Abd

Top sales list abd

Latest Offers

Pakistan (All cities)

Himalayan Chef Whole Wheat Flour is a premium quality flour made from 100% whole wheat grains sourced from the fertile lands of Pakistan. Our unbleached and unenriched flour is packed with fiber, protein, and essential nutrients, making it an ideal choice for health-conscious consumers. https://wbm.com.pk/product/whole-wheat-flour-40-lbs-1814-kg-himalayan-chef?srsltid=AfmBOooL_2OymlrRGa_iNHxMLfYjoVR1LhxPTyj5-vkxlZgANSgS57R6

Free

See product

Pakistan (All cities)

" Elevate Your Skin's Radiance at Kameleon Salon Your Premier Skincare Destination in Kokapet. Experience Tailored Treatments, Expert Care, and Revitalizing Solutions for Your Glow" https://www.kameleonsalon.com/skin-services.html

Rs 0,0

See product

Bagh (Azad Kashmir)

Eagle Racking India is a leading provider of industrial storage racks in Kanpur, offering high-quality and durable storage solutions for warehouses, factories, and commercial facilities. Our storage racks are designed to maximize space utilization, enhance efficiency, and ensure easy inventory management. We specialize in a wide range of industrial racking systems, including pallet racks, heavy-duty racks, mezzanine racks, and cantilever racks, catering to diverse storage needs. Made from premium-grade steel, our racks are built to withstand heavy loads and provide long-lasting performance. They are designed with customizable shelving options, corrosion-resistant coatings, and high load-bearing capacities to meet industrial requirements Read more: https://eagleracking.com/kanpur/industrial-storage-rack

Rs 0,0

See product

Pakistan (All cities)

We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 1.000,0

See product

2 photos

Pakistan (All cities)

Buy Verified Cash App Accounts As it acquires clients, checked accounts become fundamental for organizations and people to completely get to its highlights. A checked money application account permits you to send, get, and pull out a lot of cash, making it ideal for business people, consultants, and financial backers. Purchasing a confirmed money application account has turned into a pattern now, with numerous suppliers offering this help at a sensible cost. In any case, it means quite a bit to purchase from a confided in source to stay away from tricks or fake records. You will learn the fundamentals of purchasing verified cash app accounts and everything else you need to know before making a purchase in this article.

Free

See product

Pakistan (All cities)

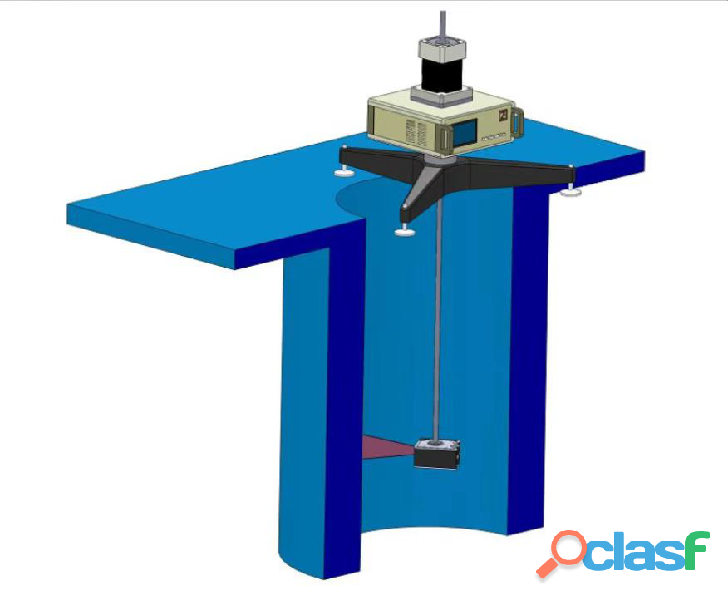

Overview: This product is a new type of mold copper plate surface detection equipment. The equipment adopts a high-precision and high-sensitivity laser ranging sensor, which scans the copper plate of the mould by scanning a laser line with a fixed width, and returns the measurement data in real time. After modeling and analyzing the data, the upper computer gives the wear data of the mold copper plate, as well as the data of surface cracks and surface flatness. The host computer software intuitively reflects the surface profile of the detected mold and thickness deviation and other data to the user in the form of data sheet, data curves and mold 3D model diagrams, providing a true and reliable theory for on-site operators to maintain the mold. The mold surface detection equipment is a high-precision instrument, which includes high-precision laser ranging sensors, two digital servomotors, encoders, horizontal sliding screws, vertical sliding screws, and calibration consoles, controllers and other components. The equipment has many advantages such as high accuracy, strong stability, convenient installation and strong observability. It is suitable for mold surface detection, surface flatness analysis, surface flaw detection, taper measurement, etc. It is also suitable for round billets, square billets, slabs, special-shaped billets, etc., widely used and powerful. The composition of the system: 1. The mold surface detection equipment is equipped with: data processing and display unit, horizontal motion mechanical power output unit, vertical mechanical power output unit, instrument motion control unit, laser measurement sensor, and instrument bracket. 2. Data processing and display unit: used for data acquisition and storage, system equipment control, parameter configuration, height display of the descent, start and stop control, etc. 3. Horizontal motion mechanical power output unit: the digital servo motor in the horizontal direction controls the sensor to move in the horizontal direction, so that the sensor can scan the horizontal inner cavity wall of the mold copper plate to detect data. 4. Vertical mechanical power output unit: the digital servo motor in the vertical direction controls the sensor to move in the vertical direction, so that the sensor can scan the vertical cavity wall of the mold copper plate to detect data. 5. Instrument motion control unit: It is used to control the motion scanning of the motor, and the running speed, running track, and control mode of the motor can be configured through parameter settings. 6. Laser measurement sensor: The laser displacement sensor adopts the principle of laser triangulation. The laser transmitter shoots the visible infrared laser to the surface of the measured object through the lens, and the laser reflected by the object passes through the receiver lens and is received by the internal line array image processing sensor. According to different distances, the corresponding positions of the light spots received on the line array sensor are also different. According to the angle of this reflection, the distance between the actual objects can be calculated by calculating the distance of the sensor spot. 7. Instrument bracket: The mold surface detection equipment need to be placed directly above the mold when it is in use, and it is required to be fixed firmly without displacement vibration during the measurement process to ensure the measurement accuracy. The parameters: Detection instrument service life: ≥5 years; Detection instrument reliability: more than 98%; Detection range: 60~1000mm (customizable) Detection accuracy: 0.01mm Spot diameter: 1.0x1.5mm (spot scan), 1.0x20mm (line scan) Falling pace: 1~20mm/step Single measurement time: less than 2min Power supply: DC24V Operating temperature: -20~80℃ Equipment warm-up time: 3~5min Shock resistance: 50G (X, Y, Z axis) Vibration resistance: 10Hz~5Hz (amplitude 1.5mm, each 2 hours in X, Y, Z axis)

Rs 0,0

See product

Pakistan (All cities)

GoLogica offers complete online training in data modeling that gives professionals the understanding and skills they need to understand data modeling methods. IT specialists, database developers, business analysts, and data analysts who want to become better in creating and managing data structures may benefit from this course. Basic topics covered in the course include entity-relational diagrams (ERDs), data mapping, normalization strategies, and abstract, logical, and physical data modeling. It also covers database design concepts, demonstrating how to build durable, scalable, and effective data models that correspond with business goals. This course, led by industry experts, gives participants practical knowledge through practical assignments, allowing them to apply what they've learned in actual situations. Whether you're new to data modeling or want to improve your existing skills, GoLogica Data Modeling Online Training provides a solid basis for creating and managing successful data models. Enroll in GoLogica Data Modeling Online Training today to obtain the knowledge you need to boost your career in data management and become a certified Data Modeling expert!

Rs 0,0

See product

Pakistan

Top class litter of kc reg Akitas pups. Puppies have a fantastic blood lines and already chunky for their age.The pups have been flead and wormed up to date and are now on solid food. Puppies will be ready to leave for there loving homes

Rs 10.000,0

See product

Pakistan (All cities)

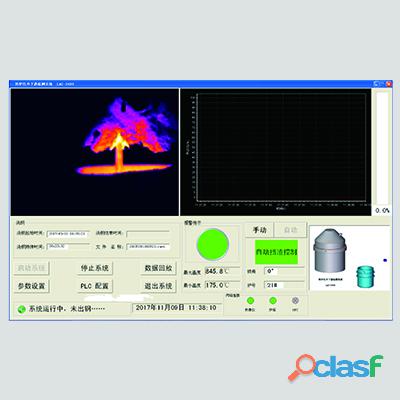

Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content. The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal. As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc. The features of thermal imager 1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set. 2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature. 3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily. 4. With hot zone tracking function 5. Equipped with special 7~14um infrared filter lens The technical parameters 1. Temperature measurement range: 200°C ~ 2000°C 2. Temperature measurement accuracy: 2% 3. Detection accuracy and alarm accuracy: ≥98% 4. Resolution: ≥ 0.5℃ 5. Pixels: 640x240PT 6. Band: 7~14um 7. Field of view: 7.5°×5.5° 8. Frame rate: ≥ 25 frames/sec 9. Equipment service life: ≥5 years 10. The normal operation rate of the automatic control system: ≥99%

Rs 0,0

See product

3 photos

Lahore (Punjab)

Boost your online presence with our expert digital marketing services. We specialize in SEO, PPC, social media management, content creation, and email marketing to drive targeted traffic and maximize ROI. Let us help grow your brand, engage your audience, and achieve measurable results in today’s competitive digital landscape.

Rs 45.000,0

See product

Lahore (Punjab)

shorthand classes, shorthand speed classes, basic shorthand classes, newspaper dictation, new groups start, morning evening classes, township lahore

Rs 54.770,0

See product

20 photos

Bela (Balochistan)

Looking for Unique Personalized Gifts in India? Look no further than www.indiaflowersgifts.com! We specialize in crafting one-of-a-kind gifts that are sure to impress your loved ones. From photo frames to customized mugs and cushions, we offer a wide array of options that can be personalized to make your gift stand out. Our service allows you to Send Customized Gifts to India with ease. Simply visit our website, select your favorite item, and personalize it with photos, names, or messages that ignite a special memory. Whether it's a birthday, anniversary, or any special occasion, our gifts are perfect for every celebration. With Personalized Gifts Online Delivery in India, you can have your unique gifts delivered right to the recipient's doorstep. Our reliable delivery network ensures that your gift reaches its destination on time and in perfect condition. Plus, with secure payment options and excellent customer support, shopping with us is a breeze.Source:www.indiaflowersgifts.com/personalized-gifts.asp

Rs 500,0

See product

Pakistan

Beautiful lemon and white female beagle pup for sale, 5 months old, fully vaccinated, microchipped, flee'd and wormed. Not kc registered and as she's our pet, mother or father can't be seen. Very playful, energetic and needs a caring family ....

Rs 200,0

See product

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos

Pakistan (All cities)

Manufacturer's Warranty. Tecno Industries (Reg) اَلحَمْدُ لِله Manufacturers of: SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. (pure copper) Since 1986 Tecno Lazer Pakistan. 0300-9433728 Ring Road, Band Road, Lahore Pakistan. A Servo Stabilizer That Decreases 30 Volts (back-from 250 to 220 & Increases 70 Volts from 150 to 220) (±) 1% {CAN STEP-UP from even low (on-demand)} اَلحَمْدُ لِله Runs your Equipment Even in Low Main Voltage. INFORMATION: 1: ( An Old Transformer / Relay carrying Stabilizer steps down or up after losing or gaining 20-25 Volts While A Servo Stabilizer steps down or up after losing or gaining 1 Volt. (±) 1%) 2: (on-demand) Buck-Boost Transformer Technology add-in 2kVA and above Models. Basically they work on DC Servo Motor Control system. Their efficiency is much better and its output voltage of either 110 or 220 AC or any required voltage, more-over TECNO 3Phase models up-to 500kVA ratings are manufactured against a confirmed order. 1 year warranty with parts. 100% genuine copper winding (GUARANTEED) Specs for (intelligent Voltage Stabilizer): SERVO MOTOR controlled, Automatic Voltage Stabilizers & Regulators. Input Voltage : 150 To 250 AC Output Voltage : 110v & 220v AC (±) 1% Frequency : 45 or 60 Hz Wave Form : Non-distorted Sine-wave Response Time : 25ms / V Efficiency : 95 % Power Factor : 0.95 Relative Humidity : 30% to 80% (without condensation) Temperature Rise : Less Then 50c Control System : DC. Servo Motor Insulation Resistance : More then 3M?? at 500V DC Tested : 1500 V We Manufacture Servo Motor Controlled Automatic Voltage Stabilizer, using Japanese technology, for UPS, Solar, AC Air-Conditioner, Split-Type, Window Type, (LCD/LED TV) Washing Machine, Treadmill, Photocopier Machine. Television, Music System, Refrigerators, Ultra sound Machines, Embroidery Machines, All Sensitive Equipment, Signalling Devices, CNC Machines, Air Conditioning Plants, Telecommunication Networks, Motor Loads, Data Processing Equipment, Bio Medical Equipment, Drives, PLC’s, Induction Heating, Hotels, Defence Application, Industrial Units, Lighting Loads, Residential/ Offices, Farm Houses, R & D Institutions, Mainline Stabilizers, Sophisticated Laboratory Equipment etc. Runs your Appliances Even in Low Main Voltage. وولٹیج سٹیبلائزر Standard Power Ratings Available in Single-Phase & 3-Phase: 500VA, 1kVA, 2kVA, 3kVA, 5kVA, 10kVA, 30kVA. Up-to 500kVA Punjab NWFP, KPK, & All Pakistan Cargo, Feel Free to Call: Rana Naeem Hammad. M.D. Tecno Industries (Pvt) Ltd Lahore. +923009433728

Rs 121,0

See product

11 photos