conveying device. The mold flux is evenly transmitted to the feed opening at the front end of the swing arm through the screw distributing device controlled by the motor. Then the mold flux can be used for mold distribution. 4. PLC and control equipment adjust and control the mold flux feeding speed, operation mode and control mode of the mold flux feeding machine, and realize various control modes and rates. 5. The swing arm transmission device controls the reciprocating motion of the swing arm according to the size of different molds, so that the mold flux is evenly distributed in the mold. The technical parameter Mold width: 500-2000mm Mold thickness: 100-500mm Type: screw conveying type mold flux feeding machine Heating method: stirring electric heating Arrangement location: on the pouring platform (with its own wheels to move) Adding capacity: 0.5~7.5L/min, continuously adjustable feeding tube Molding flux storage tank: 300 L, with material level detection and alarm Control mode: local/remote control, automatic /manual mode Molding flux type: granular flux or powder flux flux adding method: spiral swing adding flux Casting speed interlock: yes Mould size setting: yes Signal transmission: DP/Industrial Ethernet

Rs 0,0

See product

Pakistan (All cities)

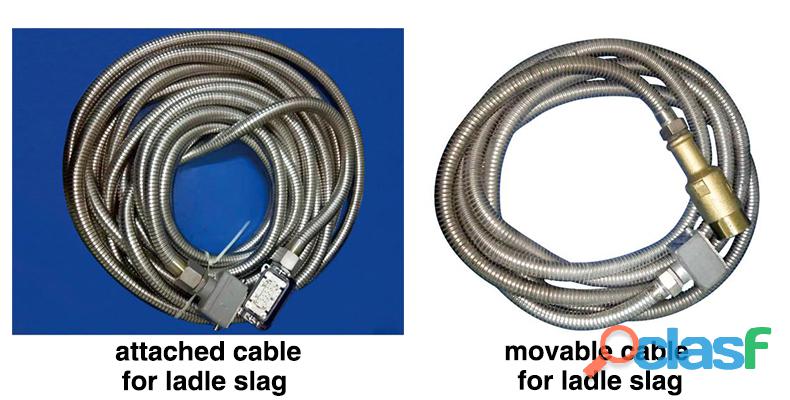

Overview Our company focuses on the production and application of the cables in continuous casting steel production. We have rich on-site usage experience, which provides us with technical guarantees for manufacturing high-quality communication cables. For cables of different applications, we have different protection requirements, such as high temperature resistance, anti-pull, acid and salt spray resistance, slightly positive pressure heavy-duty connector, anti-oil pollution, anti-interference, etc. Common industriaI cable for continuous casting 1. Breakout prediction compensation cable 2. Mold level control cable 3. Mold oscillation cable 4. VUHZ sensor cable 5. Mold width adjustment cable 6. Dynamic lightly depress the cable 7. Fixed cable for ladle slag 8. Movable cable for ladle slag The quality control All our products use proven materials to ensure stable and reliable product quality from the source. The core equipment all adopt imported raw materials. From raw material control to wire harness integrated processing, we ensure the stability and consistency of product quality. The scientific quality management system brings the product quality to a higher level. The program customization Our company has been focusing on the production and processing of wire harness products for many years. We have a professional technical team, which can realize synchronous development and technical docking with customers timely, optimize product design, and provide customers with complete solutions for wire harness products. Widely used: All kinds of wire harnesses produced by our company are widely used in major steel mills across the country, such as SHOUGANG, TISCO, HBIS GROUP, TIANJIN IRON PLANT, BAOGRANG GROUP, etc. The first-class product quality, and has won unanimous praise from domestic and abroad.

Rs 0,0

See product

5 photos

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos