LAG S400 INFRARED CONVERTER SLAG DETECTION SYSTEM IN PAKISTAN

Overview

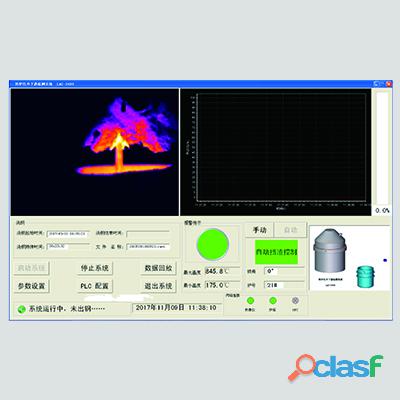

The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content.

The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal.

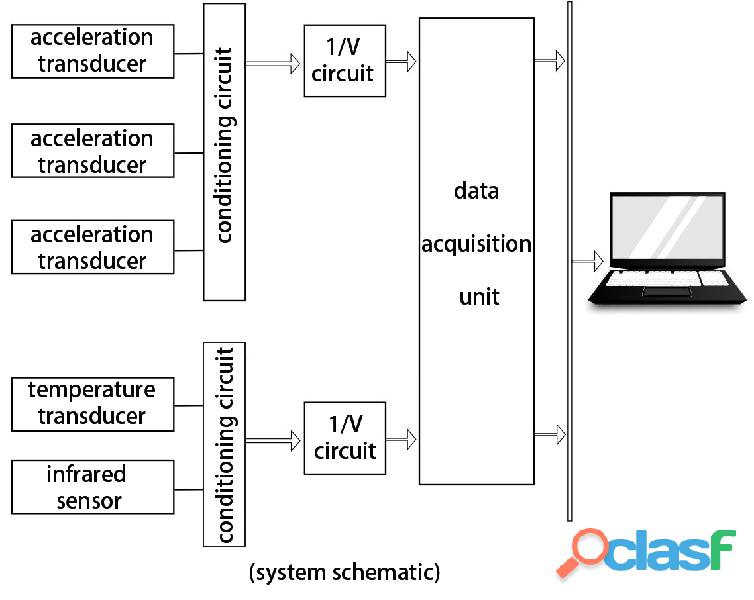

As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc.

The features of thermal imager

1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set.

2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature.

3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily.

4. With hot zone tracking function

5. Equipped with special 7~14um infrared filter lens

The technical parameters

1. Temperature measurement range: 200°C ~ 2000°C

2. Temperature measurement accuracy: 2%

3. Detection accuracy and alarm accuracy: ≥98%

4. Resolution: ≥ 0.5℃

5. Pixels: 640x240PT

6. Band: 7~14um

7. Field of view: 7.5°×5.5°

8. Frame rate: ≥ 25 frames/sec

9. Equipment service life: ≥5 years

10. The normal operation rate of the automatic control system: ≥99%

The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals. The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag. In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole. After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software. The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content.

The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount. The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager. It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect. When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal.

As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc.

The features of thermal imager

1. The temperature measurement range is 200°C ~ 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set.

2. High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature.

3. With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily.

4. With hot zone tracking function

5. Equipped with special 7~14um infrared filter lens

The technical parameters

1. Temperature measurement range: 200°C ~ 2000°C

2. Temperature measurement accuracy: 2%

3. Detection accuracy and alarm accuracy: ≥98%

4. Resolution: ≥ 0.5℃

5. Pixels: 640x240PT

6. Band: 7~14um

7. Field of view: 7.5°×5.5°

8. Frame rate: ≥ 25 frames/sec

9. Equipment service life: ≥5 years

10. The normal operation rate of the automatic control system: ≥99%

4.00/5

1 reviews

⟩

Photo 1 / 3

CONTACT