Inns ground

Top sales list inns ground

Latest Offers

Pakistan

I have available 2 stunning BSH blue kittens. 1 girls and 1 boys. Mum and dad are beautiful blues and are GCCF registered. Mum has a wonderful personality, she is friendly and extremely loving. she has an excellent 4 generations pedigree.

Rs 5.000,0

See product

Pakistan

I have a British blue shorthair male and female available for stud service. PKD NEGATIVE, BLOOD TYPE A or AB (CARRIER OF B). Tom had 8 litters so far, all healthy and chunky kittens. He is an indoor cat, fully vaccinated and in great health.

Rs 5.000,0

See product

Pakistan (All cities)

Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly cool the high-temperature molten steel continuously injected into its inner cavity through the water-cooled copper plate to export its heat and to gradually solidify it into a casting billet with the required cross-sectional shape and billet shell thickness. And the casting billet, which is still in liquid state, is continuously pulled out from the lower nozzle of the mold to create conditions for casting billet to be completely solidified in the subsequent secondary cooling area. The main function of the mould oscillation device is to make the mould perform mechanical movement according to the given characteristics of amplitude, frequency and waveform deflection. The purpose is to facilitate demoulding and prevent the occurrence of sticking and breakout accidents due to the bonding of the casting billet with the copper wall of the mold during the solidification process. MOC-K100 mould oscillation online monitoring system can three-dimensionally detect the positive and negative frequencies and waveform characteristics of the mould oscillation. The online changing data is provided in real time, which provides convenient and effective detection methods for on-site inspection personnel. The meaning of the system 1. When the continuous casting machine is not working properly, the billet quality problems (such as unstable oscillation marks, edge cracks, etc.) occur. According to the monitoring results of the system, we can combine with the actual on- site situation to analyze the cause of the failure, and efficiently evaluate and solve the problem of the oscillation table to improve product quality. 2. During the normal operation of the equipment, with the fatigue and wear of the mechanical structure of the mold, the expected oscillation parameters of the mold and the actual oscillation parameters will have a oscillation difference with time change, resulting in the internal process parameters’ changing of the continuous casting machine. Timely and accurate monitoring of changes in these parameters is helpful to schedule maintenance. 3. Transfer equipment maintenance from regular maintenance to state maintenance, do not repair when there is no problem, and arrange maintenance according to production needs when abnormal signs appear. Prevent over-repair and under-repair. 4. According to the monitoring results of the equipment, the on-site working parameters are adjusted in time to avoid adopting inaccurate or large-error oscillation to work and prevent the "breakout" accident. 5. We can timely find out that the oscillation is not stable or out of control in a small range, so as to avoid the formation of unevenness and unstable oscillation marks on the surface of the slab during the solidification of molten steel into the slab, and improve the surface quality of the product. 6. Adjust the working parameters reasonably according to the monitoring results, avoiding the use of excessive safety factor, making the entire assembly line play a normal working efficiency, increasing the output of billets, and create favorable conditions for increasing the casting speed. The functions of the system (1) Overview of monitoring parameters: Provides an overview of real-time monitoring parameters in the full screen, displaying all real-time data including oscillation parameters and process parameters. (2) Time domain waveform: This function mainly displays the oscillation waveforms of multiple measuring points and one channel standard waveform in real time, and simultaneously displays the three elements of oscillation of each measuring point in real time. (3) Waveform superposition: The difference between this function and the time domain waveform is that the waveforms of multiple measuring points are superimposed on a graph with lines of different colors on the same scale, and the oscillation difference of each channel can be calculated and displayed intuitively. (4) FFT: This functional module completes the calculation and display of the oscillation spectrum in real time. It is used to evaluate the waveform distortion of the entire oscillation table and to determine whether there is a problem with the installation of the oscillation device. (5) Bar graph: The oscillation of each measuring point is indicated by a bar graph of peak value and sensor gap voltage, which is more intuitive. (6) Trend: After starting this module, the operator can search the historical records in the database, analyze the changing trend of each parameter, and use it to analyze the rationality of the steel quality and processing parameter settings for different steels under the oscillation conditions. The parameters of the system 1. Number of measurement channels: According to the mold design, up to 16 sensors can be arranged 2. Sensor: three-dimensional oscillation sensing (X, Y, Z three axes) 3. Sensitivity: 1000mV/g 4. Frequency range: 0.04~10HZ 5. Frequency accuracy: ±0.01 Hz 6. Amplitude accuracy: 0.005mm 7. Transmission mode: wired digital transmission, wireless transmission 8. Host: 3U standard rack, handheld device 9. Sensor power supply: 24V.DC 10. Host power supply: 220V.AC/50Hz Mold oscillation curve The structure of the system The main components of the continuous casting mould online oscillation detection system are: 1. Three-dimensional oscillation measurement sensor 2. Handheld oscillation sensor calibrator 3. Dedicated signal connection cable 4. Preamplifier 5. Operation processing unit 6. Graphic display terminal 7. Industrial Ethernet (TCP/IP) or PROFIBUS-DP communication components 8. Control cabinet

Rs 200.000,0

See product

3 photos

Pakistan

One is 7 months old (not sexed); freely flying, like to be out of cage all day, freely flying around. Other one is 5 months old (breeder told male, but not sexed) has already started training; steps on a perch now on demand, wing feathers growing back, likes to be outside cage on his stand.

Rs 4.000,0

See product

Pakistan (All cities)

Welcome to Phonics Playtime with Your Private Tutor! Boost your reading skills and confidence with personalized sessions. Let's embark on a fun phonics adventure together. Why Choose Our Fun Team? Exciting Learning: Dive into phonics with games, stories, and activities. Personal Attention: Get special help from a friendly tutor just for you. Fun Adventures: Explore letters and sounds in cool ways. Join us for exciting phonics activities, games, and stories tailored just for you. Book a demo class for best phonics classes online Call us at +91 9654271931. For more visit: https://ziyyara.com/phonics-online-classes

Rs 0,0

See product

Pakistan (All cities)

Overview The taper of the narrow face of the mold has an important influence on the quality of the casting billet. Excessive taper will cause the mold to squeeze the billet shell, and a small taper will increase the air gap. With the continuous increase of the requirements of the casting billets’ quality and the continuous introduction of high-precision molds, the current taper measuring instrument in the domestic market generally have low measurement accuracy and complex measurement methods, which restrict production development. The new-generation taper measuring instrument developed by Wuhan CenterRise M&C Engineering Co., Ltd. adopts imported high-precision inclination sensor, combined with ultra-low power consumption processor, which can quickly and accurately measure the actual taper value of the narrow copper plate of the mold. The instrument is fully functional, easy to use and suitable for slab molds of various lengths. Most of the current slab molds are single-taper, a narrow flat copper plate. The taper value required for production can be achieved by adjusting the angle between the narrow copper plate and the direction of gravity. The taper measuring instrument directly measures the angle between the narrow copper plate and the direction of gravity. According to habits and production needs, the angle is converted into the value of one-sided shrinkage of the upper and lower ports. The main features 1. Easy to calibrate, stable performance, easy to operate 2. Self-supporting, self-aligning, self-balancing 3. High measurement accuracy 4. LCD data reading 5. Fast response, real-time display reading 6. Adjustment of dynamic intelligent system 7. Lithium battery power supply, suitable for on-site use of mobile operations 8. The continuous measurement time is more than 36 hours 9. The sensor adopts multiple protections to meet the needs of on-site harsh environment measurement 10. The weight of the whole system is less than 3.8 kg, and it is equipped with a set of zero-point calibration table, which is convenient for on-site installation and measurement 11. Applicable to various arc, parabolic and straight molds The performance and index 1. Measuring range: -3°~ +3° (measurement length can be customized according to users’ needs) 2. Measurement accuracy: 0.01mm 3. Temperature range: -25℃~+85℃ 4. Linearity deviation: -0.03mm ~ + 0.03 mm 5. The longest usage time after fully charged: 36 hours 6. The longest storage time after fully charged: 2 months The main components 1. Measuring instrument: central measurement and control unit, measuring sensor 2. Measuring stand 3. Standard table: standard surface, support frame, spirit level

Rs 0,0

See product

Pakistan (All cities)

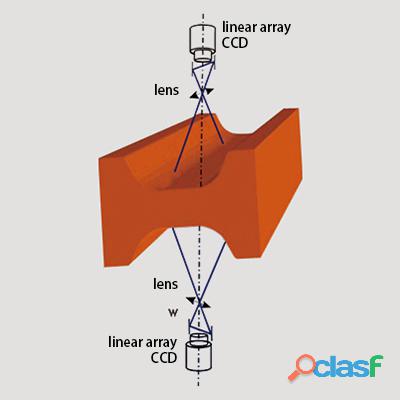

Overview The surface quality inspection of high temperature cast product is of great significance to the repair of cast product’s defects and the hot delivery of hot cast product. The ZSQ-T series of online surface quality inspection equipment for casting billets developed by Wuhan CenterRise M&C Engineering Co., Ltd can detect the defects such as scratches, cracks, holes, pits, edge cracks, edge defects on the surface of the cast products, and meet the customer's requirements for the quality inspection of the surface of the cast product. The principle of the system The ZSQ-T200 online surface quality inspection system for continuously cast products adopts the principle of optical imaging and uses a CCD image sensor to input the surface image of the cast products to be detected into the computer, and then the obtained image is processed by special image processing software to find out whether there is any defect in the image. After the defects in the image are obtained, the obtained defects are classified through a special self-learning system, and finally the requirements of the computer to automatically identify the surface defects of the cast products are achieved. The composition of the system 1. Optical part: The optical part is composed of multiple fixed-focus lenses and linear CCD, which mainly realizes scanning and imaging of the surface of the cast products. 2. Lighting part: The lighting part is composed of a high-brightness LED array and a cylindrical lens, which realizes high-brightness and high-uniformity lighting on the surface of the cast products. 3. Mechanical structure part: The mechanical structure part mainly realizes the adjustment, installation and fixing of the optical part and the lighting part, and consists of the imaging head (optical part), light box (lighting part), bracket and control cabinet. The structure is required to be stable and reliable. 4. Real-time processing: The real-time processing part is completed by the multi-CCD data real-time sampling processing unit (high-speed DSP) independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. 5. Hardware part: The hardware part consists of high-speed storage controller and storage hard disk array, Gigabit InternetMAC controller, Gigabit Ethernet PHY. Rj45, and multiple high-speed workstations. 6. Detection software: The detection software mainly realizes the functions of collection, storage, transmission, processing of CCD scanning images, extraction of defects, analysis of defect characteristics, calculation of defect size and position, storage of defect images, generation of cast product’s surface quality analysis reports. etc.

Rs 0,0

See product

Pakistan

KC BRITISHPRIDE BRED English Bulldog Hes The son of Britishpride Royal Ascot. available for STUD. HE IS A PROVEN STUD DOG producing quality puppies.

Free

See product

Lahore (Punjab)

For businesses in Lahore and beyond, IPS UNI’s SEO Training in Lahore equips you with the knowledge and skills to navigate the ever-evolving SEO landscape. Our comprehensive program, led by industry experts, empowers you to take control of your website’s visibility and achieve sustainable growth. https://ipsuni.medium.com/mastering-seo-with-ips-unis-seo-training-in-lahore-46241394811b Call us at: 03340777021 Address: Al Hafeez Executive office 1506, 30 Firdous Mkt Rd, Lahore, Pakistan Visit our website: https://ipsuni.com/

Free

See product

Gujrat (Punjab)

My Resume Builder is a free resume builder app that helps you create a modern and professional resume and curriculum vitae or CV on your mobile in just 3 simple steps. Using our One-Click LinkedIn Resume feature, You can convert your complete LinkedIn profile to a resume. For more information, visit our app: https://play.google.com/store/apps/details?id=com.myresumebuilder

Free

See product

6 photos

Multan (Punjab)

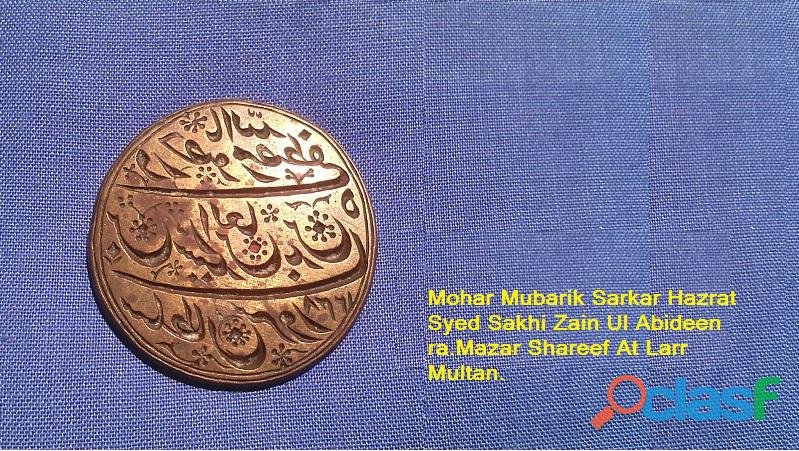

Hazrat Syed Sakhi Zain ul Abideen (RA) migrated from Baghdad to Saudi Arabia and spent 22 years in Madina Munawara.One night, holy Prophet hazrat Mohammad (may peace be upon him) appeared in a dream and instructed him to go to India, convince the people to the right path, preach or spread the teachings of Islam.Obeying the orders of the holy Prophet Hazrat Mohammad (may peace be upon him), the Sufi Saint left Madina Munawara and came to Shahkot. The Sufi saint is the father of a famous Sufi Hazrat Syed Ahmad Sultan, known as Sakhi Sarwar, the bountiful Chief, shrine at Sakhi Sarwar Pakistan. Hazrat syed sakhi Zain ul Abideen (RA) practised austerities and prayers in shahkot, The great renowned Sufi saints paternal genealogy is directly related ten generation up with Ameer ul Momeneen (commander of faithful) Hazrat Imam Ali Ibne Abu Talib R.A, thus he was a direct descendant of the holy Prophet Hazrat Mohammad (may peace be upon him). The name Zain ul Abideen was selected by his father Syed Umar due to the deep love and devotion with Imam Zain ul Abideen (A.S). Specification. Object Name: Seal stamp Description: Syed Zain ul Abideen Shah"Sultan Sarwar" Inscription Script : Arabic Inscription Technique: Engraved Date Period: A D 13th Century 1248 Time period: A D 13th Century Geography: Indian Subcontinent (Central Asia) Culture/period: Islamic Condition: Excellent Relics of the Islamic saints strengthens spiritual beliefs, inspire people and give them comfort in tough times. The holy seal is a precious asset handed down from generation to generation, extremely rare and a genuine masterpiece regarding the sacred relics of the early Islāmic saints.

Rs 100,0

See product

Pakistan (All cities)

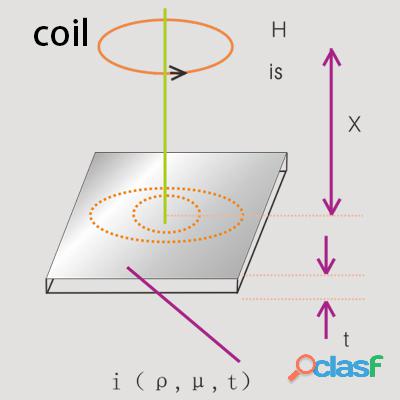

Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting. The molten steel is poured into the mold. In order to prevent overflow, the molten steel level must be kept stable. Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet. The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows: The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm. At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%. It means that the level fluctuation directly affects the surface quality of the casting billet. The principle of the system The eddy current type molten steel level gauge is the key to the system. The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time 0.10s), high detection accuracy (±05mm), and large measurement range (0-150mm). The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer. The system has the advantages of simple operation and no radiation protection problems. The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform. The sensor is cooled by compressed air during use. The principle is shown in the figure A high-frequency exciting winding is installed above the molten steel surface of the mold. The high-frequency magnetic field generated by the high-frequency exciting winding induces eddy currents on the molten steel surface to form a magnetic field. The magnetic field generated by the induced eddy current is in the opposite direction to the magnetic field generated by the high-frequency exciting winding, which changes the impedance of the high-frequency exciting winding. Under the condition that the winding material and structure, steel grade, temperature remain unchanged, the coil impedance change only has a single-value function relationship with the height of the molten steel level. As long as the impedance change of the high-frequency winding is detected, the change of the molten steel level in the mold can be converted. The components of the system Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper. The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance. The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.DC, and then transmits it to the ③ control computer to complete data processing and system control functions. We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level. 1 Eddy current sensor; 2 mold level gauge; 3 control computer; 4 On-site operation display control panel; 5 digital actuator; The control principle of the system The system can be set to four control modes: automatic, semi-automatic, manual and motor clutch. The automatic mode is the closed-loop control system of the molten steel level, and control the opening of the stopper by the digital actuator; the semi-automatic mode uses opening degree setter and digital actuator to set the opening of the stopper manually; the manual mode is to open and close the button directly to control the opening of the stopper; the motor clutch mode is quickly changed from any of the above control methods to manual stopper operation. The functions of the system also include: display and record of molten steel level, nozzle opening and casting speed; setting of molten steel level and nozzle opening; alarm of molten steel level at limit value etc. In addition to taking the detection of molten steel level as the main feedback signal of the control system, the control system also considers various interference factors that have an impact on the level control. These interference factors include: 1. The influence of the change of the flow characteristics on the control system after the melt loss of the stopper 2. The influence of the weight change of molten steel in the tundish on the control system 3. The influence of the change of the casting speed of the continuous casting machine on the control system 4. The influence of the mold width change (the mold width is adjustable) on the control system 5. The influence of the vibration frequency and amplitude of the mold on the molten steel level gauge The function and software implementation In order to overcome these disturbances, the mold level control strategy adopts PID control. And on the basis of PID control, self-adaptive correction and feedforward control are introduced to form an advanced control system. The level control is the main loop, and there is a proportional gain of the main loop controller. According to the self-adaptive correction of the mold width change and feedforward compensation of casting speed, so as to further reduce and eliminate liquid level fluctuations caused by mold width adjustment and casting speed changes. In order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates lightly. And the system will choose a shorter intergrating time when molten steel level fluctuates greatly. Thereby, the fluctuation of the controlled object caused by the frequent action of the stopper rod is suppressed. In the signal processing of molten steel level gauge, an appropriate filtering link is added and the vibration frequency synchronous filter is used for filtering processing, which can overcome the interference of mold vibration frequency and amplitude variation.

Rs 200.000,0

See product

3 photos

Ahmadpur East (Punjab)

Car rental and van rental worldwide. Discover very exciting offers and book online to save money with our convenient and hassle free booking. Find out more! https://www.rafaycars.com/

Rs 0,0

See product

Pakistan (All cities)

Specification electric motor scraps sealed units purity: 99.97% with connection box consist of aluminum case, with full copper content inside voltage220/440 voltage 50 or 60 hz. Size : 100 -500 cm3 power 2 Hp to 40 Hp Three phase Compressor weight: 6Kg, 8Kg, 10Kg, 12Kg 14kg 20kg -22 kg 40kg material : oil drained, comes copper Inside bulk quantity available

Rs 0,0

See product

Rawalpindi (Punjab)

Programmers Lab Training Institute is the best IT training institute for computer short courses in Rawalpindi Islamabad . Our mission is to empower every student with IT skills and knowledge. With a wide array of job oriented computer short courses, we ensure that our students are prepared to succeed in their careers. Our computer short courses include Website Designing Course In Rawalpindi, React-Native course,SEO course, Graphics Designing course, FUll Stack Web Development Course In Rawalpindi Social Media Marketing course, Digital Marketing course, Php course, Sql, Video Editing course, Content Writing course, Basic IT, course ,MS Office Course, and many more short courses.

Rs 0,0

See product