4th vr box

Top sales list 4th vr box

Latest Offers

Lahore (Punjab)

Aquarium for sale aquarium size is 1.5 by 1.5 ft neat and clean like a new if anyone intrested to buy then contact on my number thx 03224597050 location : Ghaziabad near MughalPura lhr

Rs 10.000,0

See product

2 photos

Pakistan (All cities)

Get the best nail polish services in Hyderabad at Kameleon Salon, from classic manicures to gel finishes.

Free

See product

Sialkot (Punjab)

Feeling intricacies in crafting a CDR application for Engineers Australia’s skills assessment? Do not worry; order CDR Writing Services in Pakistan for Engineers Australia. It is the best-known online writing assistance for CDR applicants in Pakistan. CDRAustralia.Org offers such commendable support to meet aspirants' requirements. The service comprises a complete CDR package from selecting projects to writing career episodes, a summary statement, a CPD statement, and a resume. To guide candidates in framing an EA-acceptable competency assessment report, a brilliant team of professional writers is awaiting. Expert writers offer comprehensive assistance to make the report extraordinary so that it can catch EA’s attention and undergo successful assessment. Hire top experts at CDR Australia and relieve all your writing woes. Hired native writers offer CDR support tailored to your requirements and meet all Engineers Australia standards. If you seek any information regarding the services, contact our experts free of cost by visiting the website. Contact Detail: Website: https://cdraustralia.org/pk/ Mail at: Contact@CDRAustralia.Org WhatsApp: +61-291917405

Rs 2.784.000.000,0

See product

Pakistan (All cities)

We have the Outboard Boat Engine OXE. Yamaha We are specialized in the sales of full metal scrap/ recycling material such as ac/fridge compressor , Ceramic Cpu Gold Processor Scraps , H.M.S 1&2, Copper wire scrap,Drained Battery Lead scrap in the UK (LONDON).We have all our product fully ready for sales in good quantity and quality also to be shipped out for our buyers.For Booking : https://wa.link/og0sgp Whatsapp: +15806151130

Rs 150.000,0

See product

2 photos

Pakistan (All cities)

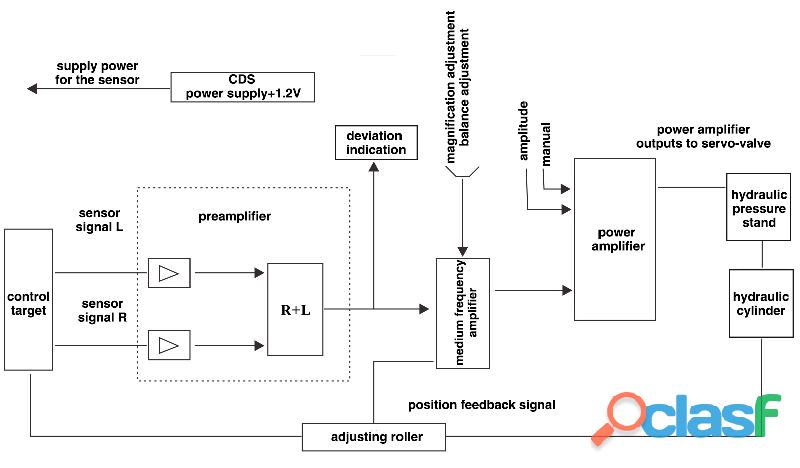

The composition of the system The photoelectric strip automatic center position control system is mainly composed of sensors, amplifiers, PLC controllers, hydraulic control and other parts. System composition block diagram The main technical parameters 1. Detection width: 300-2800mm 2. Detection light source: 220VAC. (100VAC) 30W. High frequency white light works continuously 3. Photodetector: precision die-casting components, time constant 20ms 4. Maximum working voltage: 50VDC 5. Distance from receiver to emitter: 300-1000mm 6. Operating temperature: 0℃-60℃ 7. Resolution: 0.5mm 8. Linearity: ±1%F.S (after linearization) 9. Repeatability error: △R1%, F.S 10. Servo-valve working signal: ±10V 11. Rated pressure (oil pressure): 4.5Mpa 12. Rated flow: 30L/min 13. Symmetry: 10%

Rs 0,0

See product

2 photos

Pakistan (All cities)

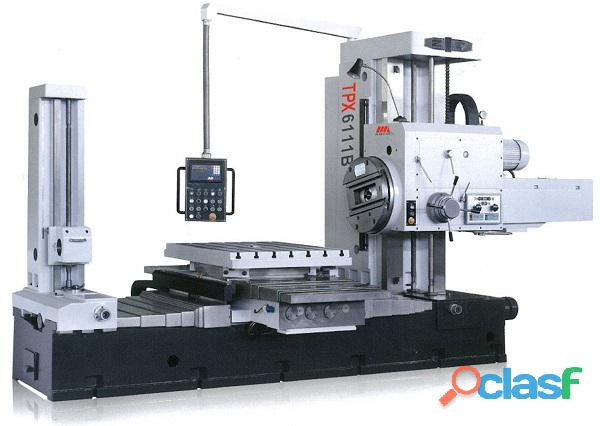

Explore the leading manufacturers of horizontal and vertical boring machines, renowned for their precision engineering, innovative technology, and reliable performance. This guide covers top companies offering high-quality machines for various industries, including construction, mining, and manufacturing. Discover key features, advantages, and the latest trends in boring machine design. Whether you're seeking new or used equipment, find trusted suppliers to meet your project needs with ease. https://www.tradebrio.com/exporters/boring-machine.html

Free

See product

Karachi (Sindh)

CCTV Market specializes in offering premium CCTV security systems for homes as well as businesses. With over 10+ years of experience and a solid reputation for happy customers, we provide affordable solutions that are customized to meet your security needs. To guarantee you get the highest level of service possible, our knowledgeable staff takes care of everything from CCTV system design and installation to maintenance and repairs. We are your one stop shop for easily CCTV security since we place a high priority on quality in both our goods and services. For dependable and effective CCTV installation and repair, rely on CCTV Market right now.

Rs 150,0

See product

Lahore (Punjab)

Boost your online presence with our expert digital marketing services. We specialize in SEO, PPC, social media management, content creation, and email marketing to drive targeted traffic and maximize ROI. Let us help grow your brand, engage your audience, and achieve measurable results in today’s competitive digital landscape.

Rs 45.000,0

See product

Pakistan (All cities)

Discover the top 10 servo voltage stabilizers for industrial applications in 2025, engineered to ensure precise voltage regulation and protect sensitive equipment from fluctuations. These high-performance stabilizers improve operational efficiency, reduce downtime, and extend the life of machinery. With advanced features like automatic voltage correction and robust build quality, they are essential for industries looking to maintain optimal power stability and safeguard valuable assets. https://voltsine.in/product/servo-voltage-stabilizer/

Free

See product

Pakistan (All cities)

Artificial Hymen Pills Price in Pakistan What is Artificial Hymen Pills? Artificial Hymen Pills in Pakistan an Artificial Hymen Could Be a Cellulose Compound That is Developed in 2010 in Germany in a Very Laboratory for Microbiology Stuffed With Synthetic Blood That Imitates Human Blood. Artificial Hymen Pills Are Useful for Fake Virginity by Creating a True Hymen. And Imitate the Loss of Blood That Happens on Your First Time. These Pills Are Formulated With 99.9% Natural Ingredients That Are Extracted From Pure Herbs Used for Hundreds of Years in Asia. Of These Ingredients Are Completely Body-safe and Do Not Have Any Side Effects Whatsoever. All You’ve Got to Try is Just Place the Artificial Pills in Pakistan Inside Your Vagina Between 25-30 Minutes Before You Derive Pleasure From Sexual Activity. Artificial Pills Newtelebrands.com the Natural Hymen of a Lady Protects the Vaginal and Its Canal. If You’ve Lost Your Hymen Due to Any Physical Activity. And You’re Worried About Your Dark That You Simply Cannot Bleed at That Point. So Stop Worrying Because There’s a Product That Comes Dead Set Reduce Your Worries, and Provides You Your Virginity Back by Using Pills. These Artificial Hymen Fake Blood Pills Will Influence the Body Heat and Vaginal Moisture and It Will Then Create a Synthetic Membrane That Acts Sort of a Hymen and Tightens the Vaginal Opening. After Successful Penetration of the Male Organ, the Fake Membrane Will Tear Similar to a True Hymen and Discharge a Touch Blood-like Liquid to Finish the Dramatic Effect. How Artificial Hymen Pills Work? Artificial Hymen Pills in Pakistan Usually Fake Virginity, an Artificial Hymen is a Prosthetic Invention for the Aim of Simulating an Intact Hymen in Women. These Pills Contain a Natural Blend. Which After Inserting in the Vagina Properly Temporarily. Giving the Looks of an Intact Hymen and Releasing a Red Liquid That Appears Like Blood When Subjected to Pressure. Artificial Hymen Kit Consists of Two Layers of Cellulose, the Blood Liquid, and Powder. The Factitious Hymen Reacts to Heat and Moisture That is Present Within the Interior of the Vagina. Thus, the Unreal Hymen/hymen Dissolves Inside the Vagina and Exit as a Blood Trail to Substantiate the Virginity. It Has Been Specifically Designed to Offer You the Chance to Introduce One a Minimum of 2 Hours and Half-hour Before Sexual Activity. Make It Easy With the Included Disposable Plastic Tweezers a Finger Deep. During Sexual Activity, It Dissolves Then Completely. And by the Interior Friction of the Penis, the Cellulose Compounds Mix With the Body Fluids. Hymen Flows Down From the Vagina After Sexual Intercourse. Artificial Hymen Pills in Pakistan This Residue is Seen on the Penis and Sheets That Bring the Result to Substantiate Your Virginity at the Specified Moment. The Utilization of Hymen Gel Also Works With the Employment of Condoms. How To Use? Artificial Pills Just Finger Deep and About 1-3 Hours Before the Planned Sexual Activity. The Capsules Contained Fake Blood Therein Which Then Completely Dissolved. During Gender, It Mixes Along With Your Vaginal Secretions and Runs as a Trace of Blood During a Natural Amount. By Tightening the Vaginal Entrance, It Intensifies the Sensation of Virginity. Use It Half-hour – 2 Hours Before the Planned Sexual Issues and Also Confirms Reliably Your Virginity by Artificial Hymen Pills in Pakistan. With Original Blood, Pills Turns Blood Red Together With Moisture and Dissolves Completely. Use 25-30 Minutes Before Sexual Intercourse: Wash Your Hands and Vagina Before Using. Slightly Insert the Synthetic Hymen Into the Vagina. It Will Dissolve Within 20-30 Minutes After Using It. Benefits of Artificial Hymen Pills? Artificial Pills Will Facilitate Your Desire for a Virgin Again Without Undergoing Vaginal Rejuvenation Surgery or Popping Any Dangerous Pills. They Will Facilitate the Reboot of Your Virginity and Feel Young Again. Artificial Pills in Pakistan Facilitates You to Restore Your Hymen to Their Original Position. And Facilitate Your Experience of Sex Sort of a Virgin. The Factitious Hymens Are the Product of Natural Material. Like Synthetic Blood and Cellulose, is Safe for Your Vaginal Health. Lady Secret Cream the Following Are Advantages of Pills Make the Vaginal Path Tighter Make You Bleed at Your Night It Has No Side Effects. It is Non-toxic and Safe No Painful Surgery, Needles, or Anesthesia From Now on Artificial Pills in Pakistan Price Prevent From Doctor’s Visits and Medications You Do Not Need Any Hymenoplasty. It Appears Like the Original Blood 99.9% Harmless, Risk-free Call & Whats App 0300-0085742 | 0330-2828742 The Largest Online Shopping Website: NewTelebrands.Com

Free

See product

Pakistan (All cities)

The Energy-Efficient Single Phase Oil Cooled Servo Stabilizer provides reliable voltage stabilization for homes and offices, protecting sensitive electronics and appliances from voltage fluctuations. Featuring an advanced oil cooling system, it ensures efficient heat dissipation and prolonged lifespan. With low energy consumption, it offers cost-effective power protection, making it the ideal solution for stable and uninterrupted electricity flow. https://voltsine.in/product/single-phase-oil-cooled-servo-stabilizer/

Free

See product

Rawalpindi (Punjab)

Programmers Lab Training Institute is the best IT training institute for computer short courses in Rawalpindi Islamabad . Our mission is to empower every student with IT skills and knowledge. With a wide array of job oriented computer short courses, we ensure that our students are prepared to succeed in their careers. Our computer short courses include Website Designing Course In Rawalpindi, React-Native course,SEO course, Graphics Designing course, FUll Stack Web Development Course In Rawalpindi Social Media Marketing course, Digital Marketing course, Php course, Sql, Video Editing course, Content Writing course, Basic IT, course ,MS Office Course, and many more short courses.

Rs 0,0

See product

Ahmadpur East (Punjab)

Online Silver Anklet in Jaipur – Chic, Elegant, and Comfortable Step up your accessory game with our gorgeous collection of online silver anklets in Jaipur at thelilacc. Crafted from 925 sterling silver, our anklets are designed to enhance your natural beauty with a perfect blend of sophistication and charm. Whether you prefer a simple design or one with delicate embellishments, our anklets add a graceful touch to any outfit, making them ideal for both everyday wear and special occasions. Why Choose Our Online Silver Anklets in Jaipur? Premium 925 Sterling Silver: Made from high-quality 925 silver, our anklets offer durability and a lasting shine that’s resistant to tarnish. Variety of Styles: From minimalist chic to ornate, detailed designs, our anklets come in a wide range of styles to suit your unique taste. Comfort and Fit: Designed for all-day wear, our anklets are lightweight, comfortable, and easy to adjust for a perfect fit. Perfect for Any Occasion: Whether you're dressing up for a celebration or adding a finishing touch to your daily look, our anklets are versatile enough for any occasion. Convenient Online Shopping: Browse and buy from the comfort of your home, with secure payment options and fast delivery across Jaipur. Shop online silver anklets in Jaipur at thelilacc and bring home the elegance and beauty of finely crafted silver jewelry. Order today and add timeless grace to your style!

Rs 3.541,0

See product

3 photos

Pakistan (All cities)

Overview: In the steelmaking production process, the ladle is the key equipment for holding molten steel, secondary refining, and continuous pouring. In a modern steelmaking plant, refractory materials are required for converters, refining, and ladles. In the steelmaking process, ladle is the main equipment for using and consuming refractory materials. Improving the service life of ladles and reducing refractory consumption is the key technology for steelmaking plants to save costs and reduce energy consumption for green production. In order to ensure the orderly operation of the ladle, save the consumption of refractory materials, prolong the service life of the ladle, and ensure the safe operation of the ladle, Wuhan CenterRise M&C Engineering CO. developed and launched the LDT-N200 integrated management system for the ladle. Introduction: LDT-N200 ladle integrated management system integrates LDT-L200 ladle lining thickness gauge, TBP-S300 ladle, tundish baking temperature and leakage monitoring system, RFD -C100 metallurgical electronic positioning system, and also integrates SQL Server database and NeuralWare (American computer software company) neural network software NeuralWorks to realize intelligent and optimized management of ladles. LDT-L200 ladle lining thickness gauge uses a laser area array scanning sensor to accurately measure the real-time thickness of the ladle lining, calculate the lining loss, and predict the service life of the ladle. TBP-S300 ladle, tundish baking temperature and leakage monitoring system uses infrared thermal imaging camera and embedded armor wire system to comprehensively monitor and prevent ladle leakage. RFD-C100 metallurgical electronic positioning system installs RFID electronic tags on all ladles to realize full-time and full-space ladle positioning and tracking. LDT-S200 ladle optimization control and analysis software, based on SQL Server database, B/S network structure, realizes online management of ladles, and adopts BP neural network system to realize intelligent optimization control of ladles. LDT-N200 ladle integrated management system can realize ladle age management based on ladle lining data and neural network algorithm, safety process control of ladle turnover and use, full-time tracking management of steelmaking production and full-space tracking management of ladle use and provide optimal control and management of steelmaking production and ladle maintenance. Comprehensive ladle measurement and monitoring, ladle positioning and management, and data management and optimization enable the LDT-N200 ladle integrated management system to fully realize ladle entire process management, optimize the service life of ladles, and comprehensively reduce the cost of refractory materials. The features: Using a lining thickness gauge to measure the thickness of the ladle lining Using infrared thermal imaging camera/embedded armor wire to realize ladle leakage detection Using RFID/number plate recognition to realize the location management of ladles Ladle age management system based on overall tracking Overall (full-time full-space) ladle management system based on database Provide overall production scheduling data Using neural network to predict ladle service life based on big data Ladle Optimal Scheduling System based on database and ladle service life Increase the service life of ladle by 12%-20% Reduce the use of refractory materials more than 15% Realize orderly management of ladle baking Realize full space and full time domain control Reduce the costs of ladle management and maintenance Improve the efficiency of ladle turnover operation

Rs 0,0

See product

Pakistan

2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds 2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds .....................2 pairs yellows for sale all in top condition ready for breeding they are 2015 bred birds

Rs 4.000,0

See product